Opitec Hobbyfix User manual

Other Opitec Toy manuals

Opitec

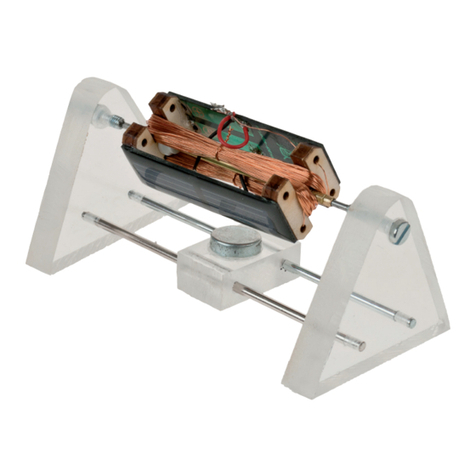

Opitec 117167 User manual

Opitec

Opitec 112.994 User manual

Opitec

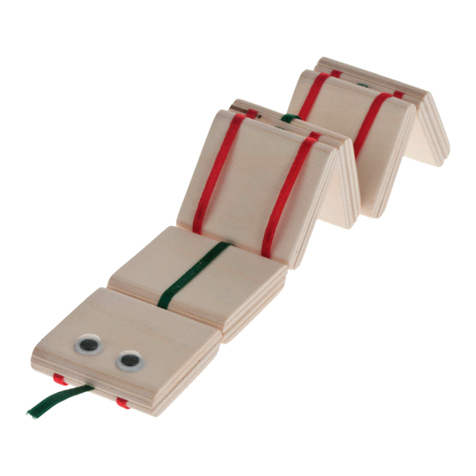

Opitec Rattle Snake User manual

Opitec

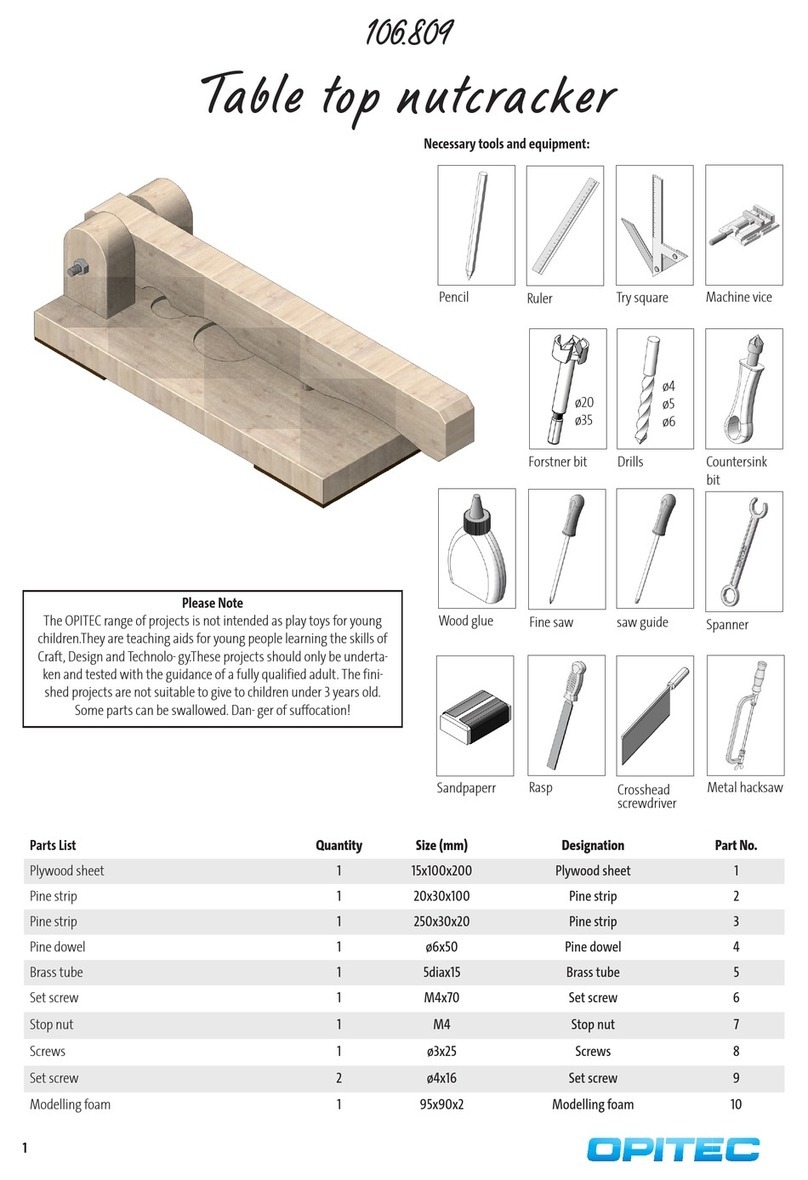

Opitec 106.809 User manual

Opitec

Opitec 111.714 User manual

Opitec

Opitec 120.852 User manual

Opitec

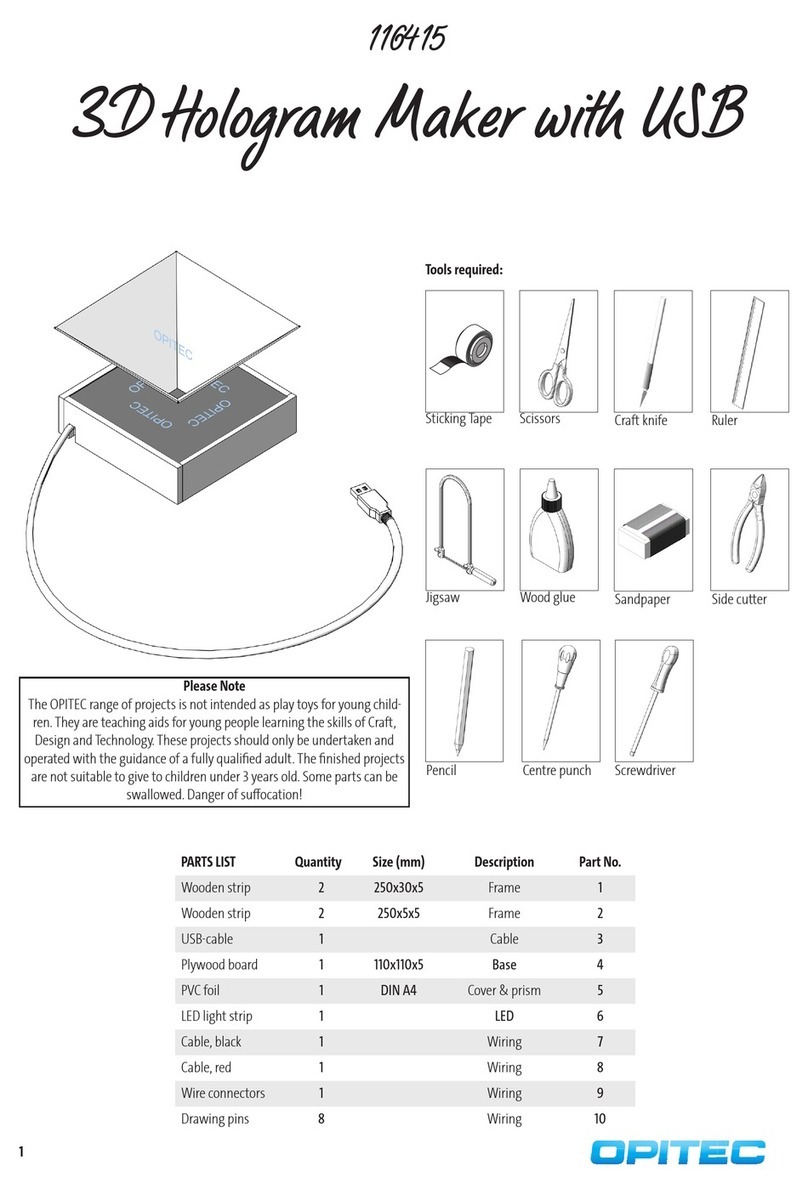

Opitec 116415 User manual

Opitec

Opitec Hobbyfix 113.727 User manual

Opitec

Opitec Wind Machine User manual

Opitec

Opitec Hobbyfix Cloud User manual

Opitec

Opitec Floating Ball User manual

Opitec

Opitec Hobbyfix 101.706 User manual

Opitec

Opitec Solar Auto with gearbox User manual

Opitec

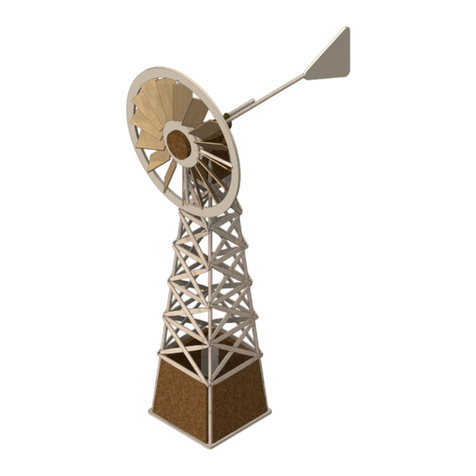

Opitec Easy-Line Wind Generator User manual

Opitec

Opitec 113.141 User manual

Opitec

Opitec 115.305 User manual

Opitec

Opitec Recycling Rowing Boat User manual

Opitec

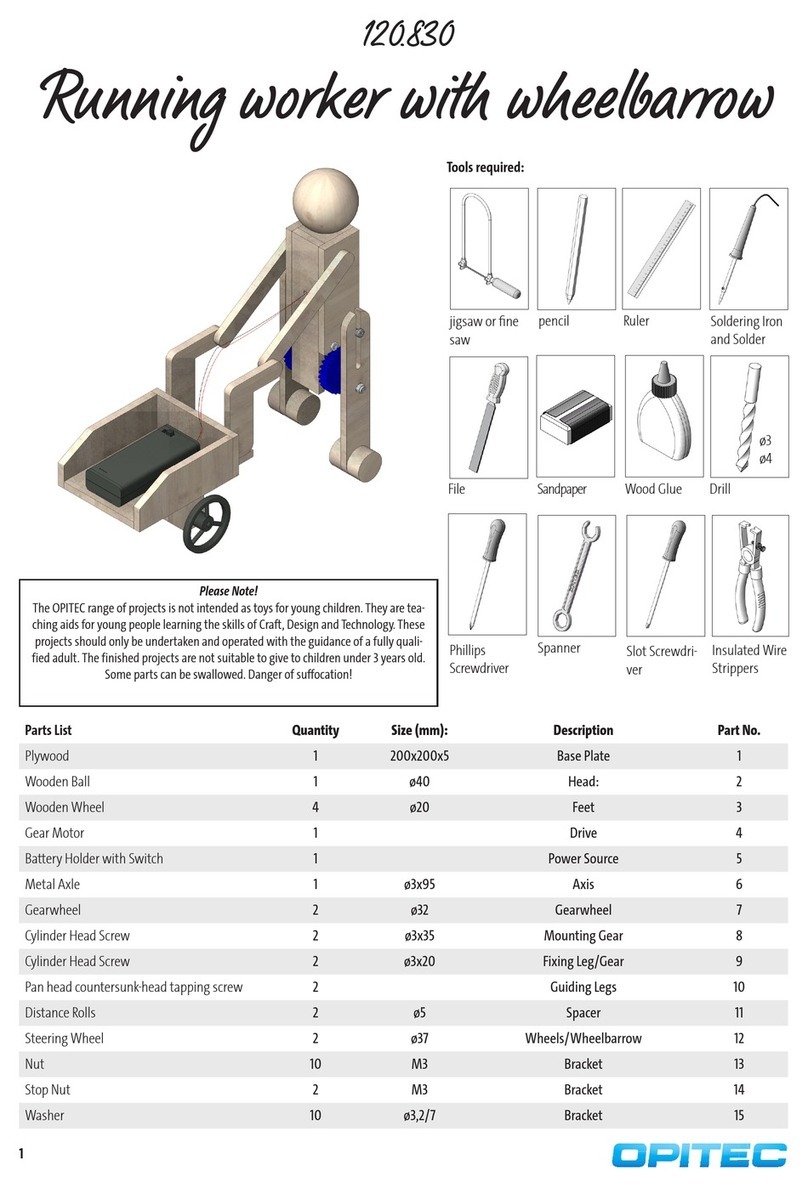

Opitec Running worker with wheelbarrow User manual

Opitec

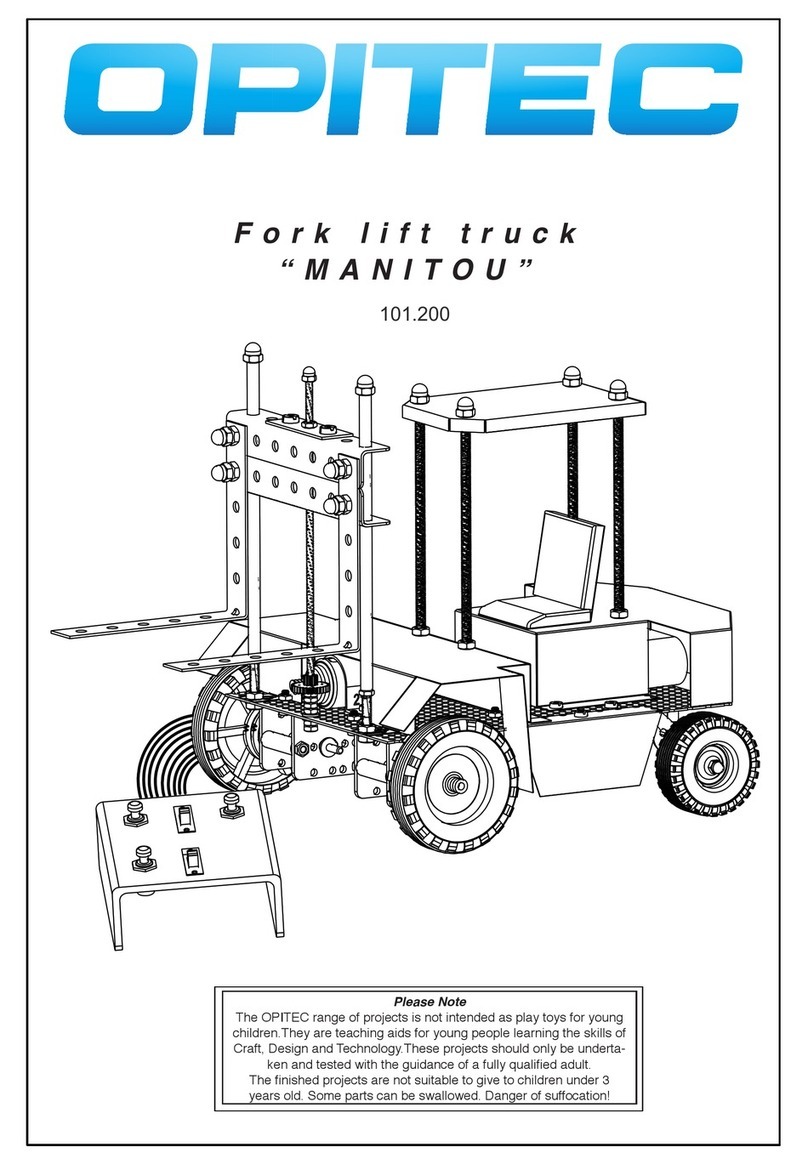

Opitec MANITOU 101.200 User manual

Opitec

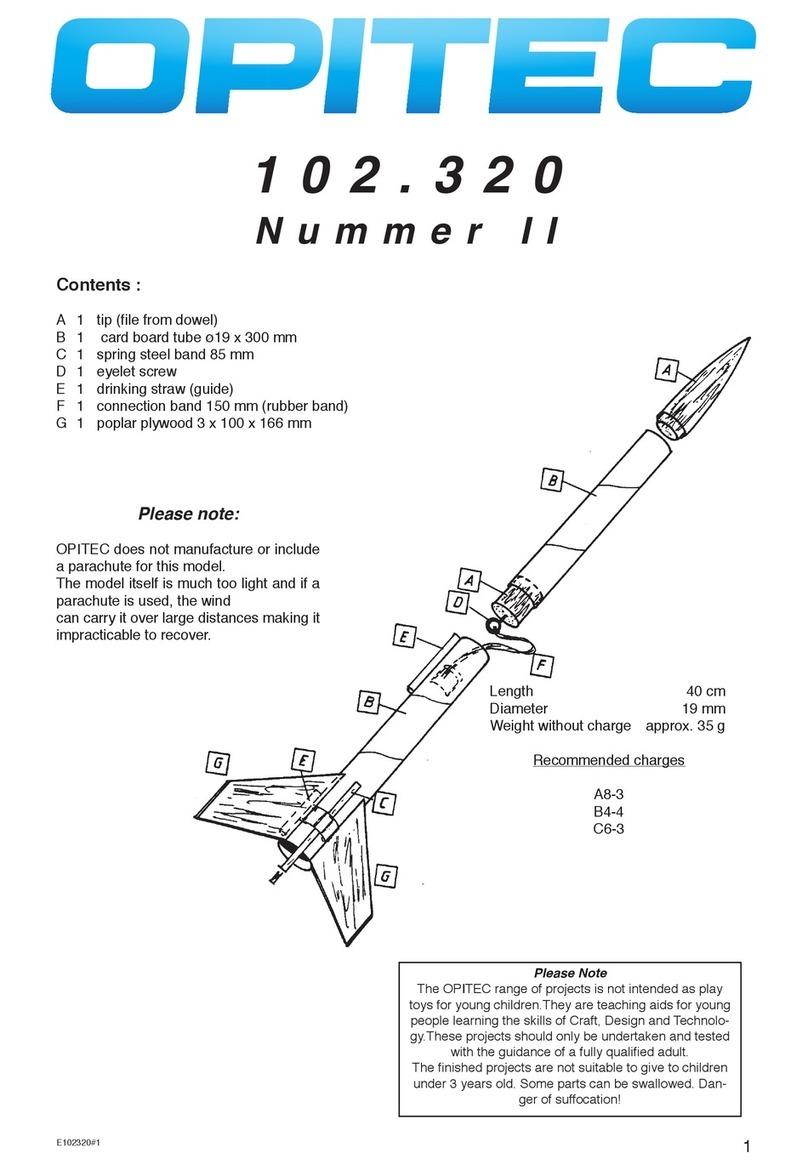

Opitec 102.320 Nummer II User manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions