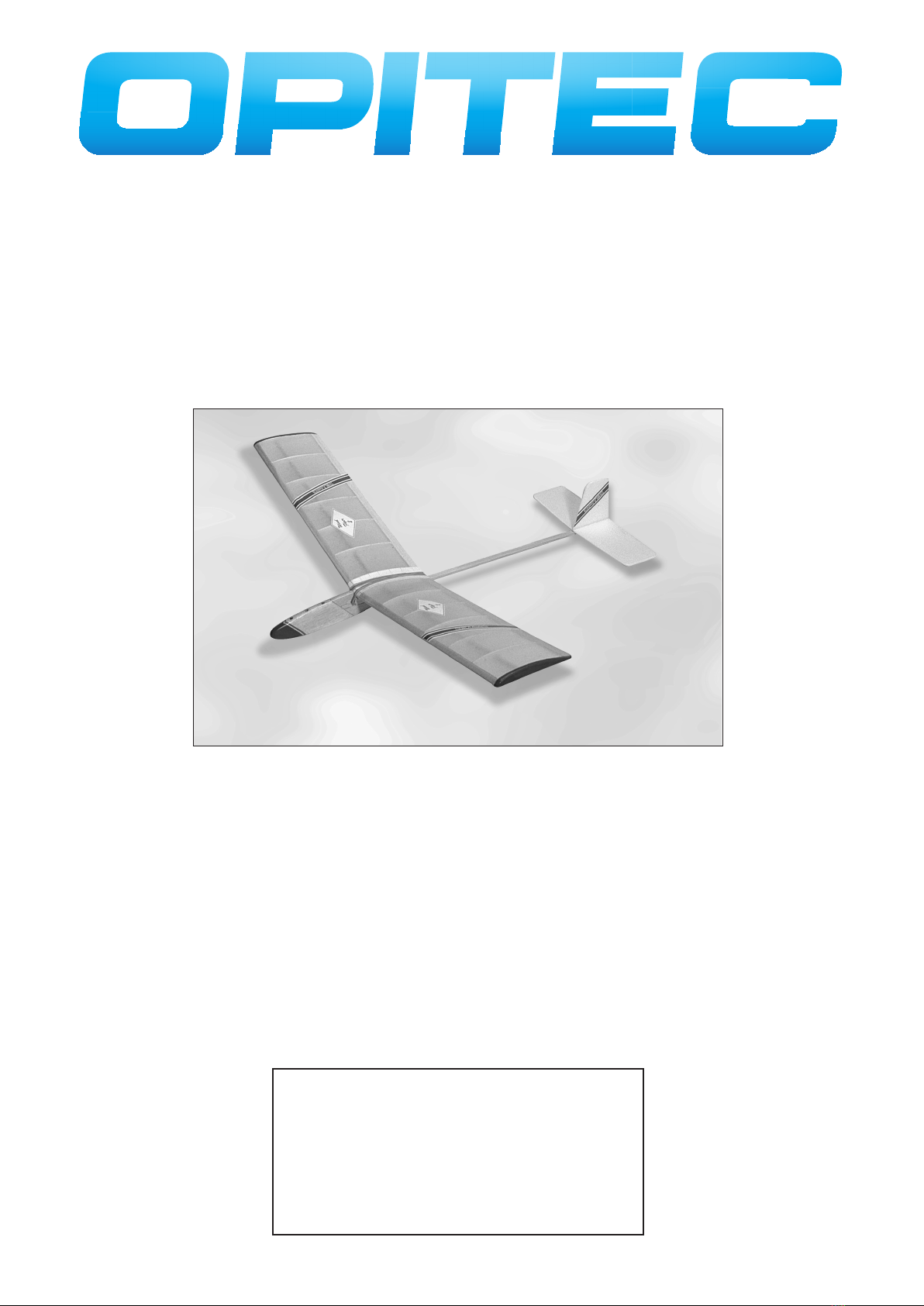

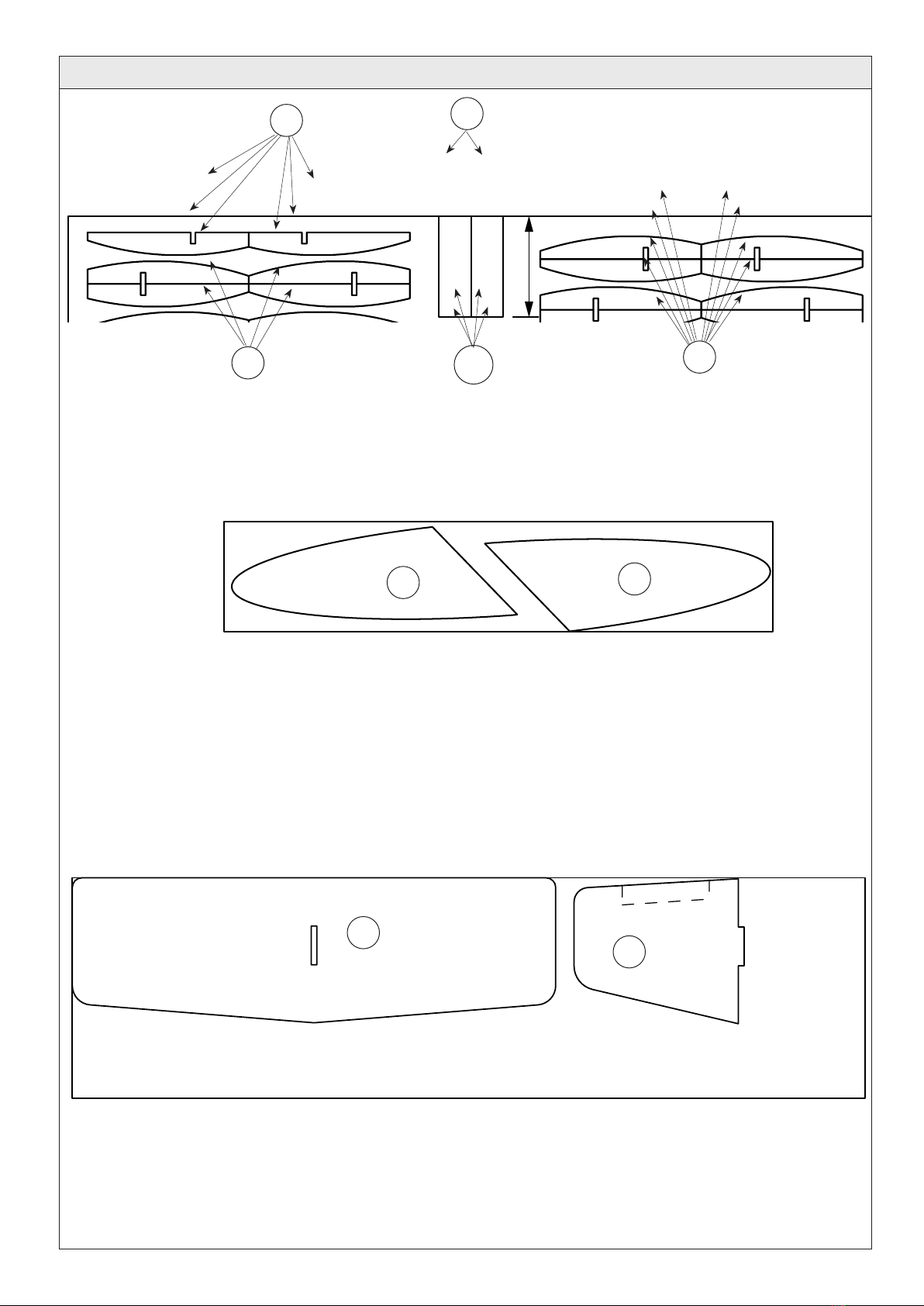

Opitec Windflyer II User manual

Other Opitec Toy manuals

Opitec

Opitec Hobbyfix User manual

Opitec

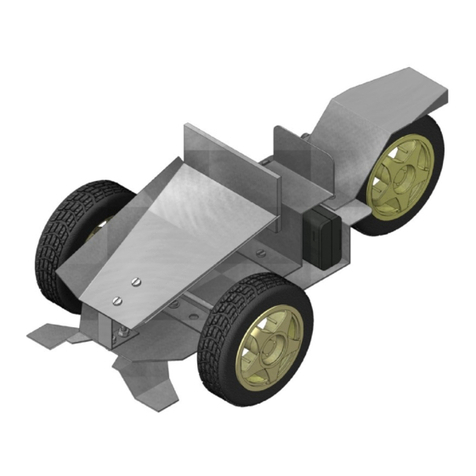

Opitec Solar Auto with gearbox User manual

Opitec

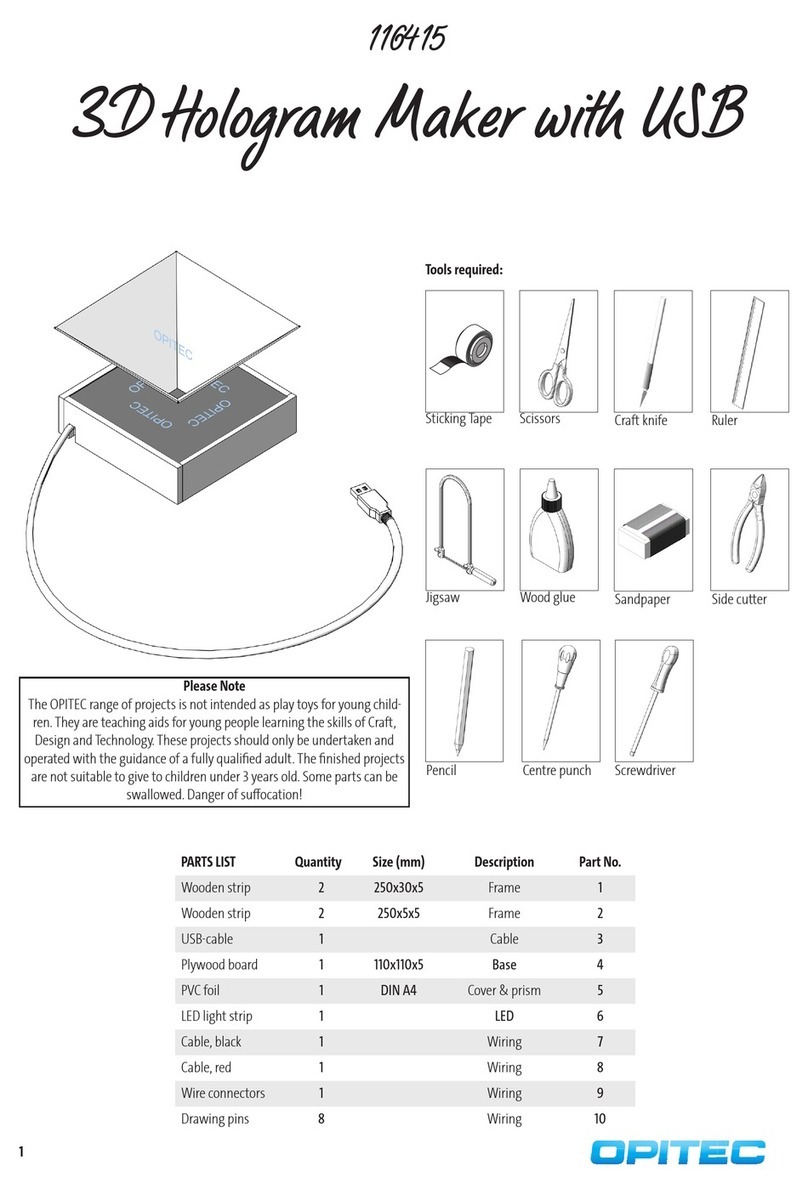

Opitec 116415 User manual

Opitec

Opitec Dragonfly 102.894 User manual

Opitec

Opitec Recycling Rowing Boat User manual

Opitec

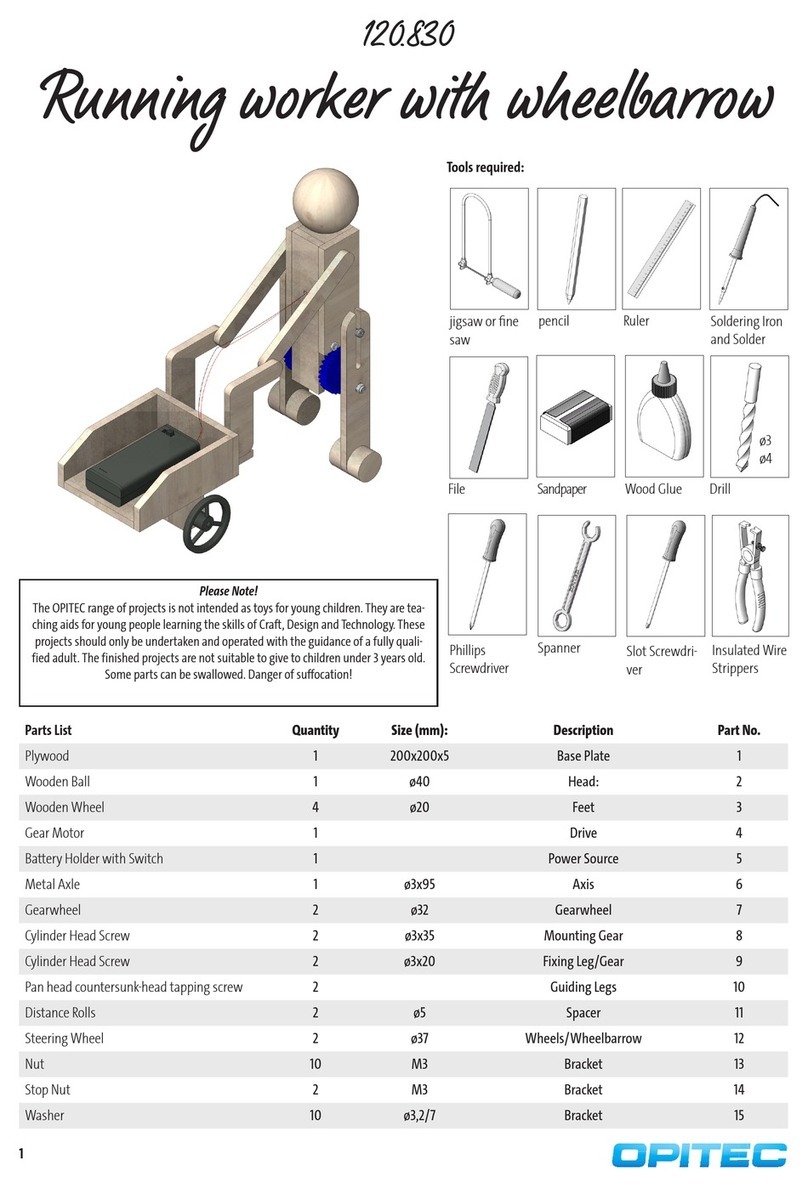

Opitec Running worker with wheelbarrow User manual

Opitec

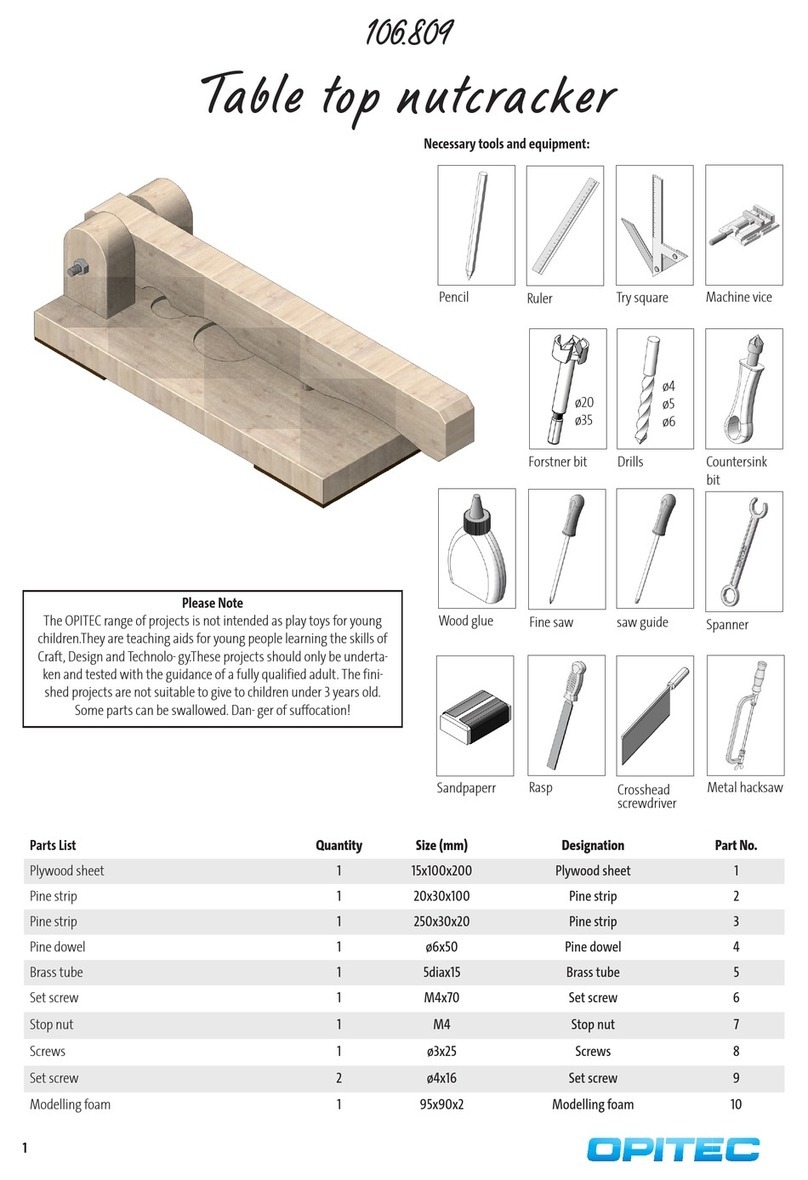

Opitec 106.809 User manual

Opitec

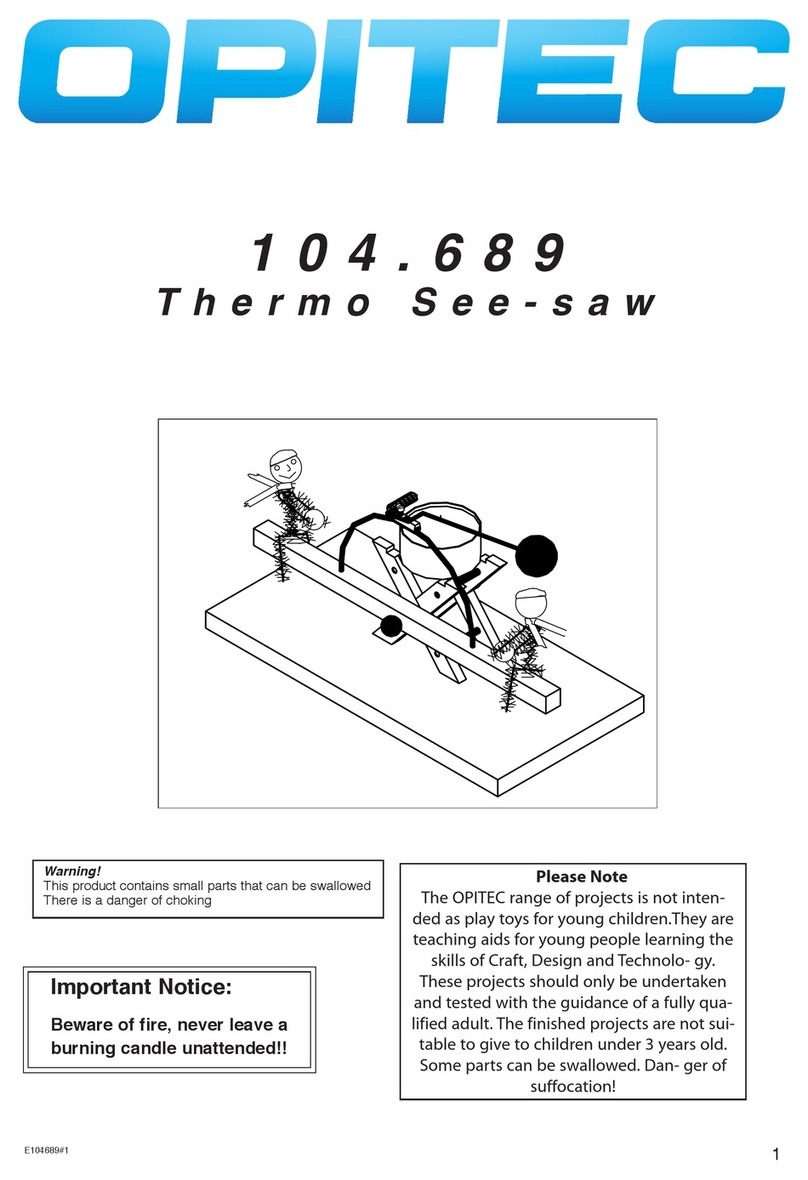

Opitec 104.689 User manual

Opitec

Opitec 117167 User manual

Opitec

Opitec 111.714 User manual

Opitec

Opitec Hobbyfix Flip User manual

Opitec

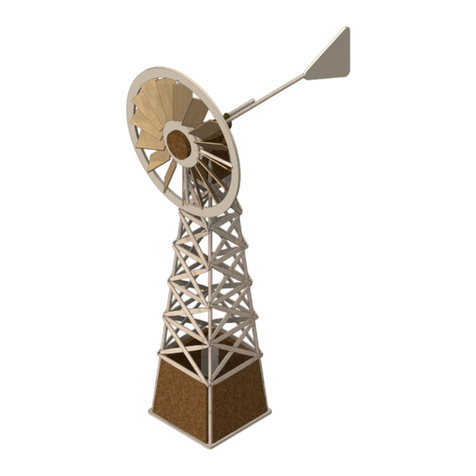

Opitec Easy-Line Wind Generator User manual

Opitec

Opitec Hobbyfix Cube User manual

Opitec

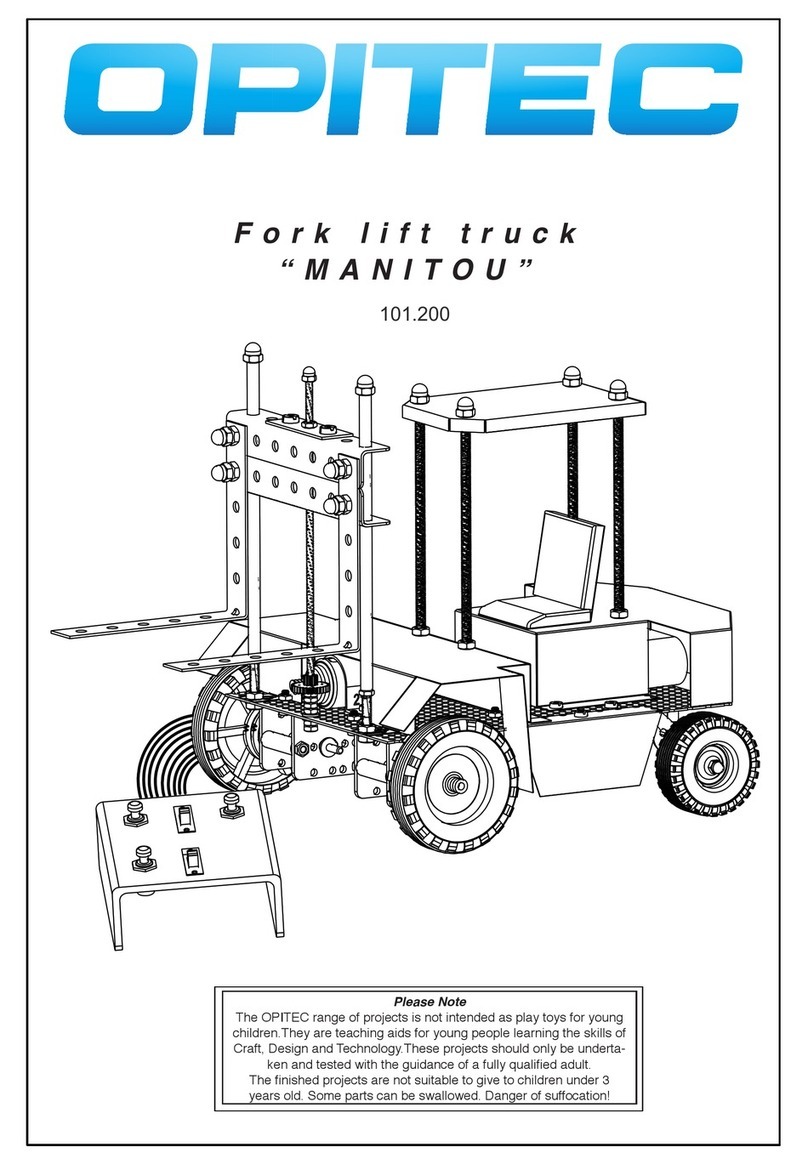

Opitec MANITOU 101.200 User manual

Opitec

Opitec Hobbyfix Stiletto 105.755 User manual

Opitec

Opitec 114.033 User manual

Opitec

Opitec Wind Machine User manual

Opitec

Opitec 113.141 User manual

Opitec

Opitec 115.305 User manual

Opitec

Opitec 120.852 User manual

Popular Toy manuals by other brands

FUTABA

FUTABA GY470 instruction manual

LEGO

LEGO 41116 manual

Fisher-Price

Fisher-Price ColorMe Flowerz Bouquet Maker P9692 instruction sheet

Little Tikes

Little Tikes LITTLE HANDIWORKER 0920 Assembly instructions

Eduard

Eduard EF-2000 Two-seater exterior Assembly instructions

USA Trains

USA Trains EXTENDED VISION CABOOSE instructions