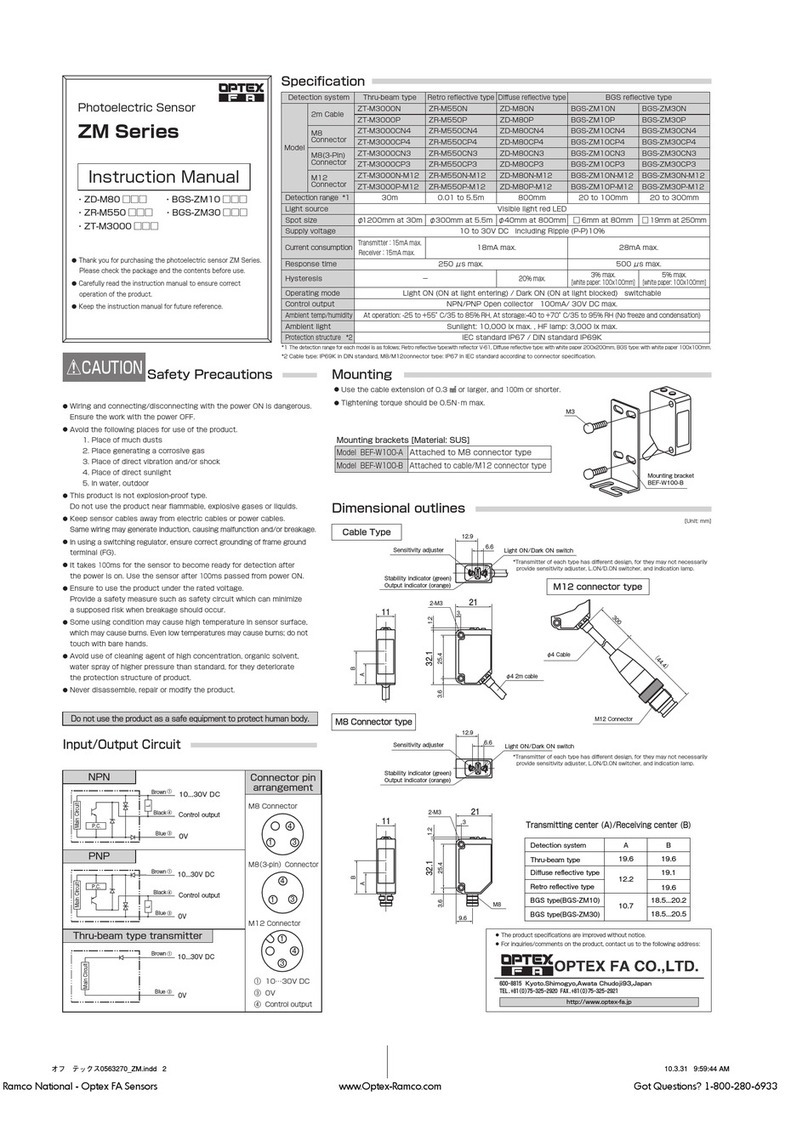

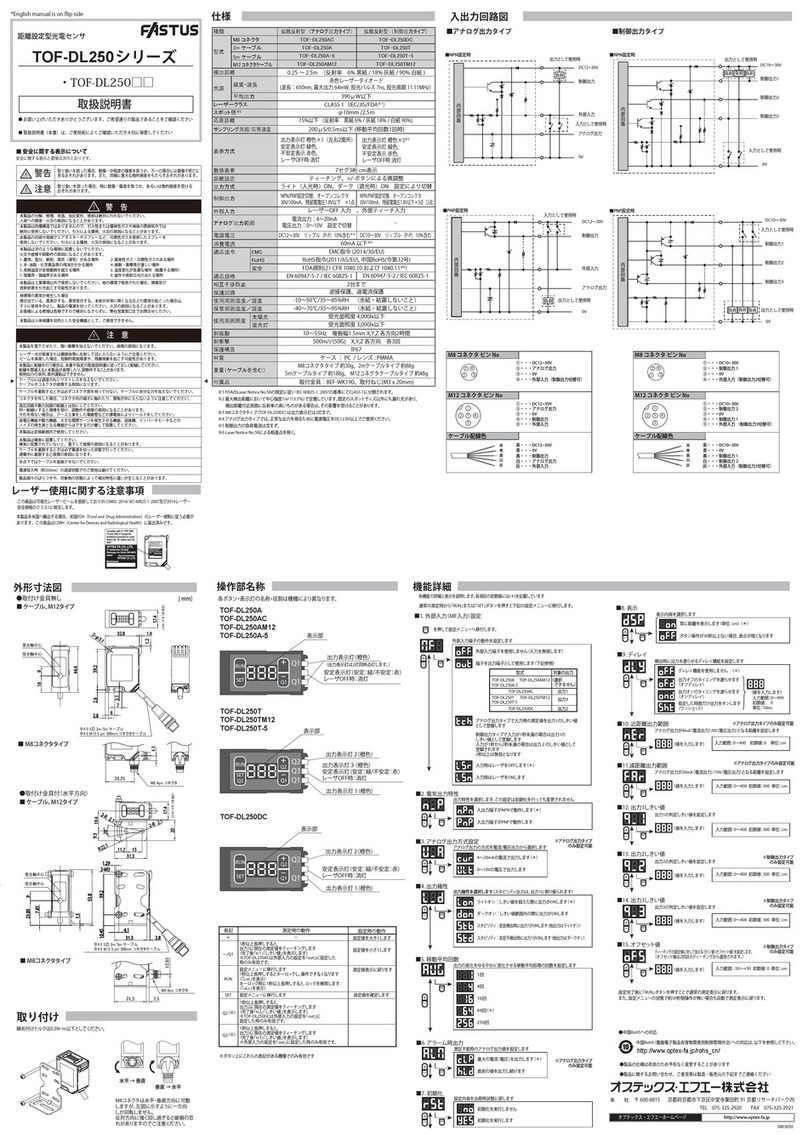

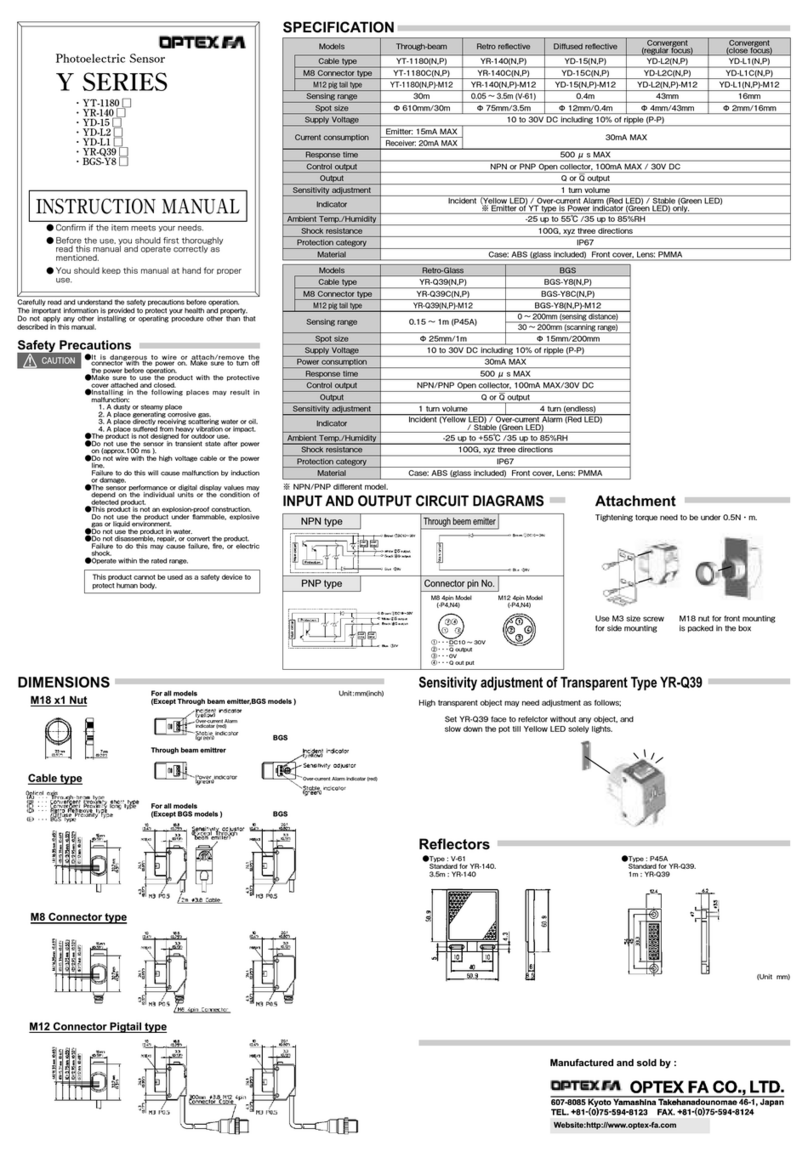

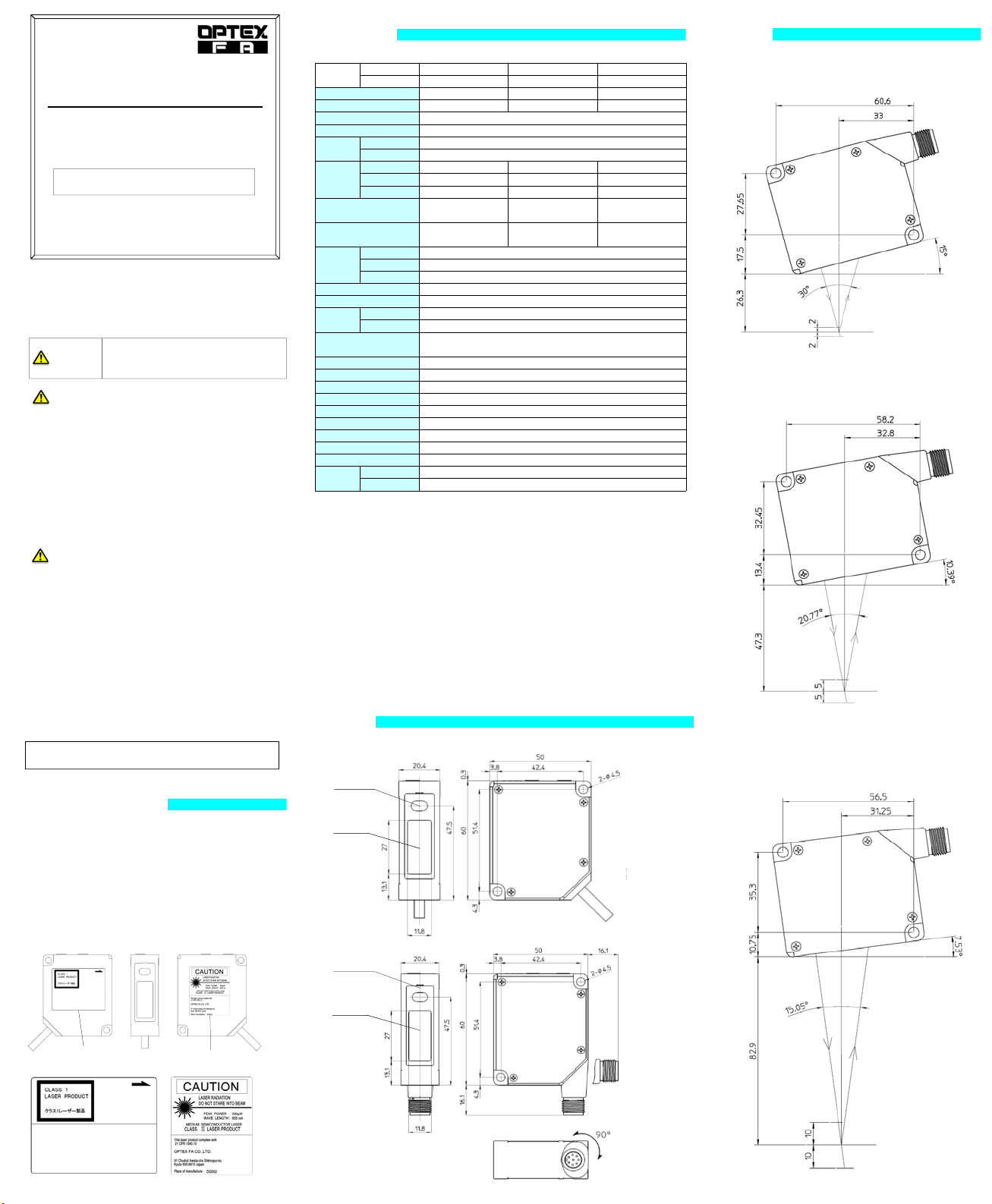

●Specifications of Measuring Range ●Teach mode

CD33-L30N(P) CD33-L50N(P) CD33-L85N(P) Functions Factory Setting

CD33-L30CN(P) CD33-L50CN(P) CD33-L85CN(P)

26.3mm 47.3mm 82.9mm

±2mm ±5mm ±10mm

0.15×0.15mm 0.15×0.15mm 0.15×0.15mm

0.1×0.1mm 0.1×0.1mm 0.1×0.1mm

0.15×0.15mm 0.15×0.15mm 0.15×0.15mm

●Special setting mode function

Functions Factory Setting

Protection Category

PBT (Case) PMMA (Front window)

Approx. 65g (without cable)

Sun light: 10,000 lx max. / Incandescent lamp: 3,000 lx max.

10 to 55 Hz, Double amplitude 1.5 mm, 2 h for XYZ axes

50G (500m/s2)

Warm up period

Material

Operating temp./humidity

Storage temp./humidity

Temperature Drift

FDA

CLASS1

CLASSⅡ

Laser Class

Sampling period

Resolution *3

averaging: 1 time 5ms max.

Sampling

period 500μs

averaging: 16 times 12.5ms max.

averaging: 64 times 36.5ms max.

500 /1000 /1500 /2000μs

±0.08% F.S./℃

Laser off、Remote teaching、Sample Hold (choose one function)

Response time :3ms max.

Reverse polarity、Over current

IP67

measures

higher peak

One shot

trigger Laser OFF

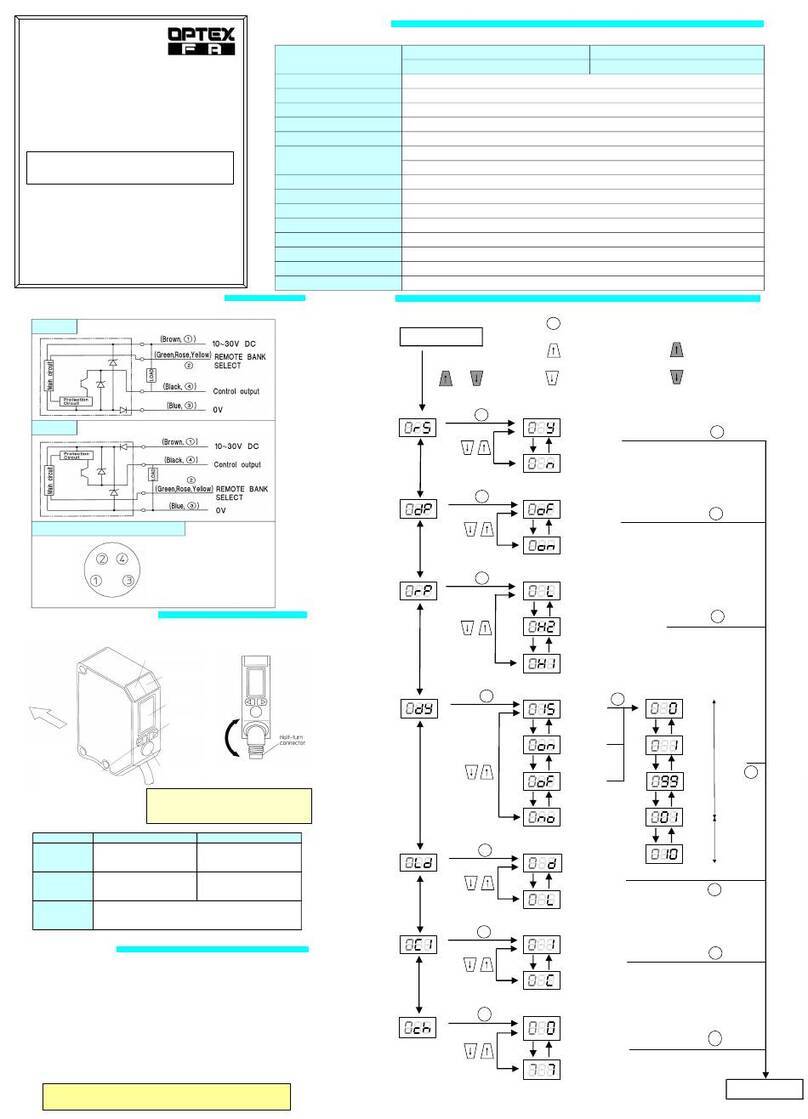

Functions indicated Details Settings and Adjustments

Measurement

settings

The output in the

measurement range

& Self-diagnosis *1

Linearity *2 ±0.2% F.S.

(F.S.=4mm)

±0.2% F.S.

(F.S.=10mm)

±0.2% F.S.

(F.S.=20mm)

Fast

Standard

5μm2.5μm1μm

Laser OFF

Averaging averaging: 16

Indicators

Response

time

Center

Measuring range

Spot size

(approx.

volume)

*1

Distance Indicator

Near

High resolution

Circuit protection

Type Cable type

Connector type

IEC/JIS

Output Indicator

MF (multi functional) input

Middle

Far

Light source

Details Settings and Adjustments

Red laser Diode (wave length 655nm)

Max. output 390μW

ON status : Orange

Bar graph LED

Peak power

-10~+45℃/35~85%RH (No condensation or freezing)

-20~+60℃/35~95%RH (No condensation or freezing)

Approx. 70g

15min max.

Functions indicated

Output setting

External input

Connector type

Ambient Light

Vibration resistance

Shock resistance

Weight Cable type

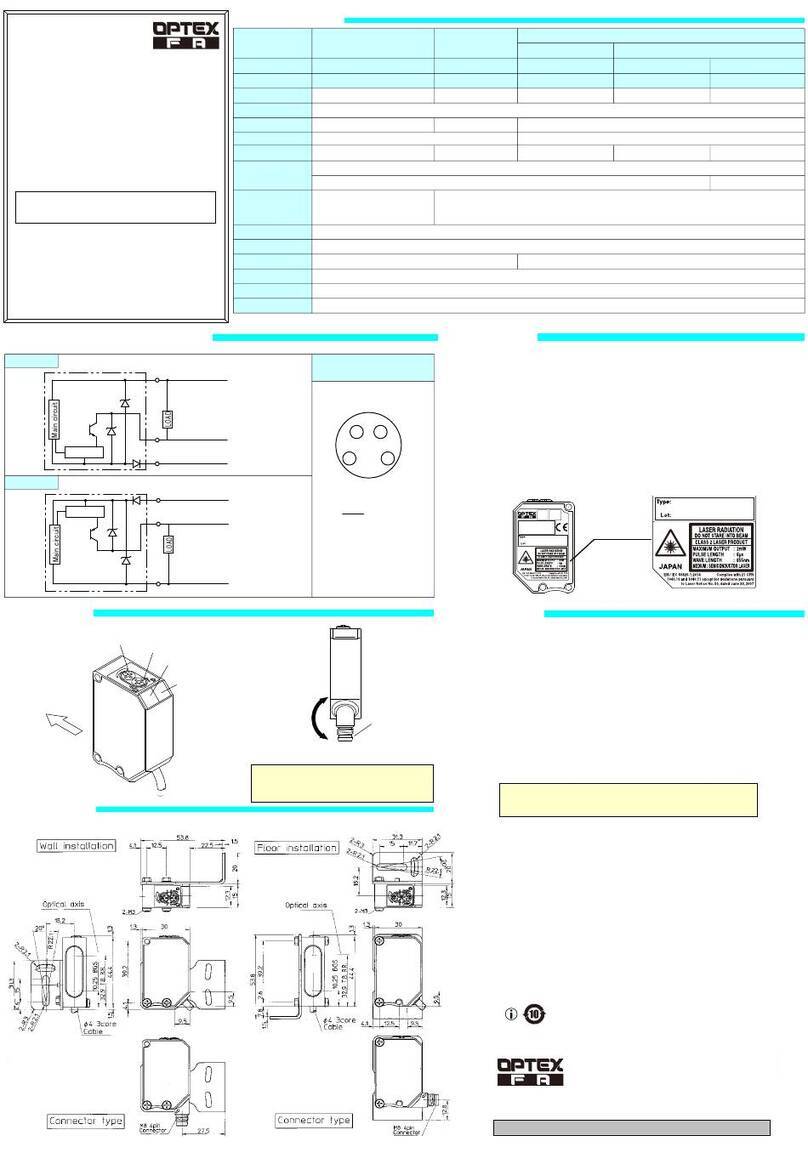

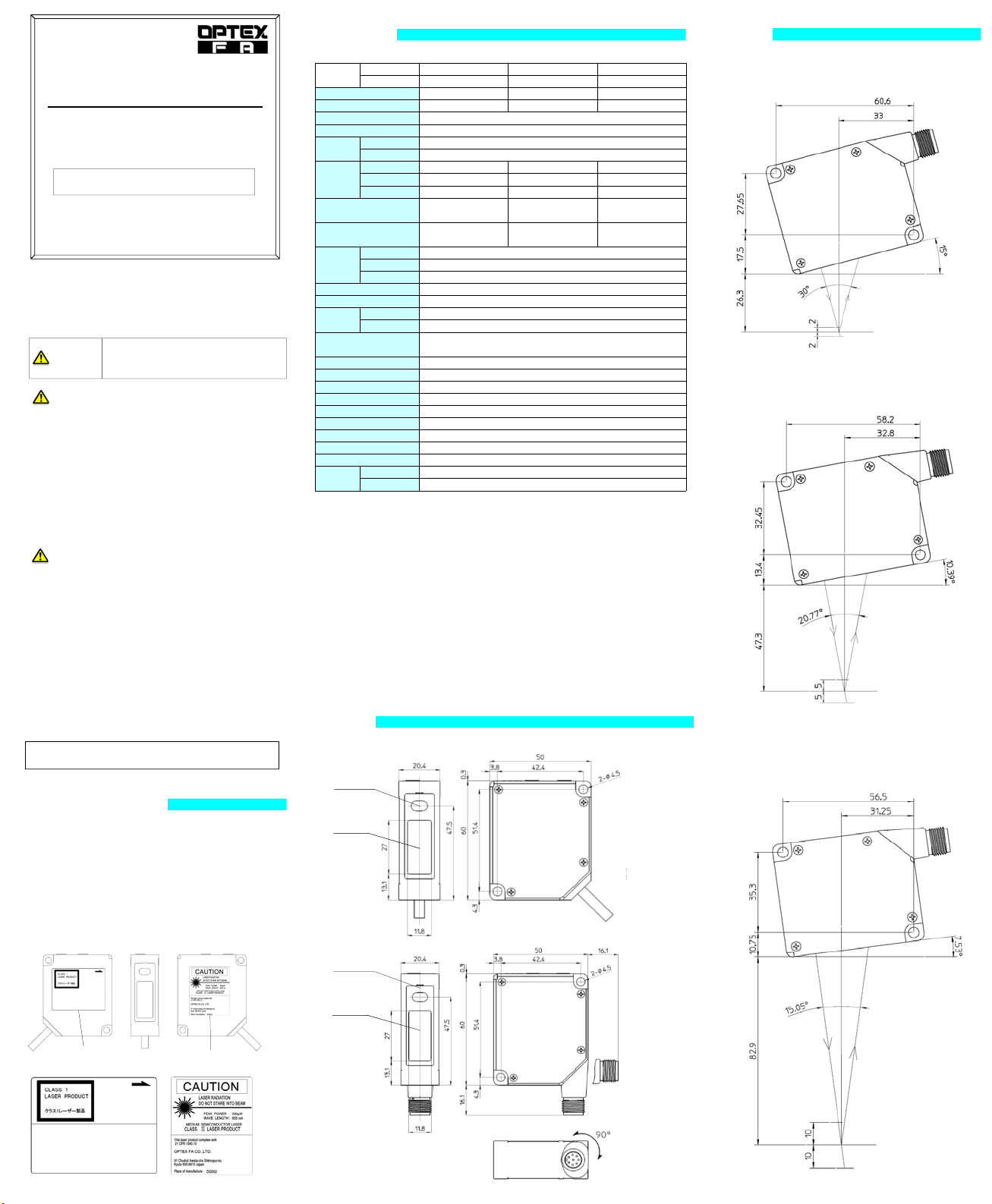

CD33-L30□□

CD33-L50□□

CD33-L SERIES

Displacement Sensor

Specifications

Specular

Laser type

Label-A Label-B

Label-BLabel-A

Installation

Install the sensor and adjust the light spot onto the measuring point so that the

distance indicator turns ON ( orange ) at the middle of measuring range.

Use M4 screw (tightening torque need to be under 0.8N・m).

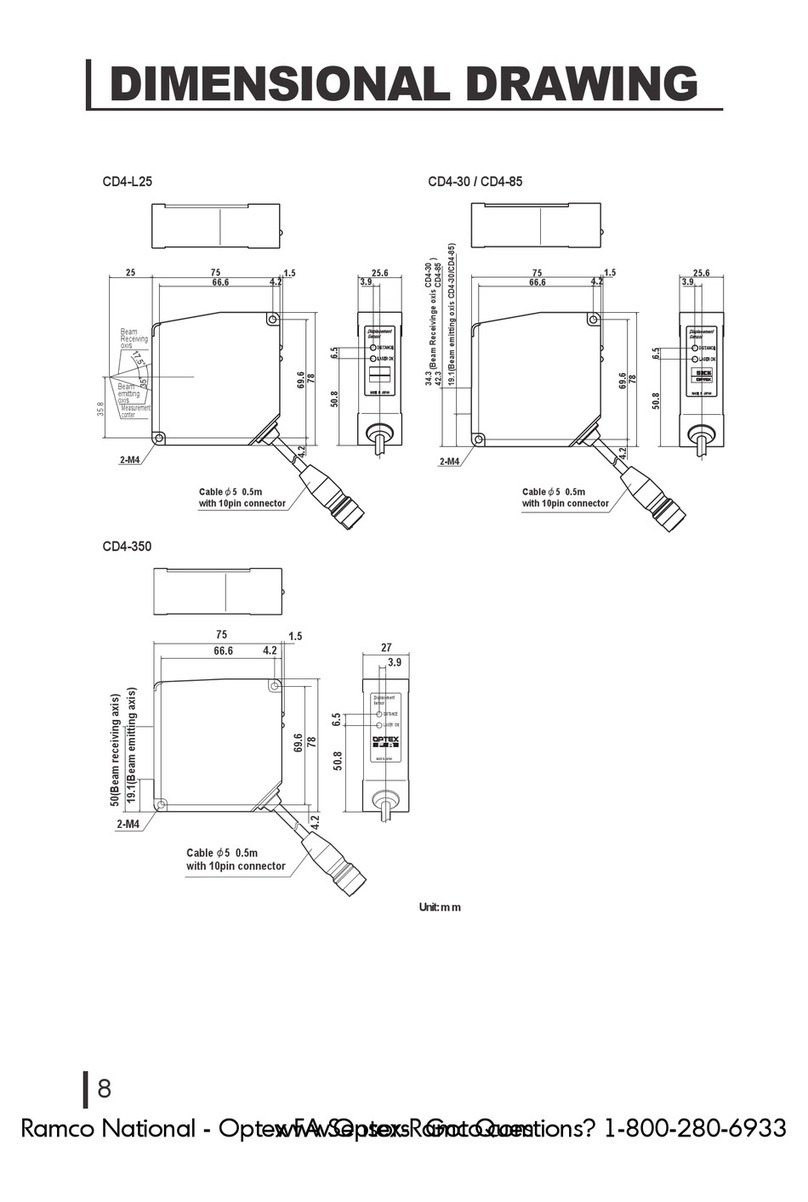

Dimension

Functions

Blink Once : measures higher peak

Blink twice : measures the 1st peak

Blink three times : measures distance

between 2 peaks

This setting is choice of measurement peak at receiver.

On : measures the 2nd peak

On Blink Once

measures

the 2nd peak measures higher peak

Blink twice

measures

the 1st peak

Blink three times measures distance

between 2 peaks

CD33-L30

CD33-L50

CD33-L85

(unit:mm)

Middle of measuring range

■Laser label

This product is classified as Class 1 by JIS C6802/IEC and ClassⅡ

by FDA Laser Product Laser Safety Standard.

●Regulations in the USA

When exporting laser devices to the USA, the USA laser control, FDA

(Food and Drug Administration) is applied. This product has been already

reported to CDRH (Center for Devices and Radiological Health). For

details, contact our customer service.

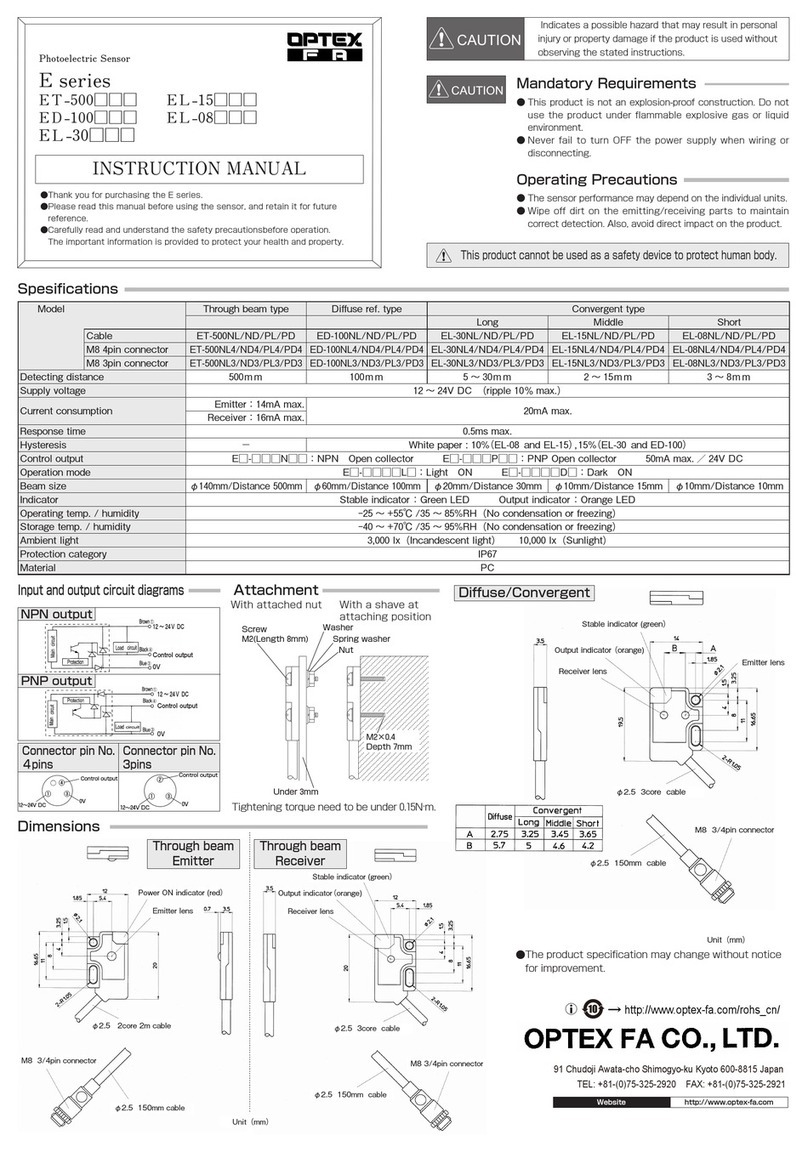

● It is dangerous to wire or attach/remove the connector with the power

on. Make sure to turn off the power before operation.

●Installing in the following places may result in malfunction:

1. A dusty or steamy place

2. A place generating corrosive gas

3. A place directly receiving scattering water or oil.

4. A place suffered from heavy vibration or impact.

●The product is not designed for outdoor use.

●Do not use the sensor in a transient state at power on(Approx. 15min.

Warm up period)

●Do not wire with the high voltage cable or the power lines.

Failure to do this will cause malfunction by induction or damage.

●Do not use the product in water.

●Operate within the rated range.

● Wipe off dirt on the emitting/receiving parts to maintain correct

detection. Also, avoid direct impact on the product.

Indicates a possible hazard that may result in death,

serious injury, WARNINGS or serious property damage

if the product is used without observing the stated

instructions.

● The light source of this product applies the visible light semiconductor

laser. Do not allow the laser beam to enter an eye, either directly or

reflected from reflective object. If the laser beam enters an eye, it may

cause blindness.

● Do not disassemble or modify the product since it is not designed to

automatically stop the laser emission when open. Disassembling or

modifying at customer's end it may cause personal injury, fire or electric

shock.

● This product is not an explosion proof construction. Do not use the

product under flammable , explosive gas or liquid environment.

● Use of controls or adjustments or performance of procedures other

than those specified herein may result in hazardous radiation exposure.

Precautions for using laser

WARNING

WARNING

WARNING

Carefully read and understand the safety precautions before operation. The

important information is provided to protect your health and property. Do

not apply any other installing or operating procedure other than that

Mandatory Requirements

Safety Precautions

Meanings of Safety Symbol

●This product cannot be used as a safety device to

protect human body.

INSTRUCTION MANUAL

● Confirm if the item meets your needs.

● Before the use, you should first thoroughly read this

manual and operate correctly as mentioned.

● You should keep this manual at hand for proper use.

*1 Defined with center strength 1/e2(13.5% ). There may be leak light other than the specified spot size.

The sensor may be damaged when there is a highly reflective object around the targets.

*2 Averaging: 64(High resolution), Sampling period:500μs, Object: white ceramic.

*3 Middle of measuring range, Object: white ceramic.

*4 Diameter of min bend cable is 40mm.

φ5-2mCable

RS422 :8core

M12 8pin connector

Beam emitting

axis

Beam receiving

area

Beam emitting

axis

Beam receiving

area

Middle of measuring range

Middle of measuring range

Select the function of the external input.

Average count setting

Blink Once : Fast (averaging 1 time)

Blink twice : Standard

avera

in

16 times

Blink three times : High Res. (averaging 64 times)

①Push the Select button more than five seconds to enter Teach mode.

②Push the Select button and let MF indication turn on.

③Choose the function you need by pushing Set button.

④Push the Select button more than five seconds to return to Run mode.

Blink Once : Laser OFF

Blink twice : Remote teaching

Blink three times : Sample Hold

①Push the Select button more than five seconds to enter Teach mode.

②Push the Select button and let Avg. indication turn on.

③Choose the function by pushing Set button.

④Push the Select button more than five seconds to return to Run mode.

MF input

Sample Hold

Analog output

One Shot Trigger

Analog output

*Possible to choose One Shot Trigger by Special setting mode.

Remote teaching

Laser output

T

Hold the output during inputs.

Update the output by edge of the input

and hold the output until next input

Input time (refer to Remote Teaching)

Range of sensing of

One Point Teaching

Range of sensing of

Two Points Teaching

One point Two points

Range of sensing of

One Point Reverse teaching

Near Far

set the range of Control Output.

One point teaching :From the position of the teaching - 0.15%(FS)

to the Near side of the sensing range.

Two points teaching :Between the position of the first point

teaching +0.15%(FS) and the position of

the second point teaching -0.15%(FS).

One point reverse teaching: From the position of the teaching

+0.15%(FS) to the Far side of the sensing

range.

●One point teaching

①Push the Select button more than five seconds to enter Teach mode.

②Push the Select button and let Q1(Q2) indication turn on.

③Set the object in the position that you want to measure and push the Set button

④ Q1(Q2) indication flashes one time.

In the case of adjustment failure, indication flashes for five seconds. Try again getting back to ② of

above.

●Two points teaching

①Push the Select button more than five seconds to enter Teach mode.

②Push the Select button and let Q1(Q2) indication turn on

③Set up the object at the first point of the range that you want to measure and push the Set button

④ Q1(Q2) indication flashes one time. In the case of adjustment failure, the indication flashes

for five seconds. Try again getting back to ② of above.

⑤Q1(Q2)) which you Set up the object to the second point you want to measure, and push the Set button.

Q1(Q2) indication flashes two times. In the case of the adjustment failure that the indication flashes

for five seconds. Try again getting back to ② of above.

⑥Push the Select button more than five seconds to return to Run mode.

●One point Reverse teaching

①Push the Select button more than five seconds to enter Teach mode.

②Push the Select button and let Q1(Q2) indication turn on

③Set the object in the position that you want to measure and push the Set button more than five

seconds .

④ Q1(Q2) indication flashes one time.

In the case of adjustment failure, the indication flashes five seconds.

Try again getting back to ② of above.

⑤Push the Select button more than five seconds to return to Run mode.

One shot trigger is possible to select through external input.

On :One shot trigger

①Push the Select and set button at same time for more than five seconds

to enter Special setting mode

②Push the Select button and let MF indication turn on.

③Choose the function by pushing Set button.

④Push the Select and set button more than five seconds to return to Run mode.

Blink Once : Laser OFF

Blink twice : Remote teaching

Blink three times : Sample Hold

Sampling period setting

①Push the Select button more than five seconds to

enter Teach mode.

②Push the Select button and let Avg. indication

turn on.

③Choose the function by pushing Set button.

④Push the Select and set button more than five seconds

to return to Run mode.

Blink Once : 500μs

Blink twice : 1000μs

Blink three times : 1500μs

On : 2000μs

Shorter sampling period

increases the response

and longer sampling

period enhances the

sensitivity.

High sensitivity

High response

①Push the Select and set button at same time for more than five seconds

to enter Special setting mode

②Push the Select button and let MF indication turn on.

③Choose the function by pushing Set button.

④Push the Select and set button more than five seconds to return to Run mode.

(Remarks)

When the Teach mode / special setting mode it returns to RUN if no operation in given for 60 seconds.

*1 Self-diagnosis output comes at the time of (1) laser stop (2) saturation by mirror-like object or (3) low sensitivity.

This function does not work when you set the output of Q2. Reset the product when you want to use self-diagnosis again.