OPUS aeroPOUCH 9 Pro Instrukcja obsługi

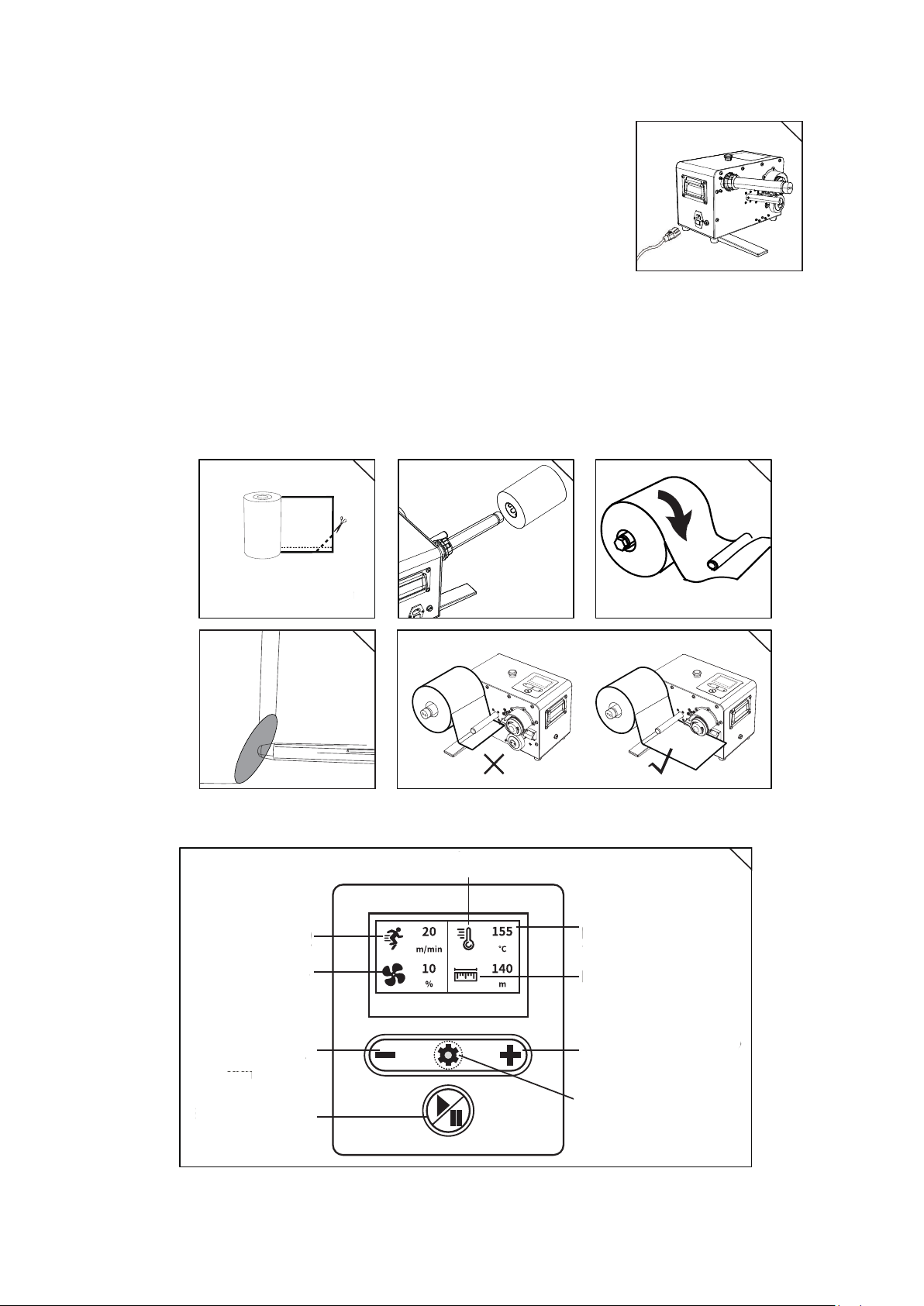

4. INSTALACJA FOLII

•Podłącz przewód zasilający do urządzenia.

•Zamontuj rolkę z folią.

oPrzytnij folię nożyczkami w prawym dolnym rogu

przed umieszczeniem jej w urządzeniu, rys. 2.

W przypadku folii z osobnym kanałem na dyszę nie

ma konieczności przycinania narożnika.

oPrawidłowo umieść rolkę folii na wałku podającym. Wałek posiada wystającą

prowadnicę, która powinna pokryć się z wycięciem wewnątrz roli folii rys. 3.

oZwróć uwagę na kierunek założenia folii na rolkę napinającą patrz rys. 4.

oPrzeprowadź folię przez dyszę powietrzną rys. 5.

oUpewnij się, że folia znajduje się dokładnie pomiędzy wałkiem zimnym

a wałkiem grzewczym tak, aby po włączeniu przycisku start rozpocząć płynne

zgrzewanie rys. 6.

5. OBSŁUGA

zmniejszenia

Przycisk zwiększenia

wartości

Przycisk wyboru funkcji. Podwójne

naciśniecie przycisku powoduje

wejście w tryb programowania,

kolejne naciśnięcie to wybór

żądanej funkcji, która miga

w trakcie edycji.

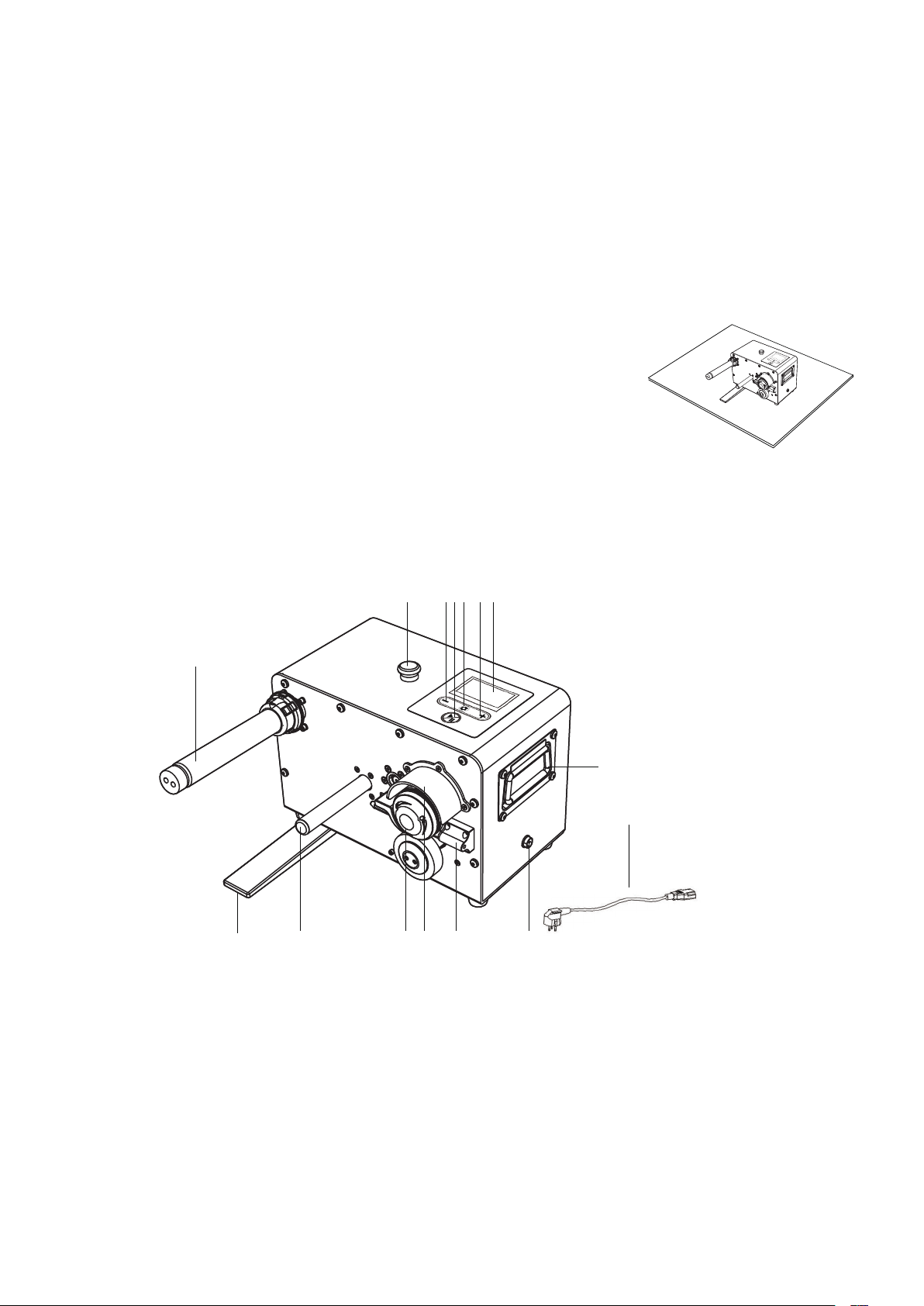

A. Feeding roller

B. Foot stand

C. Tension column

D. Heating roller

E. Roller cover

F. Air nozzle

G. Optional outlet

H. Enmergency stop

I. Decrease setting button

J. Start/Pause button

K. Function setting button

L. Increase setting button

M. Screen display

N. Hand hold

O. Electrical Cable

Please read carefully before use.

1.1 Remove the machine from the package box carefully.

1.2 Put the machine in the clean and flat working table, close to edge as well.

Refer fig.A.

2.1 Connect the correct electrical power. Refer fig.1.

2.2 Installation of film roll.

2.2.3 The roll feeding direction to pass through to the tension column, Refer fig.4.

2.2.1 The bubble film should be cut with a scissorsin the lower right corner before

loading the film, Refer fig.2.

2.2.2 Put the roll film on the feeding roller properly. There is a groove inside the roll film

header should align and feed into feeding roller’s protrusion part. Refer fig.3.

2.2.4 Threading roll film pass through the air nozzle. Refer fig.5.

2.2.5 Pulling the roll film to close enough and touch just right between the hot sealing

wheels to ensure when push start button the machine can pull out film till out of

the roller wheels, and start making air cushion smoothly. Refer fig.6.

2.3 Operations

2.3.1 Connecting the electrical power, and turn on the power switch near by power

socket, make sure the enmergency stop switch turn clockwise to its normal position.

2.3.2 After power on the display screen will indicating previous setting,and ready

for a newsetting or start to work as last time,press start/hold button the

temperature symbol will flashing and machine start to warm up,it takes

around 2~3 mins to go.

2.3.3 When temperature symbol stop flashing machine will start to making air cushions.

2.3.4 When finish making air cushion, press the start/hold button again,machine will

stop immediately. There is a perforation line on the film to tear off the necessary

length for your requirement.

2.3.5 Air density setting: Various cushion sizes are available to meet different

packaging requirements, You can press twice of function setting button in to the

set up manual, press again will shift the symbol flashing movement from one

place to another clockwise, till you move up to fan symbol, you can set the air

density volume to meet your equirements, the output range is 0~100% please

adjust the suitable air pressure to get best air cushion result, too much or too

less air pressure will result in jam or bad air cushion performance (Remark:

"5~35%" output is recommend for 200mm width film and "35~95%" output is for

400mm width film).

2.3.6 Press the start/pause button for each use of the air cushion machine.

2.3.7 If press stop button without touch any other button for more than 30 mins,

machine will going to a hibernation status, the temperature will drop to 80 ℃

until you press any button interrupt the internal timer to wake up machine for

the next use.

2.3.8 Speed setting: click twice on function button, and move the function symbol to

the ruler symbol by each click accordingly while the symbol is still flashing, speed

range is from 3~20 level, the maximum speed is about 20m/min.

2.3.9 Temperature setting: click twice on function button, and move the function symbol

to the temp. symbol by each click accordingly while the symbol is still flashing,

temperature range is from room temp.~180℃.

2.3.10 Length setting: click twice on function button, and move the function symbol to the

ruler symbol by each click accordingly while the symbol is still flashing.

2.3.11 Due to individual machine differences, above setting value is not equal to the

actual output value.

2.3.12 If want to poweroff, please make sure machine is stop, tear off the film ahead the

air nozzle, and turn off the power switch.

1. Caution

2. Installation Steps

3. Electric Safety

5. Machine Maintenance

6. Specification

3.1 Place the machine close to power socket.

3.2 Make sure the voltage meets machine’s electricity requirements.

3.3 Any extension cord used should meet the power rating of the machine.

3.4 Do not operate if the power cord is damaged.

3.5 Repair and service should be done by a qualified service technician.

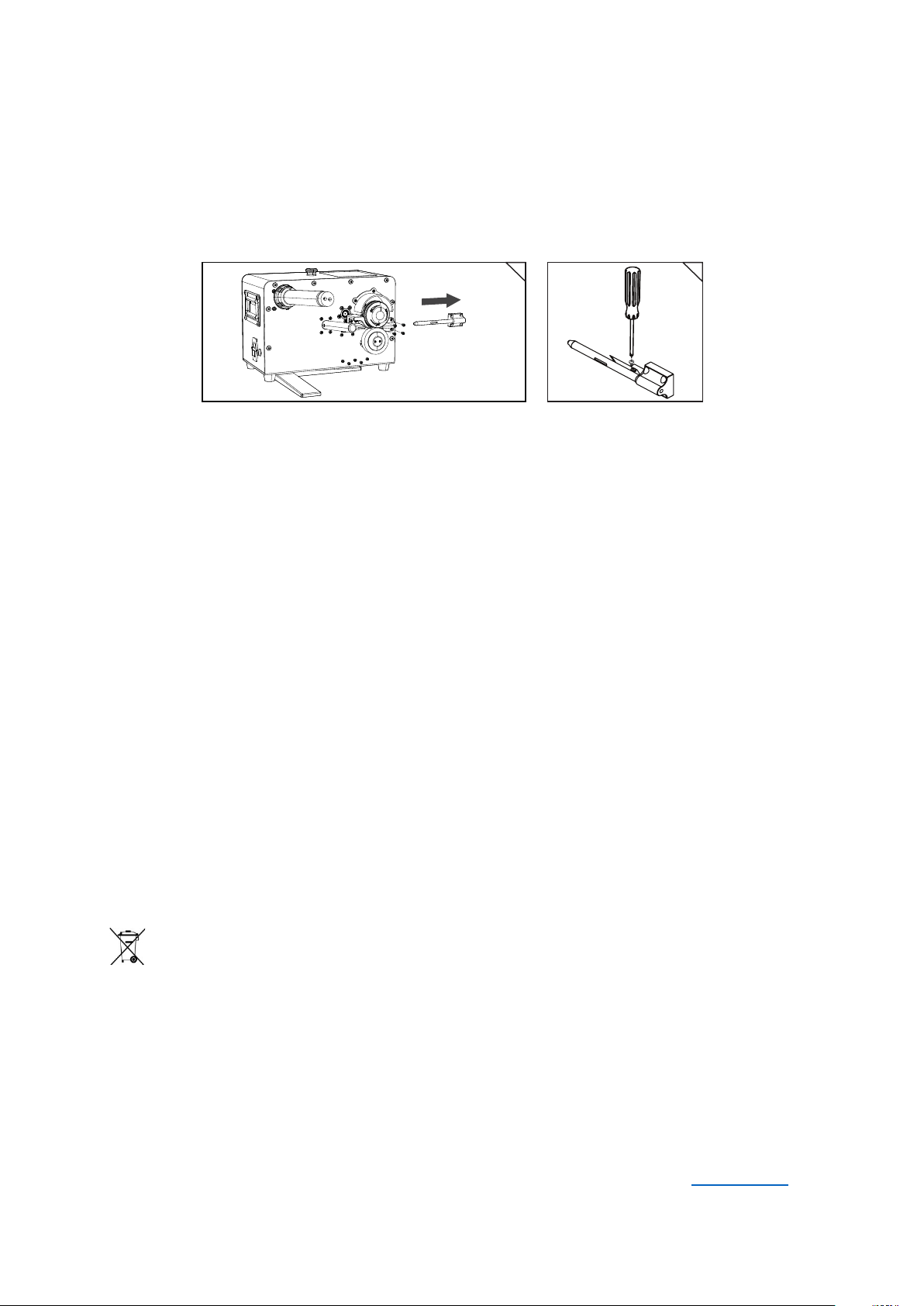

5.1 Unplug the power cord during maintenance.

5.2 Clean hot seals and rollers regularly.

5.3 Ensure there is no jammed film and dirt at the air nozzle or cutter blade.

5.4 Check the blade and rollers regularly.

5.5 Replace the cutter blade when blade is not sharp.

Air nozzle cutter blade replacement steps

4.1 Use the screw driver to remove the fix air nozzle screws. Refer fig.8A.

4.2 Pulling out the air nozzle. Refer fig.8B.

4.3 Remove the air nozzle fix screws. Refer fig.9.

4.4 Renew the new cutter blade (Caution: Be care of sharp blade may cut you fingers).

4.5 Put the air nozzle back and use the screw driver to fix tightly of the 2 fix-screws.

Refer fig.9,10.

Caution: Blade might blunt after a longer use, please check or replace the

blade every 200 rolls (300m/roll).

4. Cutter replacement

5

4

2

Approximately

3cm (1-1/2”)cut off corner.

3

20m/min±10%(adjustable)Sealing speed

Adjustable (200/400mm inadifferent

setting and operation range)

Air density control

Film roll size

200x80mm、200x100mm、200x130mm

200x150mm、200x200mm、

400x250mm、400x290mm

Power voltage 220-240VAC 50/60Hz

Machine size 385×270×280(mm)

Machine weight 17kg

Max. Film roll length

(W: Film width)

(L: Film length)

Power rate 300W

200mm ≤800M 400mm ≤500M

W L W L

1

fig.A

working table

6

7

Function setting button

Decrease Setting

button

Speed Symbol

Temperature symbol

Start/Pause button

Increase setting button

Length Symbol

Double click the function setting

button to start Choose a symbol

that you will work with until it

flashes which you can now set in

the required to function with.

Air Volume

No. Or Figures for

illustration

B

8 9

O

Air Cushion Machine

3800

A

HMJ KI L

CB D E F G

N

A

OPUS aeroPOUCH 9 Pro Instrukcja

obsługi / User guide

OPUS

aeroPOUCH 9 Pro

PL Instrukcja obsługi

A. Feeding roller

B. Foot stand

C. Tension column

D. Heating roller

E. Roller cover

F. Air nozzle

G. Optional outlet

H. Enmergency stop

I. Decrease setting button

J. Start/Pause button

K. Function setting button

L. Increase setting button

M. Screen display

N. Hand hold

O. Electrical Cable

Please read carefully before use.

1.1 Remove the machine from the package box carefully.

1.2 Put the machine in the clean and flat working table, close to edge as well.

Refer fig.A.

2.1 Connect the correct electrical power. Refer fig.1.

2.2 Installation of film roll.

2.2.3 The roll feeding direction to pass through to the tension column, Refer fig.4.

2.2.1 The bubble film should be cut with a scissorsin the lower right corner before

loading the film, Refer fig.2.

2.2.2 Put the roll film on the feeding roller properly. There is a groove inside the roll film

header should align and feed into feeding roller’s protrusion part. Refer fig.3.

2.2.4 Threading roll film pass through the air nozzle. Refer fig.5.

2.2.5 Pulling the roll film to close enough and touch just right between the hot sealing

wheels to ensure when push start button the machine can pull out film till out of

the roller wheels, and start making air cushion smoothly. Refer fig.6.

2.3 Operations

2.3.1 Connecting the electrical power, and turn on the power switch near by power

socket, make sure the enmergency stop switch turn clockwise to its normal position.

2.3.2 After power on the display screen will indicating previous setting,and ready

for a newsetting or start to work as last time,press start/hold button the

temperature symbol will flashing and machine start to warm up,it takes

around 2~3 mins to go.

2.3.3 When temperature symbol stop flashing machine will start to making air cushions.

2.3.4 When finish making air cushion, press the start/hold button again,machine will

stop immediately. There is a perforation line on the film to tear off the necessary

length for your requirement.

2.3.5 Air density setting: Various cushion sizes are available to meet different

packaging requirements, You can press twice of function setting button in to the

set up manual, press again will shift the symbol flashing movement from one

place to another clockwise, till you move up to fan symbol, you can set the air

density volume to meet your equirements, the output range is 0~100% please

adjust the suitable air pressure to get best air cushion result, too much or too

less air pressure will result in jam or bad air cushion performance (Remark:

"5~35%" output is recommend for 200mm width film and "35~95%" output is for

400mm width film).

2.3.6 Press the start/pause button for each use of the air cushion machine.

2.3.7 If press stop button without touch any other button for more than 30 mins,

machine will going to a hibernation status, the temperature will drop to 80 ℃

until you press any button interrupt the internal timer to wake up machine for

the next use.

2.3.8 Speed setting: click twice on function button, and move the function symbol to

the ruler symbol by each click accordingly while the symbol is still flashing, speed

range is from 3~20 level, the maximum speed is about 20m/min.

2.3.9 Temperature setting: click twice on function button, and move the function symbol

to the temp. symbol by each click accordingly while the symbol is still flashing,

temperature range is from room temp.~180℃.

2.3.10 Length setting: click twice on function button, and move the function symbol to the

ruler symbol by each click accordingly while the symbol is still flashing.

2.3.11 Due to individual machine differences, above setting value is not equal to the

actual output value.

2.3.12 If want to poweroff, please make sure machine is stop, tear off the film ahead the

air nozzle, and turn off the power switch.

1. Caution

2. Installation Steps

3. Electric Safety

5. Machine Maintenance

6. Specification

3.1 Place the machine close to power socket.

3.2 Make sure the voltage meets machine’s electricity requirements.

3.3 Any extension cord used should meet the power rating of the machine.

3.4 Do not operate if the power cord is damaged.

3.5 Repair and service should be done by a qualified service technician.

5.1 Unplug the power cord during maintenance.

5.2 Clean hot seals and rollers regularly.

5.3 Ensure there is no jammed film and dirt at the air nozzle or cutter blade.

5.4 Check the blade and rollers regularly.

5.5 Replace the cutter blade when blade is not sharp.

Air nozzle cutter blade replacement steps

4.1 Use the screw driver to remove the fix air nozzle screws. Refer fig.8A.

4.2 Pulling out the air nozzle. Refer fig.8B.

4.3 Remove the air nozzle fix screws. Refer fig.9.

4.4 Renew the new cutter blade (Caution: Be care of sharp blade may cut you fingers).

4.5 Put the air nozzle back and use the screw driver to fix tightly of the 2 fix-screws.

Refer fig.9,10.

Caution: Blade might blunt after a longer use, please check or replace the

blade every 200 rolls (300m/roll).

4. Cutter replacement

5

4

2

Approximately

3cm (1-1/2”)cut off corner.

3

20m/min±10%(adjustable)Sealing speed

Adjustable (200/400mm inadifferent

setting and operation range)

Air density control

Film roll size

200x80mm、200x100mm、200x130mm

200x150mm、200x200mm、

400x250mm、400x290mm

Power voltage 220-240VAC 50/60Hz

Machine size 385×270×280(mm)

Machine weight 17kg

Max. Film roll length

(W: Film width)

(L: Film length)

Power rate 300W

200mm ≤800M 400mm ≤500M

W L W L

1

fig.A

working table

6

7

Function setting button

Decrease Setting

button

Speed Symbol

Temperature symbol

Start/Pause button

Increase setting button

Length Symbol

Double click the function setting

button to start Choose a symbol

that you will work with until it

flashes which you can now set in

the required to function with.

Air Volume

No. Or Figures for

illustration

B

8 9

O

Air Cushion Machine

3800

A

HMJ KI L

CB D E F G

N

A

OPUS aeroPOUCH 9 Pro Instrukcja obsługi / User guide

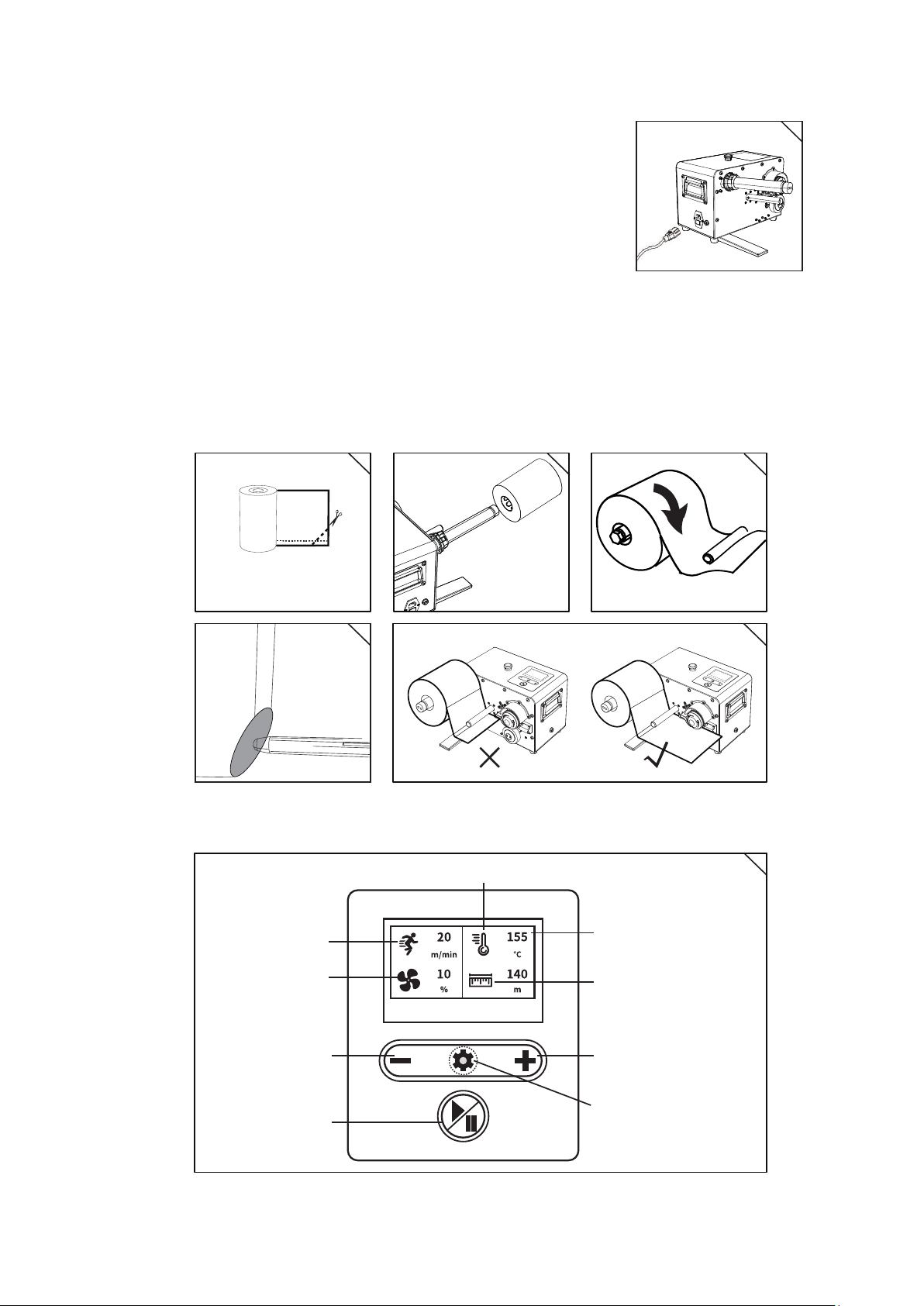

4. INSTALACJA

•Podłącz przewód zasilający do urządzenia.

•Zamontuj rolkę z folią.

oPrzytnij folię nożyczkami w prawym dolnym rogu

przed umieszczeniem jej w urządzeniu, rys. 2.

oPrawidłowo umieść rolkę folii na wałku podającym.

Wałek posiada wystającą prowadnicę, która

powinna pokryć się z wycięciem wewnątrz roli folii rys. 3.

oZwróć uwagę na kierunek założenia folii na rolkę napinającą patrz rys. 4.

oPrzeprowadź folię przez dyszę powietrzną rys. 5.

oUpewnij się, że folia znajduje się dokładnie pomiędzy wałkiem zimnym a

wałkiem grzewczym tak, aby po włączeniu przycisku start rozpocząć płynne

zgrzewanie rys. 6.

5. OBSŁUGA

Przycisk zwiększenia

wartości

Przycisk wyboru funkcji. Podwójne

naciśniecie przycisku powoduje

wejście w tryb programowania,

kolejne naciśnięcie to wybór

żądanej funkcji, która miga

w trakcie edycji.

A. Feeding roller

B. Foot stand

C. Tension column

D. Heating roller

E. Roller cover

F. Air nozzle

G. Optional outlet

H. Enmergency stop

I. Decrease setting button

J. Start/Pause button

K. Function setting button

L. Increase setting button

M. Screen display

N. Hand hold

O. Electrical Cable

Please read carefully before use.

1.1 Remove the machine from the package box carefully.

1.2 Put the machine in the clean and flat working table, close to edge as well.

Refer fig.A.

2.1 Connect the correct electrical power. Refer fig.1.

2.2 Installation of film roll.

2.2.3 The roll feeding direction to pass through to the tension column, Refer fig.4.

2.2.1 The bubble film should be cut with a scissorsin the lower right corner before

loading the film, Refer fig.2.

2.2.2 Put the roll film on the feeding roller properly. There is a groove inside the roll film

header should align and feed into feeding roller’s protrusion part. Refer fig.3.

2.2.4 Threading roll film pass through the air nozzle. Refer fig.5.

2.2.5 Pulling the roll film to close enough and touch just right between the hot sealing

wheels to ensure when push start button the machine can pull out film till out of

the roller wheels, and start making air cushion smoothly. Refer fig.6.

2.3 Operations

2.3.1 Connecting the electrical power, and turn on the power switch near by power

socket, make sure the enmergency stop switch turn clockwise to its normal position.

2.3.2 After power on the display screen will indicating previous setting,and ready

for a newsetting or start to work as last time,press start/hold button the

temperature symbol will flashing and machine start to warm up,it takes

around 2~3 mins to go.

2.3.3 When temperature symbol stop flashing machine will start to making air cushions.

2.3.4 When finish making air cushion, press the start/hold button again,machine will

stop immediately. There is a perforation line on the film to tear off the necessary

length for your requirement.

2.3.5 Air density setting: Various cushion sizes are available to meet different

packaging requirements, You can press twice of function setting button in to the

set up manual, press again will shift the symbol flashing movement from one

place to another clockwise, till you move up to fan symbol, you can set the air

density volume to meet your equirements, the output range is 0~100% please

adjust the suitable air pressure to get best air cushion result, too much or too

less air pressure will result in jam or bad air cushion performance (Remark:

"5~35%" output is recommend for 200mm width film and "35~95%" output is for

400mm width film).

2.3.6 Press the start/pause button for each use of the air cushion machine.

2.3.7 If press stop button without touch any other button for more than 30 mins,

machine will going to a hibernation status, the temperature will drop to 80 ℃

until you press any button interrupt the internal timer to wake up machine for

the next use.

2.3.8 Speed setting: click twice on function button, and move the function symbol to

the ruler symbol by each click accordingly while the symbol is still flashing, speed

range is from 3~20 level, the maximum speed is about 20m/min.

2.3.9 Temperature setting: click twice on function button, and move the function symbol

to the temp. symbol by each click accordingly while the symbol is still flashing,

temperature range is from room temp.~180℃.

2.3.10 Length setting: click twice on function button, and move the function symbol to the

ruler symbol by each click accordingly while the symbol is still flashing.

2.3.11 Due to individual machine differences, above setting value is not equal to the

actual output value.

2.3.12 If want to poweroff, please make sure machine is stop, tear off the film ahead the

air nozzle, and turn off the power switch.

1. Caution

2. Installation Steps

3. Electric Safety

5. Machine Maintenance

6. Specification

3.1 Place the machine close to power socket.

3.2 Make sure the voltage meets machine’s electricity requirements.

3.3 Any extension cord used should meet the power rating of the machine.

3.4 Do not operate if the power cord is damaged.

3.5 Repair and service should be done by a qualified service technician.

5.1 Unplug the power cord during maintenance.

5.2 Clean hot seals and rollers regularly.

5.3 Ensure there is no jammed film and dirt at the air nozzle or cutter blade.

5.4 Check the blade and rollers regularly.

5.5 Replace the cutter blade when blade is not sharp.

Air nozzle cutter blade replacement steps

4.1 Use the screw driver to remove the fix air nozzle screws. Refer fig.8A.

4.2 Pulling out the air nozzle. Refer fig.8B.

4.3 Remove the air nozzle fix screws. Refer fig.9.

4.4 Renew the new cutter blade (Caution: Be care of sharp blade may cut you fingers).

4.5 Put the air nozzle back and use the screw driver to fix tightly of the 2 fix-screws.

Refer fig.9,10.

Caution: Blade might blunt after a longer use, please check or replace the

blade every 200 rolls (300m/roll).

4. Cutter replacement

5

4

2

Approximately

3cm (1-1/2”)cut off corner.

3

20m/min±10%(adjustable)Sealing speed

Adjustable (200/400mm inadifferent

setting and operation range)

Air density control

Film roll size

200x80mm、200x100mm、200x130mm

200x150mm、200x200mm、

400x250mm、400x290mm

Power voltage 220-240VAC 50/60Hz

Machine size 385×270×280(mm)

Machine weight 17kg

Max. Film roll length

(W: Film width)

(L: Film length)

Power rate 300W

200mm ≤800M 400mm ≤500M

W L W L

1

fig.A

working table

6

7

Function setting button

Decrease Setting

button

Speed Symbol

Temperature symbol

Start/Pause button

Increase setting button

Length Symbol

Double click the function setting

button to start Choose a symbol

that you will work with until it

flashes which you can now set in

the required to function with.

Air Volume

No. Or Figures for

illustration

B

8 9

O

Air Cushion Machine

3800

A

HMJ KI L

CB D E F G

N

A

OPUS aeroPOUCH 9 Pro Instrukcja obsługi / User guide

4. INSTALACJA

•Podłącz przewód zasilający do urządzenia.

•Zamontuj rolkę z folią.

oPrzytnij folię nożyczkami w prawym dolnym rogu

przed umieszczeniem jej w urządzeniu, rys. 2.

oPrawidłowo umieść rolkę folii na wałku podającym.

Wałek posiada wystającą prowadnicę, która

powinna pokryć się z wycięciem wewnątrz roli folii rys. 3.

oZwróć uwagę na kierunek założenia folii na rolkę napinającą patrz rys. 4.

oPrzeprowadź folię przez dyszę powietrzną rys. 5.

oUpewnij się, że folia znajduje się dokładnie pomiędzy wałkiem zimnym a

wałkiem grzewczym tak, aby po włączeniu przycisku start rozpocząć płynne

zgrzewanie rys. 6.

5. OBSŁUGA

Przycisk zwiększenia

wartości

Przycisk wyboru funkcji. Podwójne

naciśniecie przycisku powoduje

wejście w tryb programowania,

kolejne naciśnięcie to wybór

żądanej funkcji, która miga

w trakcie edycji.

OPUS aeroPOUCH 9 Pro Instrukcja obsługi / User guide

4. INSTALACJA

•Podłącz przewód zasilający do urządzenia.

•Zamontuj rolkę z folią.

oPrzytnij folię nożyczkami w prawym dolnym rogu

przed umieszczeniem jej w urządzeniu, rys. 2.

oPrawidłowo umieść rolkę folii na wałku podającym.

Wałek posiada wystającą prowadnicę, która

powinna pokryć się z wycięciem wewnątrz roli folii rys. 3.

oZwróć uwagę na kierunek założenia folii na rolkę napinającą patrz rys. 4.

oPrzeprowadź folię przez dyszę powietrzną rys. 5.

oUpewnij się, że folia znajduje się dokładnie pomiędzy wałkiem zimnym a

wałkiem grzewczym tak, aby po włączeniu przycisku start rozpocząć płynne

zgrzewanie rys. 6.

5. OBSŁUGA

Przycisk zwiększenia

wartości

Przycisk wyboru funkcji. Podwójne

naciśniecie przycisku powoduje

wejście w tryb programowania,

kolejne naciśnięcie to wybór

żądanej funkcji, która miga

w trakcie edycji.

OPUS aeroPOUCH 9 Pro Instrukcja obsługi / User guide

4. INSTALACJA

•Podłącz przewód zasilający do urządzenia.

•Zamontuj rolkę z folią.

oPrzytnij folię nożyczkami w prawym dolnym rogu

przed umieszczeniem jej w urządzeniu, rys. 2.

oPrawidłowo umieść rolkę folii na wałku podającym.

Wałek posiada wystającą prowadnicę, która

powinna pokryć się z wycięciem wewnątrz roli folii rys. 3.

oZwróć uwagę na kierunek założenia folii na rolkę napinającą patrz rys. 4.

oPrzeprowadź folię przez dyszę powietrzną rys. 5.

oUpewnij się, że folia znajduje się dokładnie pomiędzy wałkiem zimnym a

wałkiem grzewczym tak, aby po włączeniu przycisku start rozpocząć płynne

zgrzewanie rys. 6.

5. OBSŁUGA

Przycisk zwiększenia

wartości

Przycisk wyboru funkcji. Podwójne

naciśniecie przycisku powoduje

wejście w tryb programowania,

kolejne naciśnięcie to wybór

żądanej funkcji, która miga

w trakcie edycji.

OPUS aeroPOUCH 9 Pro Instrukcja obsługi / User guide

4. INSTALACJA

•Podłącz przewód zasilający do urządzenia.

•Zamontuj rolkę z folią.

oPrzytnij folię nożyczkami w prawym dolnym rogu

przed umieszczeniem jej w urządzeniu, rys. 2.

oPrawidłowo umieść rolkę folii na wałku podającym.

Wałek posiada wystającą prowadnicę, która

powinna pokryć się z wycięciem wewnątrz roli folii rys. 3.

oZwróć uwagę na kierunek założenia folii na rolkę napinającą patrz rys. 4.

oPrzeprowadź folię przez dyszę powietrzną rys. 5.

oUpewnij się, że folia znajduje się dokładnie pomiędzy wałkiem zimnym a

wałkiem grzewczym tak, aby po włączeniu przycisku start rozpocząć płynne

zgrzewanie rys. 6.

5. OBSŁUGA

Przycisk zwiększenia

wartości

Przycisk wyboru funkcji. Podwójne

naciśniecie przycisku powoduje

wejście w tryb programowania,

kolejne naciśnięcie to wybór

żądanej funkcji, która miga

w trakcie edycji.

OPUS aeroPOUCH 9 Pro Instrukcja obsługi / User guide

4. INSTALACJA

•Podłącz przewód zasilający do urządzenia.

•Zamontuj rolkę z folią.

oPrzytnij folię nożyczkami w prawym dolnym rogu

przed umieszczeniem jej w urządzeniu, rys. 2.

oPrawidłowo umieść rolkę folii na wałku podającym.

Wałek posiada wystającą prowadnicę, która

powinna pokryć się z wycięciem wewnątrz roli folii rys. 3.

oZwróć uwagę na kierunek założenia folii na rolkę napinającą patrz rys. 4.

oPrzeprowadź folię przez dyszę powietrzną rys. 5.

oUpewnij się, że folia znajduje się dokładnie pomiędzy wałkiem zimnym a

wałkiem grzewczym tak, aby po włączeniu przycisku start rozpocząć płynne

zgrzewanie rys. 6.

5. OBSŁUGA

Przycisk zwiększenia

wartości

Przycisk wyboru funkcji. Podwójne

naciśniecie przycisku powoduje

wejście w tryb programowania,

kolejne naciśnięcie to wybór

żądanej funkcji, która miga

w trakcie edycji.

OPUS aeroPOUCH 9 Pro Instrukcja obsługi / User guide

4. INSTALACJA

•Podłącz przewód zasilający do urządzenia.

•Zamontuj rolkę z folią.

oPrzytnij folię nożyczkami w prawym dolnym rogu

przed umieszczeniem jej w urządzeniu, rys. 2.

oPrawidłowo umieść rolkę folii na wałku podającym.

Wałek posiada wystającą prowadnicę, która

powinna pokryć się z wycięciem wewnątrz roli folii rys. 3.

oZwróć uwagę na kierunek założenia folii na rolkę napinającą patrz rys. 4.

oPrzeprowadź folię przez dyszę powietrzną rys. 5.

oUpewnij się, że folia znajduje się dokładnie pomiędzy wałkiem zimnym a

wałkiem grzewczym tak, aby po włączeniu przycisku start rozpocząć płynne

zgrzewanie rys. 6.

5. OBSŁUGA

Przycisk zwiększenia

wartości

Przycisk wyboru funkcji. Podwójne

naciśniecie przycisku powoduje

wejście w tryb programowania,

kolejne naciśnięcie to wybór

żądanej funkcji, która miga

w trakcie edycji.

OPUS aeroPOUCH 9 Pro Instrukcja obsługi / User guide

4. INSTALACJA

•Podłącz przewód zasilający do urządzenia.

•Zamontuj rolkę z folią.

oPrzytnij folię nożyczkami w prawym dolnym rogu

przed umieszczeniem jej w urządzeniu, rys. 2.

oPrawidłowo umieść rolkę folii na wałku podającym.

Wałek posiada wystającą prowadnicę, która

powinna pokryć się z wycięciem wewnątrz roli folii rys. 3.

oZwróć uwagę na kierunek założenia folii na rolkę napinającą patrz rys. 4.

oPrzeprowadź folię przez dyszę powietrzną rys. 5.

oUpewnij się, że folia znajduje się dokładnie pomiędzy wałkiem zimnym a

wałkiem grzewczym tak, aby po włączeniu przycisku start rozpocząć płynne

zgrzewanie rys. 6.

5. OBSŁUGA

Przycisk zwiększenia

wartości

Przycisk wyboru funkcji. Podwójne

naciśniecie przycisku powoduje

wejście w tryb programowania,

kolejne naciśnięcie to wybór

żądanej funkcji, która miga

w trakcie edycji.

OPUS aeroPOUCH 9 Pro Instrukcja obsługi / User guide

4. INSTALACJA

•Podłącz przewód zasilający do urządzenia.

•Zamontuj rolkę z folią.

oPrzytnij folię nożyczkami w prawym dolnym rogu

przed umieszczeniem jej w urządzeniu, rys. 2.

oPrawidłowo umieść rolkę folii na wałku podającym.

Wałek posiada wystającą prowadnicę, która

powinna pokryć się z wycięciem wewnątrz roli folii rys. 3.

oZwróć uwagę na kierunek założenia folii na rolkę napinającą patrz rys. 4.

oPrzeprowadź folię przez dyszę powietrzną rys. 5.

oUpewnij się, że folia znajduje się dokładnie pomiędzy wałkiem zimnym a

wałkiem grzewczym tak, aby po włączeniu przycisku start rozpocząć płynne

zgrzewanie rys. 6.

5. OBSŁUGA

Przycisk

zmniejszenia

wartości

Przycisk zwiększenia

wartości

Przycisk wyboru funkcji. Podwójne

naciśniecie przycisku powoduje

wejście w tryb programowania,

kolejne naciśnięcie to wybór

żądanej funkcji, która miga

w trakcie edycji.

OPUS aeroPOUCH 9 Pro Instrukcja obsługi / User guide

4. INSTALACJA

•Podłącz przewód zasilający do urządzenia.

•Zamontuj rolkę z folią.

oPrzytnij folię nożyczkami w prawym dolnym rogu

przed umieszczeniem jej w urządzeniu, rys. 2.

oPrawidłowo umieść rolkę folii na wałku podającym.

Wałek posiada wystającą prowadnicę, która

powinna pokryć się z wycięciem wewnątrz roli folii rys. 3.

oZwróć uwagę na kierunek założenia folii na rolkę napinającą patrz rys. 4.

oPrzeprowadź folię przez dyszę powietrzną rys. 5.

oUpewnij się, że folia znajduje się dokładnie pomiędzy wałkiem zimnym a

wałkiem grzewczym tak, aby po włączeniu przycisku start rozpocząć płynne

zgrzewanie rys. 6.

5. OBSŁUGA

Przycisk zwiększenia

wartości

Przycisk wyboru funkcji. Podwójne

naciśniecie przycisku powoduje

wejście w tryb programowania,

kolejne naciśnięcie to wybór

żądanej funkcji, która miga

w trakcie edycji.

OPUS aeroPOUCH 9 Pro Instrukcja obsługi / User guide

4. INSTALACJA

•Podłącz przewód zasilający do urządzenia.

•Zamontuj rolkę z folią.

oPrzytnij folię nożyczkami w prawym dolnym rogu

przed umieszczeniem jej w urządzeniu, rys. 2.

oPrawidłowo umieść rolkę folii na wałku podającym.

Wałek posiada wystającą prowadnicę, która

powinna pokryć się z wycięciem wewnątrz roli folii rys. 3.

oZwróć uwagę na kierunek założenia folii na rolkę napinającą patrz rys. 4.

oPrzeprowadź folię przez dyszę powietrzną rys. 5.

oUpewnij się, że folia znajduje się dokładnie pomiędzy wałkiem zimnym a

wałkiem grzewczym tak, aby po włączeniu przycisku start rozpocząć płynne

zgrzewanie rys. 6.

5. OBSŁUGA

Przycisk zwiększenia

wartości

Przycisk wyboru funkcji. Podwójne

naciśniecie przycisku powoduje

wejście w tryb programowania,

kolejne naciśnięcie to wybór

żądanej funkcji, która miga

w trakcie edycji.