4

Unauthorized reproduction or copying of all or part of this manual is

prohibited.

Oriental Motor shall not be liable whatsoever for any problems relating

to industrial property rights arising from use of any information, circuit,

equipment or device provided or referenced in this manual.

Characteristics, specications and dimensions are subject to change without

notice.

While we make every eort to oer accurate information in the manual,

we welcome your input. Should you nd unclear descriptions, errors or

omissions, please contact the nearest oce.

is a registered trademark or trademark of Oriental Motor Co.,

Ltd., in Japan and other countries.

© Copyright ORIENTAL MOTOR CO., LTD. 2014

Published in December 2017

Technical Support Tel:(800)468-3982

8:30 A.M. to 5:00 P.M., P.S.T. (M-F)

7:30 A.M. to 5:00 P.M., C.S.T. (M-F)

www.orientalmotor.com

Schiessstraße 44, 40549 Düsseldorf, Germany

Technical Support Tel:00 800/22 55 66 22

www.orientalmotor.de

Tel:01256-347090

www.oriental-motor.co.uk

Tel:01 47 86 97 50

www.orientalmotor.fr

Tel:02-93906346

www.orientalmotor.it

Tel:+55-11-3266-6018

www.orientalmotor.com.br

• Please contact your nearest Oriental Motor oce for further information.

4-8-1Higashiueno,Taito-ku,Tokyo 110-8536

Japan

Tel:03-6744-0361

www.orientalmotor.co.jp

Tel:0800-060708

www.orientalmotor.com.tw

Singapore

Tel:1800-8420280

www.orientalmotor.com.sg

Tel:1800-806161

www.orientalmotor.com.my

Korea

Tel:080-777-2042

www.inaom.co.kr

Tel:1800-888-881

www.orientalmotor.co.th

Tel:400-820-6516

www.orientalmotor.com.cn

Tel:+91-80-41125586

www.orientalmotor.co.in

Hong Kong Branch

Tel:+852-2427-9800

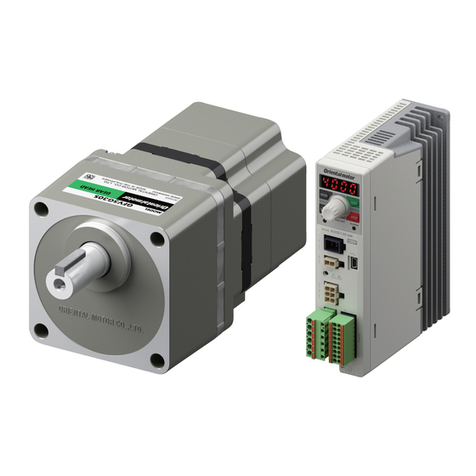

Operation

The motor rotates when the power supply is turned on.

For protection against electric shock, do not turn on the power supply until the

wiring is complete.

Note Make sure that the motor case temperature does not exceed

90 °C (194 °F) when operating the motor. Operation exceeding case

temperature 90 °C (194 °F) may signicantly deteriorate the coils and

ball bearings of the motor and shorten the motor's life span. Motor

case temperature can be measured by xing a thermometer on

the motor surface. It can also be measured using thermo tape or a

thermocouple.

Time rating

Reversible motors have a 30 minutes rating. “30 min” is indicated on the nameplate.

Overheat protection for locked condition

This motor is equipped with one of the two features listed below to prevent the

motor from burning out as a result of abnormal heating which may be caused

by misapplication.

Thermally protected motors

"TP" is marked on the motor nameplate. This motor contains a built-in

automatic return type thermal protector in the motor windings. If the motor

internal temperature exceeds the specied value, the thermal protector is

activated and the motor is stopped.

Always turn the power o before performing inspections.

Operating temperature of thermal protector:

Open (motor standstill) ............ 130±5 °C (266±9 °F)

Close (resuming operation) .... 85±20 °C (185±36 °F)

Impedance protection

"ZP" is stamped on the motor nameplate. The motor has higher coil impedance.

When the motor goes into locked rotor condition due to a malfunction, coil

impedance rises, suppressing input power to the motor and protecting the

motor coil from burnout.

Troubleshooting

When the motor cannot be operated correctly, refer to the contents provided in this

section and take appropriate action. If the problem persists, contact your nearest

oce.

Phenomena Check items

Motor does not rotate.

Motor sometimes rotates

and stops.

Check the power supply voltage.

Connect the power supply and the motor correctly.

Connect the supplied capacitor correctly.

If terminal blocks or crimp terminals are used,

check them for poor connection.

Keep the load at or below the allowable value.

The motor rotates in the

direction opposite to the

specied direction.

Connect the supplied capacitor correctly.

The connection varies depending on the gear

ratio of the gearhead.

The rotation direction is as viewed from the

output shaft end. Check the reference direction.

Motor temperature

abnormally high

[Motor case temperature

exceeds 90 °C (194 °F) ]

Check the power supply voltage.

With a single-phase motor, connect the supplied

capacitor correctly.

Review the ventilation condition.

Noisy operation

Assemble the motor and gearhead correctly.

Assemble a gearhead of the same pinion type as

the motor.

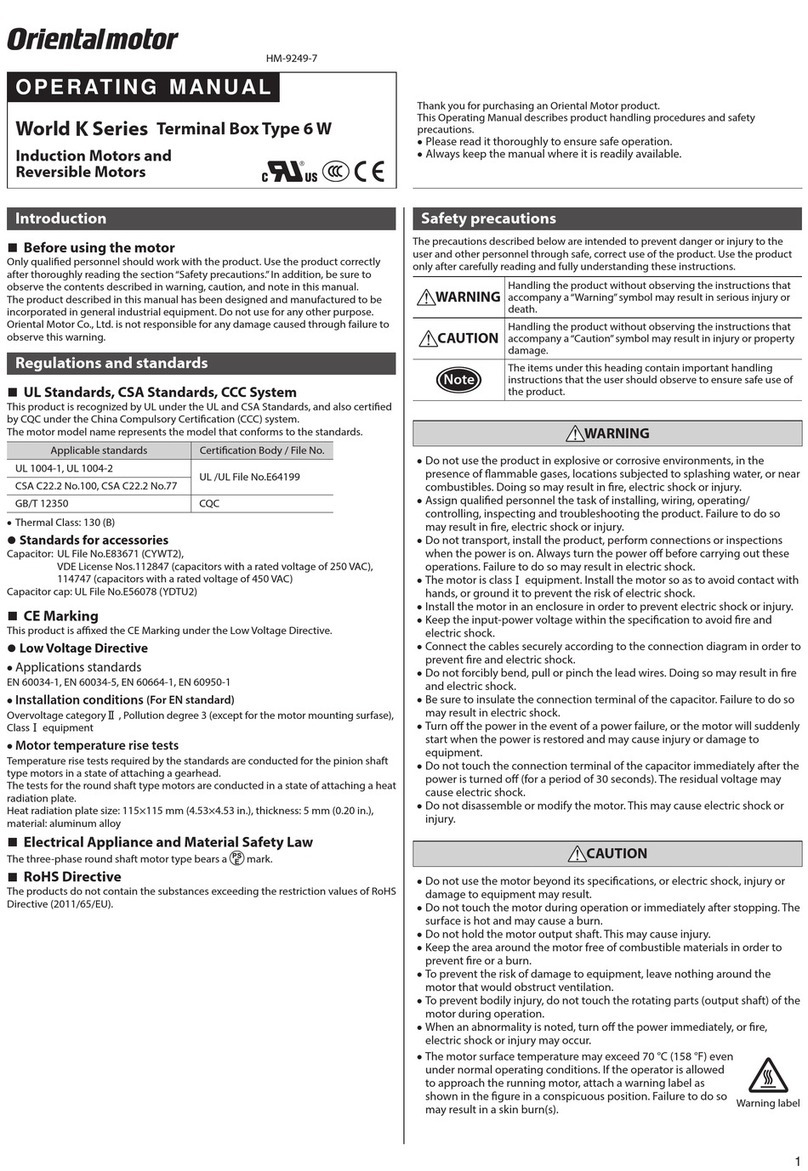

Regulations and standards

UL Standards, CSA Standards, CCC System

This product is recognized by UL under the UL and CSA Standards, and also

certied by CQC under the China Compulsory Certication (CCC) system.

The motor model name represents the model that conforms to the standards.

Applicable standards

Applicable standards Certication Body / File No.

UL 1004-1, UL 1004-2, UL 1004-3 UL /

UL File No.E64197, E64199

CSA C22.2 No.100, CSA C22.2 No.77

GB/T 12350 CQC

Thermal Class: 130 (B)

zStandards for accessories

Capacitor: UL File No.E83671 (CYWT2),

VDE License No.112847 (capacitors with a rated voltage of 250 VAC),

114747 (capacitors with a rated voltage of 450 VAC)

Capacitor cap: UL File No.E56078 (YDTU2)

CE Marking

This product is axed the CE Marking under the Low Voltage Directive.

zLow Voltage Directive

Applicable standards

EN 60034-1, EN 60034-5, EN 60664-1

Momentary excess torque based on EN 60034-1

Model Momentary excess torque Momentary excess torque represents

a maximum torque that can maintain

the operation for 15 seconds without

stalling or abrupt speed change even

if the torque is increased gently while

operating at rated voltage and rated

frequency.

2RK6

3RK15 120% of the rated torque

4RK25 150% of the rated torque

5RK40

5RK60 160% of the rated torque

5RK90 130% of the rated torque

Installation conditions (For EN standard)

Overvoltage categoryⅡ, Pollution degree 2, ClassⅠequipment

When the machinery to which the motor is mounted requires overvoltage

categoryⅢspecications, install the motor in a cabinet that connect to power

supply via an isolation transformer.

Motor temperature rise tests

Temperature rise tests required by the above standards are performed in a state

that has been attached a heat radiation plate instead of a gearhead.

The size and material for the heat radiation plates are as follows.

[Size]

2RK6: 115×115 mm (4.53×4.53 in.) 3RK15: 125×125 mm (4.92×4.92 in.)

4RK25: 135×135 mm (5.31×5.31 in.) 5RK40: 165×165 mm (6.50×6.50 in.)

5RK60, 5RK90: 200×200 mm (7.87×7.87 in.)

[Thickness] 5 mm (0.20 in.)

[Material] Aluminum alloy

RoHS Directive

The products do not contain the substances exceeding the restriction values of

RoHS Directive (2011/65/EU).