−2−

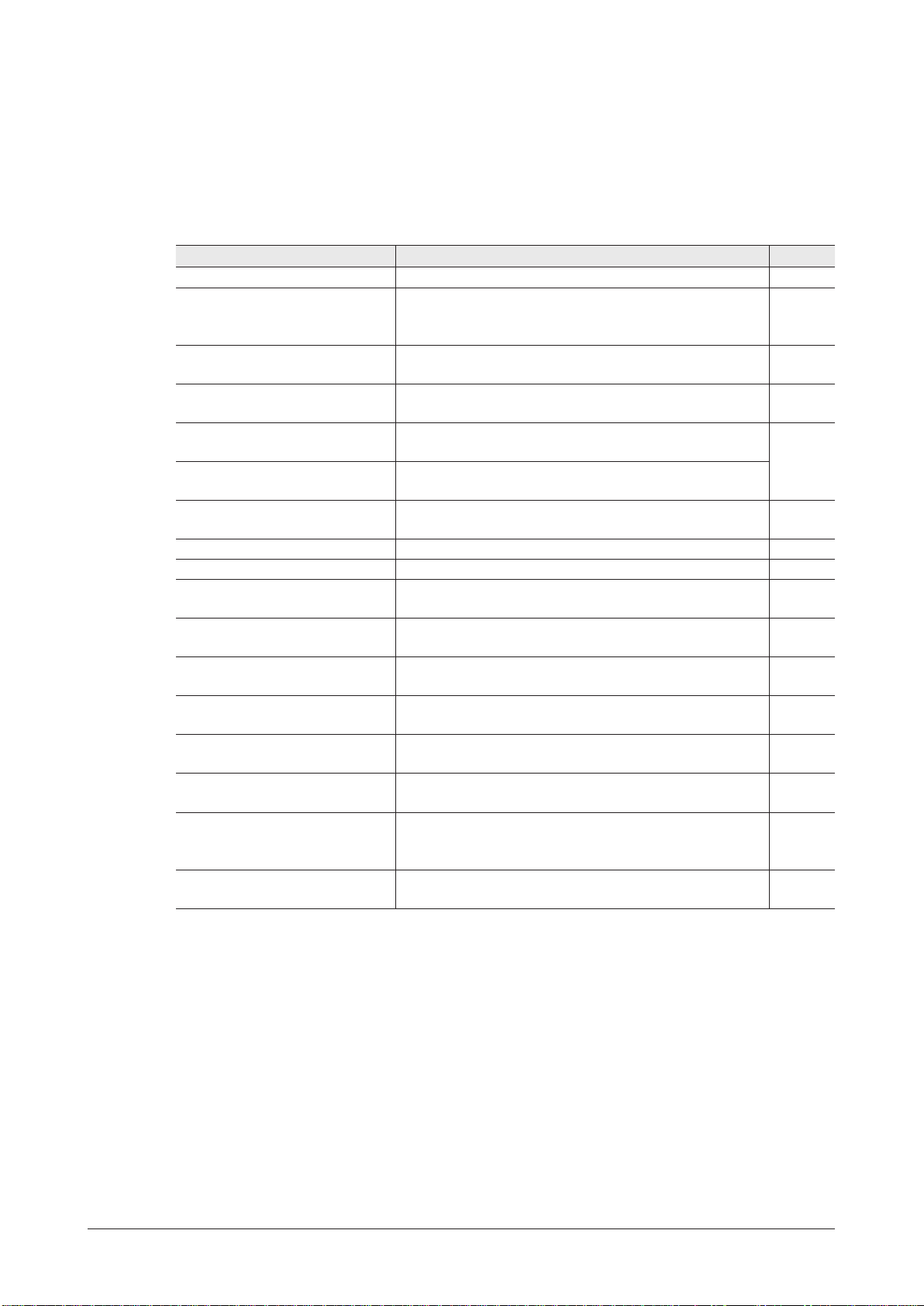

Table of contents

1 Safety precautions .................................... 3

2 Introduction ............................................... 5

3 Preparation................................................. 7

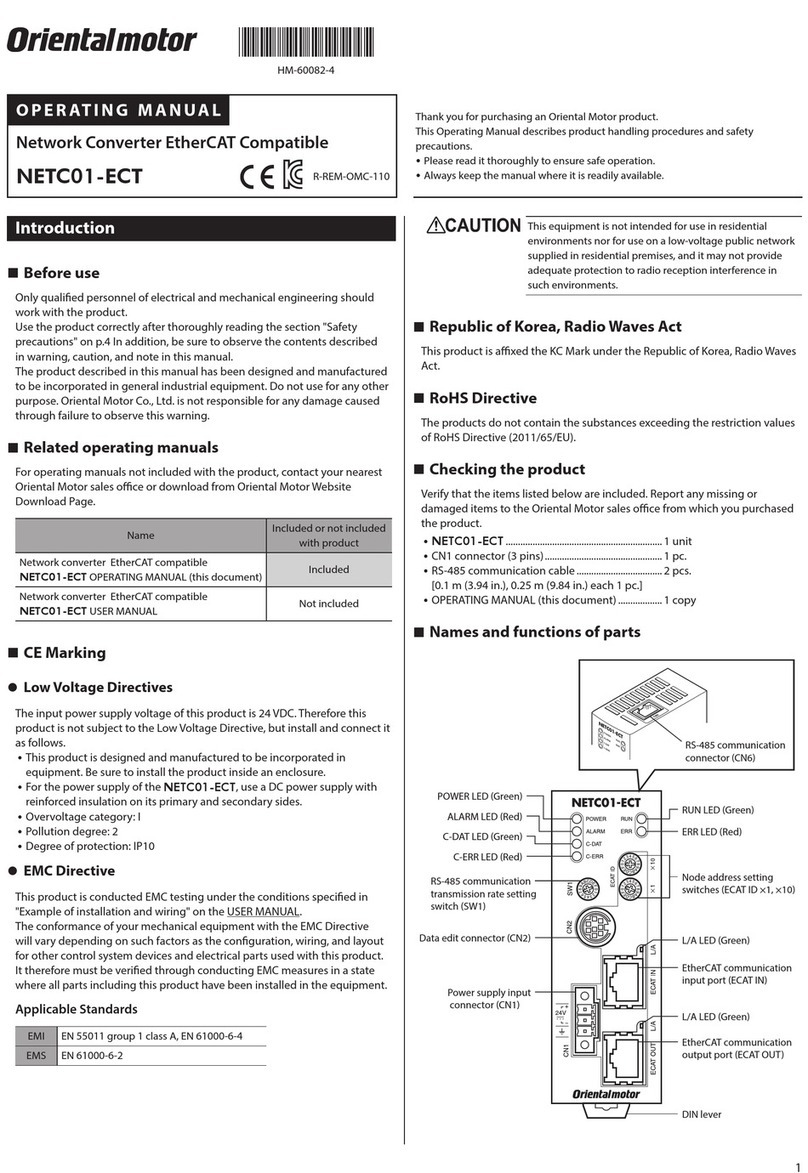

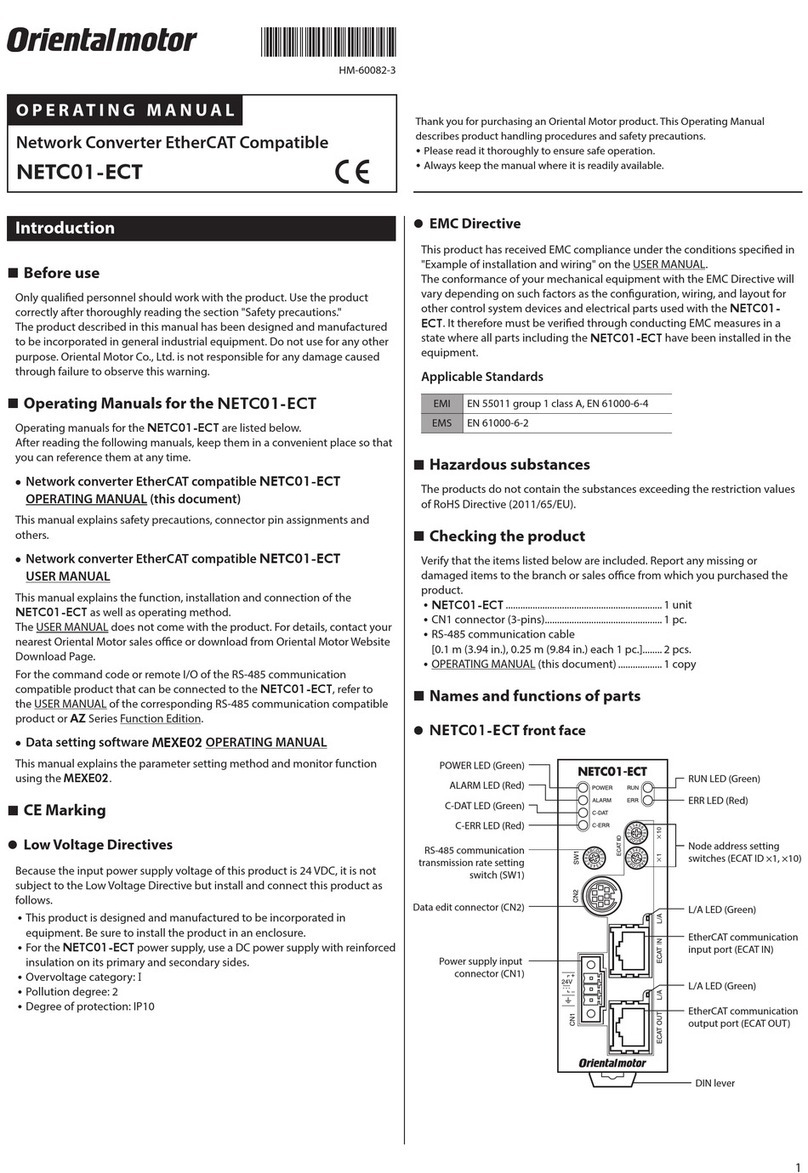

3.1 Checking the product.........................................7

3.2 Names and functions of parts..........................8

4 Installation................................................ 10

4.1 Location for installation .................................. 10

4.2 Installation method .......................................... 10

4.3 Installing and wiring in compliance with

EMC Directive ..................................................... 11

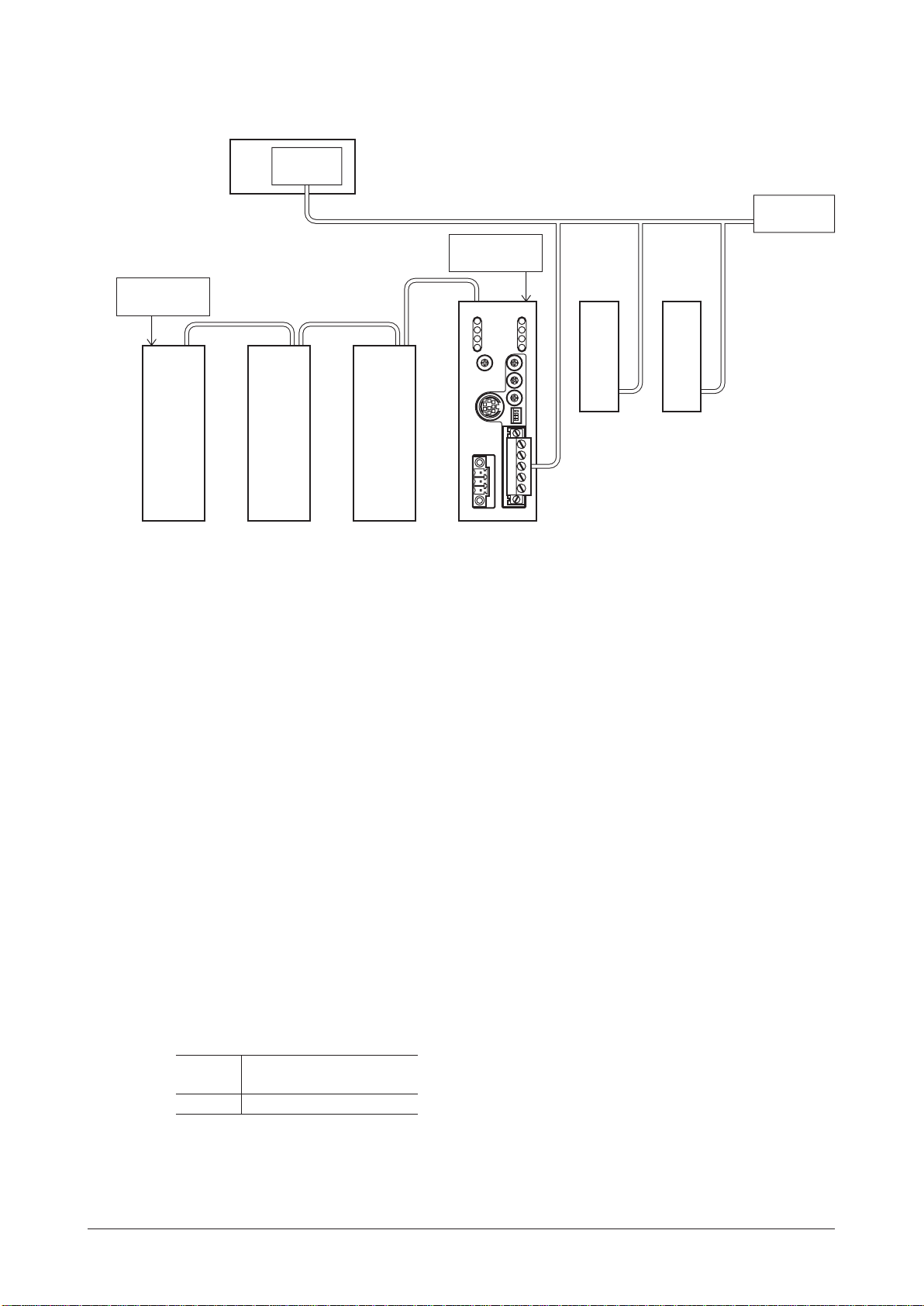

5 Connection ............................................... 13

5.1 Connection example........................................ 13

5.2 Connecting the power supply and

grounding the NETC01-CC ....................... 13

5.3 Connecting the RS-485 communication

cable ...................................................................... 14

5.4 Connecting the CC-Link

communication ................................................. 15

5.5 Connecting the data setter............................ 15

6 Guidance ................................................... 16

7 Setting ....................................................... 19

7.1 Transmission rate of RS-485

communication ................................................. 19

7.2 Operation mode ................................................ 19

7.3 CC-Link station number.................................. 20

7.4 CC-Link baud rate.............................................. 20

7.5 Termination resistor.......................................... 20

8 Basic function........................................... 21

8.1 Remote I/O list.................................................... 21

8.2 Remote register list........................................... 22

8.3 Assignment of remote I/O.............................. 22

8.4 Details of remote I/O........................................ 23

8.5 Monitor ................................................................. 25

8.6 Command execution........................................ 26

8.7 Communication error code ...........................28

8.8 Read, write, save of parameters ................... 29

9 RS-485 communication specication.. 30

9.1 Operation mode ................................................ 30

9.2 RS-485 communication conguration....... 30

9.3 RS-485 communication and scan time...... 31

9.4 RS-485 communication status...................... 32

10 Troubleshooting and remedial

actions ....................................................... 33

10.1 Alarms.................................................................... 33

10.2 CC-Link communication error....................... 35

10.3 Warning................................................................. 36

10.4 When connecting with the RS-485

communication compatible product......... 36

11 Inspection ................................................. 37

12 General specications ............................ 38

13 Operation using the OPX-2A ............... 39

13.1 Overview of the OPX-2A............................... 39

13.2 Names and functions of parts....................... 40

13.3 Notation................................................................ 40

13.4 How to read the display.................................. 40

13.5 OPX-2A error display...................................... 41

13.6 Screen transitions.............................................. 42

13.7 Monitor mode..................................................... 44

13.8 Parameter mode ................................................ 45

13.9 Copy mode .......................................................... 45

14 Command code list .................................47

14.1 Application parameter .................................... 47

14.2 System parameter ............................................. 47

14.3 Maintenance command.................................. 48

14.4 Monitor command............................................ 48

15 Accessories (sold separately) ................ 49