Safety precautions

3

1 Safety precautions

The precautions described below are intended to prevent danger or injury to the user and other personnel through

safe, correct use of the product. Use the product only after carefully reading and fully understanding these

instructions.

Handling the product without observing the instructions that

accompany a "WARNING" symbol may result in serious injury

or death.

General

•Do not use the product in explosive or corrosive

environments, in the presence of ammable gases, locations

subjected to splashing water, or near combustibles. Doing so

may result in re or injury.

•Assign qualied personnel to the task of installing, wiring,

operating/controlling, inspecting and troubleshooting the

product. Failure to do so may result in re, injury or damage

to equipment.

Connection

•Always keep the power supply voltage of the NETC01-M2

within the specied range. Failure to do so may result in re.

•For the power supply of the NETC01-M2, use a DC power

supply with reinforced insulation on its primary and

secondary sides. Failure to do so may result in electric shock.

•Connect the cables securely according to the wiring

diagram. Failure to do so may result in re.

•Do not forcibly bend, pull or pinch the cable. Doing so may

result in re. Repetitive stress or overstress on the

connection part may cause damage to the product.

Operation

•Turn o the NETC01-M2 power in the event of a power

failure. Otherwise, the motor may suddenly start when the

power is restored, causing injury or damage to equipment.

•When an alarm of the NETC01-M2 is generated, stop the

motor. Failure to do so may result in re, injury or damage to

equipment.

Repair, disassembly and modication

•Do not disassemble or modify the NETC01-M2. Doing so

may result in injury. Refer all such internal inspections and

repairs to the Oriental Motor sales oce from which you

purchased the product.

Handling the product without observing the instructions that

accompany a "CAUTION" symbol may result in injury or

property damage.

General

•Do not use the NETC01-M2 beyond its specications.

Doing so may result in injury or damage to equipment.

•Keep your ngers and objects out of the openings in the

NETC01-M2. Failure to do so may result in re or injury.

Installation

•Install the NETC01-M2 inside an enclosure. Failure to do so

may result in injury.

•Keep the area around the NETC01-M2 free of combustible

materials in order to prevent re or a skin burn(s).

•Do not leave anything around the NETC01-M2 that would

obstruct ventilation. Doing so may result in damage to

equipment.

Connection

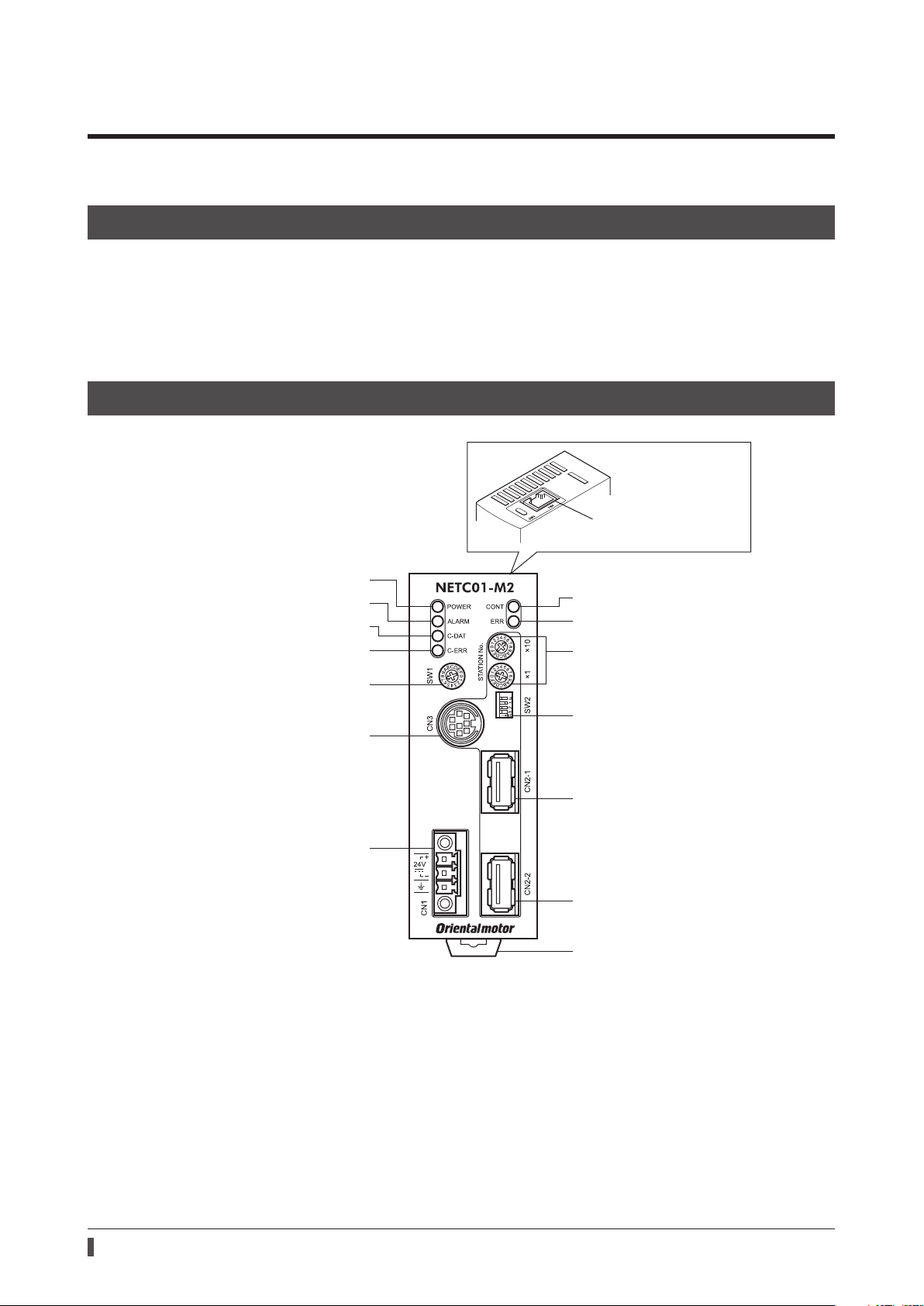

•The power supply connector (CN1), MECHATROLINK-II

communication connectors (CN2-1, CN2-2), data edit

connector (CN3) and RS-485 communication connector

(CN6) of the NETC01-M2 are not electrically insulated.

When grounding the positive terminal of the power supply,

do not connect any equipment (PC, etc.) whose negative

terminal is grounded. Doing so may result in the

NETC01-M2 and these equipment to short, damaging

both.

Operation

•Use the NETC01-M2 in combination with the designated

applicable product. Failure to do so may result in re.

•When operating the product, do so after making

preparations that an emergency stop can be performed at

any time. Failure to do may result in injury.

•Set a suitable operation speed and acceleration/deceleration

rate. Improper setting may cause loss of the motor

synchronism and moving the load to an unexpected

direction, which may result in injury or damage to

equipment.

•Immediately when trouble has occurred, stop running and

turn o the NETC01-M2 power. Failure to do so may result

in re or injury.

•Static electricity may cause the NETC01-M2 to malfunction

or suer damage. Do not touch the NETC01-M2 while the

power is input. Always use an insulated screwdriver to adjust

the switches of the NETC01-M2.

Disposal

•Dispose the product correctly in accordance with laws and

regulations, or instructions of local governments.