▌2

1 Safety precautions ................................................. 3

2 Overview of the product ...................................... 5

2-1 System conguration ...................................................5

2-2 What is EtherCAT? .........................................................5

3 Introduction ............................................................ 7

4 Preparation ............................................................. 8

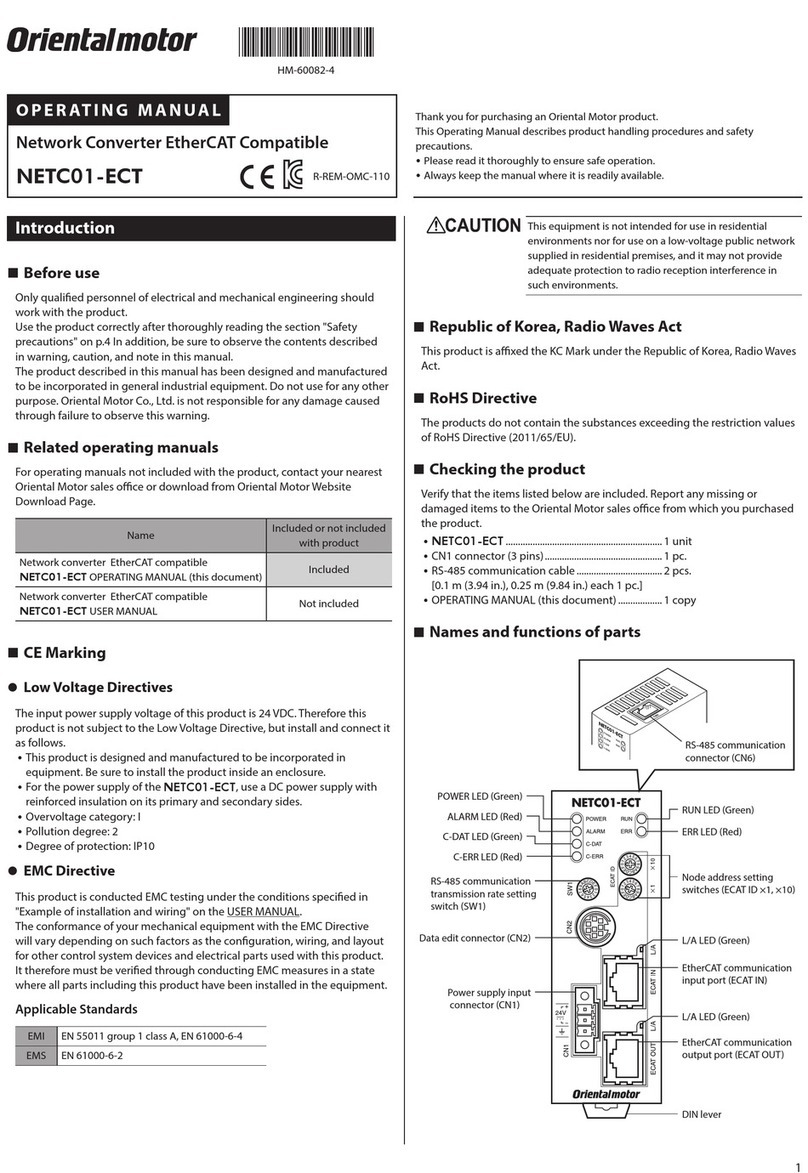

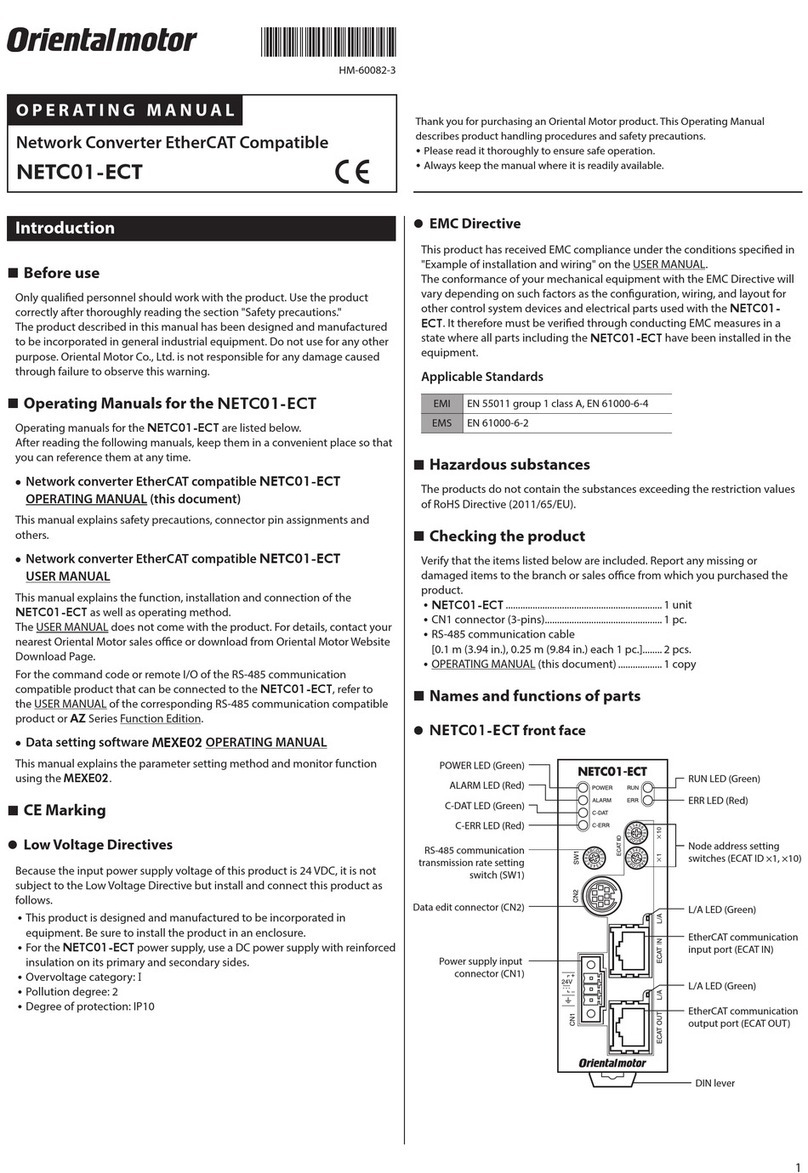

4-1 Checking the product ..................................................8

4-2 Names and functions of parts ...................................8

5 Installation ............................................................ 10

5-1 Location for installation ............................................ 10

5-2 Installation method .................................................... 10

5-3 Installing and wiring in compliance with

EMC Directive ............................................................... 11

6 Connection ............................................................13

6-1 Connection example ................................................. 13

6-2 Connecting the power supply and

grounding the NETC01-ECT ............................... 13

6-3 Connecting the RS-485 communication

cable ................................................................................ 14

6-4 Connecting the EtherCAT communication

cable ................................................................................ 15

6-5 Connecting the data setter ..................................... 15

7 Guidance................................................................16

8 Setting .................................................................... 21

8-1 Transmission rate of RS-485 communication ... 21

8-2 Node address of EtherCAT ....................................... 21

9 Basic function ....................................................... 22

9-1 Remote I/O list.............................................................. 22

9-2 Remote register list .................................................... 23

9-3 Remote monitor list ................................................... 27

9-4 Objects of the NETC01-ECT ................................ 30

9-5 Read, write, save of parameters ............................. 33

9-6 Basic operating procedures .................................... 34

10 Specications of RS-485 communication ........37

10-1 Operation mode .......................................................... 37

10-2 RS-485 communication conguration ................ 37

10-3 RS-485 communication process and

scan time ........................................................................ 37

10-4 RS-485 communication status ............................... 39

11 Troubleshooting...................................................40

11-1 Alarms ............................................................................. 40

11-2 EtherCAT communication error ............................. 41

11-3 Warning .......................................................................... 41

11-4 Relationship with the RS-485 communication

compatible product ................................................... 42

12 Inspection .............................................................. 43

13 General specications ......................................... 44

14 Operation using the OPX-2A ............................ 45

14-1 Overview of the OPX-2A ........................................ 45

14-2 Names and functions of parts ................................ 46

14-3 How to read the display ............................................ 46

14-4 OPX-2A error display ............................................... 47

14-5 Screen transitions ....................................................... 48

14-6 Monitor mode .............................................................. 50

14-7 Parameter mode .......................................................... 51

14-8 Copy mode .................................................................... 52

15 CoE communication area ................................... 53

15-1 CoE communication area ......................................... 53

16 Accessories ............................................................61