1SDH000510R0001

1/28

Page N.

L2388

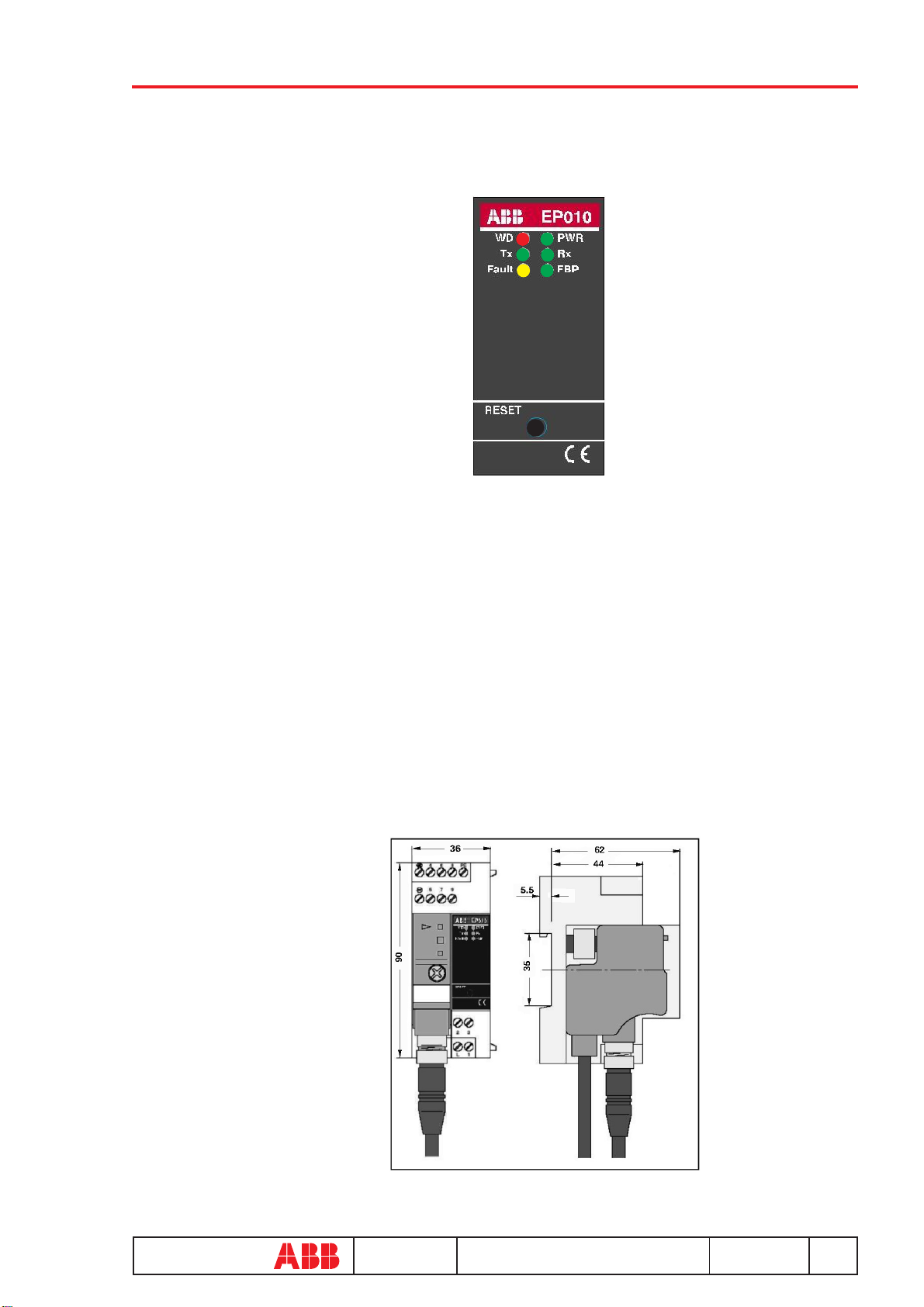

EP010ABB SACE

INDEX PAGE

1 INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1 Applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Acronyms and Definitions . . . . . . . . . . . . . . . . 3

1.2.1 Acronyms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2.2 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Bibliography . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. DEVICE INDEPENDENT SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Purpose and connection of EP010 . . . . . . . . . . 4

2.2 Device description . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.1 FieldBusPlug connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2.2 Modbus terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2.3 LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Electrical connections . . . . . . . . . . . . . . . . . . . . 6

2.3.1 Earthing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4 Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.4.1 Addressing using a handheld programming unit . . . . . . . . . 7

2.4.2 Addressing via the field bus . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.5 Replacement of a defective EP010 . . . . . . . . . . 7

2.6 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6.1 General data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6.2 Power supply for EP010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.6.3 Connection of the FieldBusPlug . . . . . . . . . . . . . . . . . . . . . . 8

2.6.4 Connection to a Modbus device . . . . . . . . . . . . . . . . . . . . . . 8

2.6.5 LED displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.6.6 Mechanical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.7 Identification . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.8 Product specification . . . . . . . . . . . . . . . . . . . 10

2.8.1 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.8.2 Run state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.8.2.1 Communication with the FBP . . . . . . . . . . . . . . . . . . . . . . . 11

2.8.2.2 Communication with the Modbus device . . . . . . . . . . . . . . 11

2.8.3 Command interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.8.4 Permanent (non volatile) information saving . . . . . . . . . . . 12

2.8.5 Performance data and conditions . . . . . . . . . . . . . . . . . . . . 12

2.9 Diagnostics & Troubleshooting . . . . . . . . . . . 12

2.9.1 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.9.2 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3. DEVICE DEPENDENT SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1 PR222DS/PD . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1.1 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1.2 Detailed information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.1.3 Performance data and conditions . . . . . . . . . . . . . . . . . . . . 17

3.2 PR122/3 with PR120/D . . . . . . . . . . . . . . . . . . . 18