HOMEOWNER’S GARAGE DOOR MANUAL

Models: 981, 982, 983, 984

Read this manual carefully and observe all

warnings when operating or maintaining your

garage door.

1-800-929-DOOR

www.OverheadDoor.com

Keep this manual for future reference.

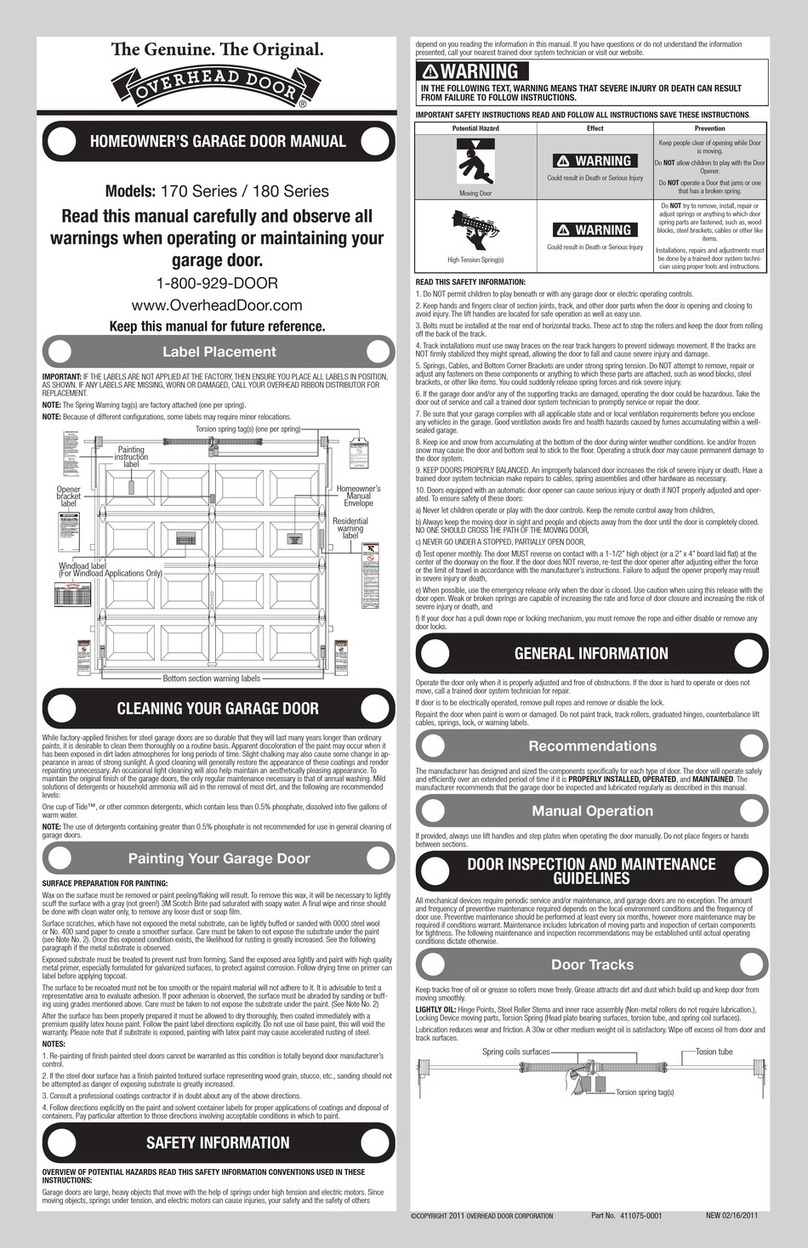

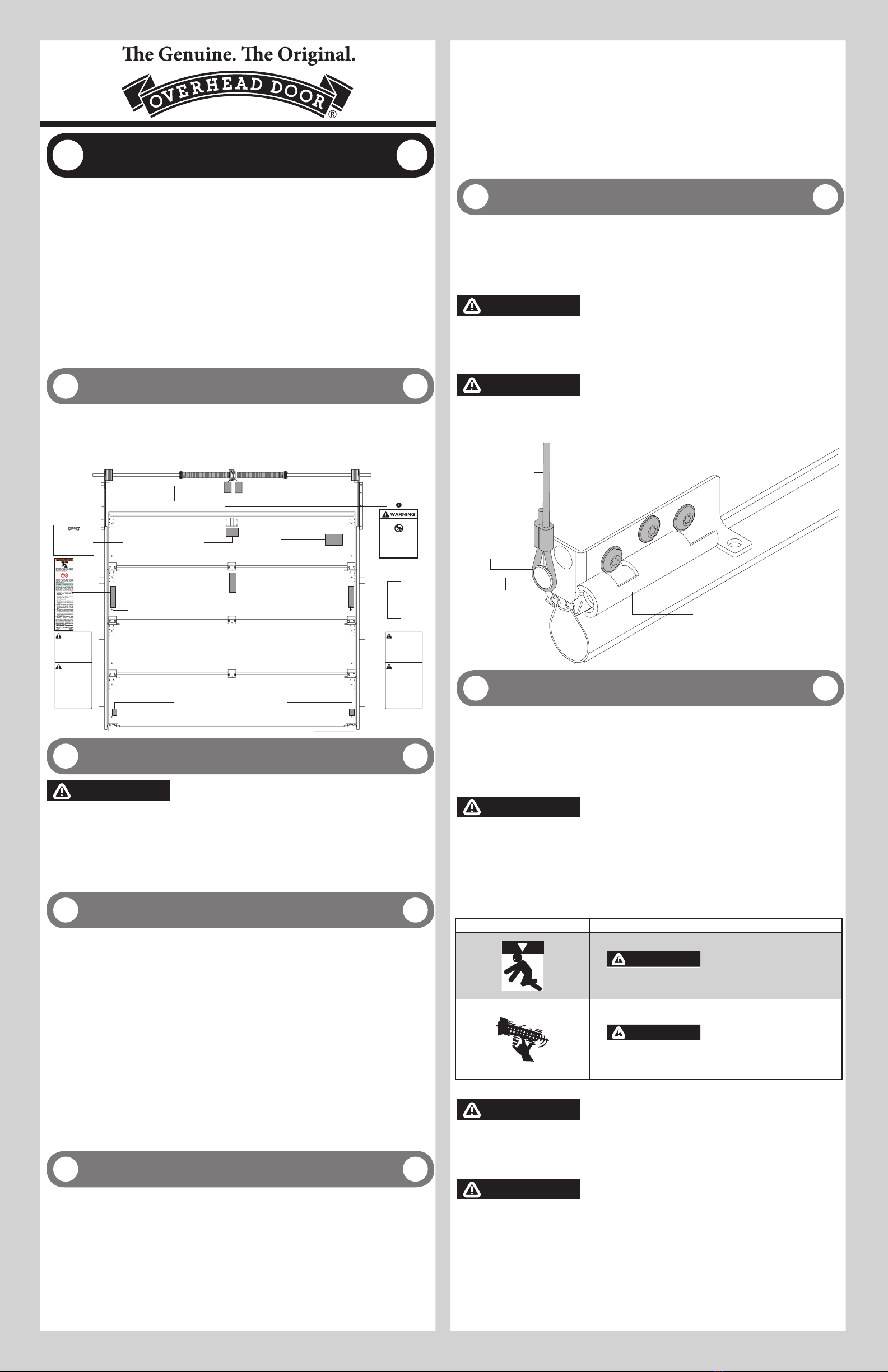

Label Placement

IMPORTANT: IF THE LABELS ARE NOT APPLIED AT THE FACTORY, THEN ENSURE YOU PLACE ALL LABELS IN POSITION,

AS SHOWN.

NOTE: The Spring Warning tag(s) are factory attached (one per spring).

NOTE: Because of different configurations, some labels may require minor relocations.

WARNING

WARNING

Lift handles/gripping points are required

on this door, located as spelled out in the

installation instructions, even if the door

is motor operated.

Failure to install and use these lift handles/

gripping points on this door can result in

serious injury to fingers and/or hands, if

placed in the opening between sections,

when the door is operated manually.

The adjacent bottom corner bracket and

all cable retention features including

milford pins, cotter pins, & clevis pins are

under HIGH SPRING TENSION.

Adjustments and repairs must only be

made by a trained door systems

technician, using proper tools and

instructions.

DO NOT REMOVE, COVER OR PAINT OVER

THIS LABEL. PRODUCT USER SHOULD

INSPECT THIS LABEL PERIODICALLY FOR

LEGIBILITY AND SHOULD ORDER A

REPLACEMENT FROM THE DOOR

MANUFACTURER AS NEEDED.

WARNING

WARNING

Lift handles/gripping points are required

on this door, located as spelled out in the

installation instructions, even if the door

is motor operated.

Failure to install and use these lift handles/

gripping points on this door can result in

serious injury to fingers and/or hands, if

placed in the opening between sections,

when the door is operated manually.

The adjacent bottom corner bracket and

all cable retention features including

milford pins, cotter pins, & clevis pins are

under HIGH SPRING TENSION.

Adjustments and repairs must only be

made by a trained door systems

technician, using proper tools and

instructions.

DO NOT REMOVE, COVER OR PAINT OVER

THIS LABEL. PRODUCT USER SHOULD

INSPECT THIS LABEL PERIODICALLY FOR

LEGIBILITY AND SHOULD ORDER A

REPLACEMENT FROM THE DOOR

MANUFACTURER AS NEEDED.

HIGH SPRING TENSION CAN CAUSE

SERIOUS INJURY OR DEATH.

DO NOT adjust, repair or remove springs or

parts to which springs are connected, such

as steel brackets, cables, wood blocks,

fasteners or other parts of the

counterbalance system.

Adjustments or repairs must ONLY be made

by a trained door systems technician using

proper tools and instructions.

DO NOT remove, cover or paint over this tag.

Product user should inspect this tag

periodically for legibility and should order a

replacement tag from the door

manufacturer, as needed.

TO AVOID POTENTIAL INJURY OR DAMAGE TO DOOR WHEN

CONNECTING A GARAGE DOOR OPENER TO THIS DOOR, AN

OVERHEAD DOOR OPENER BRACKET DESIGNED

SPECIFICALY FOR THIS DOOR MUST BE SECURELY

ATTACHED TO THE TOP SECTION OF THE DOOR, ALONG

WITH ANY STRUTS PROVIDED WITH THE DOOR. THE

INSTALLATION OF THE OPENER MUST BE IN ACCORDANCE

WITH THE MANUFACTURER'S INSTRUCTIONS AND FORCE

SETTINGS MUST BE ADJUSTED PROPERLY.

CAUTION!

Like any other exterior surface, Overhead Door

garage doors will have dirt exposure from

atmospheric conditions. Ordinarily, the cleaning

action of rainfall will be adequate to wash the

door, or the door can be washed periodically by

hosing with a garden hose and clear water (in

particular) for the areas not accessible to rain. If

you desire to do a more thorough cleaning, or

where soil collection conditions occur, follow

these simple instructions.

1. Use a soft-bristled, long-handled washing

brush. It attaches to your garden hose and makes

washing your garage door easier. Do not rub

vigorously which may create glossy areas over

the vinyl finish.

2. For hard-to-remove dirt, such as soot and

grime found in industrial areas, wash the garage

door down with a mild solution consisting of the

following ingredients:

One cup detergent (with less than 0.5%

phosphate) dissolved into five gallons of warm

water.

NOTE: The use of detergents containing greater

than 0.5% phosphate is not recommended for

use in general cleaning of garage doors.

NOTE: Be sure to clean behind weather stripping

on both sides and top of door.

3. Start at the bottom and work up to the top, as

less streaking will result. Immediately following

all washing operations, thoroughly rinse the

surface area with fresh water from a garden

hose.

This cleaning and maintenance information is

suggested in an effort to be of assistance;

however, manufacturer cannot assume

responsibility for results obtained which are

dependent on the cleaning solution and method

of application.

CAUTION: DO NOT PAINT DOOR. PAINTING

DOOR WILL VOID YOUR WARRANTY.

NOTE: DO NOT remove, cover or paint over this

label.

Painting instruction label

Residential warning label

The warning label either be on the right or the left end stile.

Bottom section warning labels

Homeowner’s Manual Envelope

Operator bracket label

Torsion spring tag(s) (one per spring)

Counterbalance Assemblies

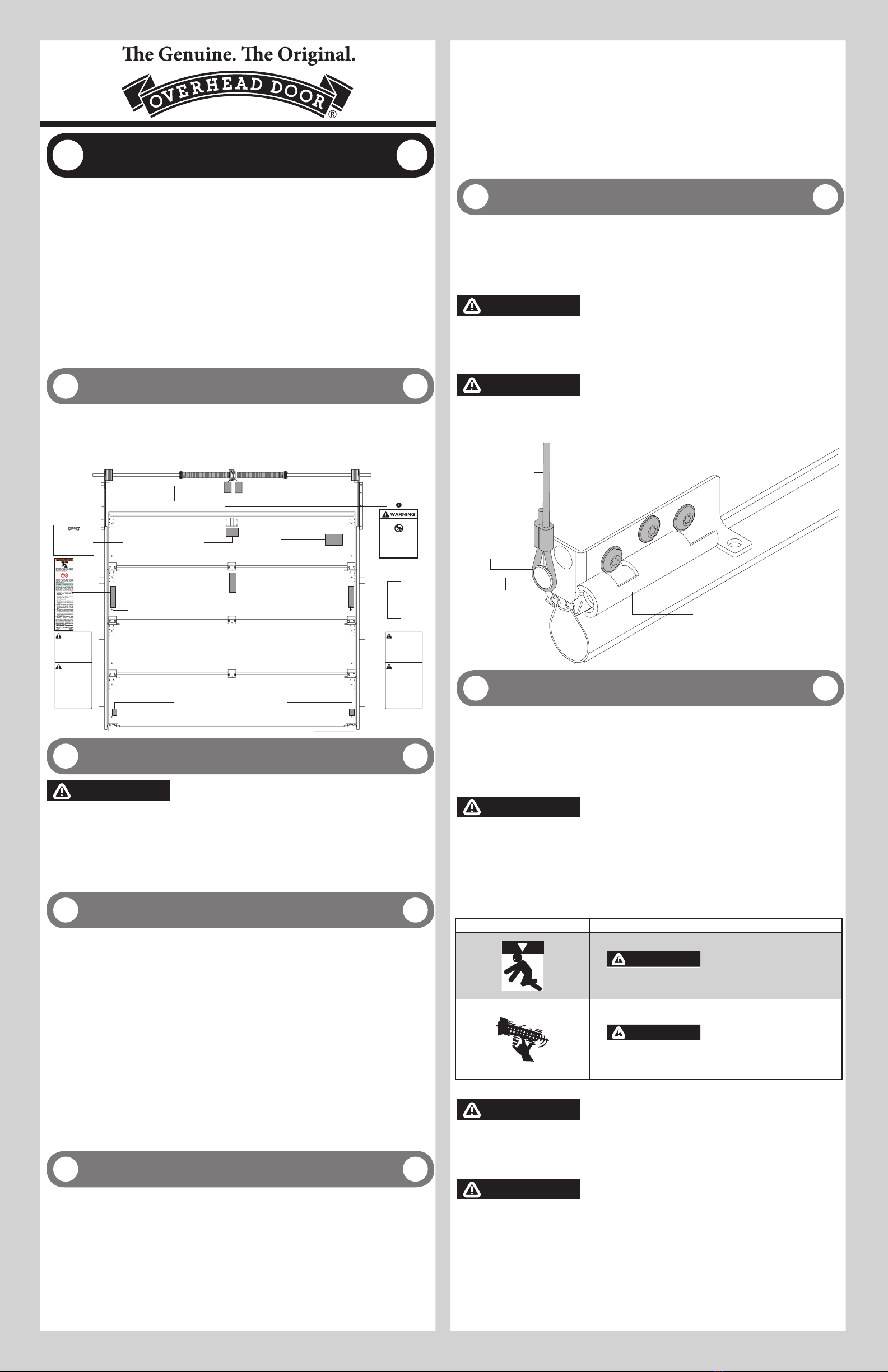

WARNING WARNING

HOMEOWNER! TORSION SPRINGS SHOULD ONLY BE REMOVED, INSTALLED, REPAIRED OR AD-

JUSTED BY A TRAINED DOOR SYSTEM TECHNICIAN. ATTEMPTING TO REMOVE, INSTALL, REPAIR

OR ADJUST A TORSION SPRING ASSEMBLY WITHOUT PROPER TRAINING AND TOOLS MAY RESULT

IN AN UNCONTROLLED RELEASE OF SPRING FORCES WHICH COULD CAUSE SERIOUS OR FATAL

INJURY.

BOTTOM FIXTURES, CABLES, DRUMS, PULLEYS, SHAFTS, AND BRACKETS ARE UNDER HIGH

SPRING TENSION. DO NOT ATTEMPT REPAIRS ON ANY OF THESE ITEMS. CALL A TRAINED DOOR

SYSTEM TECHNICIAN.

Cleaning Your Steel And Fiberglass

Garage Door

IMPORTANT: DO NOT USE A PRESSURE WASHER ON GARAGE DOOR!

While factory-applied finishes on garage doors are durable, it is desirable to clean them on a routine basis. Some

discoloration of the finish may occur when a door has been exposed to dirt-laden atmosphere for a period of time. Slight

chalking may also occur as a result of direct exposure to sunlight.

Cleaning the door will generally restore the appearance of the finish. To maintain an aesthetically pleasing finish of the

garage door, a periodic washing of the garage door is recommended.

A mild detergent solution consisting of one cup detergent (with less than 0.5% phosphate) dissolved into five gallons of

warm water is recommended to aid in the removal of most dirt.

NOTE: The use of detergents containing greater than 0.5% phosphate is not recommended for use in general cleaning of

garage doors.

NOTE: Be sure to clean behind weather stripping on both sides and top of door.

CAUTION: NEVER MIX CLEANSERS OR DETERGENTS WITH BLEACH.

GLASS CLEANING INSTRUCTIONS:

Clean with a mild detergent solution (same as above) and a soft cloth. After cleaning, rinse thoroughly.

ACRYLIC CLEANING INSTRUCTIONS:

Clean acrylic glazing with nonabrasive soap or detergent and plenty of water. Use your bare hands to feel and dislodge

any caked on particles. A soft, grit-free cloth, sponge or chamois may be used to wipe the surface. Do not use hard or

rough cloths that will scratch the acrylic glazing. Dry glazing with a clean damp chamois.

NOTE: DO NOT USE any window cleaning fluids, scouring compounds, gritty cloths or solvent-based cleaners of any kind.

Steel Preparation For Painting

STEEL (SURFACE PREPARATION FOR PAINTING):

Wax on the surface must be removed or paint peeling/flaking will result. To remove this wax, it will be necessary to lightly

scuff the surface with a fine steel wool pad, saturated with soapy water. A final wipe and rinse should be done with clean

water only, to remove any loose particles and any soapy film residue.

Surface scratches, which have not exposed the metal substrate, can be lightly buffed or sanded out with 0000 steel wool

or No. 400 sand paper. Care must be taken to not expose the substrate under the paint. Once the substrate is exposed,

the likelihood for rusting is greatly increased.

If substrate is exposed, it must be treated to prevent rust from forming. Sand the exposed area lightly and paint with a

high quality metal primer, specifically intended for galvanized surfaces, to protect the area from corrosion. Allow for drying

time shown on primer can label before applying topcoat.

The surface of the factory-applied finish, that is being painted, must not be too smooth, or the paint will not adhere to it.

It is advisable to test in an inconspicuous area, to evaluate adhesion. If poor adhesion is observed, surface preparation for

painting the factory-applied finish must be repeated until desired results are achieved. Again, care must be taken to not

expose the substrate under the paint.

STEEL (PAINTING):

After surface has been properly prepared, it must be allowed to dry thoroughly, and then coated immediately with premi-

um quality latex house paint. Follow paint label directions explicitly. Oil base or solvent base paints are not recommended.

Please note that if substrate is exposed and not properly primed, painting with latex paint may cause accelerated rusting

of the steel in the exposed area.

NOTES:

1. Re-painting of finish painted steel doors cannot be warranted, as this condition is totally beyond the door manufac-

turer’s control.

2. Consult a professional coatings contractor if in doubt about any of the above directions.

3. Follow directions explicitly on the paint container labels for proper applications of coatings and disposal of containers.

Pay attention to acceptable weather and temperature conditions in which to paint.

Fiberglass Refinishing and Finishing

REFINISHING:

The top coat on a factory finished fiberglass door may require a re-coat after 1-3 years if the surface appears chalky or

faded. Reapply a top coat as follows: (Always test on a small area prior to top coating the entire door).

1. Clean surfaces with soap and water, mineral spirits or naptha.

NOTE: Light scuffing of surface may be required using Scotch-Brite™ pads.

2. Apply a commercial brand of exterior grade top coat for fiberglass, following the manufacturer’s instructions.

WARNING WARNING

HOMEOWNER! TORSION SPRINGS SHOULD ONLY BE REMOVED, INSTALLED, REPAIRED OR AD-

JUSTED BY A TRAINED DOOR SYSTEM TECHNICIAN. ATTEMPTING TO REMOVE, INSTALL, REPAIR

OR ADJUST A TORSION SPRING ASSEMBLY WITHOUT PROPER TRAINING AND TOOLS MAY RESULT

IN AN UNCONTROLLED RELEASE OF SPRING FORCES WHICH COULD CAUSE SERIOUS OR FATAL

INJURY.

WARNING WARNING

BOTTOM FIXTURES, CABLES, DRUMS, PULLEYS, SHAFTS, AND BRACKETS ARE UNDER HIGH

SPRING TENSION. DO NOT ATTEMPT REPAIRS ON ANY OF THESE ITEMS. CALL A TRAINED DOOR

SYSTEM TECHNICIAN.

Milford pin

Typical bottom

bracket fasteners

Typical bottom bracket

Bottom section

Counterbalance

cable

Counterbalance

cable loop

Safety Information

OVERVIEW OF POTENTIAL HAZARDS READ THIS SAFETY INFORMATION CONVENTIONS USED IN THESE

INSTRUCTIONS:

Garage doors are large, heavy objects that move with the help of springs under high tension and electric motors. Since

moving objects, springs under tension, and electric motors can cause injuries, your safety and the safety of others

depend on you reading the information in this manual. If you have questions or do not understand the information

presented, call your nearest trained door system technician or visit our website.

The following Safety Alert symbol and signal words are used throughout this manual to call attention to and identify dif-

ferent levels of hazard and special instructions.

WARNING WARNING

THIS IS THE SAFETY ALERT SYMBOL. THIS SYMBOL ALERTS YOU TO POTENTIAL HAZARDS THAT

CAN KILL OR HURT YOU AND OTHERS. ALL SAFETY MESSAGES WILL FOLLOW THE SAFETY ALERT

SYMBOL AND THE WORD “DANGER”, “WARNING”, OR “CAUTION”.

DANGER: Indicates an imminently hazardous situation which, if NOT avoided, will result in death or serious injury.

WARNING: Indicates a potentially hazardous situation which, if NOT avoided, could result in death or serious injury.

CAUTION: Indicates a potentially hazardous situation which, if NOT avoided, may result in injury or property damage.

NOTE: Indicates important steps to be followed or important considerations.

IMPORTANT SAFETY INSTRUCTIONS READ AND FOLLOW ALL INSTRUCTIONS SAVE THESE INSTRUCTIONS.

Potential Hazard Effect Prevention

Could result in Death or Serious Injury

Keep people clear of opening while Door

is moving.

Do NOT allow children to play with the Door

Opener.

Do NOT operate a Door that jams or one

that has a broken spring.

Could result in Death or Serious Injury

Do NOT try to remove, install, repair or

adjust springs or anything to which door

spring parts are fastened, such as, wood

blocks, steel brackets, cables or other like

items.

Installations, repairs and adjustments must

be done by a trained door system techni-

cian using proper tools and instructions.

READ THIS SAFETY INFORMATION:

WARNING WARNING

IF YOUR OLD DOOR OR NEW DOOR USES TORSION SPRINGS, DO NOT ATTEMPT TO REMOVE,

INSTALL, REPAIR OR ADJUST THE SPRINGS YOURSELF. HAVE A TRAINED DOOR SYSTEM TECHNI-

CIAN REMOVE, INSTALL, REPAIR OR ADJUST THEM. ATTEMPTING TO REMOVE, INSTALL, REPAIR

OR ADJUST A TORSION SPRING ASSEMBLY WITHOUT PROPER TRAINING OR TOOLS MAY RESULT

IN AN UNCONTROLLED RELEASE OF SPRING FORCES WHICH CAN CAUSE SERIOUS INJURY.

WARNING WARNING

BE SURE THAT YOUR GARAGE COMPLIES WITH ALL APPLICABLE STATE AND OR LOCAL VENTILA-

TION REQUIREMENTS BEFORE YOU ENCLOSE ANY VEHICLES IN THE GARAGE. GOOD VENTILATION

AVOIDS FIRE AND HEALTH HAZARDS CAUSED BY FUMES ACCUMULATING WITHIN A WELL-

SEALED GARAGE.

1. Do NOT permit children to play beneath or with any garage door or electric operating controls.

2. Keep hands and fingers clear of section joints, track, and other door parts when the door is opening and closing to

avoid injury.

3. Bolts must be installed at the rear end of horizontal tracks. These act to stop the rollers and keep the door from rolling

off the back of the track.

4. Track installations must use sway braces on the rear track hangers to prevent sideways movement. If the tracks are

NOT firmly stabilized they might spread, allowing the door to fall and cause severe injury and damage.

344970 NEW 08/05/2010Part No.

©COPYRIGHT 2010 OVERHEAD DOOR CORPORATION