WARNING! Read all safety warnings and all instructions. Failure to follow

the warnings and instructions may result in electric shock, re and/or serious

injury.

Save these instructions

RISK OF EXPLOSION OR FIRE

What can happen:

• Spilled petrol and its vapours can become ignited from cigarette sparks, electrical arcing,

exhaust gases and hot engine components such as the mufer.

• Heat will expand fuel in the tank which could result in a re.

• Operating the tool in an explosive environment could result in a re.

• Mufer exhaust heat can damage painted surfaces, melt any materials sensitive to heat

(such as siding plastic, rubber or vinyl) and damage live plants. Keep hot tool away from

other objects.

• Improperly stored fuel could lead to accidental ignition. Fuel improperly secured could get

into the hands of children or other unqualied persons.

How to prevent it:

• Shut off engine and allow it to cool before adding fuel to the tank.

• Use care when lling the tank to avoid spilling fuel. Move tool away from fuelling area

before starting engine.

• Keep maximum fuel level 20mm below top of tank to allow for expansion.

• Operate and refuel in well ventilated areas free from obstructions.

• Store fuel in a approved container (AS/NZS 2906-1999) for petrol. Store in a secure

location away from the work area. Make sure the container is clearly marked “fuel”.

RISK TO BREATHING

What can happen:

• Breathing exhaust fumes can cause serious injury or death.

How to prevent it:

• Operate tool in a well ventilated area. Avoid enclosed areas.

• Never operate unit in a location occupied by other people or animals.

SAVE THESE INSTRUCTIONS

1) Work area

a) Keep work area clean and well lit. Cluttered and dark areas invite accidents.

b)

Do not operate petrol tools in explosive atmospheres, such as in the presence of

ammable liquids, gases, or dust. Power tools create sparks which may ignite the dust

or fumes.

c) Keep children and bystanders away while operating a petrol tool.

Distractions can cause you to lose control.

2) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a

petrol tool. Do not use a power tool while you are tired or under the inuence of drugs,

alcohol, or medication. A moment of inattention while operating power tools may result in

serious personal injury.

b) Use safety equipment. Always wear eye protection. Safety equipment such as a

dust mask, non-skid safety shoes, hard hat, or hearing protection used for appropriate

conditions will reduce personal injuries.

c) Remove any adjusting key or wrench before turning the tool on. A wrench or a key

that is left attached to a rotating part of the petrol tool may result in personal injury.

d) Do not overreach. Keep proper footing and balance at all times. This enables better

control of the petrol tool in unexpected situations.

e) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

f) If devices are provided for the connection of dust extraction and collection

facilities ensure that these are connected and properly used. Use of these devices

can reduce dust-related hazards.

3) Petrol tool use and care

a) Do not force the petrol tool. Use the correct petrol tool for your application. The

correct petrol tool will do the job better and safer at the rate for which it was designed.

b) Do not use the petrol tool if the switch does not turn it on and off. Any petrol tool that

cannot be controlled with the switch is dangerous and must be repaired.

c) Turn tool off completely before making any adjustments, changing accessories,

or storing petrol tools. Such preventive safety measures reduce the risk of starting the

petrol tool accidentally. Hair can be caught in moving parts.

d) Store idle petrol tools out of the reach of children and do not allow persons

unfamiliar with the petrol tool or these instructions to operate the petrol tool. Petrol

tools are dangerous in the hands of untrained users.

e) Maintain petrol tools. Check for misalignment or binding of moving parts, breakage

of parts and any other condition that may affect the petrol tool’s operation. If

damaged, have the petrol tool repaired before use. Many accidents are caused by poorly

maintained petrol tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are easier to control.

g)Use the petrol tool, accessories and tool bits etc., In accordance with these

instructions and in the manner intended for the particular type of petrol tool, taking

into account the working conditions and the work to be performed. Use of the petrol

tool for operations different from intended could result in a hazardous situation.

h) This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge,

unless they have been given supervision or instruction concerning use of the appliance

by a person responsible for their safety.

i) Children should be supervised to ensure that they do not play with the appliance.

4) Service

a) Have your petrol tool serviced by a qualied repair personnel using only identical

replacement parts. This will ensure that the safety of the petrol tool is maintained.

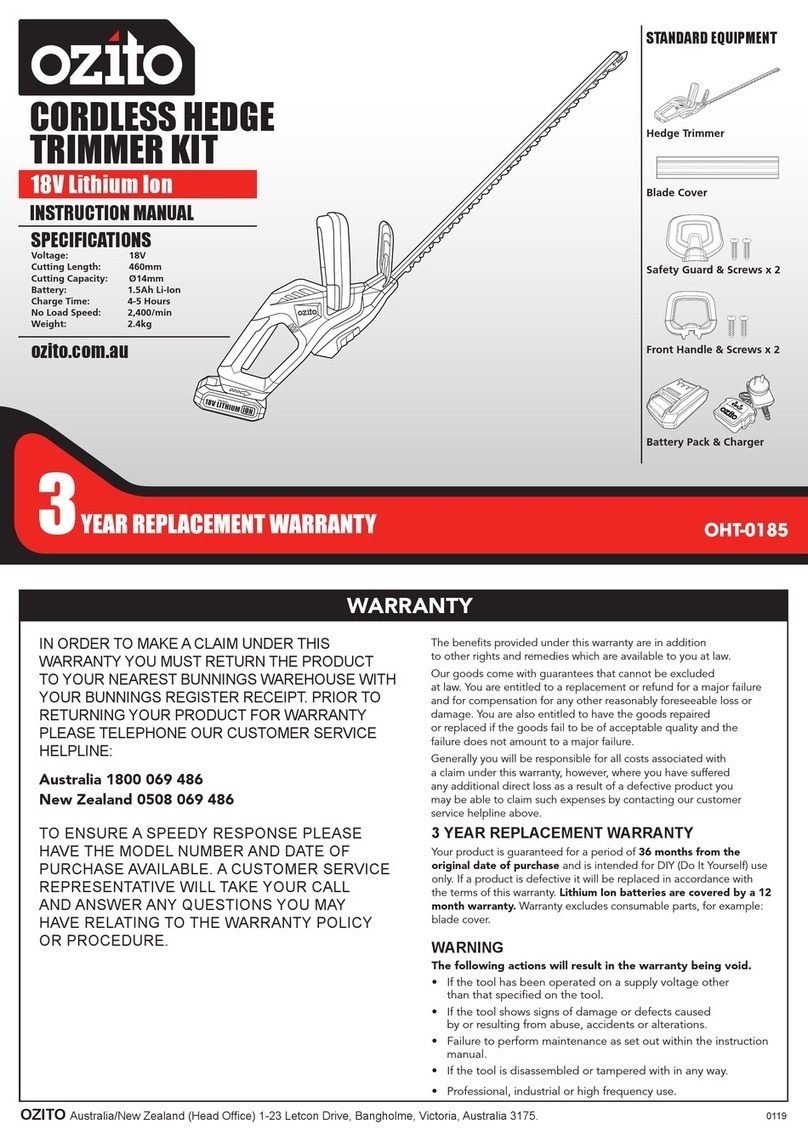

ADDITIONAL SAFETY INSTRUCTIONS FOR HEDGE TRIMMERS

SAFETY INSTRUCTIONS

• Keep all parts of the body away from the cutter blade. Do not remove cut material

or hold material to be cut when blades are moving. Make sure the switch is off when

clearing jammed material. A moment of inattention while operating the hedge trimmer

may result in serious personal injury.

• Carry the hedge trimmer by the handle with the cutter blade stopped. When

transporting or storing the hedge trimmer always t the cutting device cover. Proper

handling of the hedge trimmer will reduce possible personal injury from the cutter

blades.

• Hold the power tool by insulated gripping surfaces only, because the cutter blade

may contact hidden wiring. Cutter blades contacting a “live” wire may make exposed

metal parts of the power tool “live” and could give the operator an electric shock.

• Perform visual inspection on the hedge being trimmed. To ensure no wire fences or

foreign objects that the hedge trimmer may contact during operation.

• Never allow children or people unfamiliar with these instructions to use the Hedge

Trimmer.

• Avoid using the Hedge Trimmer, while people, especially children or pets, are nearby.

• Use the Hedge Trimmer only in daylight or good articial light.

• Never operate the Hedge Trimmer with damaged guards or without guards in place.

• Start the Hedge Trimmer only when the hands and feet are away from the cutting

blades.

• Use only the manufacturer’s recommended replacement parts and accessories.

• Always remove the spark plug from the Hedge Trimmer before carrying out

maintenance or cleaning work.

• Inspect and maintain the Hedge Trimmer regularly. Have the Hedge Trimmer repaired

only by an authorized repairer.

• When not in use, store the Hedge Trimmer out of the reach of children.

• Face the cutting blades away from yourself, other people and animals while the Hedge

Trimmer is in operation.

• Disconnect the spark plug from the Hedge Trimmer before making any adjustments.

• Ensure you use oil-mix fuel. Ensure that you mix 40 parts unleaded fuel to 1 part

2-stroke oil. If not, the engine will overheat and cause damage to your hedge trimmer.

• Use both handles.

• Keep ventilation openings clear of debris. Keep handles dry, clean and free of oil and

grease.

• Never reach underneath the Hedge Trimmer (the cutting blade area) until it has

completely stopped and the engine stopped.

WARNING! When servicing, use only identical replacement parts. Use of any

other parts may create a hazard or cause product damage. To ensure safety and

reliability, all repairs should be performed by a qualied service technician.

WARNING! This appliance is not intended for use by young or inrm persons

unless supervised by a responsible person to ensure that they can use the

appliance safely. Young children should be supervised to ensure that they do not

play with the appliance.