Front and Rear Panel 150-412-171-04, Revision 04

4 November 23, 1999 HRU-412 List 7A

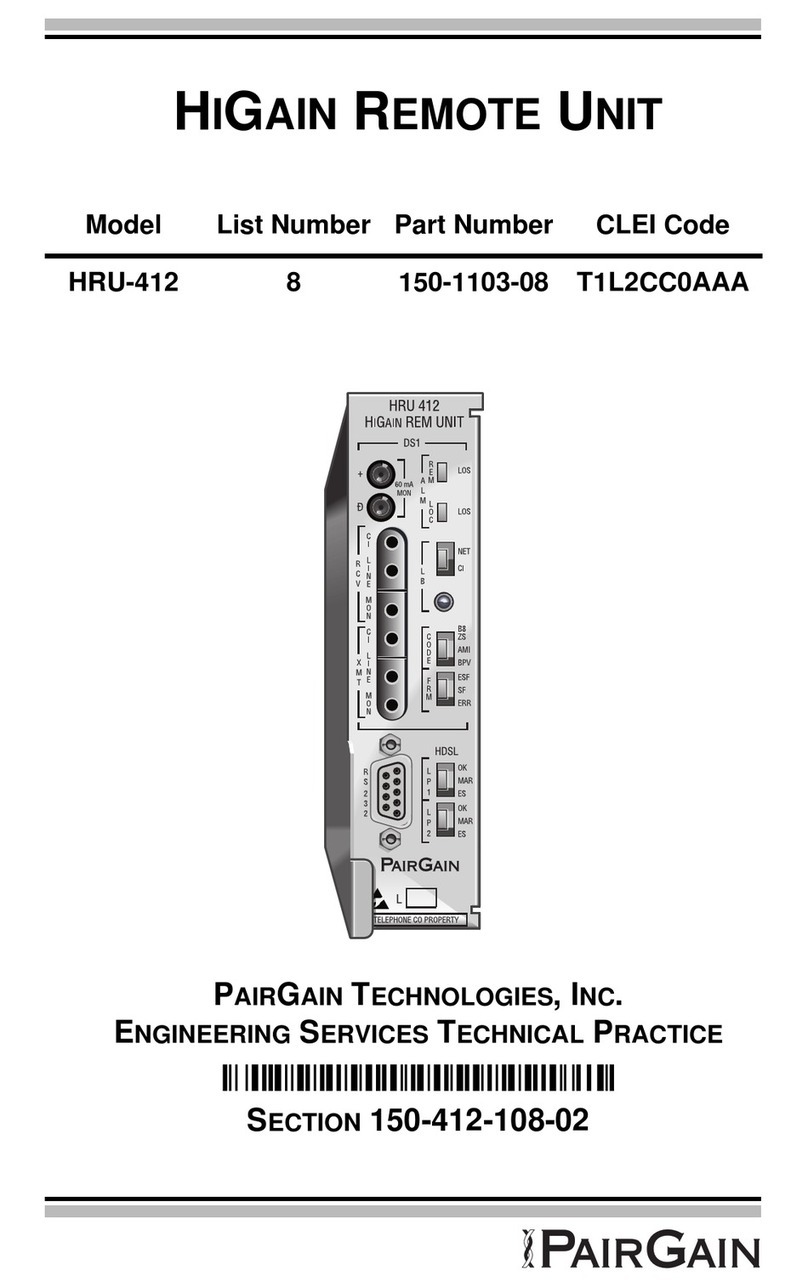

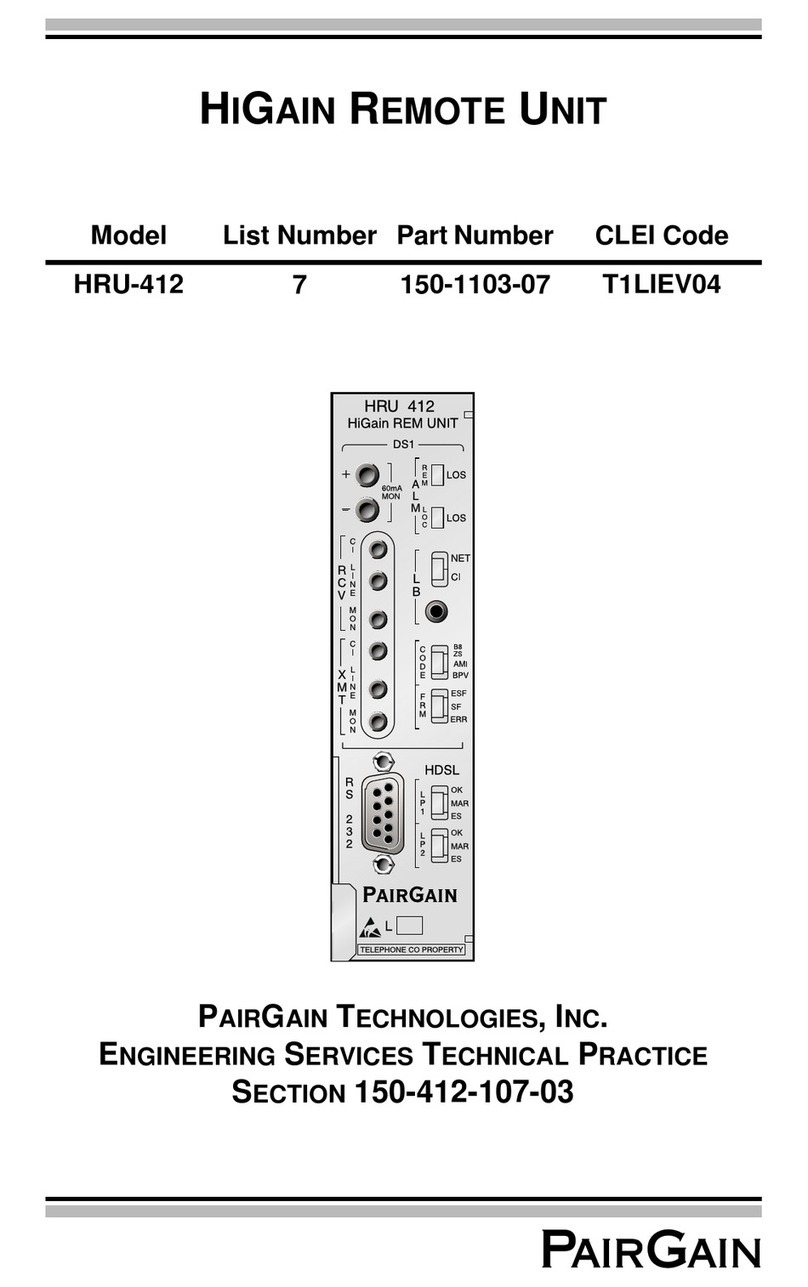

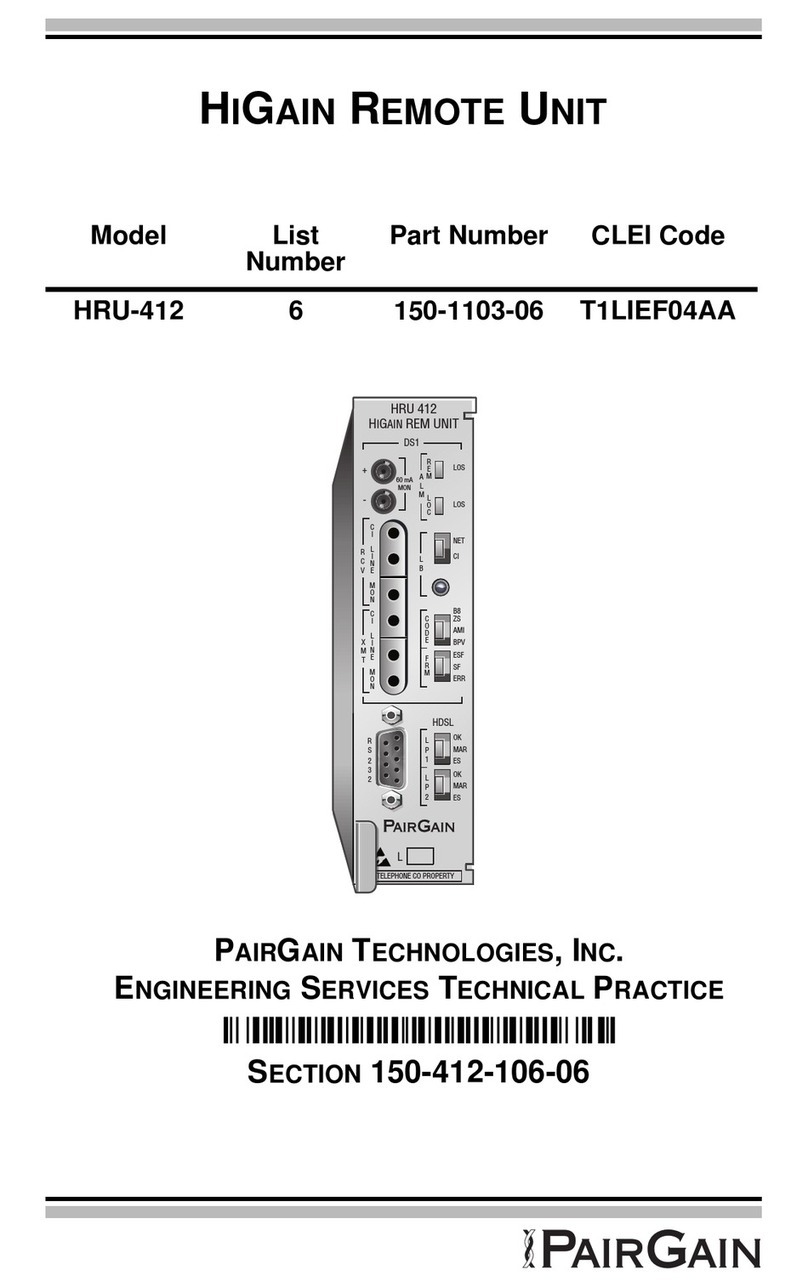

Table 1. HRU-412 List 7A Front Panel Components

Name Function

Test points Allow measurement of the 60 mA CPE current. The current is related

to the voltage measurement across the + and - test points by the

following relationship: CPE CURRENT=1 mA / 1 mV. Typical readings

range from 55 to 65 mV which equate to a 55 to 65 mA current range.

Receive (RCV)

and transmit

(XMT) jacks

Provide splitting and monitor access to the CPE DS1 interface. The

jacks are isolated from the CPE DS1 metallic interface by a

transformer.

Alarm LEDs The REM LOS LED is steady red indicating a loss of signal (LOS) at the

T1 input to the HLU. This LOS condition causes the HRU-412 to

transmit the alarm indicating signal (AIS) pattern toward the CPE.

The LOC LOS LED is steady red indicating a loss of signal (LOS) at the

T1 input to the HRU-412. This LOS condition transmits the AIS pattern

toward the DSX-1 (TLOS Disabled) or to execute a logic loopback in

the HRU-412 (TLOS Enabled).

Loopback (LB)

LEDs

The NET LED is steady green indicating the HRU-412 is in a loopback

state in which the signal from the network is looping back to the

network.

The CI LED is steady yellow indicating the HRU-412 is in a loopback

state in which the signal from the customer interface (CI) is looping

back to the CI.

CODE LEDs The B8ZS LED is steady green indicating that the user DS1 code

option is set to B8ZS.

The AMI LED is steady yellow indicating that the user DS1 code option

is set to AMI.

The BPV LED is steady red indicating that the user DS1 code option is

set to BPV.

If the user DS1 code option is set to AUTO, the lit LED indicates what

DS1 signal is being received.

Note that the settings are made on the HLU.

Framing LEDs The framing option is set on the HLU.

The ESF LED is steady green indicating that the framing pattern of the

received signal is Extended Super Frame (ESF).

The SF LED is steady yellow indicating that the framing pattern of the

received signal is Super Frame (SF).

The ERR LED is steady red indicating that a DS1 frame error has

occurred. No frame LED lights when the HRU-412 input pattern is

unframed or when the framing option is set to UNFR (unframed).