Section 150-319-124

Revision 03

Page 8

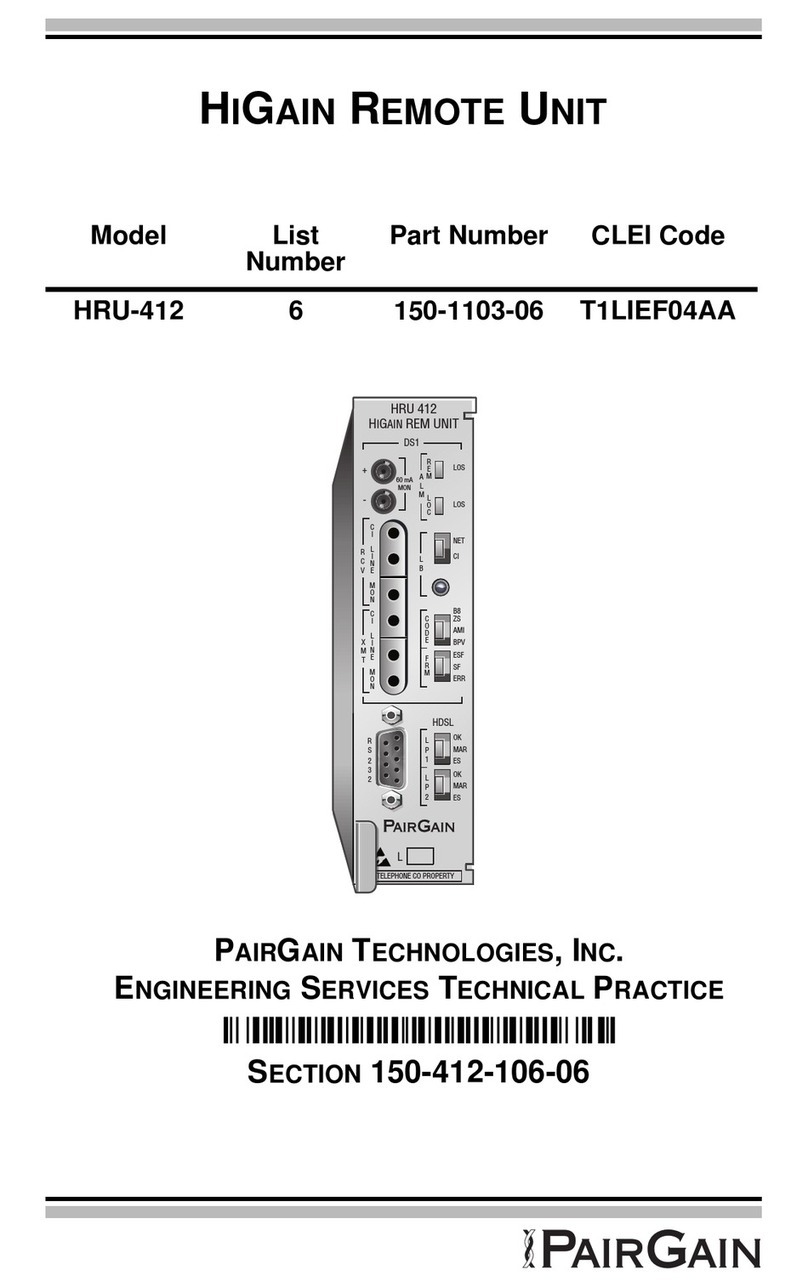

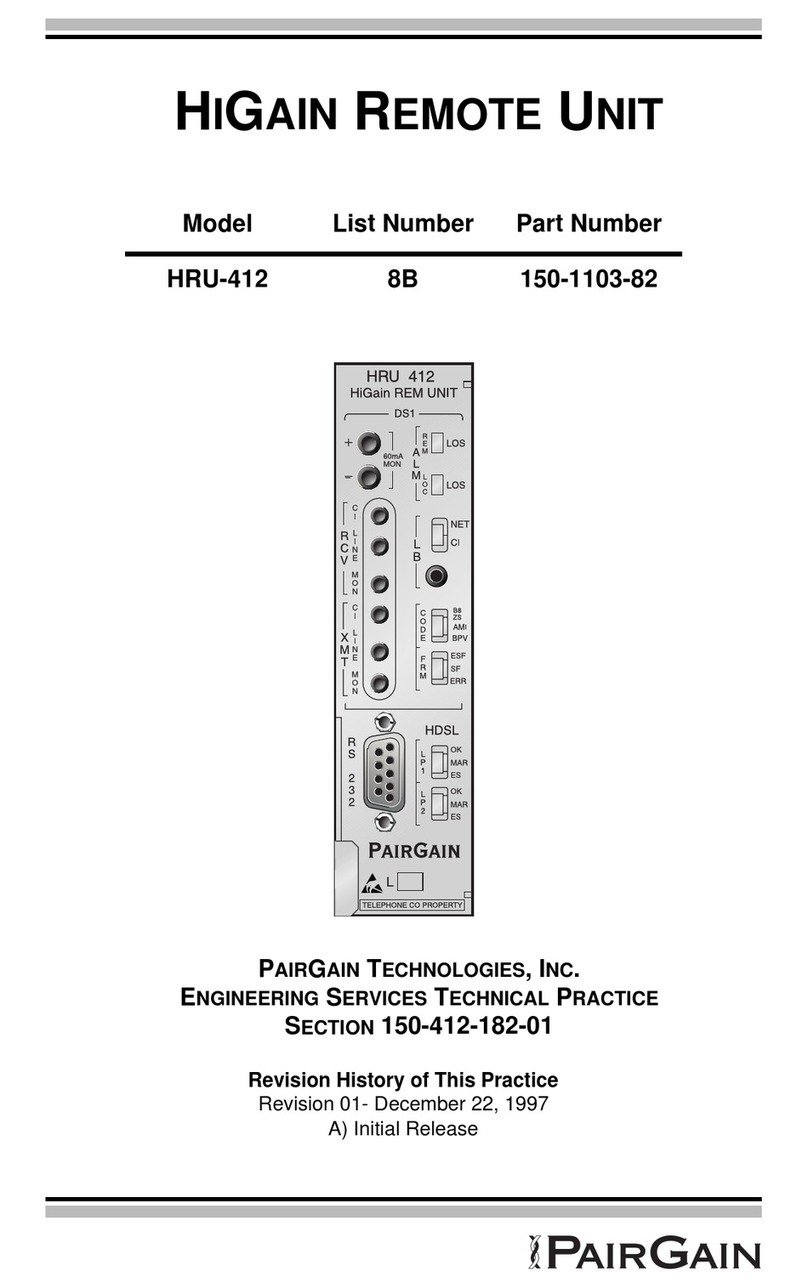

5.07 The Circuit ID option is set by choosing the

Hoption from the terminal Main Menu screen (see

Figure 7 for non-doubler applications and Figure 16

for doubler applications). The message “ENTER

CIRCUIT ID#:” (24 characters max) follows the “H”

selection. Press Enter after entering the chosen set

of alpha-numeric ID characters; choose Cto confirm.

Note that if more than 24 characters are entered, a

“Beep” is emitted, and only the first 24 characters are

accepted. The ID appears in all HLU-319, List 2D

screens, as shown in Figures 7 through 14 for non-

doubler applications and Figures 16 through 34 for

doubler applications. The ID does not appear on the

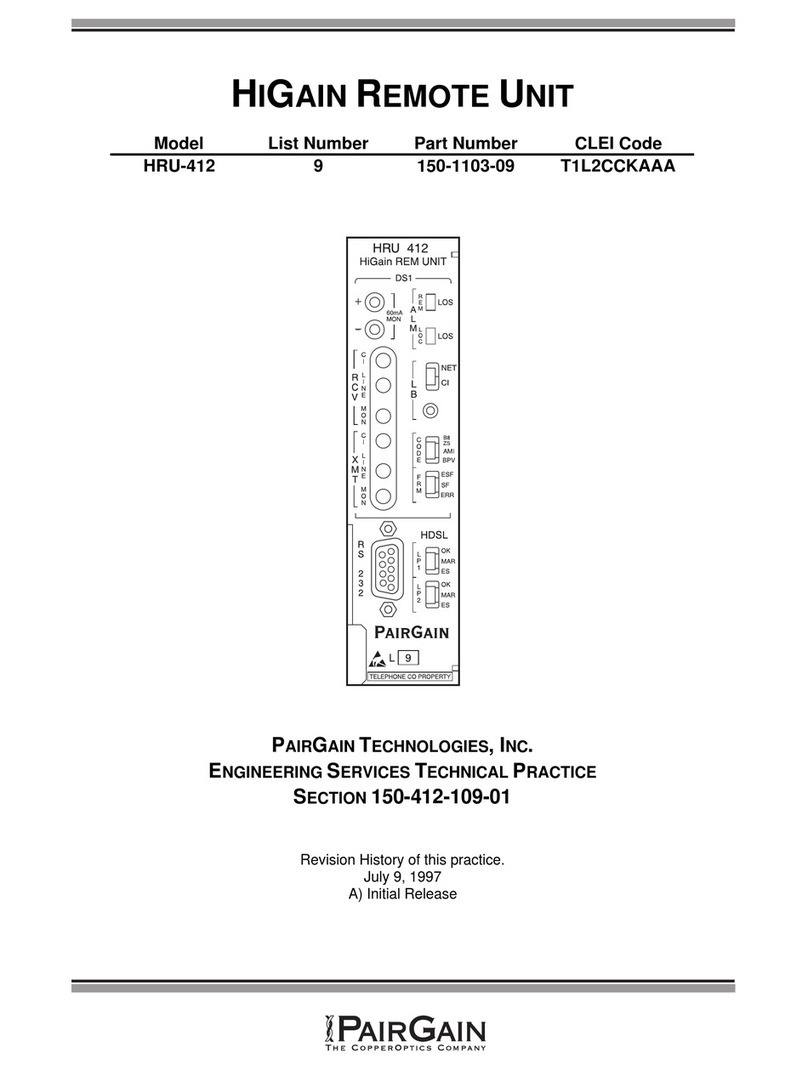

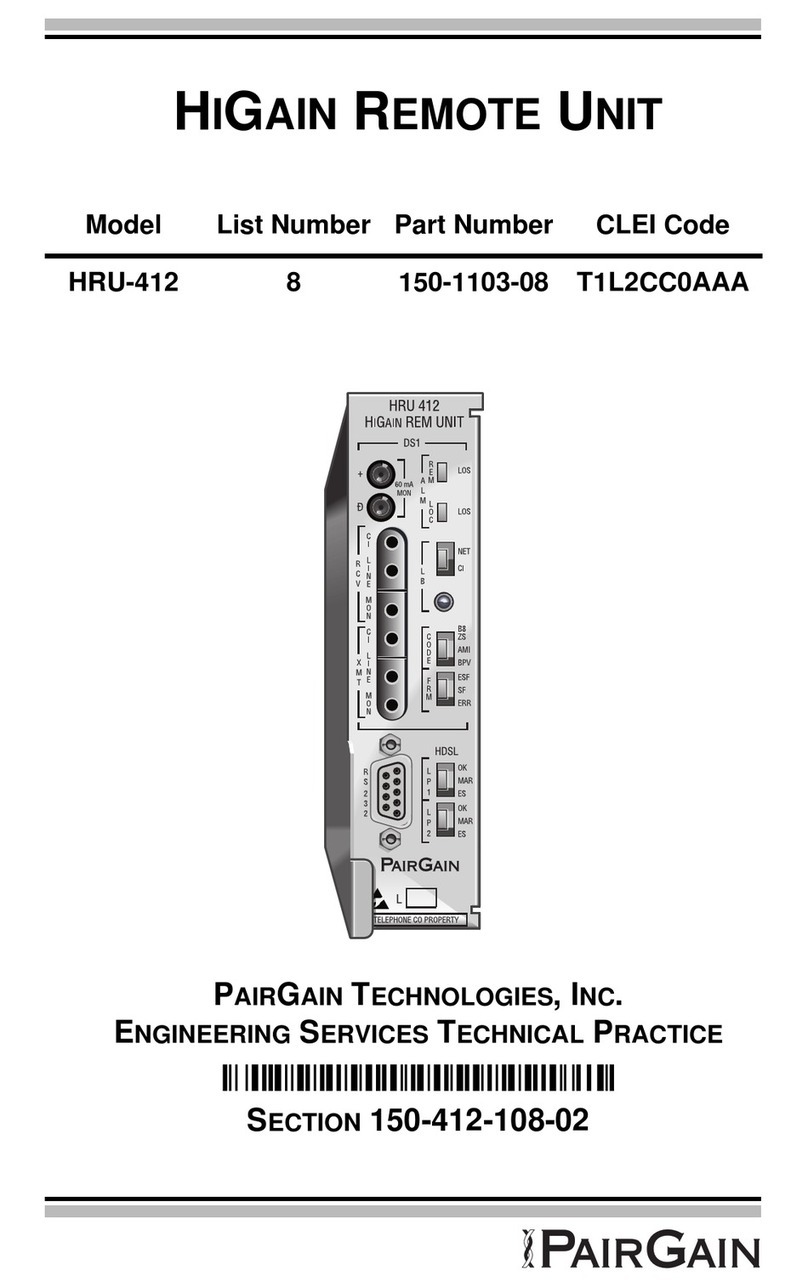

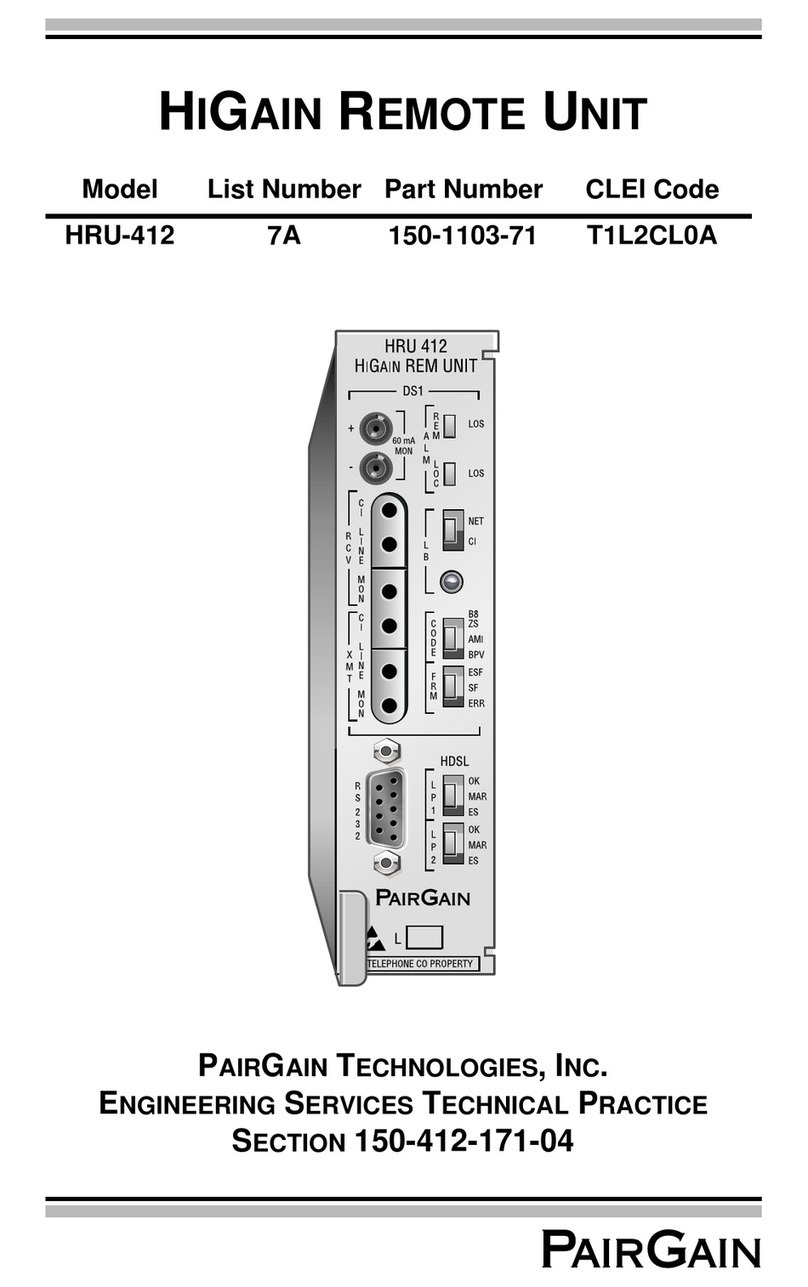

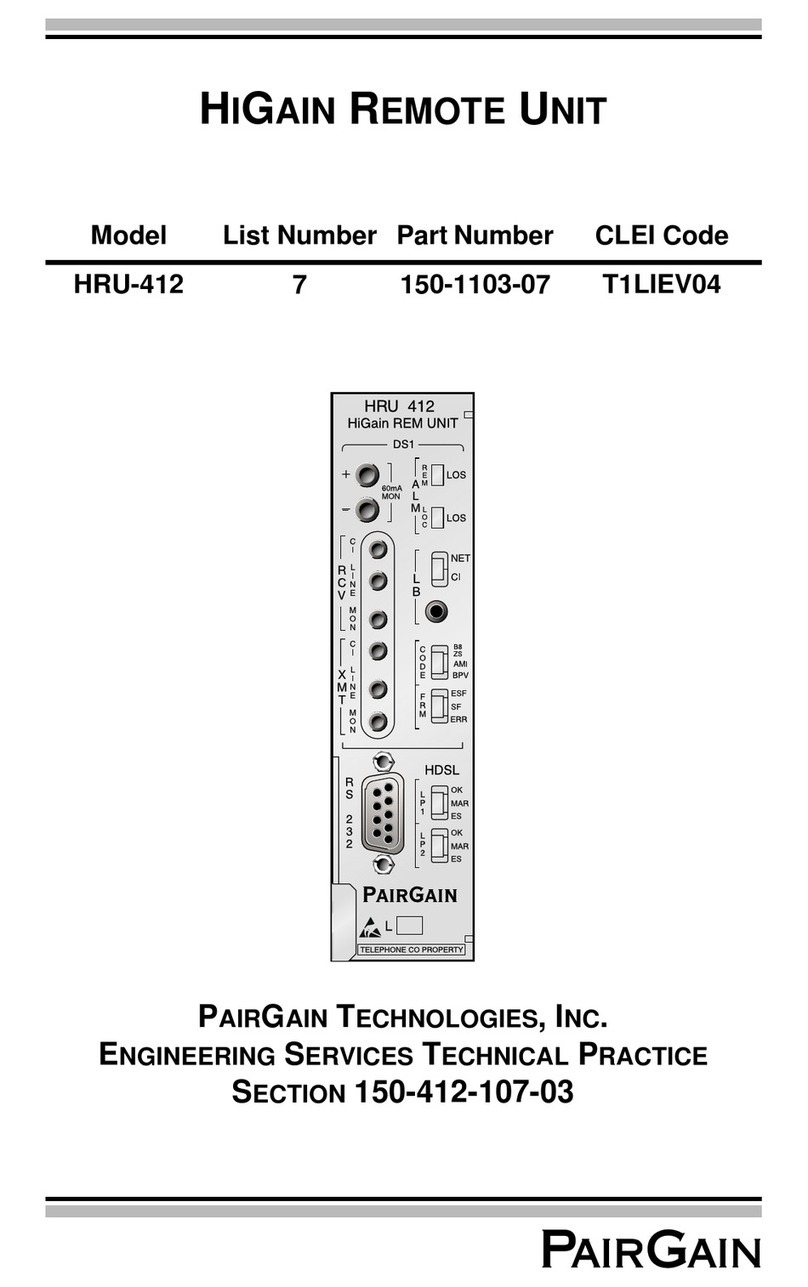

HRU-412 screens when the maintenance port is

accessed at the remote unit. Note that the Circuit ID

can not be set to its factory setting (all blanks) setting

when the DFLT setting option is utilized (see Section

A Paragraph 5.03).

5.08 To set the DS0 Blocking option, from the Main

Menu screen, press Cto select the System Settings

Menu screen. The menu shown in Figure 10 (for non-

doubler applications) and Figure 22 (for doubler

applications) appears. Press B, as shown in

parentheses of the DS0 blocking selection. The DS0

channels are blocked or unblocked by entering each

channel number. Multiple channels can be selected

by inserting a space between each entry. After all the

new settings have been made, press E(“Exit”) and C

(“Confirm”). The new choices are now installed. Also,

all blocked channels are temporarily “unblocked” for

all HiGain system loopback tests. This allows the

standard full bandwidth T1 loopback tests to be

performed.

5.09 To set the Margin Alarm Threshold, select G

from the System Settings Menu screen. Enter the

desired minimum acceptable alarm threshold from the

0 to 15 dB range. This causes a minor alarm to occur

if either the margin on HDSL loop 1 (MAL1) or loop 2

(MAL2) of any span drops

below

the selected

threshold value (see Section 4). Since the margin can

never drop below 0, choosing 0for the margin

threshold turns the margin alarm off.

5.10 Other system settings are set by using a

terminal in a similar manner. Enter the key

represented by the letter in parentheses of the

parameter to be changed. Each entry of this letter

scrolls the parameter to its next value. Hit the Enter

key after making each selection. After all selections

have been made, press Eto “Exit” and Cto “Confirm”

the changes. This activates the new choices and

returns control to the Main Menu screen.

5.11 The new T1 transceiver chip in the List 2D

allows the unit to process both B8ZS and AMI code

inputs, regardless of the DS1 code setting (AMI or

B8ZS). Earlier units caused input BPV, if B8ZS

patterns were processed while in the AMI mode.

When the newer units are in the AMI mode, they can

receive B8ZS but can only transmit AMI. For this

reason, mixed systems (those consisting of both HLU-

319, List 2D and older Lists 1, 2, 3, 3A and 4 HRU-

412 units) will respond differently in each direction for

B8ZS inputs when in their AMI modes.

5.12 The Self-test mode, which occurs when both

HDSL loops are not in-sync, has been enhanced to

include the input DS1 transceiver chip in the self-test

procedure. This process can cause the Alarm

Indicating Signal (AIS) pattern, which is normally

transmitted from the HLU-319, List 2D during these

out-of-sync intervals, to exhibit occasional BPVs.

5.13 The HAIS option provides two selections (1LP

and 2LP) for the T1 transmit outputs at both the HLU-

319, List 2D and HRU-412 for HDSL loss-of-sync

conditions. The “1LP” selection causes the AIS

pattern to be transmitted at both T1 outputs when

either of the two HDSL loops experience a loss-of-

sync (LOSW) condition or when a margin alarm

occurs. This choice causes the 12 channels on the

surviving loop to be lost as they are replaced by the

AIS pattern. However, it allows both down and

upstream equipment to be made aware of the loss of

one HDSL loop or a loop with low margin. The 1LP

selection is the preferred setting to be able to initiate

an AIS state with just one conductor open in either of

the HDSL pairs. Short loops, below about 16 dB of

loss at 200 kHz, can remain in-sync with one

conductor open. Since the loop is still in-sync, no

LOSW condition occurs. However, the margin on a

one-conductor loop drops from 5 to 10 dB. Thus, if

the margin alarm is set to 5 dB below the normal

margin at turn-up, when one conductor opens, a minor

alarm occurs and causes the AIS condition. This

alerts the maintenance personnel of the problem. The

“2LP” choice requires both HDSL loops to be out-of-

sync (LOSW) before the AIS signal is transmitted.

This choice preserves the integrity of the 12 surviving

channels when just one loop is lost.

5.14 All user options that affect the operation in

both the HLU-319, List 2D and HRU-412, (such as

HAIS, SAIS and DS0 blocking) are not available in

older versions of the HRU-412, Lists 1, 2, 3, 3A, and 4

that do not support these newer options.