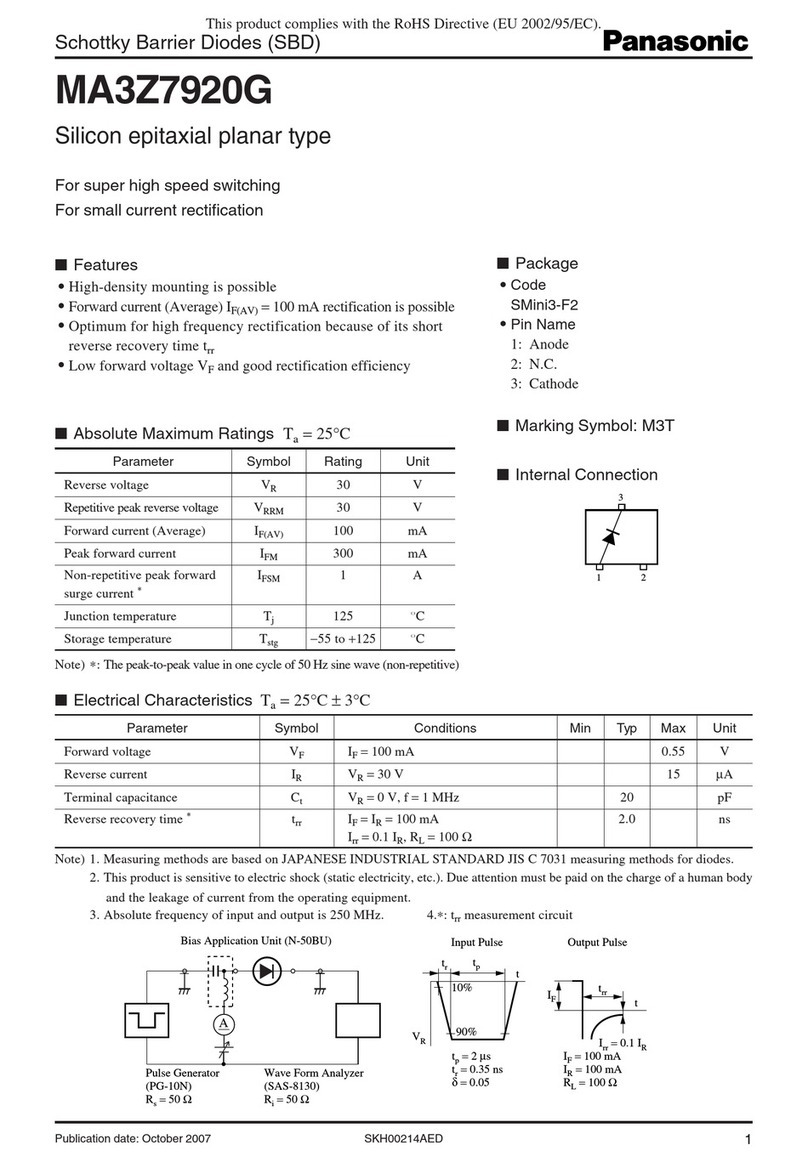

SPECIFICATIONS

1

Notes: 1) Highly viscous liquid may not be stably detected.

2) Fluorinert TM is the worldwide trademark of 3M.

3) Liquid being detected should be also kept within the rated ambient temperature range.

Type SUS mounting bracket type PVC mounting bracket type

2m cable length type 5m cable length type 2m cable length type 5m cable length type

Model

NPN output

EX-F71 EX-F71-C5 EX-F72 EX-F72-C5

Item

No.

PNP output

EX-F71-PN EX-F71-PN-C5 EX-F72-PN EX-F72-PN-C5

Sensing object Water, Fluorinert TM (Note 1) (Note 2)

Supply voltage 12 to 24V DC ± 10% Ripple P-P 10% or less

Current consumption 10mA or less (PNP output type: 15mAor less)

Output

<NPN output type>

NPN open-collector transistor

Maximum sink current: 50mA

Applied voltage: 30V DC or less (between output and 0V)

Residual voltage: 1.0V or less (at 50mAsink current)

0.4V or less (at 16mA sink current)

<PNP output type>

PNP open-collector transistor

Maximum source current: 50mA

Applied voltage: 30V DC or less (between output and +V)

Residual voltage: 1.0V or less (at 50mA source current)

0.4V or less (at 16mA source current)

Output operation ON when normal operation, OFF when leak is detected or the sensor is mounted improperly.

Short-circuit protection

Incorporated

Response time 50ms or less

Abnormal indicator Red LED (lights up when leak is detected or the sensor is mounted improperly.)

Normal indicator Green LED (lights up when the sensor is mounted properly.)

Protection IP67 (IEC)

Ambient temperature –10 to +60°C (No dew condensation or icing allowed) (Note 3), Storage: –20 to +70°C

Ambient humidity 35 to 85% RH, Storage: 35 to 85% RH

Ambient illuminance Incandescent light: 1,000Ɛx or less at the light-receiving face

Emitting element Infrared LED (non-modulated)

Material Enclosure: Polypropylene

Cable 0.1mm23-core PVC

cabtyre cable, 2m long 0.1mm23-core PVC

cabtyre cable, 5m long 0.1mm23-core PVC

cabtyre cable, 2m long 0.1mm23-core PVC

cabtyre cable, 5m long

Weight Approx. 25g Approx. 55g Approx. 25g Approx. 55g

Accessories SUS mounting bracket: 1 pc.

PVC mounting bracket: 1 pc. each for two-point-¿xing and adhesive-¿xing

CAUTIONS

2ƔThis product has been developed / produced for

industrial use only.

ƔAvoid using the product in an explosive

atmosphere because this product does not have

an explosive-proof protective construction.

ƔMake sure that the power supply is off while wiring.

ƔTake care that wrong wiring will damage the sensor.

ƔVerify that the supply voltage variation is within

the rating.

Take care that if a voltage exceeding the rated

range is applied, or if anAC power supply is directly

connected, the sensor may get burnt or damaged.

ƔIf power is supplied from a commercial switching

regulator, ensure that the frame ground (F.G.)

terminal of the power supply is connected to an

actual ground.

ƔDo not use during the initial transient time (approx.

50m sec. ) after the power supply is switched on.

ƔIn case noise generating equipment (switching

regulator, inverter motor, etc.) is used in the vicin-

ity of this product, connect the frame ground (F.G.)

terminal of the equipment to an actual ground.

ƔCable extension is possible up to total 50m with

0.3mm2, or more, cable. However, in order to re-

duce noise, make the wiring as short as possible.

ƔDo not run the wires together with high-voltage lines

or power lines or put them in the same raceway.

This can cause malfunction due to induction.

ƔIn case a surge is generated in the used power sup-

ply, connect a surge absorber to the supply and ab-

sorb the surge.

Ɣ%e sure to use the exclusive mounting bracket when installing

the sensor to avoid human error, etc. Reliable detection can-

not be guaranteed when this mounting bracket is not used.

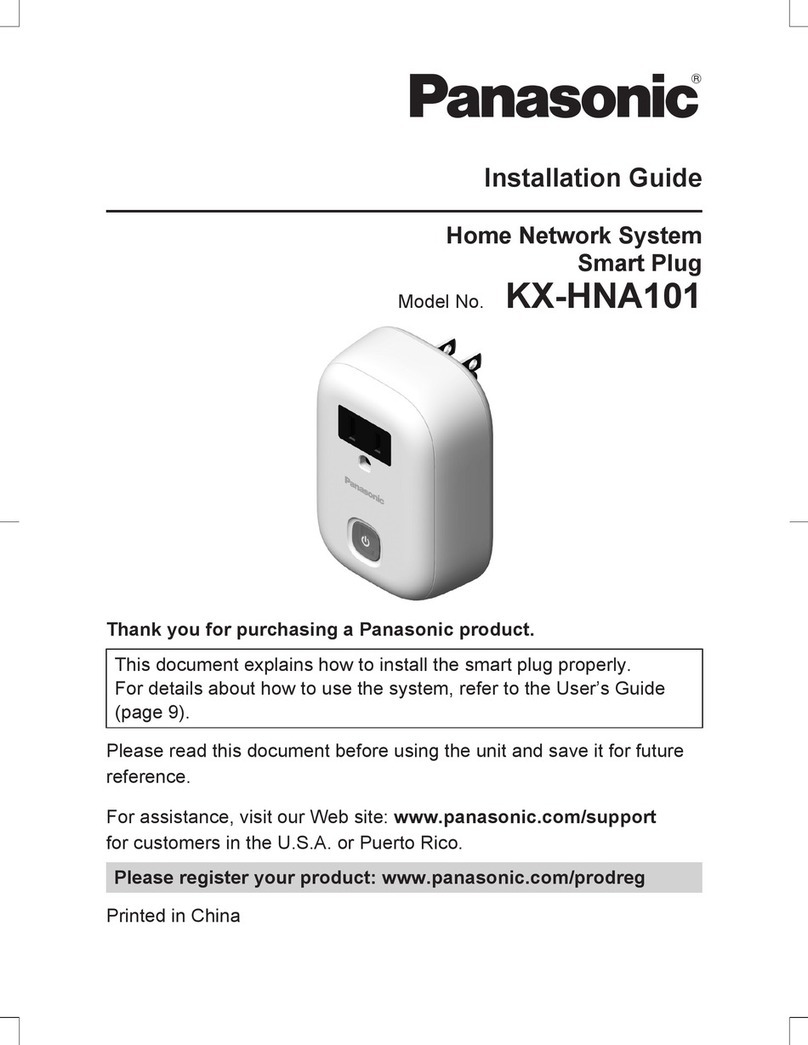

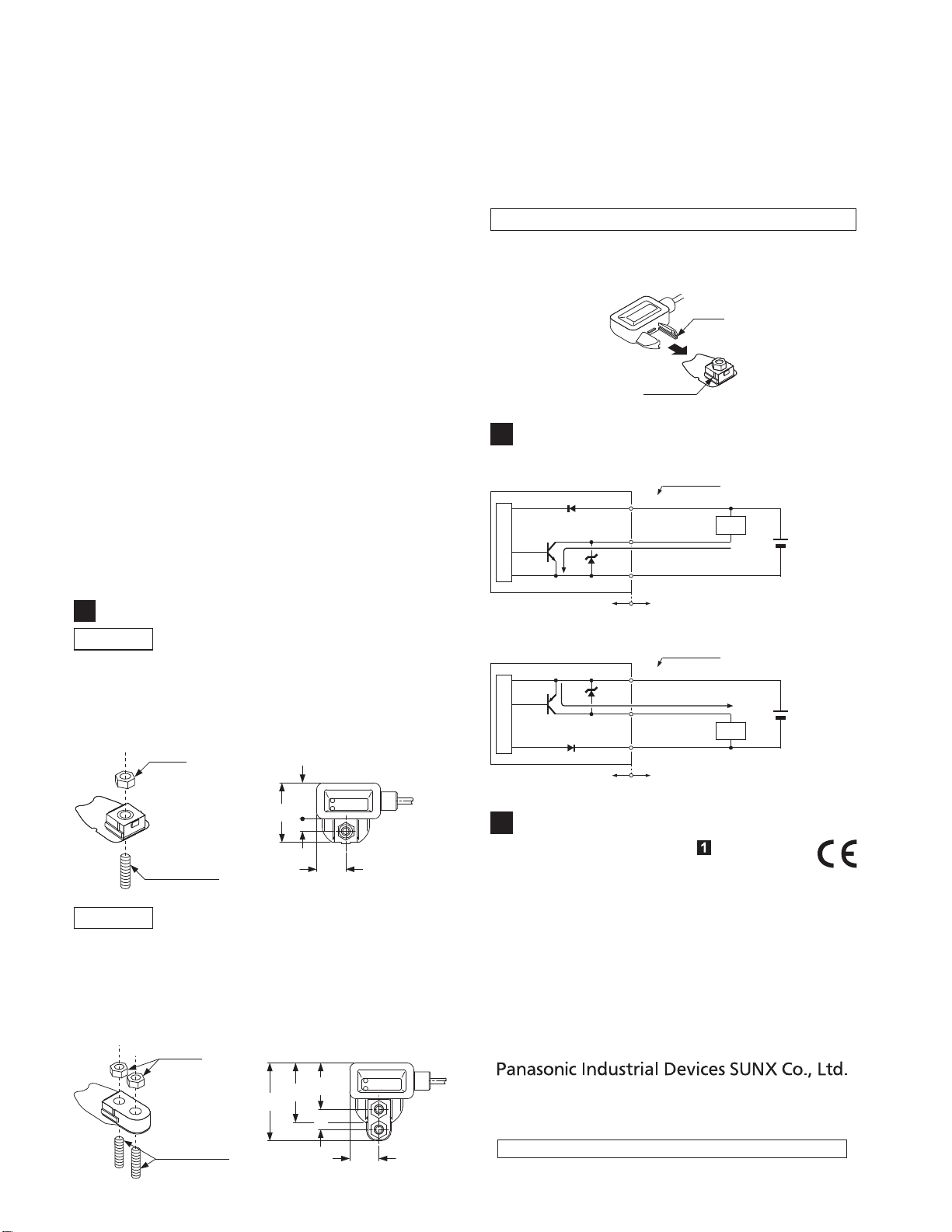

MOUNTING

3

(;)Ƒ

ƔInsert the M4 stud-bolt (length 10mm or more)

welded on the user’s facilities into the mounting

hole of the SUS mounting bracket and screw with

an M4 nut (please arrange separately).

The tightening torque should be 0.98N·m or less.

M4 nut <Mounting dimensions (Unit: mm)>

M4 stud-bolt

(straight type)

26.516

13

5.5

(;)Ƒ

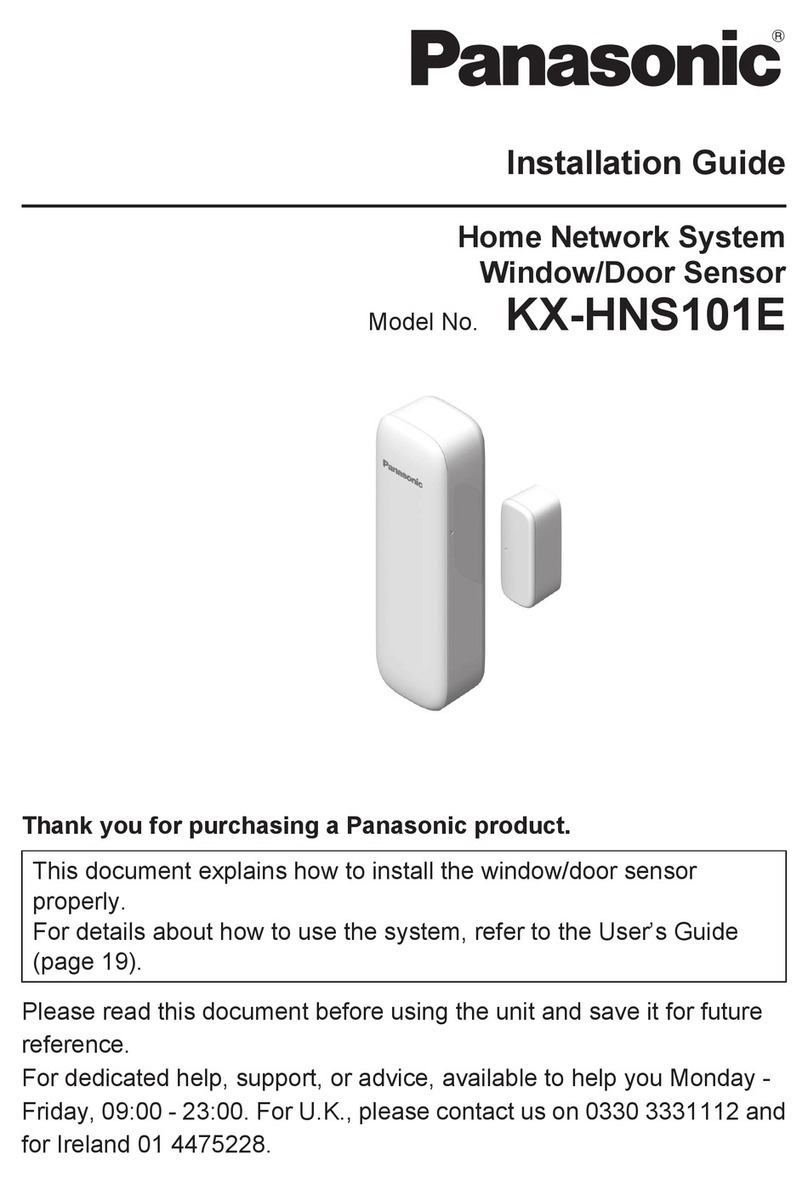

,QFDVHRIXVLQJWKHWZRSRLQW¿xing PVC mounting bracket>

ƔInsert M4 stud-bolts (length 10mm or more) welded

on the user’s facilities into the mounting holes of

the two-point-fixing mounting bracket and screw

with M4 nuts (please arrange separately).

The tightening torque should be 0.49N·m or less.

M4 nuts

M4 stud-bolts

(straight type)

<Mounting dimensions (Unit: mm)>

26.5

34.7

13

9

20.7

How to ¿t the sensor body to the exclusive mounting bracket

<In case of using the PVC mounting bracket for adhesive ¿xing>

ƔUse adhesive to stick fast the mounting bracket

on the mounting surface. Please note that if the

adhesive sticks out from the bottom surface of

the mounting bracket or is 0.5mm, or more thick,

the sensor body cannot be ¿tted to the mounting

bracket.

ƔMatch the notch in the sensor body with the

projection of the exclusive mounting bracket and

slide till a click is felt.

Notch

Projection

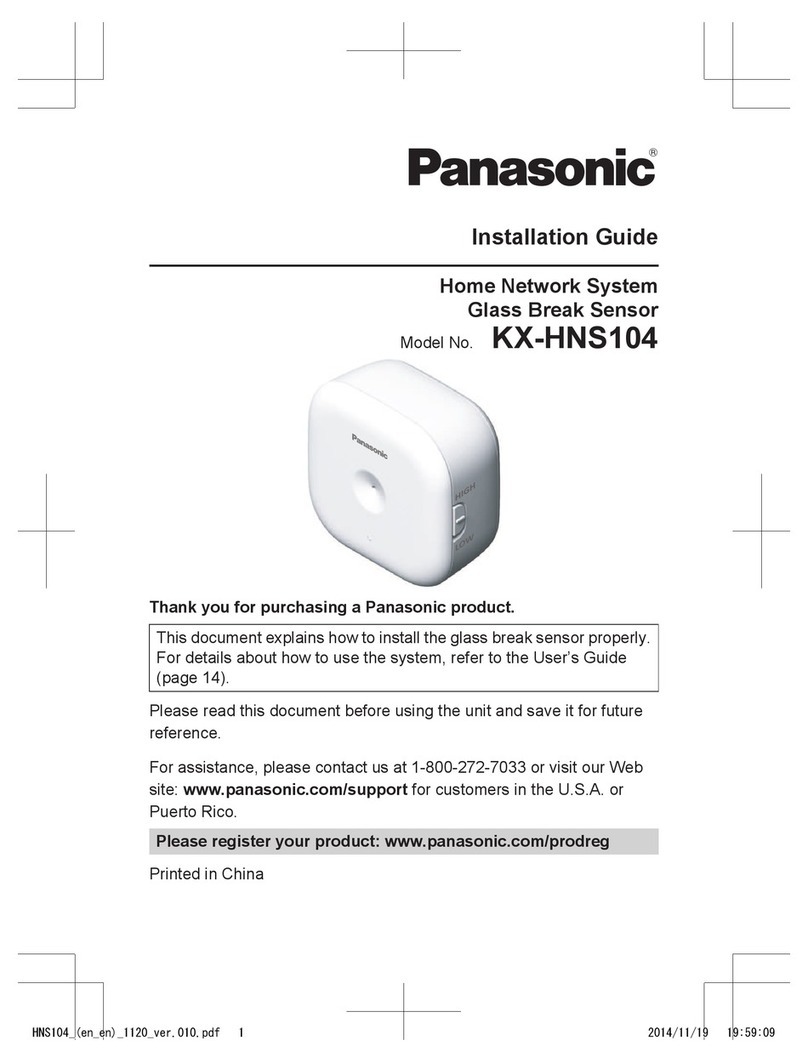

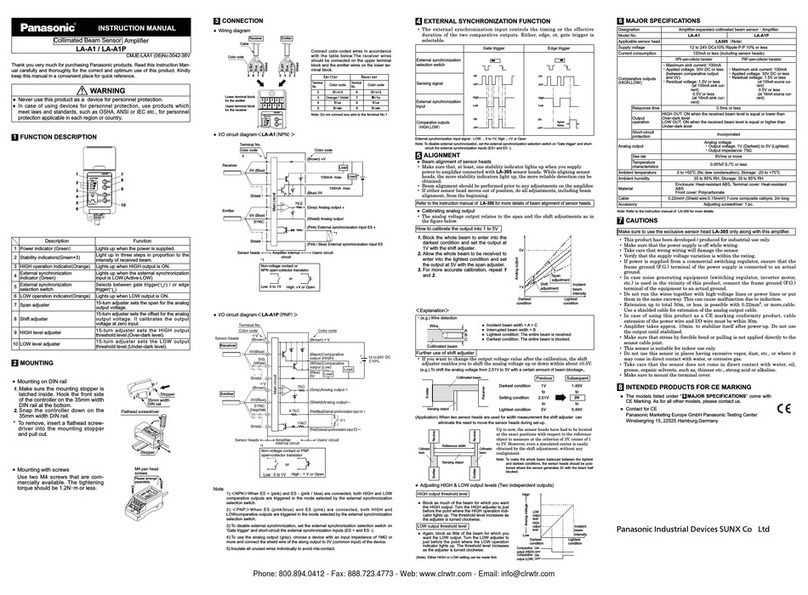

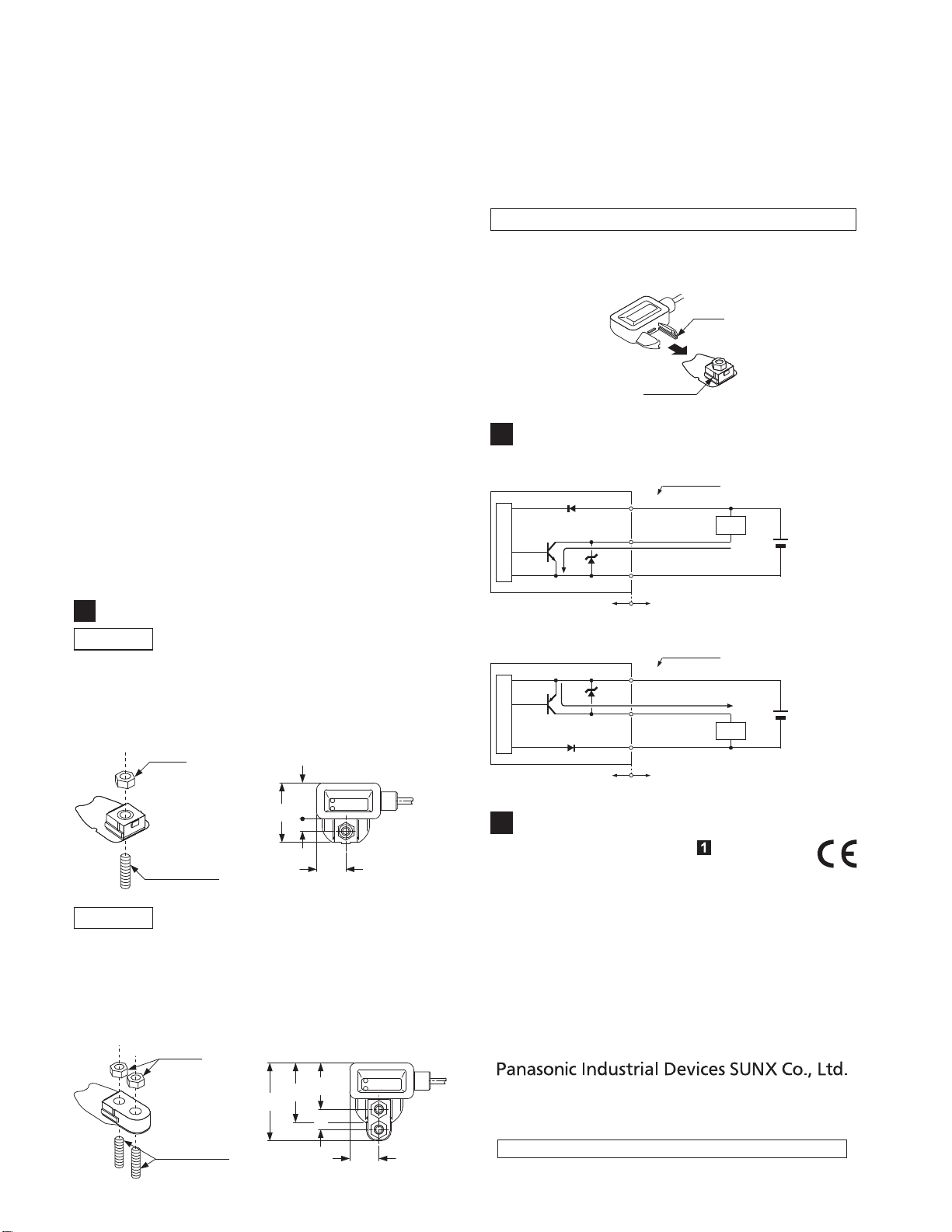

I/O CIRCUIT DIAGRAMS

4

ƔNPN output type

ƔPNP output type

Load

Internal circuit Users’ circuit

(%rown) +V

(%lue) 0V

50mA max.

(%lack) Output

12 to 24V DC

±10%

+

-

Color code

Main circuit

Load

Internal circuit Users’ circuit

(%rown) +V

(%lue) 0V

50mA max.

(%lack) Output

12 to 24V DC

±10%

+

-

Color code

Main circuit

INTENDED PRODUCTS FOR CE MARKING

5ƔThe models listed under “ SPECIFICA-

TIONS” come with CE Marking.

As for all other models, please contact our

of¿ce.

ƔTake care not to use the SUS mounting bracket for

EX-F72Ƒor the PVC mounting bracket for EX-F71Ƒ

mistakenly, since normal detection cannot be performed.

ƔMake sure to use an isolation transformer for the

DC power supply. If an auto-transformer (single

winding transformer) is used, this product or the

power supply may get damaged.

ƔIn case air bubbles are drawn into the sensing part,

take care that it may take some time for sensing to

stabilize, or sensing may even become unstable.

ƔWhen conducting maintenance after operation,

wipe all liquid from the sensor and mounting

bracket with a soft cloth.

ƔIf there is liquid remained or scratch on the sensing

surface or the exclusive mounting bracket, normal

operation cannot be performed.

ƔSince this sensor employs non-modulated infrared

LED, take suf¿cient care against extraneous light.

Do not expose the sensing part directly to the

extraneous light.

ƔAvoid dust, dirt, and steam. Further, do not use this

product in an environment containing organic solvents.

ƔTake care that the product does not come in

contact with oil, grease or organic solvents, such

as, thinner, etc.

ƔIn case this sensor is used where electrostatic

charge is present, use a metal leak pan, which

should be connected to an actual ground.

Thank you very much for purchasing Panasonic products.

Please read this Instruction Manual carefully and thor-

oughly for the correct and optimum use of this product.

Kindly keep this manual in a convenient place for quick reference.

ƔNever use this product as a sensing device for

personnel protection.

ƔI

n case of using sensing devices for personnel protec-

tion, use products which meet laws and standards, such

as OSHA, ANSI or IEC etc., for personnel protection ap-

plicable in each region or country.

INSTRUCTION

MANUAL

Ampli¿er %uilt-in Leak Detection Sensor

EX-F70 Series

MJEC-EXF71 No.0044-45V

http://panasonic.net/id/pidsx/global

Overseas Sales Division (Head Of¿ce)

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

Phone: +81-568-33-7861 FAX: +81-568-33-8591

About our sale network, please visit our website.

© Panasonic Industrial Devices SUNX Co., Ltd. 2014

PRINTED IN JAPAN

ƔContact for CE

Panasonic Marketing Europe GmbH Panasonic Testing Center

Winsbergring 15, 22525 Hamburg,Germany