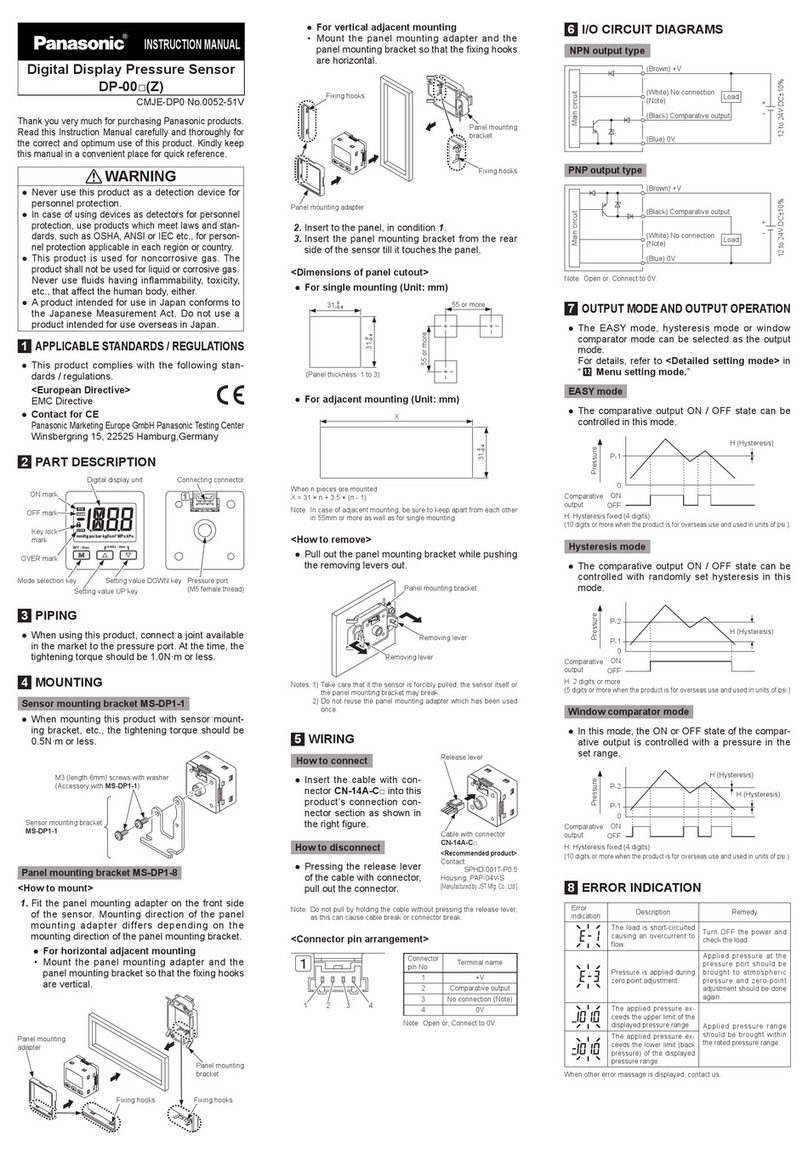

ERROR INDICATION

16

When an error is displayed, remedy as follows.

Error indication Cause Remedy

due to a short-circuit.

Switch off the power supply and

check the load.

The teaching is abnor-

mal.

Check the installation condition of the

fiber, or whether the fiber has come

out, and then do teaching again.

Press MODE key to cancel “ .”

After the cancellation, the sensor oper-

ates at the set value conditions before

the error. However, in case the sensitiv-

ity selection function has been set to the

automatic sensitivity setting “ ,” the

sensor operates at optimum sensitivity.

The communication is

abnormal.

Check if the amplifiers mounted in

cascade are disconnected. After the

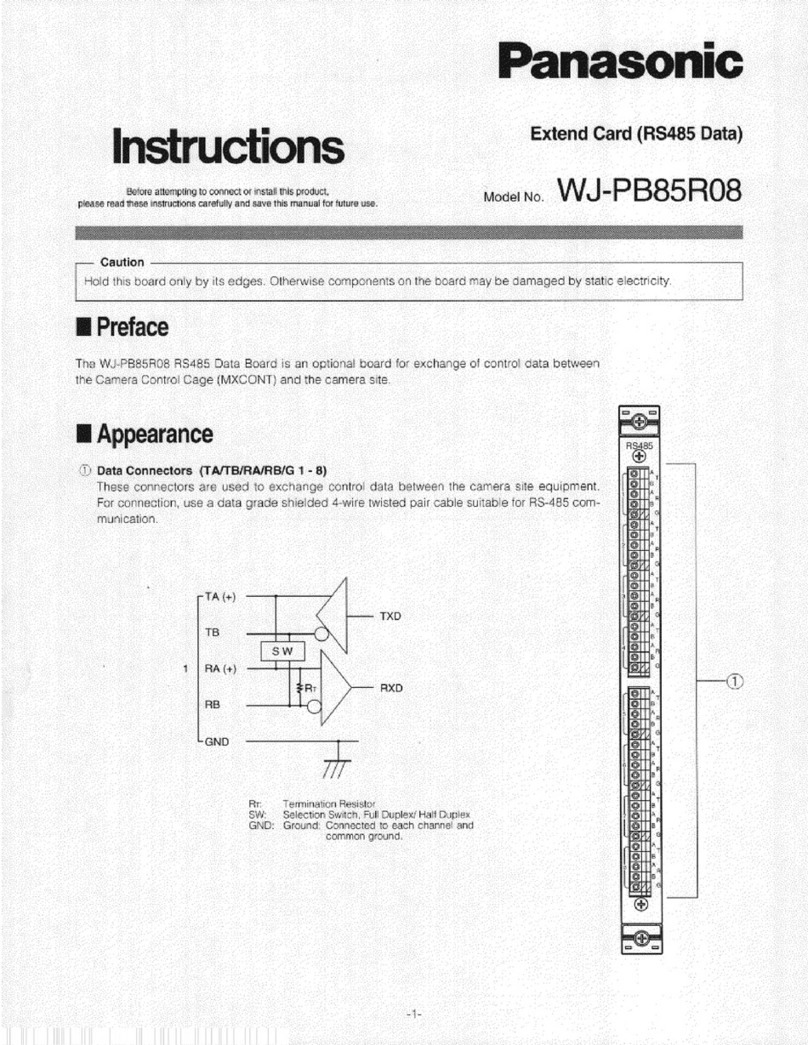

SPECIFICATIONS

18

Type NPN output type PNP output type

Item

Model No.

FX-301-F FX-301P-F

FD-F7 series, FD-F9 series

Supply voltage 12 to 24V DC±10% Ripple P-P 10% or less

Power consumption

Normal operation: 960mW or less

(Current consumption 40mA or less at 24V supply voltage)

Eco-operation: 600mW or less

Output

NPN open-collector transistor

Maximum sink current:

100mA (Note 1)

Applied voltage: 30V DC or less

(between output and 0V)

[at 100mA (Note 1) sink current]

PNP open-collector transistor

Maximum source current:

100mA (Note 1)

Applied voltage: 30V DC or less

(between output and +V)

[at 100mA (Note 1) source current]

Output operation

When Leak is set (F7 mode): OFF when leak is detected.

When Liquid is set (F9 mode): Selectable, either OFF when

no liquid is detected (NC) or

ON when liquid is detected

(NO), with jog switch.

Short-circuit protection

Incorporated

Response time

Sensitivity setting

method Individual teaching / Collective teaching

Fine sensitivity ad-

justment function Incorporated

Ambient temperature

Ambient humidity

Emitting element Red LED (modulated)

Material

Enclosure: Heat-resistant ABS, Transparent cover: Polycarbonate

Weight Approx. 20g

connected together.

2)

If a leak is detected (output: OFF) in

Leak (F7 mode), since the emission

is put in blinking operation, only the

response to return to ON gets de-

layed. (approx. 1 sec.)

Leak removed

Approx.

1

ON

OFF

use the optional quick-connection cables given below.

Main cable (3-core):

CN-73-C1 (cable length 1m), CN-73-C2 (cable length 2m), CN-73-C5

Sub cable (1-core):

CN-71-C1 (cable length 1m), CN-71-C2 (cable length 2m), CN-71-C5

This product has been developed / produced for industrial use only.

Make sure that the power supply is off while wiring and cascading.

Take care that if a voltage exceeding the rated range is applied, or if an AC

power supply is directly connected, the sensor may get burnt or damaged.

Take care that short-circuit of the load or wrong wiring may burn or dam-

age the sensor.

Do not run the wires together with high-voltage lines or power lines or put

them in the same raceway. This can cause malfunction due to induction.

Verify that the supply voltage variation is within the rating.

If power is supplied from a commercial switching regulator, ensure that the frame

ground (F.G.) terminal of the power supply is connected to an actual ground.

In case noise generating equipment (switching regulator, inverter motor,

etc.) is used in the vicinity of this product, connect the frame ground (F.G.)

terminal of the equipment to an actual ground.

-

ply is switched on.

Make sure to use the optional quick-connection cable for the connection of the

2

, or more, cable.

However, in order to reduce noise, make the wiring as short as possible.

Make sure that stress by forcible bend or pulling is not applied to the

sensor cable joint.

Take care that the sensor is not directly exposed to fluorescent lamp

from a rapid-starter lamp, a high frequency lighting device or sunlight

etc., as it may affect the sensing performance.

This product is suitable for indoor use only.

Avoid dust, dirt, and steam.

Take care that the product does not come in contact with oil, grease, or-

ganic solvents, such as thinner, etc., strong acid or alkaline.

and carry out sensitivity teaching periodically.

or explosive gases.

Never disassemble or modify the product.

EEPROM is adopted to this product. It is not possible to conduct teach-

ing 100 thousand times or more, because of the EEPROM's lifetime.

CAUTIONS

17

15

Note: The initial setting at the time of factory shipment is the normal close setting “ .”

Step Digital display Description

1

Confirm if the sensor is in Liquid (F9) mode “ ” in

“INDIVIDUAL TEACHING MODE” or “ COLLEC-

TIVE TEACHING MODE.”

2

Press MODE key to light up MODE indicator / OUT (yellow).

3

Press Jog switch for 3 sec., or more.

(The sensor goes into the NO / NC setting condition.)

MODE indicator / RUN (green) blinks.

4

When Jog switch is turned to “+” side or “–” side, the

digital display (red) and MODE indicator / RUN (green)

blinks, and NO / NC can be chosen.

: Normal close (OFF in liquid absent condition.)

: Normal open (OFF in liquid present condition.)

When Jog switch is pressed, setting display blinks 3

6The sensor returns to Step 2.

7

When MODE key is pressed, the sensor returns to RUN

mode and the incident light intensity is displayed in the

digital display (red).

MODE indicator / RUN (green) lights up.

The setting is complete.

The NO / NC selection can be done by pressing the jog switch for 3

sec., or more, when Liquid (F9) mode “ ” has been set and MODE

indicator / DISP (yellow) lights up. In case of Leak (F7) mode “ ,” the

display does not change to NO / NC selection function.

For the selection method of Leak (F7) mode / Liquid (F9) mode, refer to

“INDIVIDUAL TEACHING MODE” or “ COLLECTIVE TEACHING MODE.”

INTENDED PRODUCTS FOR CE MARKING

19

٨

٨

The models listed under “ SPECIFICATIONS” come with CE

Marking.

As for all other models, please contact our office.

E

<Until June 30 ,2013>

Panasonic Electric Works Europe AG

Rudolf-Diesel-Ring 2, D-83607 Holzkirchen, Germany

<From July 1 ,2013>

Panasonic Marketing Europe GmbH Panasonic Testing Center

18

http://panasonic.net/id/pidsx/global

PRINTED IN JAPAN © Panasonic Industrial Devices SUNX Co., Ltd. 2012

2431-1 Ushiyama-cho, Kasugai-shi, Aichi, 486-0901, Japan

About our sale network, please visit our website.