SPECIFICATIONS

1

Notes: 1)

2)

3)

4)

5)

Set model Nos. having the suffix 'I' are different frequency type.

These values are for a range which is 20 to 60% of the maximum sensing distance.

The length of the sensor head cable cannot be changed.

The given weight of the threaded type sensor head is the value including the nuts and the

toothed lock washer.

Take care that the output voltage is reduced due to the resistance of the wiring cable.

Temperature

characteristics

(Note 2)

24V DCr10% Ripple P-P 10% or less

Supply voltage

NPN open-collector transistor

Maximum sink current: 100mA

Applied voltage: 30V DC or less (between alarm output and 0V)

Residual voltage: 1.6V or less (at 100mA sink current)

0.4V or less (at 16mA sink current)

Alarm output

Input condition: Non-voltage contact or NPN open-collector transistor input

Signal condition: Low ... 0 to 1V (duration 30ms or more)

High ... 5 to 30V, or open

Operation: Low ... External zero-adjustment setting

High ... External zero-adjustment ineffective

External zero-adjustment

input

150mA or less

Current consumption

1.6kHz (-3dB)

Response frequency

0.04% F.S.

Resolution

Turns ON when the sensor head connection is improper or the sensor

head cable is disconnected

Output operation

㧙

㧙

Short-circuit protection

Within r0.5% F.S.

Linearity

Analog voltage

Output voltage: 0 to 5V

Output impedance: 100ǡapprox.

Analog current

Output current: 4 to 20mA

Load resistance: 0 to 350ǡ

GP-A14F(I)GP-A5S(I)

GP-A12ML(I)

GP-A8S(I)GP-A10M(I)

Front sensing

type sensor head

Non-threaded

type sensor head

Threaded type

sensor head

Non-threaded

type sensor head

Threaded type

sensor head

Set model No. (Note 1)

For 3mm sensingFor 1mm sensing For 5mm sensing

For 2mm sensing

0 to 3mm0 to 1mm 0 to 5mm0 to 2mm

Type

Item

170g approx.

Accessories

35 to 85% RH, Storage: 35 to 85% RHAmbient humidity

Sensor head

Amplifier

Amplifier

Power indicator

Yellow LED (lights up when alarm output is ON)Alarm indicator

ԘShift adjustment (by push-buttons)

ԙSpan adjustment (by 14-turn adjuster)

Adjustment functions

Orange LED (lights up when sensing range is exceeded)Over indicator

Green LED (lights up when the power is ON)

Zero-adjustment setting

method Push button setting / External input setting

Sensing range

Iron sheet

1515t1mm

Iron sheet

88t1mm

Iron sheet

3030t1mm

Iron sheet 1212t1mm

1.2Ǵm/0.4Ǵm/2.0Ǵm/0.8Ǵm/

50g approx.40g approx. 45g approx.

(Note 5)

50g approx.

(Note 5)

2 pcs. each of

M3 countersunk

head screws,

spring washers,

plain washers

and M3 nuts

Adjusting screw-

driver: 1 pc.

Adjusting screwdriver: 1 pc.

Nut: 2 pcs.

Toothed lock washer: 1 pc.

Adjusting screwdriver: 1 pc.

Protection

Sensor head

IP67 (IEC), IP67g (JEM)

Cable (Note 3)

Sensor head

Connector attached high frequency coaxial cable, 3m long

Cable length

(Note 4) Amplifier Up to total 100m with 0.3mm2, or more, cable

0 to +50(No dew condensation), Storage: 0 to +50

Amplifier

Ambient

temperature

Sensor head

Amplifier

Weight

Sensor head

-10 to +55, Storage: -20 to +70

Sensor head

Material

Amplifier Enclosure: ABS

0.5Ǵm/

Standard sensing object

Analog output

Analog voltage output

Analog current output

0.6Ǵm/

1Ǵm/for GP-A8SI and

GP-A10MI

1.5Ǵm/

2.5Ǵm/for

GP-A12MLI

0.9Ǵm/

1.5Ǵm/for

GP-A14FI

Enclosure: Stainless steel

(SUS303)

Sensing part: ABS

Enclosure:

Brass

(Nickel plated)

Sensing part:

Nylon

Enclosure:

Stainless steel

(SUS303)

Sensing part:

ABS

Enclosure:

Stainless steel

(SUS303)

Sensing part:

Polyalylate

Note: Do not apply excess torque.

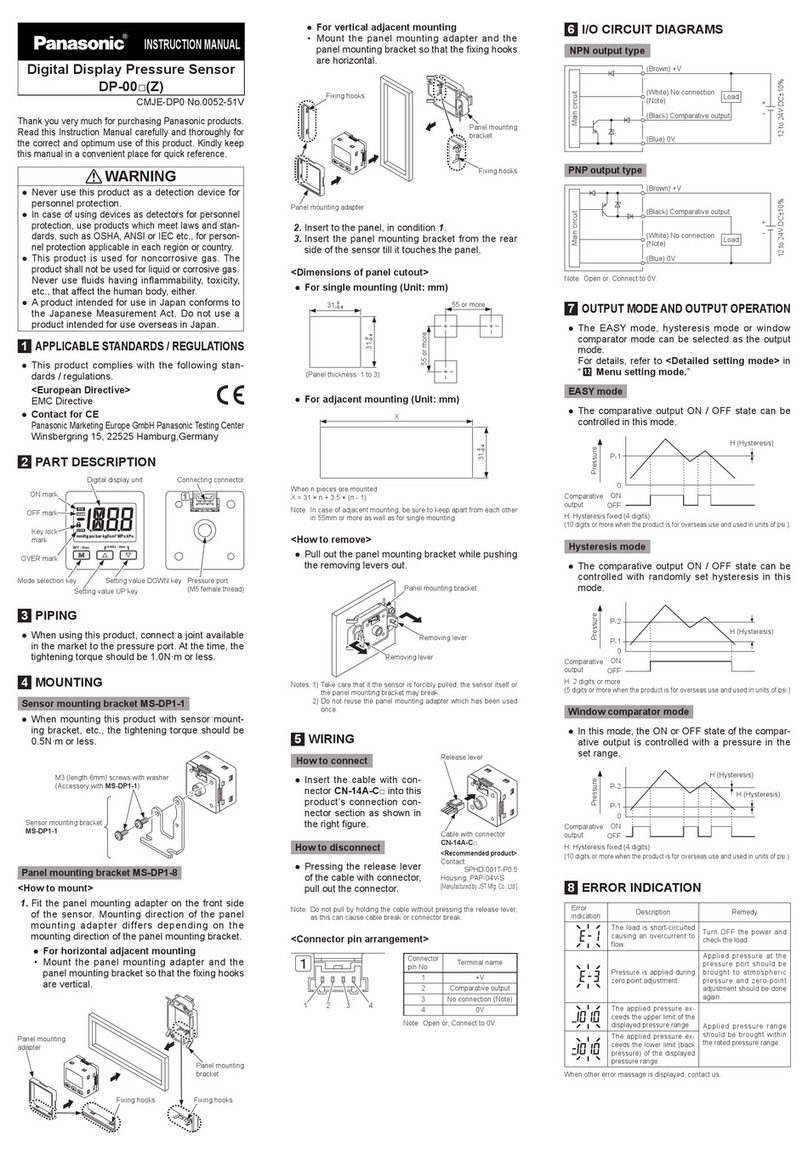

MOUNTING

3

٨

Mounting sensor head

The tightening torque should be under the values given below.

Make sure to use an M3, or smaller, set screw having a cup-point.

Mounting with set screw [GP-A5S(I), GP-A8S(I) only]

Mount such that the nuts do not protrude from the threaded portion.

Mounting with nut [GP-A10M(I), GP-A12ML(I) only]

GP-A10M(I)

Mounting GP-A14F(I)

GP-A12ML(I)

Make sure that the sensor head and the amplifier which have the same

production serial number (7 digit) are used in combination.

The length of the sensor head cable cannot be changed.

٨

٨

Set screw (M3 or less)

(Cup-point)

A

Model No. Set screw posi-

tion A (mm)

Tightening

torque

GP-A5S(I)0.44N㨯m

5 or more

GP-A8S(I)0.58N㨯m

Model No. B part (mm) Tightening

torque

GP-A10M(I)9.8N㨯m7 or more

14 or more

GP-A12ML(I)20N㨯m

B

Attached toothed

lock washer

Mounting plate

Attached toothed

lock washer

Mounting plate

B

<Threaded type>

M3 counter sunk

head screw

2-M3 tapped holes

or thru-holes

Plain washer

Spring washer

M3 nut

8mm

٨

Distance from surrounding metal

As metal around the sensor may affect the sensing performance, pay

attention to the following points.

Since the analog output may change if the sensor is completely embed-

ded in metal, keep the minimum distance specified in the table below.

Non-threaded type sensor head, threaded type sensor head

GP-A14F(I) can be used by being completely

embedded in metal. However, the surrounding metal

should not protrude beyond the sensing face.

Front sensing type sensor head

Model No. C (mm) D (mm)

GP-A5S(I)4

Ǿ18

GP-A8S(I)

GP-A10M(I)7

Ǿ50

GP-A12ML(I)14

<Embedding of the sensor in metal>

D

C

Metal

Metal

Non-threaded type sensor head, threaded type sensor head

Front sensing type sensor head

٨

Mutual interference

If several sensor heads are mounted together, since the specifications

may not be met, keep the minimum separation distance given below.

Notes: 1)

2)

'I' type is different frequency type.

If the required resolution is lower than the specification

(0.04% F.S.), it is possible to bring the sensor heads

nearer than the separation distance given in the table

above. For further details, please contact our office.

Model No.

E (mm) F (mm)

GP-A5S(I)

Condition

Between 'I' type and non-'I' type

Between two 'I' types

or two non-'I' types

Between two 'I' types

or two non-'I' types

Between two 'I' types

or two non-'I' types

Between 'I' type and non-'I' type

Between 'I' type and non-'I' type

GP-A12ML(I)

1118

3650

1122

3860

1424

130210

GP-A8S(I)

GP-A10M(I)

Model No.

G (mm) H (mm)

GP-A14F(I)

Condition

Between 'I' type and non-'I' type

Between two 'I' types

or two non-'I' types

014

3068

<Parallel mounting>

F

<Face to face mounting>

E

<Parallel mounting>

H㧴

<Face to face mounting>

G

Sensing face

Mounting on DIN rail

٨Mounting amplifier

Ԙ

ԙ

*

With the stopper pressed in the direction of the

arrow (it locks), fit the front portion of the

amplifier mounting section on the 35mm width

DIN rail.

Lightly press the grooved section of the

stopper downwards when pressing the

stopper in.

Press and fit the rear portion of the amplifier

mounting section on the 35mm width DIN rail.

To remove, insert a flathead screwdriver into

the stopper and pull out. Stopper

Flathead

screwdriver

GP-A8S

ANALOGPROXIMITYSENSOR

MADEINJAPAN

1234

POWER ALARM

OVER

35mm width DIN rail

Stopper

Ԙ

ԙ

Mounting with screws

Nut

(Please arrange separately.)

M4 (length 10mm or more)

pan head screw

(Please arrange separately.)

GP-A8S

ANALOGPROXIMITYSENSOR

MADEINJAPAN

1234

POWERALARM

OVER

Use two commercially available M4 (length

10mm or more) pan head screws.

The tightening torque should be 1.2N㨯m or less.

Please arrange the pan head screws and

nuts separately. The mounting holes for the

screws can be accessed by removing the

terminal cover. To remove the terminal cover,

insert a flathead screwdriver into the groove

of the terminal cover and lift up.

Notes: 1)

2)

If two, or more, amplifiers are mounted together, make sure to leave a gap of at least 10mm

between them.

If the amplifier is installed in a control box, etc., ensure proper ventilation.

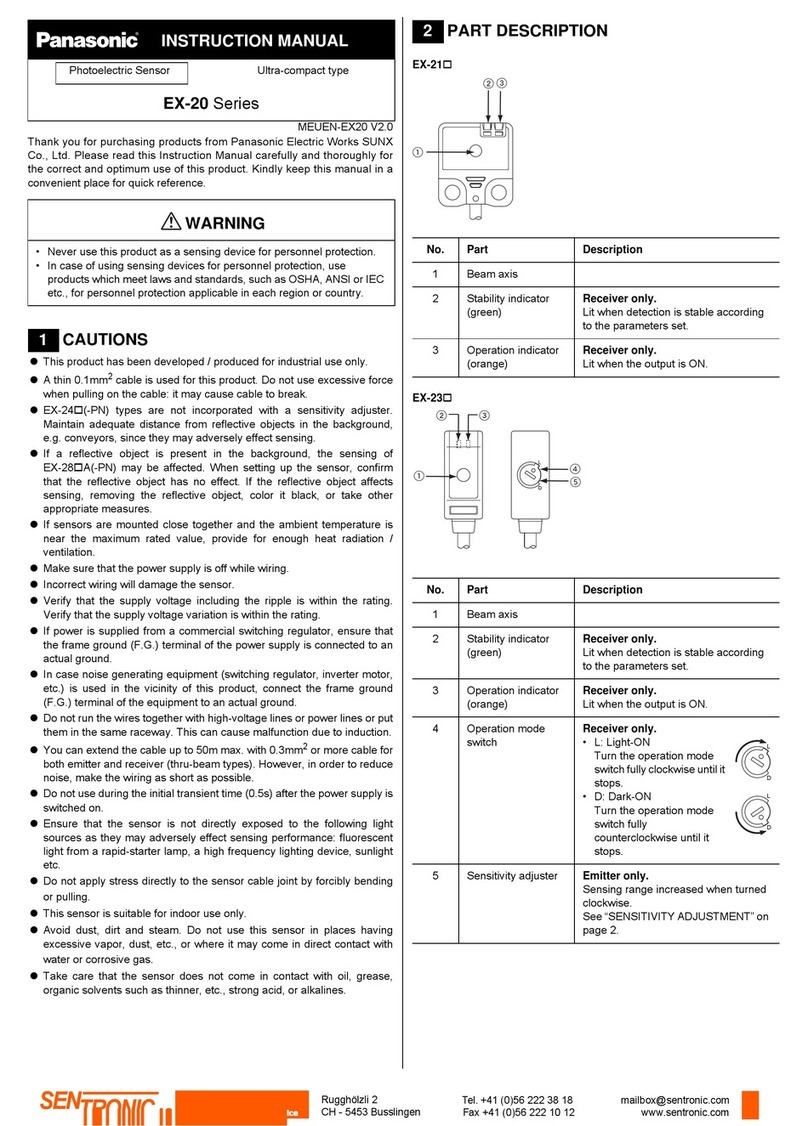

Thank you very much for using our products. Please read this Instruction

Manual carefully and thoroughly for the correct and optimum use of this

product. Kindly keep this manual in a convenient place for quick reference.

٨

٨

Never use this product as a sensing device for personnel protection.

In case of using sensing devices for personnel protection, use

products which meet laws and standards, such as OSHA, ANSI

or IEC etc., for personnel protection applicable in each region

or country.

WARNING

CAUTIONS

2

Make sure that the sensor head and the amplifier which have the same

production serial number (7 digit) are used in combination. Since adjust-

ment is done before shipment, if items with different production serial

numbers are combined, the sensing characteristics will deteriorate even if

they have the same model Nos.

<Sensor head> <Amplifier>

(Example)

Serial number: 4A6N 055

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

٨

Make sure that the power supply is off while wiring.

Take care that wrong wiring will damage the sensor.

Verify that the supply voltage variation is within the rating.

If power is supplied from a commercial switching regulator, ensure that

the frame ground (F.G.) terminal of the power supply is connected to an

actual ground.

In case noise generating equipment (switching regulator, inverter motor,

etc.) is used in the vicinity of this product, connect the frame ground

(F.G.) terminal of the equipment to an actual ground.

Do not run the wires together with high-voltage lines or power lines or put

them in the same raceway. This can cause malfunction due to induction.

Do not use during the initial transient time (0.5 sec.) after the power

supply is switched on.

The length of the sensor head cable cannot be changed.

Make sure that stress by forcible bend or pulling is not applied directly to

the sensor cable joint.

The alarm output is not incorporated with a short-circuit protection

circuit. Do not connect it directly to a power supply or a capacitive load.

Do not use the sensor at places having intense vibrations, as this can

cause malfunction.

Take care that the product does not come in direct contact with water, oil,

grease, organic solvents, such as, thinner etc., strong acid or alkaline.

Make sure that the sensing end is not covered with metal dust, scrap or

spatter. It will result in malfunction.

For stable sensing, carry out the adjustments 30 min., or more, after the

power supply is switched on.

٨

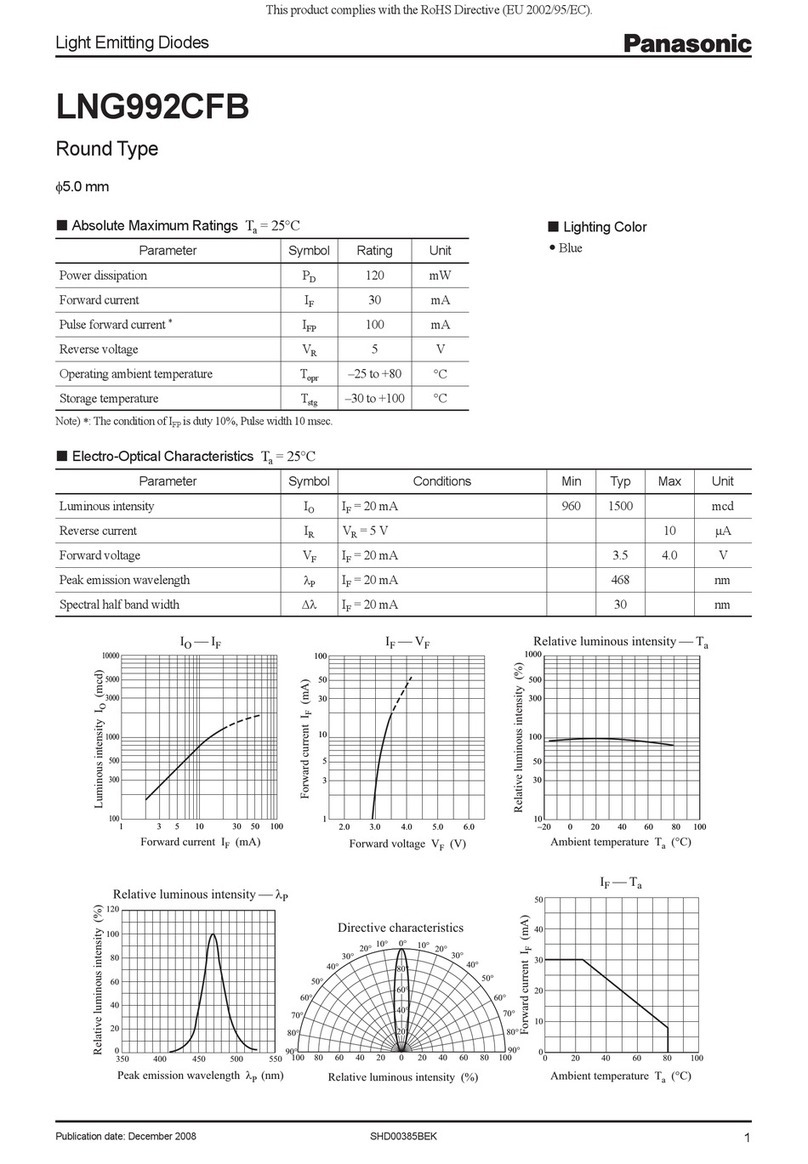

Dependence of output characteristics on material (typical)

Take care that, depending upon the material of the sensing object, the

output differs as shown in the figures below.

GP-A5S(I) GP-A8S(I), GP-A10M(I)

GP-A12ML(I) GP-A14F(I)

0.2 0.4 0.6 0.8 1

0

2

4

6

520

4

8

Setting distance (mm)

Aluminum

Brass

Iron

Stainless steel

(SUS304)

Stainless steel

(SUS410)

Output voltage (V)

Output current (mA)

Setting distance (mm)

0.5 1 1.5 2

0

2

4

6

520

4

8

Output voltage (V)

Output current (mA)

Aluminum

Brass

Iron

Stainless steel

(SUS304) Stainless steel

(SUS410)

Setting distance (mm)

0

2

5

4

6

8

4

20

12345

Output voltage (V)

Output current (mA)

Aluminum

Brass

Iron

Stainless steel

(SUS304)

Stainless steel

(SUS410)

Setting distance (mm)

0

2

5

4

6

8

4

20

1234

Output voltage (V)

Output current (mA)

Aluminum Brass

Iron

Stainless steel

(SUS304)

Stainless steel

(SUS410)

CONNECTION

4

٨I/O circuit diagram

Symbols ... D1

D2

ZD

Tr

: Input protection diode

: Reverse supply polarity protection diode

: Surge absorption zener diode

: NPN output transistor

Note: In case of using the analog voltage output, connect a device having a high input impedance.

Also, take care that the output voltage is reduced due to the resistance of the wiring cable.

Non-voltage contact or NPN open-collector transistor

Low (0 to 1V) (duration 30ms or more): External zero-adjustment setting

High (5 to 30V, or open): External zero-adjustment ineffective

or

Terminal No.

Ԝ

ԝ

*1

٨

Connection of sensor head and amplifier

Hold the sensor head's connector by the outer ring and insert it into the

connector provided on the amplifier for sensor head connection. Insert

till you hear a click sound.

Insert till the connector

outer ring makes contact.

* To remove the sensor head, hold its connector by the outer ring and pull

it straight out.

Do not pull by holding the cable, as this can result in cable

disconnection.

Insert

Connector for

sensor head

GP-A8S

ANALOG PROXIMITY SENSOR

MADEIN JAPAN

1234

Amplifier

Connector

outer ring

0V

+V

D1

D2

Tr ZD

100ǡ

47ǡ47ǡԘ

ԙ

Ԛ

ԛ

Ԝ

ԝ

Ԟ

ԟ

Analog voltage output

(0 to 5V) (Note)

Analog current output

(4 to 20mA)

0V (Analog output)

Alarm output

*1

External

zero-adjustment

input

Analog output

+

-

24V DCr10%

100mA max.

Terminal No.

Amplifier

Uses' circuitInternal circuitSensor head

Connector for sensor head connection

Main circuit

Load

٨Dimensions of suitable crimp terminal

Note: Please use crimp terminals which have insulation sleeves.

Recommended crimp terminal: Type 1.25 - 3.0

(Unit: mm)

(When crimped) (When crimped)

10

or less

19 or less

6

or less

6

or less

Ǿ3.2

or more 10

or less

19 or less

6

or less

6

or less

3.2

or more

Round type Y-shaped type

GP-A Series

High Accuracy Eddy Current Type Displacement Sensor

Magnetic Displacement Sensor

INSTRUCTION MANUAL

CME-GPA(01) No.0031-88V