CONTENTS

PART I Page

1. INTRODUCTION ...................................................................................................................................................................... 1

2. MODELS AND MODEL NUMBERS ...................................................................................................................................... 1

2.1 5.25inch FDD Series................................................................................................................ 1

3. SPECIAL TOOLS ...................................................................................................................................................................... 1

4. OUTLINE OF M AINTE NAN CE................................................................................................................................................ 2

4.1 Alignment Diskette ................................................................................................................................. 2

4.2 Exerciser .................................................................................................................................................... 2

5. DIAGNOSTIC PROCEDURES .................................................................................................................................................. 2

5.1 Error Symptom Recognition .................................................................................................................... 2

5.2 Soft Error Detection and Correction ....................................................................................................... 2

5.3 Write Error ................................................................................................................................................. 2

5.4 Read Error .................................................................................................................................................. 3

5.5 Seek Error .................................................................................................................................................. 3

5.6 Interchangeability Error .......................................................................................................................... 3

6. TROUBLE ANALYSIS .............................................................................................................................................................. 3

6.1 Trouble Analysis Procedure .................................................................................................................... 3

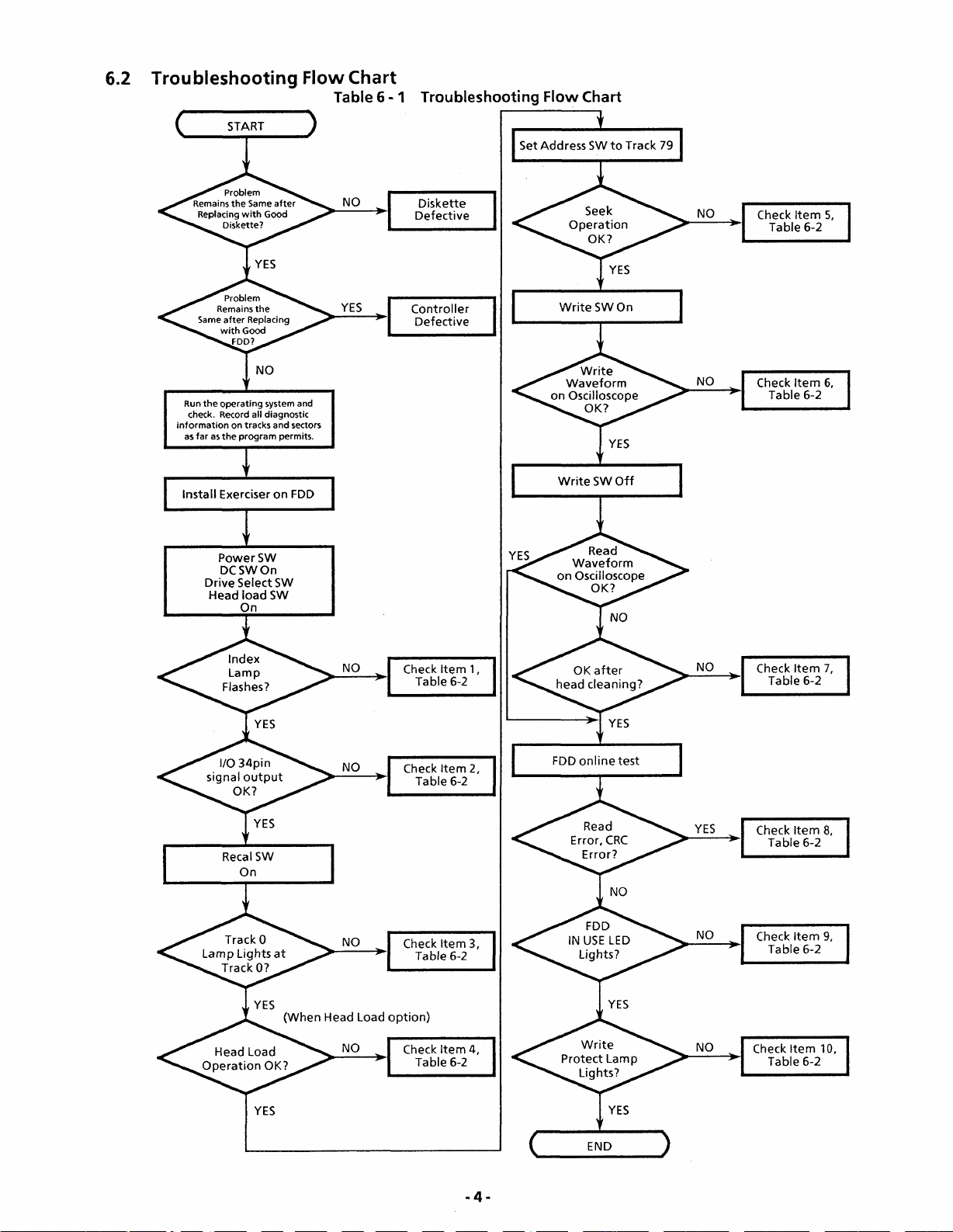

6.2 Troubleshooting Flowchart .................................................................................................................... 4

6.3 Trouble Analysis Table .............................................................................................................................. 5

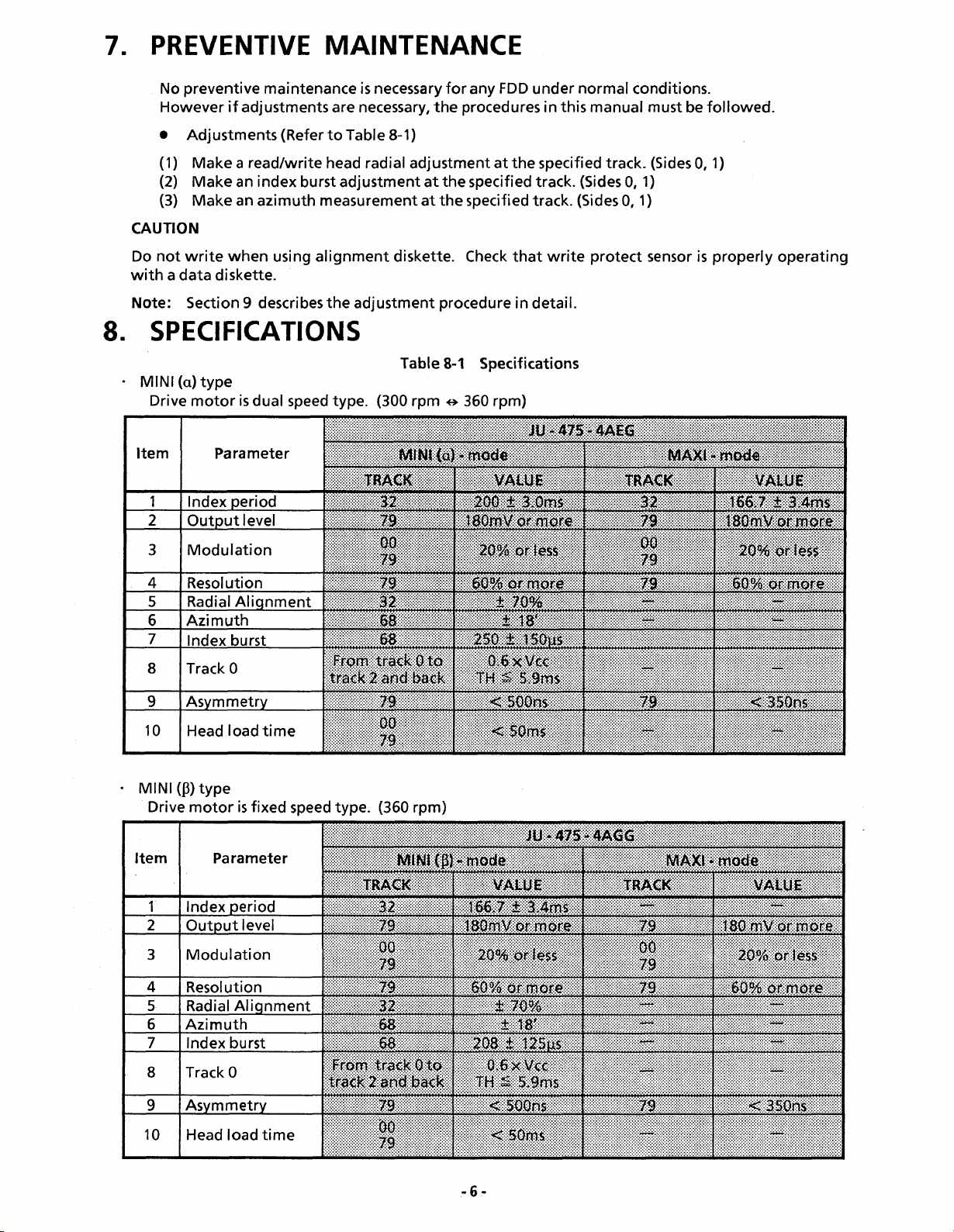

7. PREVENTIVE MAINTENANCE .............................................................................................................................................. 6

8. SPECIFICATIONS .................................................................................................................................................................... 6

9. ADJUSTMENTS AND VERIFICATIONS ................................................................................................................................ 7

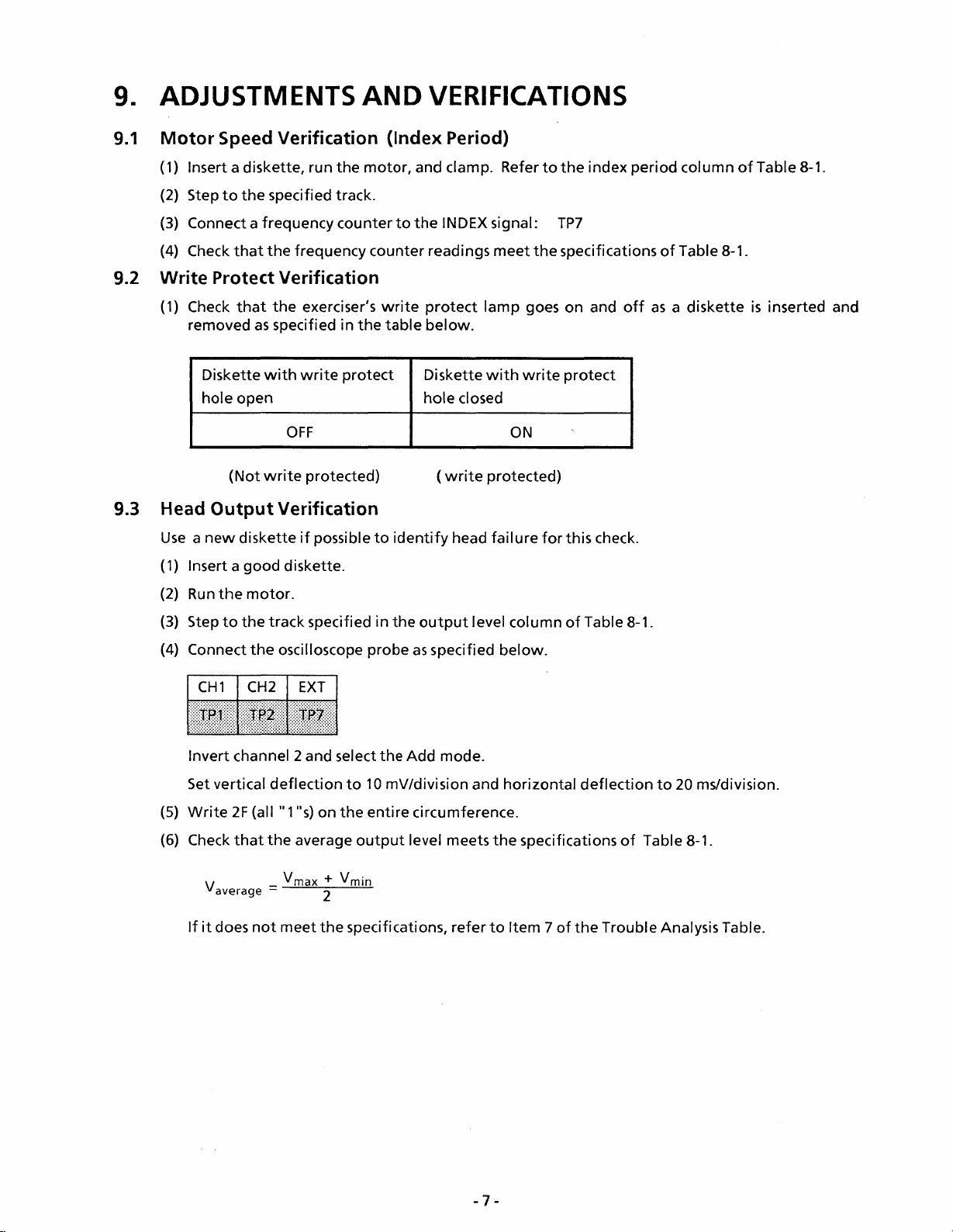

9.1 Motor Speed Verification (Index Period) ................................................................................................ 7

9.2 Write Protect Verification ........................................................................................................................ 7

9.3 Head Output Verification ........................................................................................................................ 7

9.4 Output Modulation Verification ............................................................................................................. 8

9.5 Resolution Verification

........................................................................

8

9.6 Radial Alignment Verification and Adjustment

....................................................................................

8

9.7 Azimuth Verification ............................................................................................................................... 9

9.8 Index Burst Verification and Adjustment .............................................................................................. 10

9.9 Track 0 Sensor Adjustment ...................................................................................................................... 10

9.10 Asymmetry Verification ............................................................................................................................ 11

10. TEST P O IN TS ............................................................................................................................................................................ 12

11. PANASONIC ALIGNMENT DISKETTE .................................................................................................................................. 13

PART II

12. REMOVALS AND INSTALLATIONS ...................................................................................................................................... 14

12.1 PCB Removal and Installation ................................................................................................................... 14

12.2 Front Plate and Handle Removal and Installation ................................................................................. 14

12.3 Track 0 Sensor Removal and Installation ................................................................................................ 15

12.4 Collet Assembly Removal, Installation, and Adjustment

.....................................................................

15

12.5 Clamp Assembly Removal and Installation ............................................................................................ 16

12.6 Write Protect Sensor Assembly and Index Sensor Assembly Removal and Installation

.....................

16

12.7 Cartridge Guide Assembly Removal and Installation ........................................................................... 17

12.8 Stepper Motor Assembly Removal and Installation ............................................................................. 18

12.9 Head Carriage Assembly Removal and Installation ............................................................................. 18 — 19

12.10 Drive Motor Removal and Installation ........................................................................... 20

12.11 LED Assembly Removal and Installation ................................................................................................ 21

12.12 Lifter Unit Removal and Installation ....................................................................................................... 21

12.13 Media Lifter Removal and Installation .................................................................................................... 22

12.14 Media Sensor Assembly Removal and Installation ................................................................................. 22

13. EXPLODED VIEW .................................................................................................................................................................... 23

14. REPLACEMENT PARTS LIST .................................................................................................................................................. 24

15. REPLACEMENT PARTS LIST FOR PCB .................................................................................................................................. 2 5 - 2 6

16. SCHEMATIC DIAGRAM ........................................................................................................................................................ 27

17. CIRCUIT BOARD ...................................................................................................................................................................... 2 8 -2 9

18. BLOCK DIAGRAM .................................................................................................................................................................. 30

- i -