1014

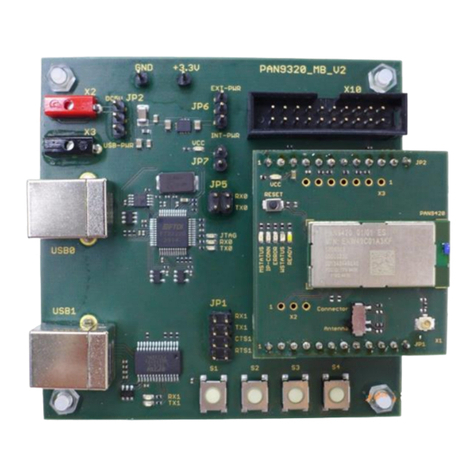

NN30320A-EVB

User’s Guide

for Evaluation Board

Revised

Total Pages Page

Automotive & Industrial Systems Company, Panasonic Corporation

Regulations

No. 320R202E

2013-05-07

Note: The parameters above is subject to change for improvement without notice.

Reference Designator QTY Value Description Size *3 Manufacturer Part Number

C-AVIN1 1 10uF Capacitor, Ceramic, 50V, X7R, 20% 1210 TAIYO YUDEN UMK325AB7106MM-T

C-AVIN2 1 10uF Capacitor, Ceramic, 50V, X7R, 20% 1210 TAIYO YUDEN UMK325AB7106MM-T

C-AVIN3 1 0.1uF Capacitor, Ceramic, 100V, X7R, 10% 0603 Murata GRM188R72A104KA35L

C-BST 1 0.1uF Capacitor, Ceramic, 100V, X7R, 10% 0603 Murata GRM188R72A104KA35L

C-DCDCOUT1 1 22uF Capacitor, Ceramic, 25V, X7R, 10% 1210 Murata GRM32ER71E226KE15L

C-DCDCOUT2 1 22uF Capacitor, Ceramic, 25V, X7R, 10% 1210 Murata GRM32ER71E226KE15L

C-DCDCOUT3 - - - - - -

C-PVIN1 1 10uF Capacitor, Ceramic, 50V, X7R, 20% 1210 TAIYO YUDEN UMK325AB7106MM-T

C-PVIN2 1 10uF Capacitor, Ceramic, 50V, X7R, 20% 1210 TAIYO YUDEN UMK325AB7106MM-T

C-PVIN3 1 0.1uF Capacitor, Ceramic, 100V, X7R, 10% 0603 Murata GRM188R72A104KA35L

C-SS 1 10nF Capacitor, Ceramic, 100V, X7R, 10% 0603 Murata GRM188R72A103KA01L

C-VREG 1 1.0uF Capacitor, Ceramic, 25V, X7R, 10% 0603 Murata GRM188R71E105KA12L

L-LX 1 1.0uH Inductor, 8.1A, 6.9mΩ 0.276×

0.260 inch Panasonic ETQP3W1R0WFN

R-AVIN 1 0 Resistor, Chip, 0.1W 0603 Panasonic ERJ3GEY0R00V

R-FB1 *2 1 3.3k Resistor, Chip, 0.1W, 1% 0603 Panasonic ERJ3EKF3301V

R-FB2 *2 1 1.2k Resistor, Chip, 0.1W, 1% 0603 Panasonic ERJ3EKF1201V

R-RB3 *2 1 1.0k Resistor, Chip, 0.1W, 1% 0603 Panasonic ERJ3EKF1001V

R-FB4 *2 1 0 Resistor, Chip, 0.1W 0603 Panasonic ERJ3GEY0R00V

R-VFB 1 0 Resistor, Chip, 0.1W 0603 Panasonic ERJ3GEY0R00V

R-FB5 1 0 Resistor, Chip, 0.1W 0603 Panasonic ERJ3GEY0R00V

R-PG 1 100k Resistor, Chip, 0.1W, 1% 0603 Panasonic ERJ3EKF1003V

C99 - - - - - -

5 Bill of Materials

*2 : These resistors determineoutput voltage.

The setting in the above table sets the output voltage for 3.3V.

To change the output voltage, it is necessary to change these resistors following Equation (1) in the section 4.2.

*3 : These values comply with EIA standards.

Table 9 presents the bill of materialsfor the Evaluation Board.

Table 9. Evaluation Board Bill of Materials