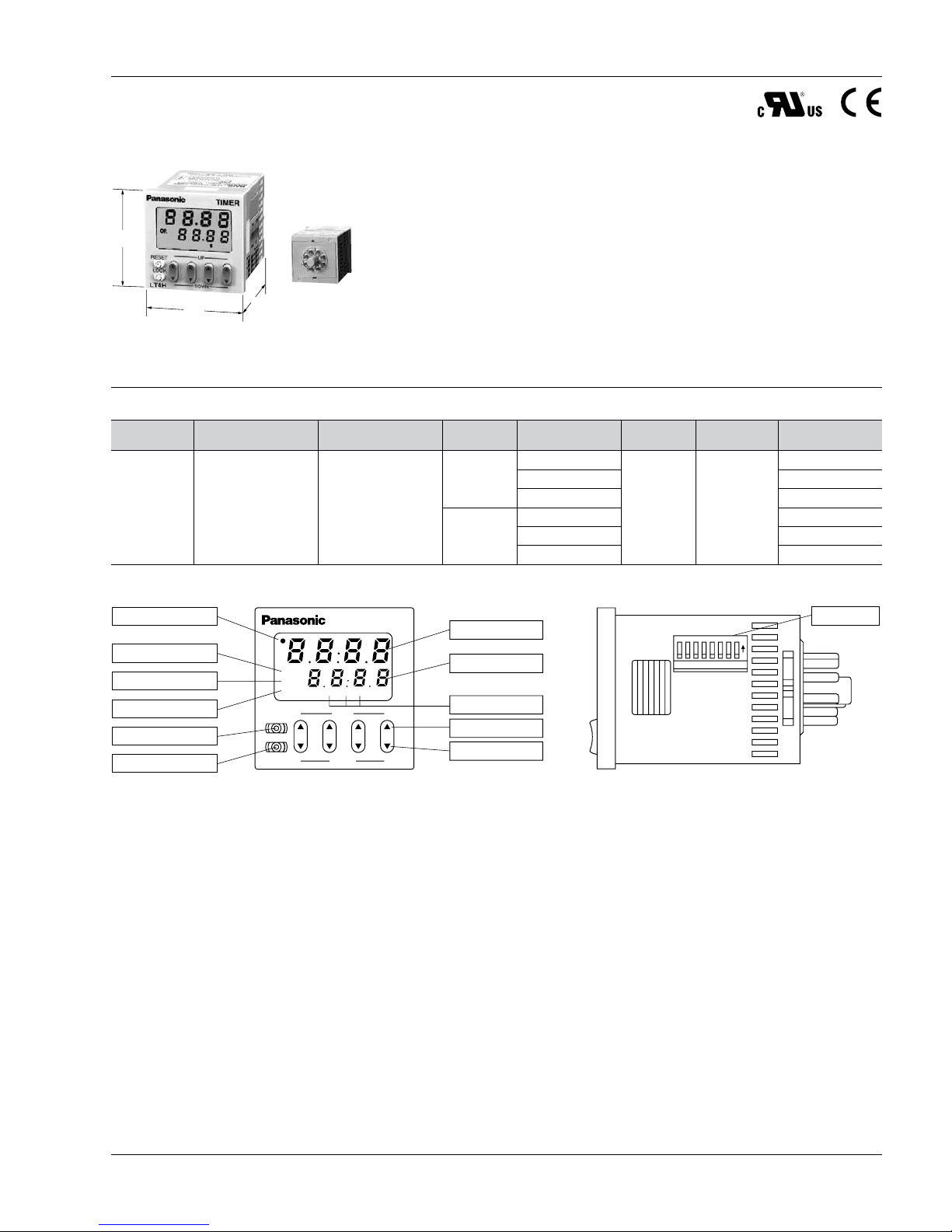

Type

Item

Ralay output type

AC type AC/DC type

100 to 240 V AC, 24 V AC,

24 V AC/DC

50/60 Hz common

Max. 10 V A

5 A, 250 V AC (resistive load)

9.999 s, 99.99 s, 999.9 s, 9999 s, 99 min 59 s, 999.9 min, 99 h 59 min, 999.9 h (selected by DIP switch)

Addition (UP)/Subtraction (DOWN)

(2 directions selectable by DIP switch)

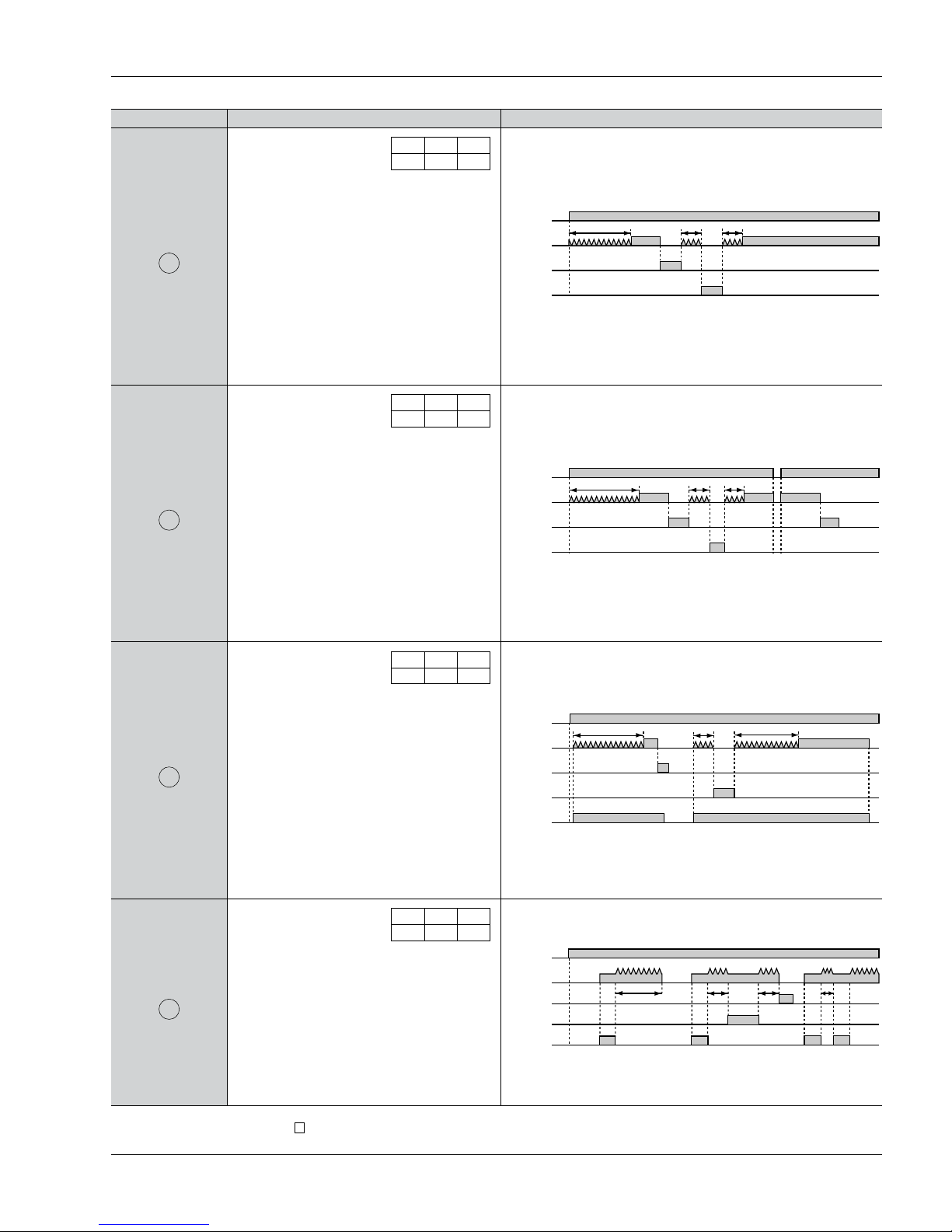

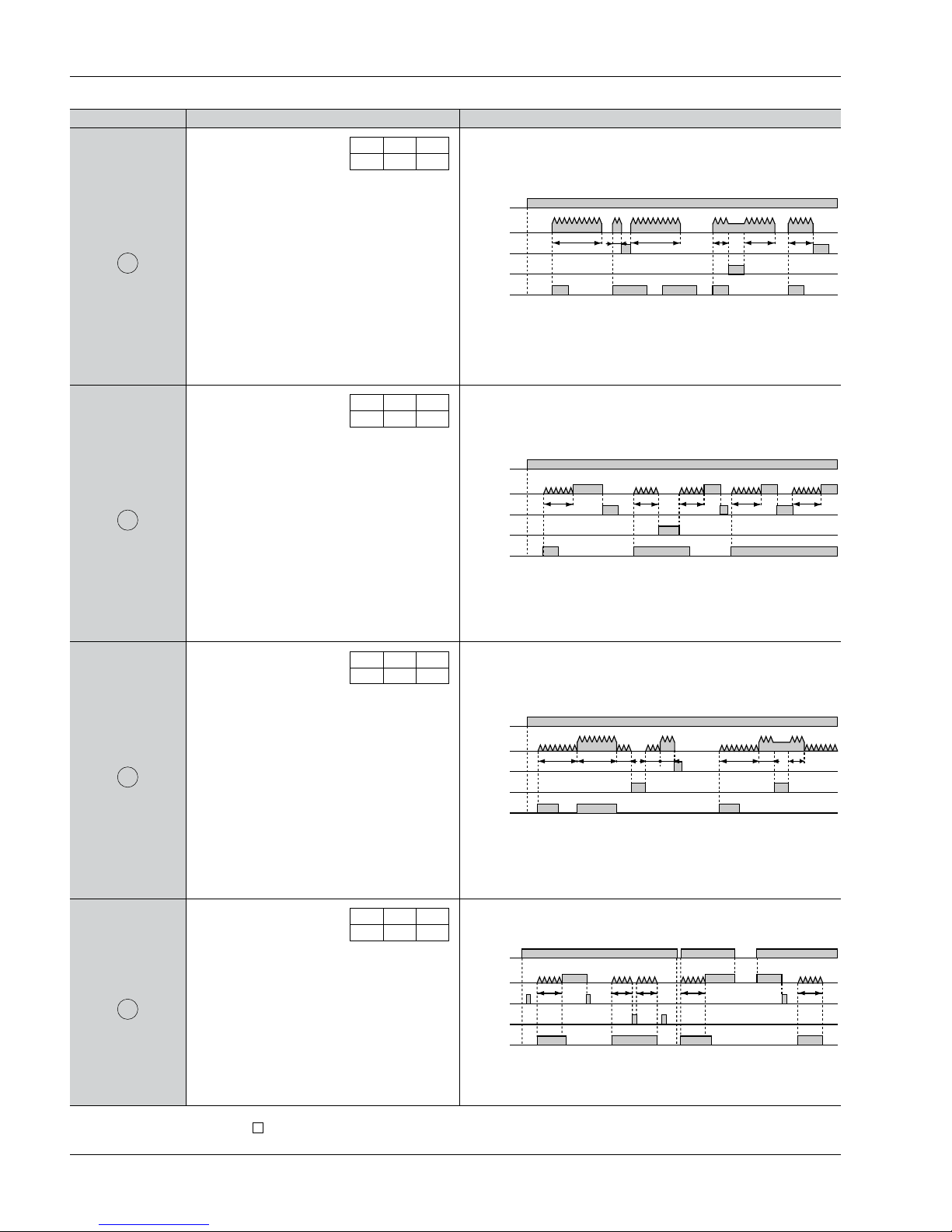

A (Power ON delay 1), A2 (Power ON delay 2), B (Signal ON delay), C (Signal OFF delay), D (Pulse one-shot),

E (Pulse ON delay), F (Signal Flicker), G (Totalizing ON delay) (selectable by DIP switch)

Min. input signal width: 1 ms, 20 ms (2 directions by selected by DIP switch) (The 8-pin type does not have a stop input.)

Min. input signal width: 20 ms (The 8-pin type does not have a lock input.)

Open collector input Input impedance: Max. 1 kΩ; Residual voltage: Max. 2 V

Open impedance: 100kΩor less, Max. energized voltage: 40V DC

7-segment LCD (LT4H, LT4H-L common), Elapsed value (backlight red LED), Setting value (backlight yellow LED)

EEP-ROM (Min. 105overwriting)

±(0.005 % + 50 ms) in case of power on start

±(0.005 % + 20 ms) in case of input signal start

Operating voltage: 85 to 110%

Temperature: –10 to +55°C +14 to +131°F

Min. input signal width: 1ms

Timed-out 1 Form C

100 mΩ(at 1 A 6 V DC)

Ag alloy/Au flash

Min. 2 ×107ope. (Except for switch operation parts)

1.0 ×105ope. (At rated control voltage)

85 to 110 % of rated operating voltage

2,000 Vrms for 1 min: Between live and dead metal parts (Pin type)

2,000 Vrms for 1 min: Between input and output

2,000 Vrms for 1 min: Between live and dead metal parts (11-pin)

2,000 Vrms for 1 min: Between input and output

1,000 Vrms for 1 min: Between contacts

Between live and dead metal parts

Min. 100 MΩ:Between input and output (At 500V DC)

Between contacts

Min. 100 MΩ:Between live and dead metal parts

Between input and output (At 500V DC)

Max. 0.5 s

10 to 55 Hz: 1 cycle/min single amplitude of 0.35 mm .014 inch (10 min on 3 axes)

10 to 55 Hz: 1 cycle/min single amplitude of 0.75 mm .030 inch (1 h on 3 axes)

Timed-out 1 Form A (Open collector)

—

—

—

Min. 107ope. (At rated control voltage)

12 to 24 V DC

—

Max. 3 W

100 to 240 V AC, 24 V AC,

24 V AC/DC

50/60 Hz common

Max. 10 V A

100 mA, 30 V DC

12 to 24 V DC

—

Max. 3 W

DC type

Transistor output type

AC type AC/DC type DC type

Rating

Time

accuracy

(max.)

Contact

Life

Electrical

Mechanical

Operating

conditions

Rated operating voltage

Rated frequency

Rated power consumption

Rated control capacity

Time range

Time counting direction

Operation mode

Start/Reset/Stop input

Lock input

Input signal

Indication

Power failure memory

method

Operating time fluctuation

Temperature error

Voltage error

Setting error

Contact arrangement

Contact resistance (Initial value)

Contact material

Mechanical (contact)

Electrical (contact)

Allowable operating voltage range

Breakdown voltage

(Initial value)

Insulation resistance

(Initial value)

Operating voltage reset

time

Max. 65° C

(under the flow of nominal operating current at nominal voltage)

—Temperature rise

Functional

Destructive

Vibration

resistance

Min. 98 m 321.522 ft./s2(4 times on 3 axes)

Min. 294 m 964.567 ft./s2(5 times on 3 axes)

–10° C to 55° C +14° F to +131° F

Max. 85 % RH (non-condensing)

860 to 1,060 h Pa

—

8-pin/11-pin/screw terminal

IP66 (front panel with rubber gasket)

20 % or less — 20 % or less

Functional

Destructive

Ambient temperature

Ambient humidity

Air pressure

Ripple rate

Connection

Protective construction

Shock

resistance

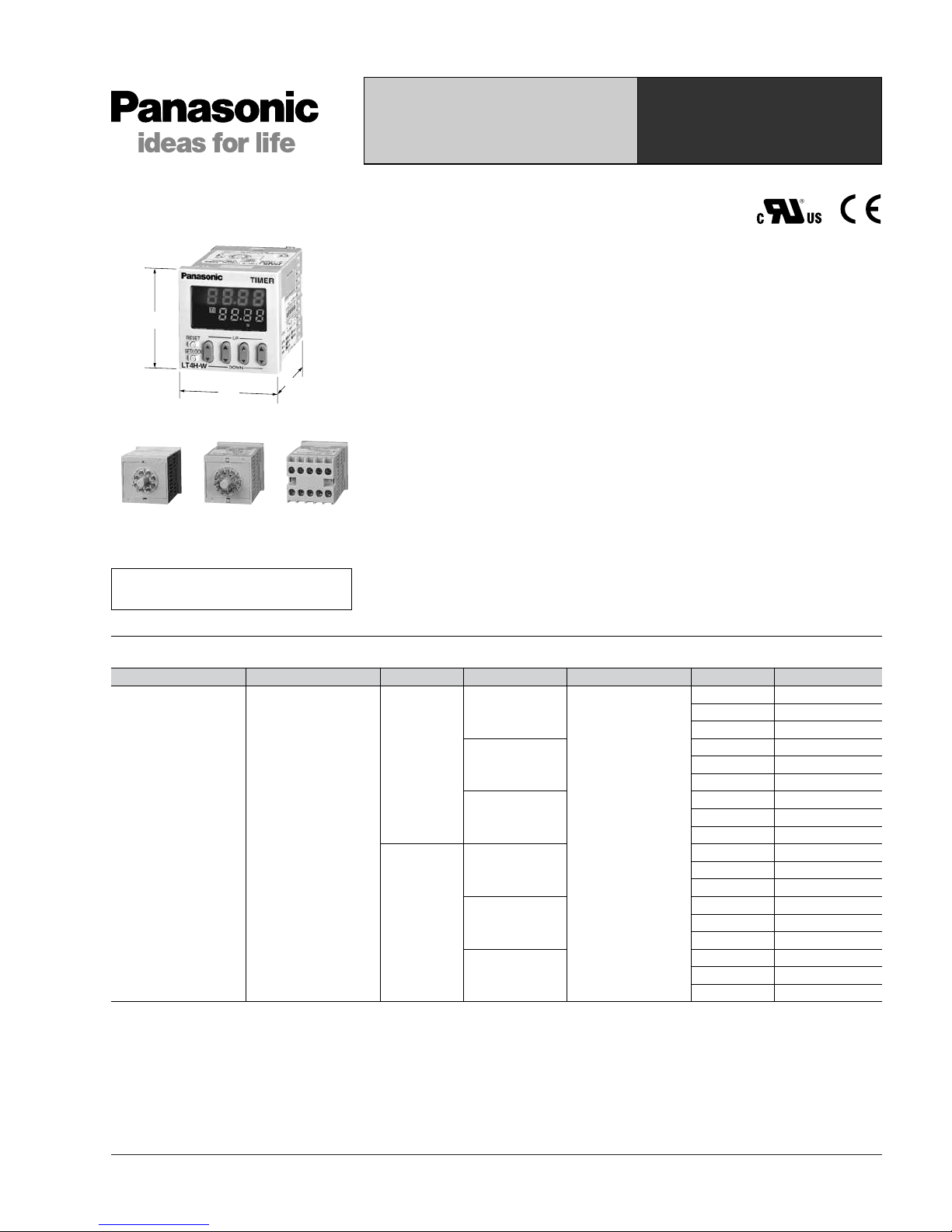

Specifications

[]

LT4H/-L

Applicable standard

Safety standard EN61812-1 Pollution Degree 2/Overvoltage Category II

EMC

(EMI)EN61000-6-4

Radiation interference electric field strength

Noise terminal voltage

(EMS)EN61000-6-2

Static discharge immunity

RF electromagnetic field immunity

EFT/B immunity

Surge immunity

Conductivity noise immunity

Power frequency magnetic field immunity

Voltage dip/Instantaneous stop/Voltage fluctuation immunity

EN55011 Group1 ClassA

EN55011 Group1 ClassA

EN61000-4-2 4 kV contact

8 kV air

EN61000-4-3 10 V/m AM modulation (80 MHz to 1 GHz)

10 V/m pulse modulation (895 MHz to 905 MHz)

EN61000-4-4 2 kV (power supply line)

1 kV (signal line)

EN61000-4-5 1 kV (power line)

EN61000-4-6 10 V/m AM modulation (0.15 MHz to 80 MHz)

EN61000-4-8 30 A/m (50 Hz)

EN61000-4-11 10 ms, 30% (rated voltage)

100 ms, 60% (rated voltage)

1,000 ms, 60% (rated voltage)

5,000 ms, 95% (rated voltage)