SECTION 1: MANDATORY MAINTENANCE NOTES

THESE NOTES AND INSTRUCTIONS MUST BE

PRECISELY FOLLOWED FOR ANY MAINTENANCE OF

PARKER P-SERIES BELLOWS VALVES.

DISASSEMBLY OF BELLOWS VALVES:

1. WARNING: MAKE CERTAIN THE SYSTEM IN WHICH

THE VALVE IS INSTALLED IS DRAINED AND/OR

EXHAUSTED OF ALL PRESSURE BEFORE STARTING

ALVE REMOVAL OR DISASSEMBLY. FAILURE TO

DO SO CAN CAUSE DEATH, PERSONAL INJURY AND

PROPERTY DAMAGE.

2. Verify that the Bellows Valve Maintenance Kit being used

is appropriate for the Valve's size and service

requirements. Always contact your authorized Parke

representative if any questions arise.

REASSEMBLY OF BELLOWS VALVES:

1. Make certain all parts are free of dirt or othe

contamination before starting reassembly of the Valve.

2. Any instruction to lubricate any Valve component assumes

the End User will select a lubricant that is consistent with

the Valve's service requirements. Always contact you

authorized Parker representative if any questions arise.

Table I

Maximum Allowable Working Pressure and Temperature

Bellows Valve Model Max Allowable Working

Pressure and Temperature

Air Supply Pressure 50 - 150 psig

(0.3 MPa to 1.0 MPa)

Normally Open 600 psig at 70° F

(4.1 MPa at 21° C)

Normally Closed 200 psig at 70° F

(1.4 MPa at 21° C)

Double Acting 700 psig at 70° F

(4.8 MPa at 21° C)

PARKER

P6 and P8 Series Miniature Actuator

Bellows Valve

Maintenance Instructions

MI-132

Parker Hannifin Corporation

Veriflo Division

250 Canal Blvd.

Richmond, Ca 94804

Phone (510) 235-9590

Fax (510) 232-7396

Copyright 1995 Parker-Hannifin Corporation

All Rights Reserved

WARNING

FAILURE OR IMPROPER SELECTION OR IMPROPER

USE OF THE PRODUCTS AND/OR SYSTEMS

DESCRIBED HEREIN OR RELATED ITEMS CAN CAUSE

DEATH, PERSONAL INJURY AND PROPERTY DAMAGE.

This document and other information from Parker Hannifin

Corporation, its subsidiaries and authorized distributors

provide product and/or system options for furthe

investigation by users having technical expertise. It is

important that you analyze all aspects of your application

and review the information concerning the product o

system in the current product catalog. Due to the variety o

operating conditions and applications for these products o

systems, the user, through its own analysis and testing, is

solely responsible for making the final selection of the

products and systems and assuring that all performance,

safety and warning requirements of the application are met.

The products described herein, including without limitation,

product features, specifications, designs, availability and

pricing, are subject to change by Parker Hannifin

Corporation and its subsidiaries at any time without notice.

ALL PARKER VALVES MUST PASS A RIGID

OPERATIONAL AND LEAKAGE TEST BEFORE

LEAVING THE FACTORY. IT IS RECOMMENDED AFTER

NY REASSEMBLY, THE VALVE SHOULD BE TESTED

BY THE USER FOR OPERATION AND LEAKAGE. IF

THESE INSTRUCTIONS ARE NOT FULLY COMPLIED

WITH, THE REPAIRED PRODUCT MAY FAIL AND

CAUSE DAMAGE TO PROPERTY OR INJURY TO

PERSONS. PARKER HANNIFIN CANNOT ASSUME

RESPONSIBILITY FOR PERFORMANCE OF A

CUSTOMER SERVICED VALVE.

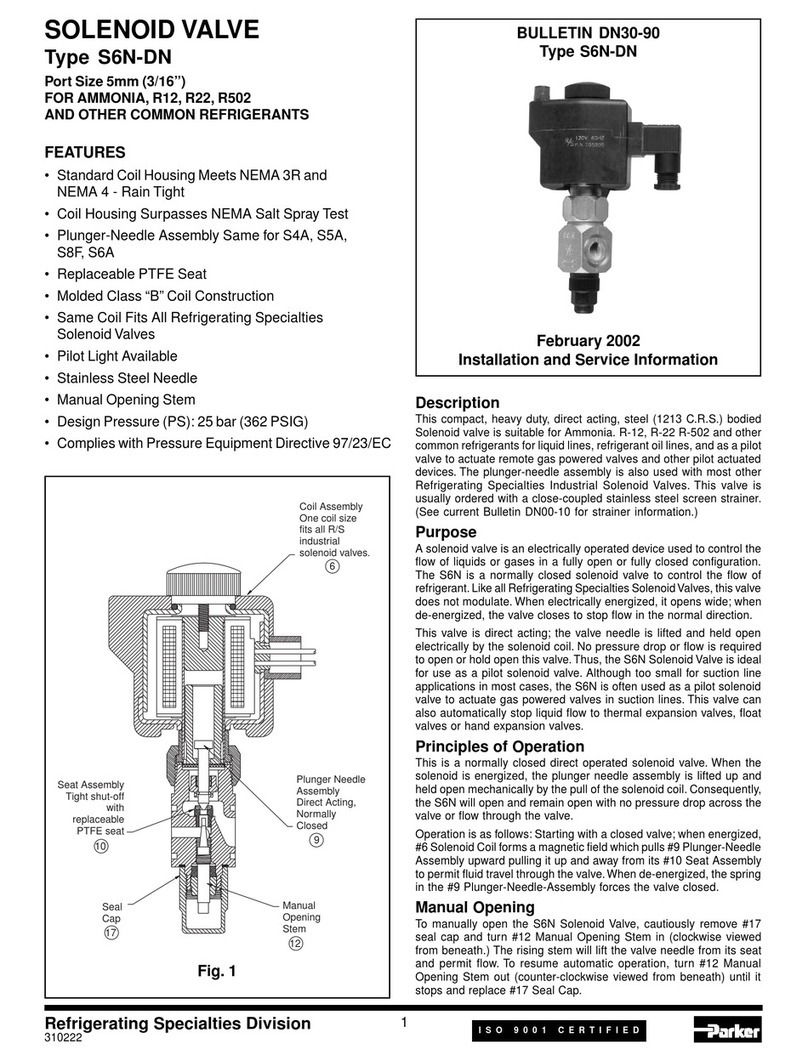

2C: BELLOWS SUB-ASSEMBLY REPLACEMENT

DISASSEMBLY

1. Remove the Air Operator Cap from the Actuator Body using a

3/16 inch hex socket wrench.

2. Remove the Piston by first removing the Snap Ring from the

upper portion of the stem.

3. Remove the Bonnet Sub-assembly by unthreading the Union

Nut with a 1 inch hex socket wrench.

4. Remove the Gasket from the Valve Body.

5. Remove the Stem Sub-assembly from the Bonnet Sub-

assembly.

6. Remove the O-ring/Bushing/Spring from the Stem Sub-

assembly.

7. Remove the Stem Tip Sub-assembly from the Stem Sub-

assembly by unthreading with a 7/16 inch hex socket wrench.

A screw driver slot on the stem can be used to prevent rotation

of the Stem Sub-assembly. Do not hold the Bellows or the

Bellows Ring to prevent damage to the Bellows.

REASSEMBLY

1. Engage the Stem Tip Sub-assembly into the new Stem Sub-

assembly to 1/8 turn past finger-tight or preferably torque to 15

In-lbs.(1.7 N-m). Rotate the Stem Tip Sub-assembly with a

7/16 inch hex socket wrench. A screw driver slot on the stem

can be used to prevent rotation of the Stem Sub-assembly.

Do not hold the Bellows or the Bellows Ring to prevent

damage to the Bellows.

2. Insert the Bushing and Spring over the Stem Sub-assembly.

3. Install the assembly of step 2 into the Bonnet Sub-assembly.

Exercise caution to prevent damage to the O-rings.

4. Place the new Gasket onto the Valve Body.

5. Lightly lubricate the Valve Body or Union Nut threads with an

appropriate lubricant, as consistent with the Valve's service

requirements.

6. Engage the Bonnet Sub-assembly onto the Valve Body finge

tight.

7. Insert the O-ring and Piston onto the Stem Sub-assembly and

secure the Piston with the Snap Ring.

8. Engage the Actuator Cap into the Actuator Body.

9. Preferably, pressurize the Bonnet Sub-assembly at the 10-32

UNF port in the Body to open the valve prior to the following

step.

10. Install the Bonnet Sub-assembly and torque the Union Nut to

50 Ft-lbs. (67 N-m) maximum.

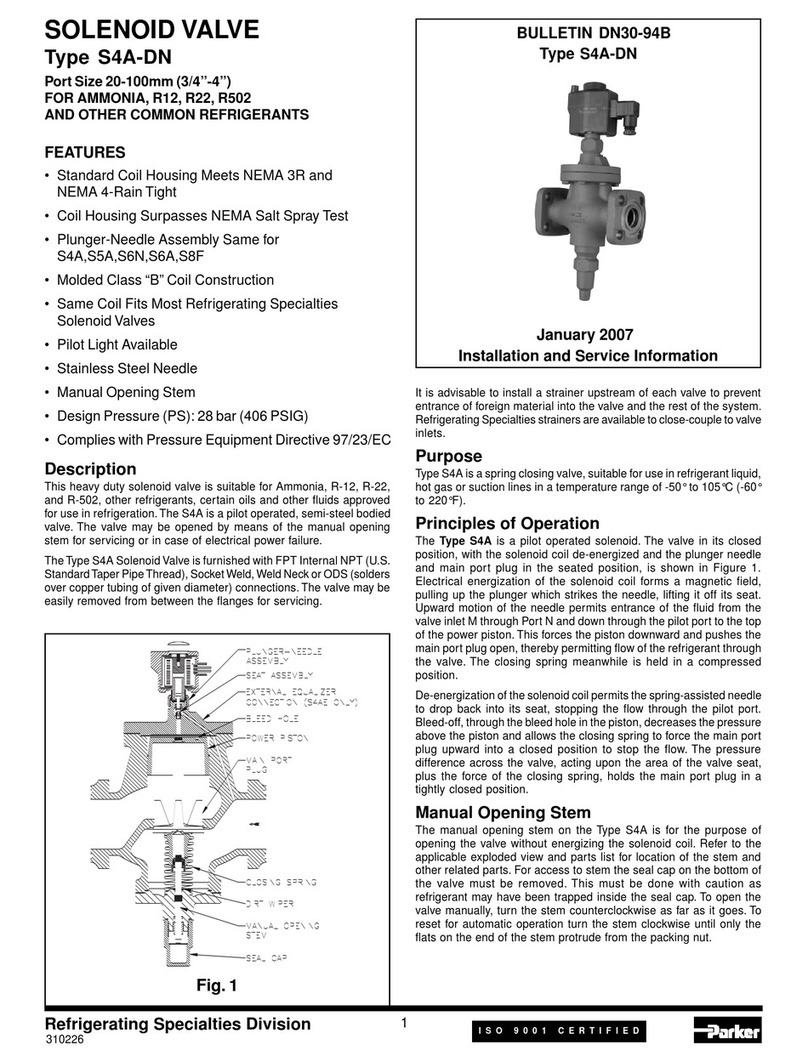

FIGURE 1:

NORMALLY CLOSED VALVE

(P6 AND P8-12AC)

FIGURE 2:

NORMALLY CLOSED VALVE

(P6 AND P8-12AC)

SPRING

BUSHING

O-RING

ACTUATOR

CAP

STEM

SUB-ASSY

STEM TIP

SUB-ASSY

O-RING

SNAP RING

PISTON

O-RING

ACTUATOR

BODY

UNION

NUT

BONNET

VALVE

BODY

BUSHING &

RETAINING RING

GASKET O-RING

BONNET

SUB-ASSY

SECTION 2: NORMALLY CLOSED VALVE

(P6 and P8 -12AC)

For NORMALLY CLOSED VALVES (P6 & P8-12AC) refer to Figures 1 and 2.

2A:GASKET REPLACEMENT

DISASSEMBLY

1. Remove the Bonnet Sub-assembly by unthreading the Union Nut from the

Valve Body with a 1 inch hex socket wrench.

2. Remove the Gasket from the Valve Body.

REASSEMBLY

1. Place the new Gasket in the Valve Body.

2. Lightly lubricate the Body or Union Nut threads with an appropriate

lubricant, as consistent with the Valve's service requirements.

3. Preferably, pressurize the Bonnet Sub-assembly at the 10-32 UNF port in

the Actuator Body to open the valve for the following step.

4. Engage the Bonnet Sub-assembly onto the Valve Body and torque the

Union Nut to 50 Ft-lbs. (67 N-m) maximum.

2B: STEM TIP REPLACEMENT

DISASSEMBLY

1. Remove the Bonnet Sub-assembly by unthreading the Union Nut from the

Valve Body with a 1 inch hex socket wrench.

2. Remove the Stem Tip Sub-assembly from the Stem Sub-assembly by

unthreading with a 7/16 inch hex socket wrench. Insert a screw driver into

the 10-32 UNF port of the Actuator Cap to prevent rotation of the Stem

Sub-assembly. Do not hold the Bellows or the Bellows Ring to prevent

damage to the Bellows.

3. Remove the Gasket from the Valve Body.

REASSEMBLY

1. Engage the new Stem Tip Sub-assembly into the Stem Sub-assembly to

1/8 turn past finger-tight or preferably torque to 15 In-lbs. (1.7 N-m).

Rotate the Stem Tip Sub-assembly with a 7/16 inch hex socket wrench,

while securing the Stem Sub-assembly from rotation with a screw drive

inserted into the 10-32 UNF port in the Actuator Cap. Do not hold the

Bellows or the Bellows Ring to prevent damage to the Bellows.

2. Place the new Gasket in the Valve Body.

3. Lightly lubricate the Valve Body or Union Nut threads with an appropriate

lubricant, as consistent with the Valve's service requirements.

4. Preferably, pressurize the Bonnet Sub-assembly at the 10-32 UNF port in

the Actuator Body to open the valve for the following step.

5. Engage the Bonnet Sub-assembly onto the Valve Body and torque the

Union Nut to 50 Ft-lbs. (67 N-m) maximum.