Refrigerating Specialties Division 2

Thedual-positionfeatureoftheS4ADisspecically

designedtohelpaidagainstthedamagingeffectsof

liquidhammerandsuddenliquiddeceleration.This

valveistypicallyappliedasacombinationhotgasvalve

andsoftgasvalveorasaliquidsolenoid.

Principles of Operation

TheTypeS4ADisa pilotoperateddual-positionso-

lenoid.Thevalveincludestwosolenoidassemblies.

Whenbothsolenoidscoilsareenergizedthemainvalve

is100%open.Withsolenoidcoil#2isenergized,the

valve is open approximately 10% of its' full stroke.

Whensolenoidcoil#1isenergized,thevalvewillthen

befullyopen.Ifbothsolenoidcoilsarede-energized,

themainvalveisclosed.

Propersequencing(energizingandde-energizing)of

thesolenoidcoilsisessentialforproperoperationof

thevalve.

From the closed position

Toopenthevalvetotherststageenergizesolenoid

coil#2 and leavesolenoidcoil#1 de-energized.

Thisforcesthesecondarypistondownfullyandthe

primarypistondownpartially,openingthevalveto

therststageposition.Thisisapproximately10%

ofvalve'stotalcapacity.Thevalvewillstayinthis

positionaslongascoil#2staysenergized.

From the first stage position

Toopenthevalvecompletely,keepsolenoidcoil#2

energizedandenergizesolenoidcoil#1.Thisforces

theprimarypistondownwhichinturnforcesthe

mainvalveplugtothefullopenposition.Note,in

orderforthevalvetoopencompletelycoil#2must

beenergizedpriortoorsimultaneouslytocoil#1,

andbothsolenoidsmustremainenergizedtohold

thevalvefullyopen.

From the wide open position

Topartiallyclosethevalve,de-energizesolenoid

coil#1whilekeepingsolenoidcoil#2energized.

Thisallowsthespringtopushthemainplugand

primary piston back against the bottom of the

secondarypistonattherststageposition.Again,

thevalvewillstayinthispositionaslongascoil

#2remainsenergized.

To completely close the valve

De-energizebothcoils.Thisallowsthetrapped

pilotgastobleedoffaroundthesecondarypiston

andthroughanoriceintheprimarypistontothe

downstreamsideofthevalve.Oncethetrapped

gasisallowedtobleedoff,thereturnspringforces

thevalveclosed.

Forexisting120&240voltinstallationsRefrigerat-

ingSpecialtiesoffersanadjustabletimedelayrelay

(108723) which can be used to control the solenoid

sequencing.

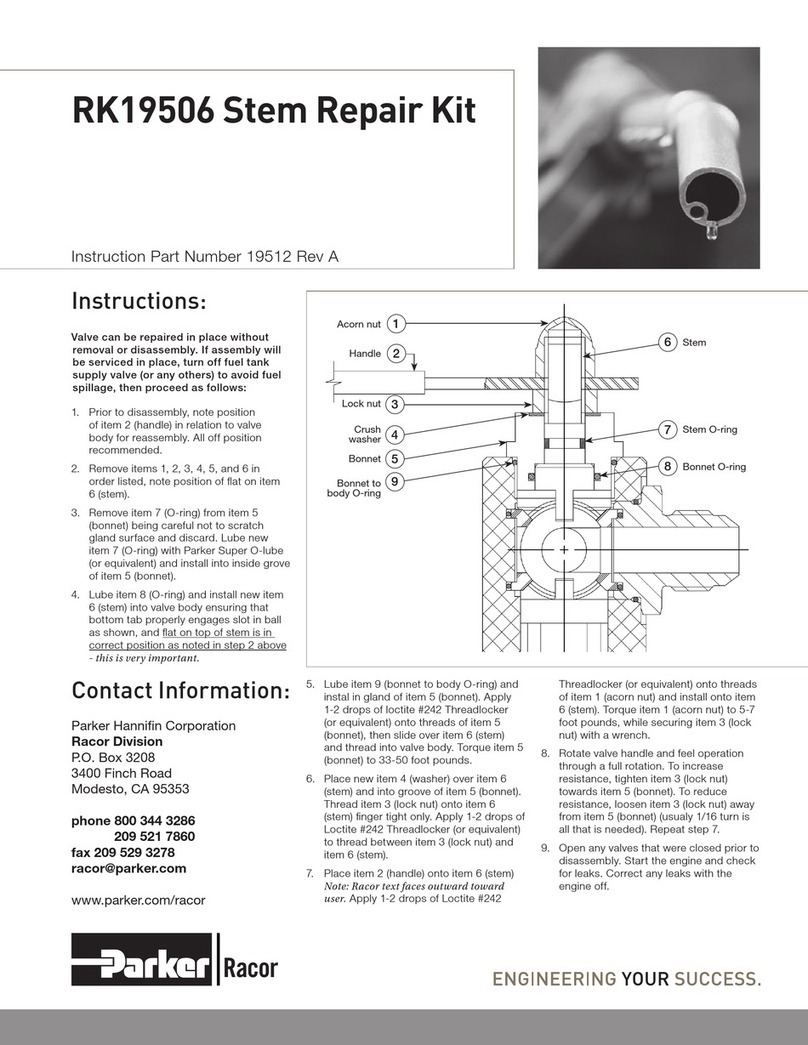

Manual Opening Stem

ThemanualopeningstemontheTypeS4ADisforthe

purposeofopeningthevalvewithoutenergizingthe

solenoidcoil.Foraccesstothestemthesealcapon

thebottomofthevalvemustberemoved.Thismustbe

donewithcautionasrefrigerantmayhavebeentrapped

insidethesealcap.Toopenthevalvemanually,turn

thestemcounterclockwiseasfarasitgoes.Toreset

forautomaticoperationturnthestemclockwiseuntil

onlytheatsontheendofthestemprotrudefromthe

packingnut.

Installation

Protectinsideofvalvefromdirt,chipsandmoisture

duringinstallation.Mountonlyinthehorizontalpipe

linewithsolenoidcoilatthetop;thisvalvewillwork

properlyonlyinthisposition.InaliquidlinetheSole-

noidValveshouldbeneartheexpansionvalveinlet.Itis

advisabletoinstalltheS4ADclosecoupledcompanion

straineraheadofthevalveforprotectionagainstdirt

andchips.

TheS4ADsolenoidvalvemustbeinstalledwiththear-

rowonthevalvebodyinthedirectionofowthrough

thevalve.Ifthevalveisbackwards,theowwillnot

bestoppedwhenthevalveiselectricallyde-energized.

LikeallSolenoidValves,theS4ADcanstopowonlyin

thedirectionfromthenormalinlettonormaloutlet(as

shownbythearrowonthebody).Ifreversalofpressure

occursinthesystemsotheoutletpressureexceeds

theinletpressurethepistonwillbeblownawayfrom

itsseatandreverseowwilloccur.Ifasystemhasthis

typeofpressurereversal(asencounteredduringhot

gasdefrostwithliquidrecirculationsystems),acheck

valvesuchasRefrigeratingSpecialtiesDivisionType

CK4Ainserieswiththesolenoidvalvewillpreventow

reversal.(CK4Amustbeinstalleddownstreamtoavoid

trappingliquid.)

Electrical

TheRefrigeratingSpecialtiesDivisionmoldedwater

resistantsolenoidcoilisdesignedforlonglifeandpow-

erfulopeningforce.Thestandardcoilhousingmeets

NEMA3Rand4requirements.Thissealedconstruc-

tioncanwithstanddirectcontactwithmoistureand

ice.Thecoilhousingfarexceedstherequirementsof

NEMAstandardICS,1-110.57saltspraytestforrust

resistance.