Page

AC10 Inverter

Chapter 1 Introduction .......................................................................................................... 1-1

1.1 Understanding the Product Code ............................................................. 1-1

1.2 Nameplate Example ................................................................................. 1-1

1.3 Product Range .......................................................................................... 1-2

Chapter 2 Product Overview................................................................................................. 2-1

2.1 Designed Standards for Implementation .................................................. 2-1

2.2 Control Features ....................................................................................... 2-2

Chapter 3 Installation ............................................................................................................ 3-1

3.1 Equipment Precautions ............................................................................ 3-1

Chapter 4 Maintenance ........................................................................................................ 4-1

4.1 Periodic Checking .................................................................................... 4-1

4.2 Storage ..................................................................................................... 4-1

4.3 Daily Maintenance .................................................................................... 4-1

Chapter 5 The Keypad .......................................................................................................... 5-1

5.1 The Display .............................................................................................. 5-1

5.2 Remote-control ......................................................................................... 5-1

5.2.1 Panel Mounting Diagram .................................................................... 5-2

5.2.2 Port of control panel ............................................................................ 5-2

Chapter 6 The Menu Organisation ....................................................................................... 6-1

6.1 Parameters Setting ................................................................................... 6-1

6.2 Function Codes Switchover in/between Code-Groups ............................ 6-2

6.3 Panel Display ........................................................................................... 6-3

Chapter 7 Installation & Connection ..................................................................................... 7-1

7.1 Installation ................................................................................................ 7-1

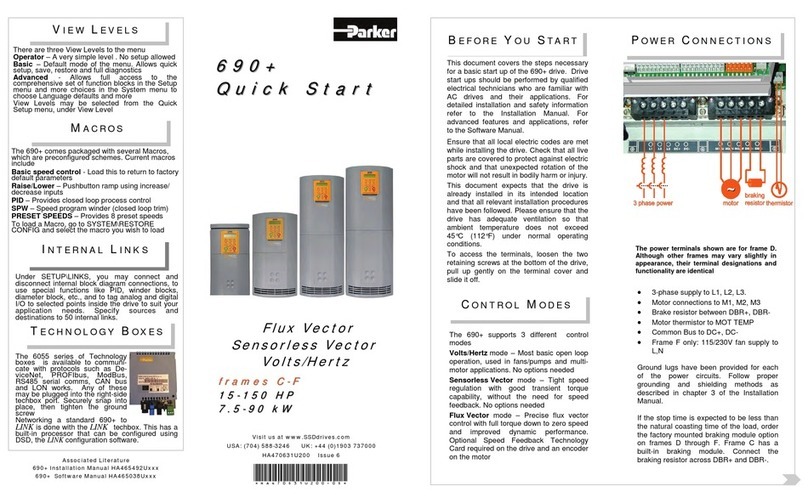

7.2 Connection ............................................................................................... 7-3

7.3 Measurement of Main Circuit Voltages, Currents and Powers ................ 7-5

7.4 Functions of Control Terminals ................................................................. 7-7

7.5 Wiring for Digital Input Terminals: ............................................................ 7-8

7.5.1 Wiring for positive source electrode (NPN mode). ........................... 7-8

7.5.2 Wiring for active source electrode .................................................... 7-8

7.5.3 Wiring for positive Sink electrode (PNP mode) ................................ 7-8

7.5.4 Wiring for active drain electrode (PNP mode) .................................. 7-9

7.6 Connection Overview ............................................................................. 7-10

7.7 Basic methods of suppressing the noise................................................ 7-12

7.7.1 Noise propagation paths and suppressing methods ...................... 7-12

7.7.2 Basic methods of suppressing the noise ........................................ 7-13

7.7.3 Field Wire Connections .................................................................. 7-14

7.7.4 Earthing .......................................................................................... 7-14

7.7.5 Leakage Current ............................................................................. 7-15

7.7.6 Electrical Installation of the Drive ................................................... 7-15

7.7.7 Application of Power Line Filter ...................................................... 7-16

Chapter 8 Operation and Simple Running ............................................................................ 8-1