Peak PCAN-miniPCIe User manual

Other Peak Computer Hardware manuals

Peak

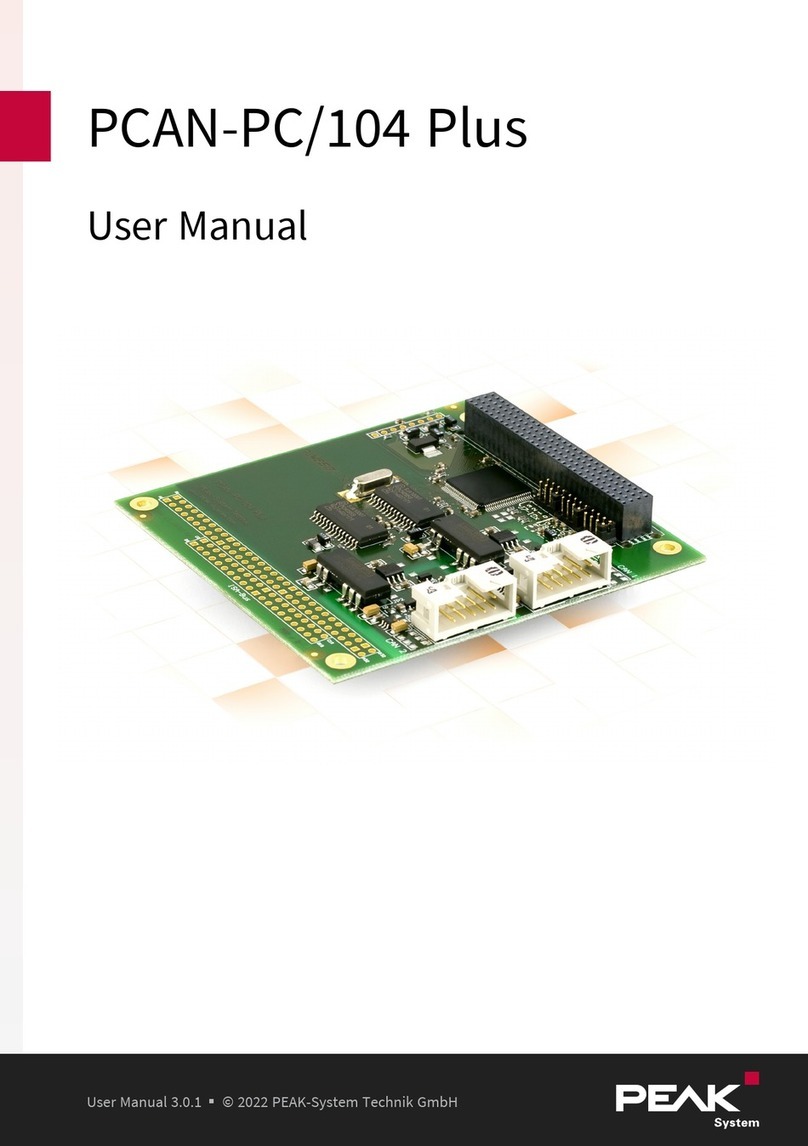

Peak PCAN-PC/104-Plus User manual

Peak

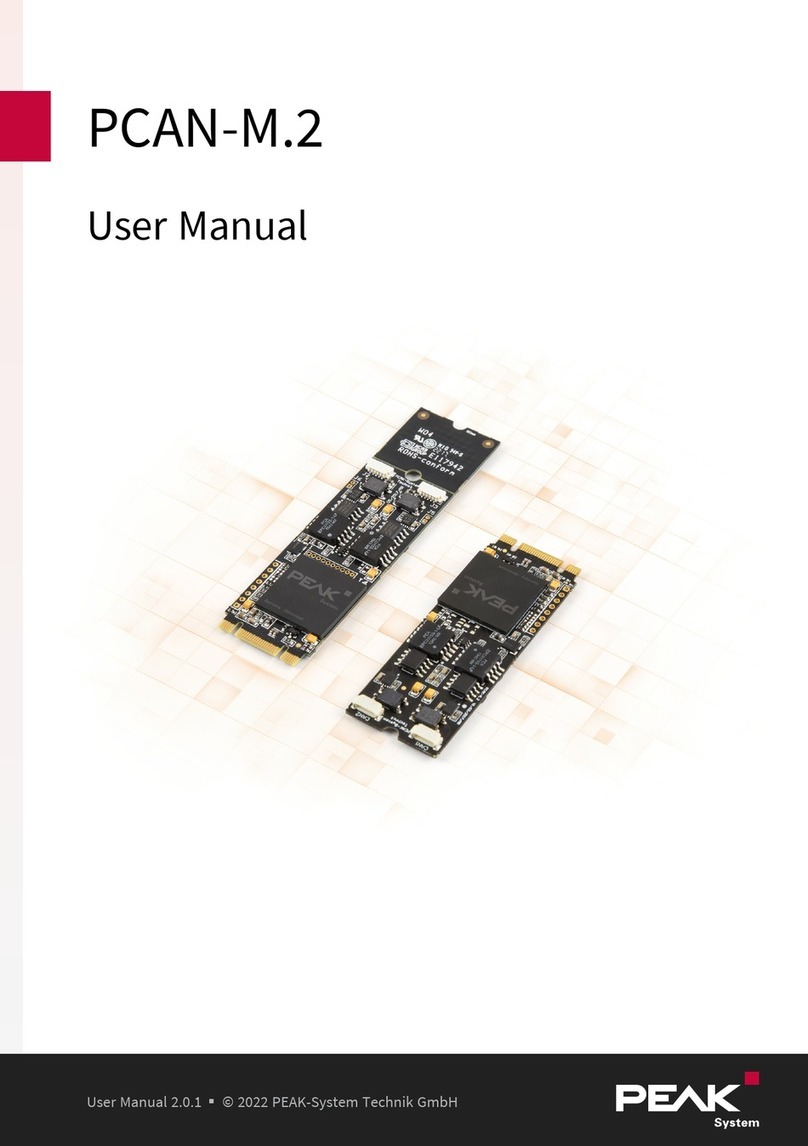

Peak PCAN-M.2 User manual

Peak

Peak PCAN-Chip USB User manual

Peak

Peak PCAN-PC Card Series User manual

Peak

Peak PCAN-miniPCIe FD User manual

Peak

Peak PCAN-PCI Express User manual

Peak

Peak PCAN-ExpressCard User manual

Peak

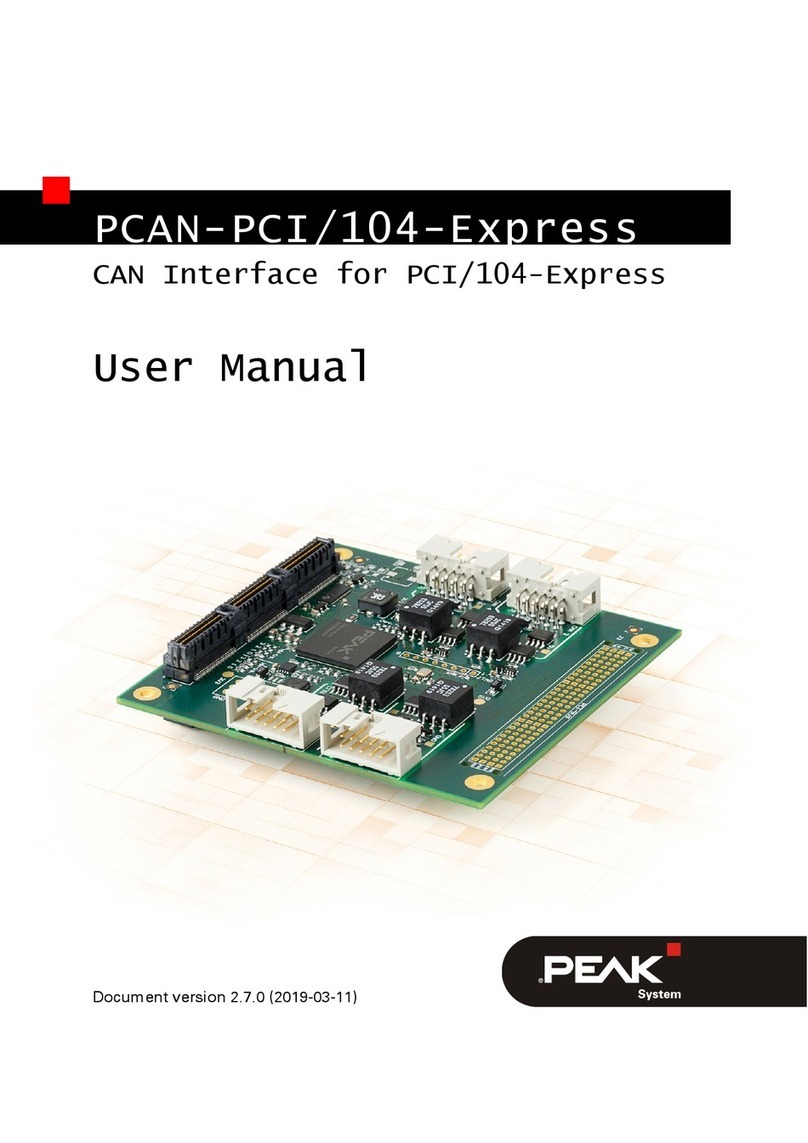

Peak PCAN-PCI/104-Express User manual

Peak

Peak PCAN-Dongle User manual

Peak

Peak CANopen User manual

Popular Computer Hardware manuals by other brands

EMC2

EMC2 VNX Series Hardware Information Guide

Panasonic

Panasonic DV0PM20105 Operation manual

Mitsubishi Electric

Mitsubishi Electric Q81BD-J61BT11 user manual

Gigabyte

Gigabyte B660M DS3H AX DDR4 user manual

Raidon

Raidon iT2300 Quick installation guide

National Instruments

National Instruments PXI-8186 user manual