© COPYRIGHT 2011 PECO, INC. ALL RIGHTS RESERVED. P/N 70568 3220-2287 REV 00

1

Thank you for choosing the PECO® Performance PRO™ T4900 School Series™ thermostat.

The T4900 provides comfort conditioning for educational environments, reducing energy

consumption and the bottom line. One-touch simplicity means users simply push the

“Teacher” key to apply an energy-ef cient School Schedule. The T4900 supports up to

3-HEAT/ 2-COOL con gurations in conventional and heat pump applications. Users can

choose between two modes in which to operate the T4900: as a standard Performance

PRO or as a School Series.

The Performance PRO T4900 School Series is comprised of the T4932SCH-001

programmable and the T4932SCH-002 programmable thermostat with humidi cation/

dehumidi cation control. T4900 School Series standard features include: 4 square inches

of blue backlit display; Secure Digital (SD) card interface; locking cover; auto-changeover;

School Schedule; inputs for occupancy/ remote sensors; three levels of keypad lockout

and PIN access; furnace and UV lter reminders; Heat/Cool Demand Indicator; a 365-day

calendar, 20 holidays; Power Harvesting (a.k.a. “power stealing”); and humidity control

(T4932SCH-002 only).

The T4900 Series can be powered by 24 VAC or batteries or both (recommended). The

T4900 Series can control up to 7 outputs and monitor three external sensors (including a

CO2 sensor). The T4900 Series mounts on any PECO Performance PRO Series common

wallplate.

The PECO Performance PRO thermostat is intended for use in conventional and heat

pump applications.

• System mode selections: Off-Heat-Cool-Auto-Emergency

• Stages: 1 Heat/1 Cool, 2 Heat/1 Cool, 1 Heat/2 Cool; 2 Heat/ 2 Cool; 3 Heat/ /2 Cool

• Fan control: Cycling (Auto) or Continuous (On); 1 Speed

• Permanent memory: All device settings are stored in permanent memory.

• Connections for Remote Sensors (indoor/ outdoor/ occupancy/ CO2)

• SD card interface (card not included)

•

•

•

Temperature Control

Range: 50° to 90° F (10° to 32° C)

Differential: 1° F (0.5°C)

Input Power: 24 VAC (20-30 VAC) 50/60 Hz (+/- 10%) or AA alkaline batteries

(both recommended); 5mm terminals accept 14-24 AWG

stranded or solid wire.

Operating Temperature: 0° to 120°F (-17° to 48°C)

Shipping Temperature: -20° to 130°F (-28° to 54°C)

Operating Humidity: 5% to 95% RH, non-condensing

Physical Dimensions: T4900 Thermostat: 4.3” H x 5.7” W x 1.3”D

with 2.7” x 1.5” / 4.05 square inch liquid crystal display (LCD)

Output Ratings

Voltage (50/60 Hz): 20-30 VAC

Current: 0.02-1.0 A per terminal; W1 (B/O), W2 (AUX), G, A, E, Y1, Y2.

Note: Collectively, total current draw must not exceed 2.5 A.

Select an appropriate thermostat location

Locate the thermostat about ve feet (1.5 m) above the oor on a wall in an area with good

ventilation and an average temperature, where it will be responsive to changes in room

temperature.

The Performance PRO T4900 School Series may be mounted on a:

• Horizontal or vertical 2” X 4” device box

• Horizontal 4” X 4” device box

• Flat surface

Do locate the thermostat where it can be affected by:

• Direct sunlight

• Drafts or dead areas behind doors

• Radiant heat from appliances

• Concealed pipes or chimneys

• Outside walls or unheated/uncooled areas

Required components (not included, unless otherwise speci ed):

• Two new AA batteries (included)

• Screws and wall anchors (included)

• Screwdrivers: Phillips (for wallplate); small athead (for terminal blocks)

• Drill with 3/16” drill bit (or 7/32” for plaster)

• Wirecutter and stripper

• Level

• Performance PRO School Series T4900 Thermostat (included)

• Performance PRO School Series T4900 Thermostat Operating Manual (included)

www.pecomanufacturing.com/controls/

• READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO INSTALL,

OPERATE, OR SERVICE THIS THERMOSTAT.

• Failure to observe safety information and comply with instructions could result in

PERSONAL INJURY, DEATH AND/OR PROPERTY DAMAGE.

• To avoid electrical shock or damage to equipment, disconnect power before

installing or servicing and use only wiring with insulation rated for full thermostat

operating voltage.

• To avoid potential re and/or explosion do not use in potentially ammable or

explosive atmospheres.

• Retain these instructions for future reference.

• This product, when installed, will be part of an engineered system whose

speci cations and performance characteristics are not designed or controlled

by PECO. Review applications and national and local codes to assure that the

installation will be functional and safe.

▲

i

T4900

▲

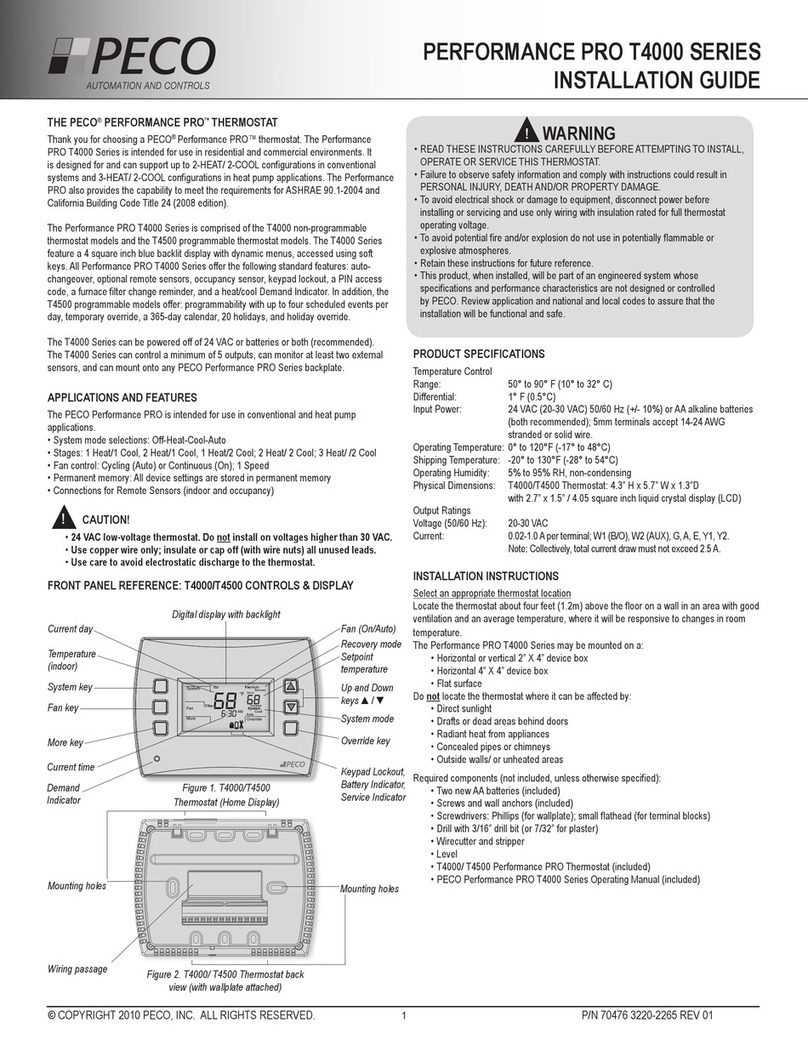

Digital display with backlight

Teacher/

Override key

Keypad Lockout,

Battery Indicator,

Service Indicator

System mode

System key

Temperature

(indoor)

Current day

Up and Down

keys ▲/ ▼

Fan key

SD Card

Interface

SD Card Indicator

More key

Current time

Demand

Indicator

Fan (On/Auto)

Recovery mode

Setpoint

temperature

Figure 1. T4900 Thermostat (Home Display).

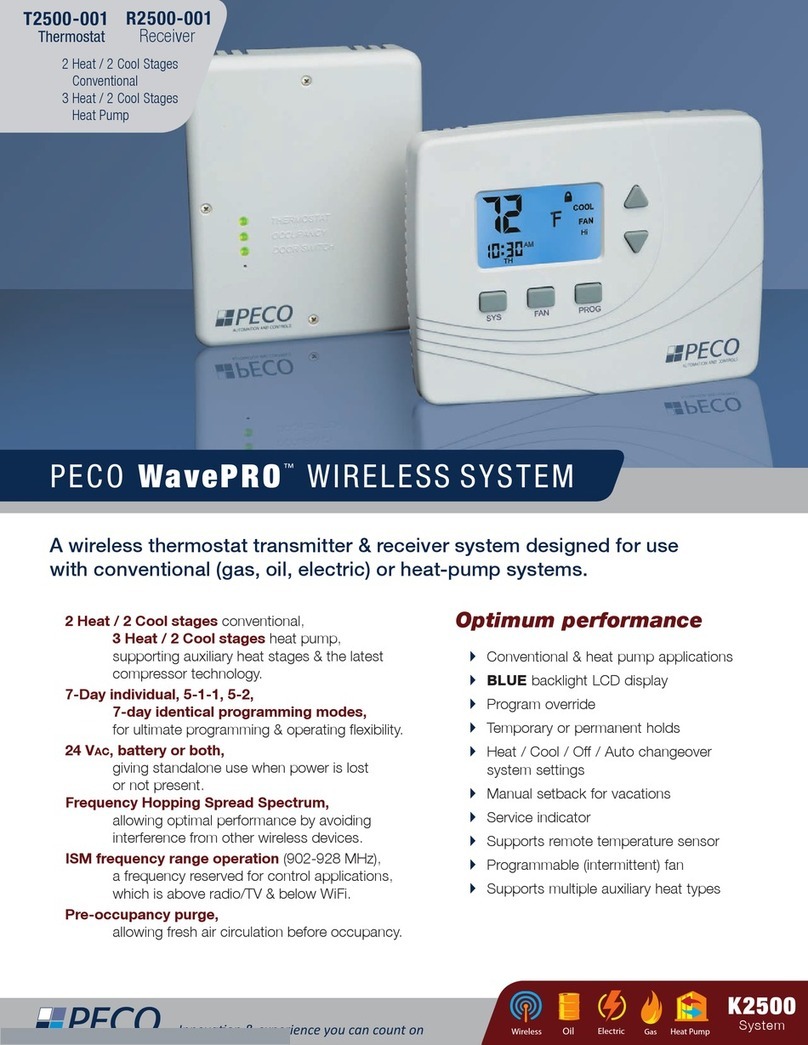

Mounting holesMounting holes

Figure 2. T4900 Thermostat back view (with wallplate attached).

Wiring passage