2 QC7I SERIES FILTERS INSTALLATION AND OPERATION GUIDE

OPERATING SPECIFICATIONS*

Combined

Model Name

Replacement

Cartridges Flow Rate Capacity

QC7I Single - MC MC 1.67 gpm (6.3 Lpm) 9,000 gal (34,068 L)

QC7I Single - MC2MC21.67 gpm (6.3 Lpm) 9,000 gal (34,068 L)

QC7I Single - MH MH 1.67 gpm (6.3 Lpm) 9,000 gal (34,068 L)

QC7I Single - MH2MH21.67 gpm (6.3 Lpm) 9,000 gal (34,068 L)

QC7I Single - TO TO 1.5 gpm (5.6 Lpm) 30,000 gal (113,562 L)

QC7I Single - CV CV 1.67 gpm (6.3 Lpm) 7,500 gal (28,390 L)

QC7I Single - XCV XCV 1.67 gpm (6.3 Lpm) 10,000 gal (37,854 L)

QC7I Single - XC XC 1.67 gpm (6.3 Lpm) 12,000 gal (45,424 L)

QC7I Single - XC2XC21.67 gpm (6.3 Lpm) 12,000 gal (45,424 L)

QC7I Single - 7CB5 7CB5 2.5 gpm (9.4 Lpm) 10,000 gal (37,854 L)

QC7I Single - 7CB5-K 7CB5-K 2.5 gpm (9.4 Lpm) 10,000 gal (37,854 L)

QC7I Single - 7CB5-S 7CB5-S 2.5 gpm (9.4 Lpm) 10,000 gal (37,854 L)

Combined

Model Name

Replacement

Cartridges Flow Rate Capacity

QC7I Twin - MC MC 3.3 gpm (12.4 Lpm) 18,000 gal (68,137 L)

QC7I Twin - MC2MC23.3 gpm (12.4 Lpm) 18,000 gal (68,137 L)

QC7I Twin - MH MH 3.3 gpm (12.4 Lpm) 18,000 gal (68,137 L)

QC7I Twin - MH2MH23.3 gpm (12.4 Lpm) 18,000 gal (68,137 L)

QC7I Twin - TO TO 3.0 gpm (11.3 Lpm) 60,000 gal (227,124 L)

QC7I Twin - CV CV 3.3 gpm (12.4 Lpm) 15,000 gal (56,781 L)

QC7I Twin - XCV XCV 3.3 gpm (12.4 Lpm) 20,000 gal (75,708 L)

QC7I Twin - XC XC 3.3 gpm (12.4 Lpm) 24,000 gal (90,849 L)

QC7I Twin - XC2XC23.3 gpm (12.4 Lpm) 24,000 gal (90,849 L)

QC7I Twin - 7CB5 7CB5 5.0 gpm (18.9 Lpm) 20,000 gal (75,708 L)

QC7I Twin - 7CB5-K 7CB5-K 5.0 gpm (18.9 Lpm) 20,000 gal (75,708 L)

QC7I Twin - 7CB5-S 7CB5-S 5.0 gpm (18.9 Lpm) 20,000 gal (75,708 L)

Combined

Model Name

Replacement

Cartridges Flow Rate Capacity

QC7I Triple - MC MC 5.0 gpm (18.9 Lpm) 27,000 gal (102,206 L)

QC7I Triple - MC2MC25.0 gpm (18.9 Lpm) 27,000 gal (102,206 L)

QC7I Triple - MH MH 5.0 gpm (18.9 Lpm) 27,000 gal (102,206 L)

QC7I Triple - MH2MH25.0 gpm (18.9 Lpm) 27,000 gal (102,206 L)

QC7I Triple - TO TO 4.5 gpm (17.0 Lpm) 90,000 gal (340,687 L)

QC7I Triple - CV CV 5.0 gpm (18.9 Lpm) 22,500 gal (85,171 L)

QC7I Triple - XCV XCV 5.0 gpm (18.9 Lpm) 30,000 gal (113,562 L)

QC7I Triple - XC XC 5.0 gpm (18.9 Lpm) 36,000 gal (136,274 L)

QC7I Triple - XC2XC25.0 gpm (18.9 Lpm) 36,000 gal (136,274 L)

QC7I Triple - 7CB5 7CB5 7.5 gpm (28.3 Lpm) 30,000 gal (113,562 L)

QC7I Triple - 7CB5-K 7CB5-K 7.5 gpm (28.3 Lpm) 30,000 gal (113,562 L)

QC7I Triple - 7CB5-S 7CB5-S 7.5 gpm (28.3 Lpm) 30,000 gal (113,562 L)

Combined

Model Name

Replacement

Cartridges Flow Rate Capacity

QC7I Quad - MC MC 6.6 gpm (24.9 Lpm) 36,000 gal (136,274 L)

QC7I Quad - MC2MC26.6 gpm (24.9 Lpm) 36,000 gal (136,274 L)

QC7I Quad - MH MH 6.6 gpm (24.9 Lpm) 36,000 gal (136,274 L)

QC7I Quad - MH2MH26.6 gpm (24.9 Lpm) 36,000 gal (136,274 L)

QC7I Quad - TO TO 6.0 gpm (22.7 Lpm) 120,000 gal (454,249 L)

QC7I Quad - CV CV 6.6 gpm (24.9 Lpm) 30,000 gal (113,562 L)

QC7I Quad - XCV XCV 6.6 gpm (24.9 Lpm) 40,000 gal (151,416 L)

QC7I Quad - XC XC 6.6 gpm (24.9 Lpm) 48,000 gal (181,699 L)

QC7I Quad - XC2XC26.6 gpm (24.9 Lpm) 48,000 gal (181,699 L)

QC7I Quad - 7CB5 7CB5 10.0 gpm (37.8 Lpm) 40,000 gal (151,416 L)

QC7I Quad - 7CB5-K 7CB5-K 10.0 gpm (37.8 Lpm) 40,000 gal (151,416 L)

QC7I Quad - 7CB5-S 7CB5-S 10.0 gpm (37.8 Lpm) 40,000 gal (151,416 L)

*For individual cartridge specifications, refer to cartridge literature.

Temperature: 35 - 100°F (2 - 38°C)

Pressure: 10 - 125 psi (0.7 - 8.6 bar), non-shock

For cold water use only.

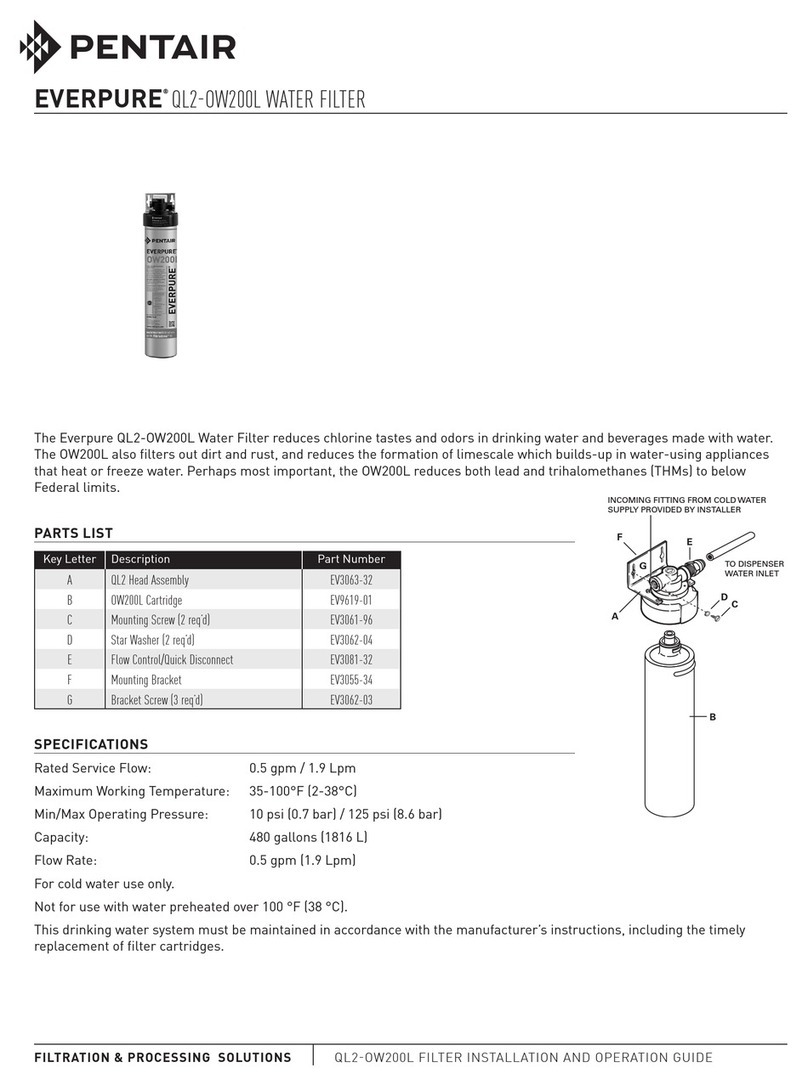

INSTALLATION

1. Use the predrilled mounting holes in the manifold bracket

as guides. Mark and drill anchor holes. Mount securely.

2. Shut off power to machine.

3. Connect outlet port of QC7I unit to equipment served.

Always use a NSF approved pipe dope or plumber tape

at all connections. Use a backup wrench on all fittings

while connecting to avoid excessive stress on the

system components.

NOTE: If the optional Everpure®E-Series Filter is used,

install a manual shut-off valve leading to the system

for servicing.

4. Connect minimum 3/8-inch water line to inlet side of QC7I

single. Use minimum 1/2-inch line for other systems.

5. The cross fitting has a flushing valve installed on the bottom.

Connect tubing to the flushing valve and run to drain.

NOTE: Some municipal plumbing codes

and good sanitary practices

require an air gap at the drain

termination point.

Air Gap

6. Install the cartridge(s) into the QC7I head(s) following

directions on the cartridge label or as shown in the

Cartridge Change illustrations.

7. Turn on water to filter and check for leaks.

8. Flush the cartridge by running water through at full force

for five (5) minutes. This will set the filtering media and

purge air and fines, insuring maximum filter life.

9. After flushing, close the flushing valve and turn on power

to equipment and plug the LPA (if so equipped) into the

electrical outlet.