2

BEFORE INSTALLATION

This manual contains important information for the safe

use of this product. Read this manual completely and

follow the instructions carefully. Reasonable care and

safe methods relating to the installation and operation

of this product should be practiced. Check local codes

and requirements before installation.

m DANGER: Risk of Electrical Shock or

Electrocution. May result in serious injury or death

or fire hazard. Installer must disconnect all electrical

sources prior to installation, handling or servicing.

Only qualified personnel may install this system.

NFPA 70/National Electric Code (NEC) or local

codes must be followed. System must be properly

grounded according to NEC. Do not lift pump by

power cord.

m DANGER: Biohazard Risk. Once wastewater

source has been connected to system, biohazard

risk exists. Installer(s) and/or service personnel

must use proper personal protective equipment

and follow handling procedures per OSHA 29

CFR 1910.1030 when handling equipment after

wastewater source has been connected to system.

m DANGER: Risk of Asphyxiation. Installer(s) and/

or service personnel must use proper personal

protective equipment and follow OSHA 29 CFR

1910.146 or OSHA 29 CFR 1926. Pump may be

installed in a location classified as a confined space.

m DANGER: Risk of Fire or Explosion. Do not

smoke or use open flames in or around this system.

This system is not intended for use in hazardous

locations per NFPA 70 National Electric Code.

Do not pump flammable liquids. Consult factory

for optional equipment rated for hazardous

location use.

m DANGER: Cutting Risk. Risk of serious cutting

or amputation exists. Disconnect all power

sources prior to servicing pump. Pump may start

without warning.

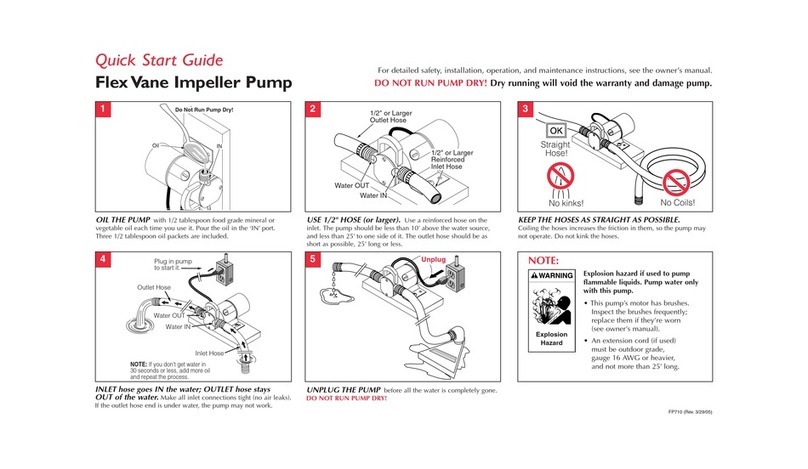

m DO NOT run the pump dry. Dry running can overheat

the pump (causing burns to anyone handling it) and

will void the warranty.

CALIFORNIA PROPOSITION 65 WARNING:

This product and related accessories

contain chemicals known to the State of California to

cause cancer, birth defects or other reproductive harm.

APPLICATION

These pump systems are designed for pumping effluent

or sewage water with a pH ranging from 5 to 9, specific

gravities from 0.9 to 1.1, viscosities ranging from 28 to

35 S.S.U. and temperatures up to 140ºF.

UNPACKING PUMP

Remove pump from carton. When unpacking unit,

check for concealed damage. Claims for damage

must be made at the receiving end through the delivery

carrier. Damage cannot be processed from the factory.

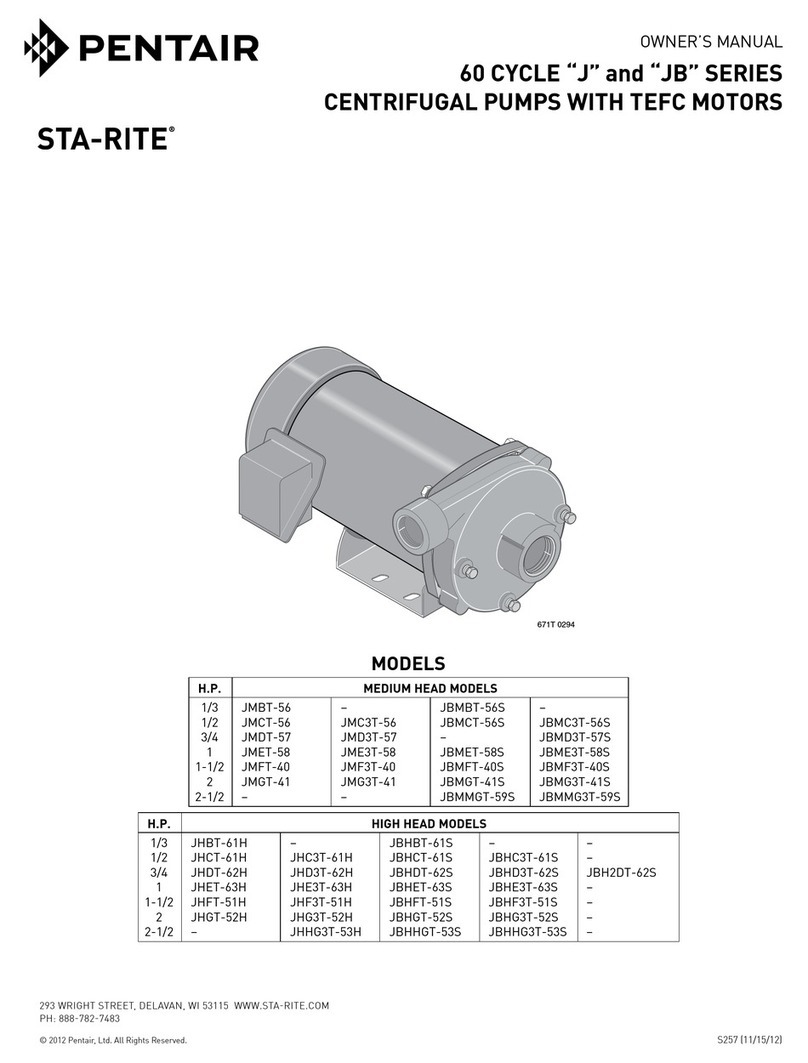

PUMP MODELS

These instructions cover the installation of the AG3 and

AG5 series of agricultural pumps. The pumps are designed

for handling raw agricultural sewage and wastewater.

The AG3 and AG5 series are made with a recessed

impeller. All models will pass 3" diameter solids and have

a 4" standard flange discharge.

VOLTAGES

All single phase motors are for 230 volts only.

ELECTRICAL

To reduce risk of electrical shock, disconnect the pump

from the power source before handling or servicing.

Never operate a pump with a power cord that has frayed

or brittle insulation. Never let cords or plugs lie in water or

handle connected power cords with wet hands.

PUMPS

Pump builds up heat and pressure during operation.

Allow time for pump to cool before handling or servicing.

Make sure lifting handles are securely fastened each time

before lifting and do not lift pump by the power cord.

Do not exceed manufacturer’s recommendation for

maximum performance, as this could cause the motor

to overheat.

Submersible solids handling pumps are not approved for

use in swimming pools, recreational water installations,

decorative fountains or any installation where human

contact with the pumped fluid is common.

Do not operate pump without safety devices in place.

IMPORTANT! Myers is not responsible for losses, injury

or death resulting from a failure to observe these safety

precautions, misuse or abuse of pumps or equipment.

SEAL FAILURE

All motors have a probe installed in seal chamber near the

bottom so that any leakage past the lower seal into seal

chamber is detected.

A red warning light at the control panel comes on if water

enters seal chamber. This is an indicator only and does

not stop motor, but warns that seal should be replaced

immediately. RUNNING WITHOUT SEAL REPLACEMENT

COULD DAMAGE MOTOR.

HEAT SENSOR

All motors have a heat sensing thermostat installed in top

winding of motor. Any motor winding temperature above

248°F will open thermostat and stop motor. Thermostat

will automatically reset as soon as it has cooled.

CAUTION: WITH AUTOMATIC RESET, MOTOR CAN

START AT ANY TIME AFTER THERMOSTAT IS TRIPPED,

SO NEVER DO SERVICE WORK ON PUMP UNLESS

POWER SUPPLY IS DISCONNECTED.

IMPORTANT: BE SURE HEAT SENSOR WIRES AND

SEAL FAILURE WIRES ARE CONNECTED AT PANEL

TERMINAL BLOCK. WARRANTY IS VOID IF WIRES ARE

NOT CONNECTED OR ARE JUMPED.