Instruction Manual

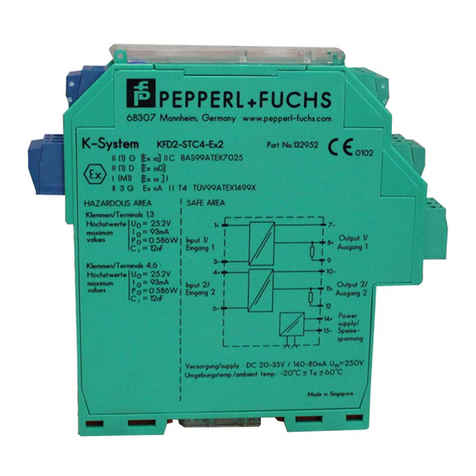

1. Marking

DC Power Supply

PSU1100-J1-DC-*

Equipment protection level Gb

ATEX marking: 1 II 2G Ex eb q IIC T4 Gb

IECEx marking: Ex eb q IIC T4 Gb

Equipment protection level Db

ATEX marking: 1 II 2D Ex tb IIIC T85°C Db

IECEx marking: Ex tb IIIC T85°C Db

DC Power Supply

PSU1200-J2-DC-*

Equipment protection level Gc

ATEX marking: 1 II 3G Ex ec q IIC T4 Gc

IECEx marking: Ex ec q IIC T4 Gc

Equipment protection level Dc

ATEX marking: 1 II 3D Ex tc IIIC T85°C Dc

IECEx marking: Ex tc IIIC T85°C Dc

The *-marked letters of the type code are placeholders for versions of the

device.

Pepperl+Fuchs Group

Lilienthalstraße 200, 68307 Mannheim, Germany

Internet: www.pepperl-fuchs.com

2. Target Group, Personnel

Responsibility for planning, assembly, commissioning, operation,

maintenance, and dismounting lies with the plant operator.

The personnel must be appropriately trained and qualified in order to carry

out mounting, installation, commissioning, operation, maintenance, and

dismounting of the device. The trained and qualified personnel must have

read and understood the instruction manual.

3. Reference to Further Documentation

Specific processes and instructions in this instruction manual require

special provisions to guarantee the safety of the operating personnel.

Observe directives, standards, and national laws applicable

to the intended use and the operating location.

Observe Directive 1999/92/EC in relation to hazardous areas.

Observe directives, standards, and national laws applicable to the

intended use and the operating location.

The corresponding datasheets, manuals, declarations of conformity, EU-

type examination certificates, certificates, and control drawings

if applicable (see datasheet) are an integral part of this document. You can

find this information under www.pepperl-fuchs.com.

For specific device information such as the year of construction,

scan the QR code on the device. As an alternative, enter the serial number

in the serial number search at www.pepperl-fuchs.com.

Due to constant revisions, documentation is subject to permanent change.

Please refer only to the most up-to-date version, which can be found under

www.pepperl-fuchs.com.

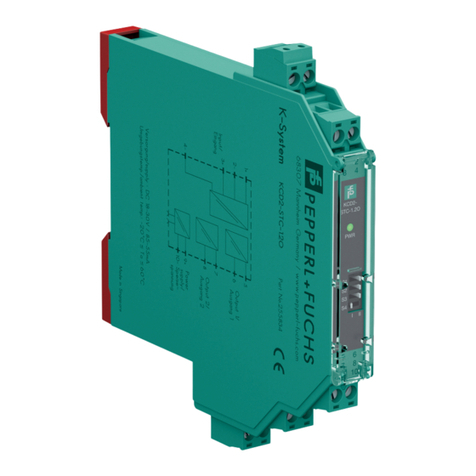

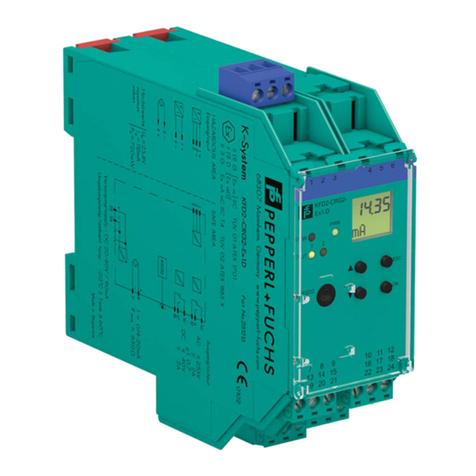

4. Intended Use

The device is an apparatus certified for use in hazardous areas rated

according to ATEX directive and IECEx Zones 1 and 21 and Zones 2

and 22 depending on the type version used. The device is also UL listed

for use in Class I and Class II, Division 2 and Class III hazardous areas.

The device is a DC-DC power supply. The device supplies explosion-

protected equipment in the hazardous area. The device provides an

output voltage of 24 V DC based on 18 V to 36 V DC input voltage.

The output power has a derating from 50 °C to 65 °C (80 W to 50 W).

The device is optimized to be used with the following devices:

lDisplay Unit DPU1*00-*

lThin Client Unit TCU1*00-*

lPC Unit PCU1*00-*

The device is only approved for appropriate and intended use.

Ignoring these instructions will void any warranty and absolve

the manufacturer from any liability.

Use the device only within the specified ambient and operating conditions.

Take the intended use of the connected devices from the corresponding

documentation.

The device is an electrical apparatus for hazardous areas.

Devices for which specific conditions of use apply have the X marking at

the end of the certificate number.

5. Improper Use

Protection of the personnel and the plant is not ensured if the device

is not used according to its intended use.

6. Mounting and Installation

Prior to mounting, installation, and commissioning of the device you

should make yourself familiar with the device and carefully read the

instruction manual.

Observe the installation instructions according to IEC/EN 60079-14.

The device must be disconnected from the power supply prior to

installation and maintenance. The power supply may be activated only

after all the circuits required for operation have been fully assembled and

connected.

The device is not suitable for separating hazardous areas.

The device may be installed in gas group IIC.

Safety-relevant markings are found on the nameplate supplied.

Ensure that the nameplate is present and legible. Take the ambient

conditions into account.

Only use accessories specified by the manufacturer.

Protect the circuit against overvoltage (e. g., lightning).

Supply the device with a power supply that meets the requirements for

safety extra-low voltage (SELV) or protective extra-low voltage (PELV).

Ensure that all fasteners are present.

Observe the tightening torque of the screws.

The housing has a ground connection. Connect to this ground connection

an equipotential bonding conductor with a minimum cross section of

4 mm2.

Connect all bare non-energized metal parts to the protective conductor.

Ensure that external ground connections exist, are in good condition, and

are not damaged or corroded.

Ensure that the terminals are in good condition and are not damaged

or corroded.

Only remove the cover in the absence of a potentially explosive

atmosphere.

Mount the device in a weatherproof location.

Ensure that the operating location has a sufficient floor load capacity.

If mounting the enclosure on concrete use expansion anchors.

When mounting the enclosure to a steel framework use vibration resistant

mounting material.

Protect the device against long-term or excessive mechanical vibrations.

The device is heavy. In order to avoid personal injuries or property

damage, make appropriate provisions for the mounting procedure.

Do not damage the breather drain.

Do not cover the breather drain.

Specific Conditions of Use

Mount the device in a location with low electrostatic charge.

6.1. Requirements for Cables and Connection Lines

Install the cables and connection lines in such a way that they are

protected from ultraviolet radiation.

Install cables and cable glands in a way that they are not exposed to

mechanical hazards.

The dielectric strength of the insulation must be at least 500 V according to

IEC/EN 60079-14.

Observe the permissible core cross section of the conductor.

The insulation stripping length must be considered.

When installing the conductors the insulation must reach

up to the terminal.

When using stranded conductors, crimp wire end ferrules

on the conductor ends.

Observe the minimum bending radius of the conductors.

The nominal core cross section of a connected conductor is 2.5 mm2

(solid, finely stranded, and stranded).

6.2. Requirements for Cable Glands

Use only one connection line per opening.

Use only one conductor per terminal.

Adjust the sealing element of the cable gland to the diameter of the cables

and connection lines used.

Ensure that all cable glands are in good condition and are securely

tightened.

6.3. Requirements in Relation to Electrostatics

Avoid electrostatic charges which could result in electrostatic discharges

while installing, operating, or maintaining the device.

Avoid inadmissibly high electrostatic charge of the cables and connection

lines.

Observe the maximum permissible length of cables and connection lines.

Include the metal housing components in the equipotential bonding.

An electrostatic charge poses an ignition hazard in case of discharge.

DOCT-4906D / 2023-06 1 / 2