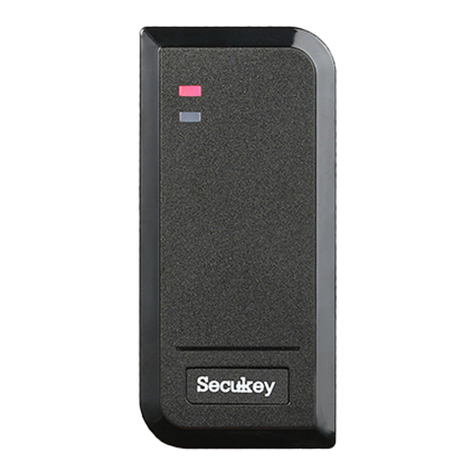

IR-04.1 Proximity Reader

9

7 POSSIBLE FAULTS AND REMEDY

Possible faults that can be resolved by the Customer and their remedy are given in the

table below:

FAULT POSSIBLE CAUSE REMEDY

At the power-up reader does not react

on card presentation No supply voltage to the

reader

Check the accuracy of

reader connection to power

supply

Reader reacts on card presentation but

there is no output data events for it and

LED indication does not light

No contact with external

controller via RS-485 Check the accuracy of

RS-485 connection.

If the fault is not cleared please contact the Manufacturer.

8 PERCO WARRANTY

PERCo (the Manufacturer) warrants that the IR-04.1 proximity reader complies with

applicable statutory safety requirements, electromagnetic compatibility provided that the

instructions on storage, installation and operation, given in the Assembly & Operation

Manual are observed.

The warranty period is 5 (five) years commencing from the date of sale.

Should there be no date of sale on the warranty card, the warranty period shall commence

from the date of manufacture specified in the Certificate and on the Product label.

In the post-warranty period the replacement parts/components are warranted to be free

from defects in material or workmanship for a period of 3 (three) months from the date of

shipment of the repaired/replaced Product to the Customer.

All claims with regard to quantity, completeness and defects to appearance of the Product

delivered are accepted by the Manufacturer in writing within no more than 5 (five) working

days after the products are received by the Customer. In case of failure to meet the

abovementioned deadline no claims are accepted.

The Warranty does not cover:

products, parts and components with:

- external mechanical damages resulting in the Product’s fault;

- defects resulting from Customer's improper testing, operation, installation,

maintenance, modification, alteration, or adjustment;

- damages due to force majeure circumstances (natural disasters, vandalism etc.)

or defects as a result of external circumstances (power surges, electric discharge,

etc);

fuses, accumulators, galvanic elements and other components, replacement of which

is performed by the Customer in accordance with the Product’s in-line

documentation.

To the maximum extent permitted by the acting law, the Manufacturer does not incur a

liability for any direct or indirect losses of the Customer, including but not limited to loss of

profit or data, losses caused by idle period, missed profit, and etc related to use or

impossibility to use products and software, including possible software errors and failures.

Within the warranty period the products are repaired free of charge at the Manufacturer’s

site. The Manufacturer reserves the right to repair failed product or replace it with an

operational one. Time of repair is specified at the moment the Product is accepted for

repair. Transportation cost to and back from the place of repair shall be borne by the

Customer.