Certificate & Operation Manual

2. TECHNICAL SPECIFICATIONS

Rated operating voltage......................................................................................... 12VDC

Operating voltage limits............................................................................... 10.5 – 14VDC

Consumption current ........................................................................................ max. 60 mA

Power consumption ......................................................................................... max. 0.85 W

Card reading distance at the rated operating voltage for different card (trinket) types:

HID ProxCard II cards .............................................................................. min. 6 cm

EM-Marin cards ........................................................................................ min. 8 cm

Trinkets .................................................................................................... min. 4 cm

Card reading distance at reader mounting on metal base-plate for different card (trinket)

types:

HID ProxCard II cards .............................................................................. min. 5 cm

EM-Marin cards ........................................................................................ min. 7 cm

Trinkets .................................................................................................... min. 3 cm

Controller connection interface ............................................................................. Wiegand

Output and operation signal voltage:

Logic «1» ................................................................................................. min. 4.3 V

Logic «0» ................................................................................................ max. 0.4 V

Distance between the reader and external controller ........................................ max. 150 m

Connection cable standard length .............................................................................. 0.9 m

Ingress protection rating ........................................................................... IP54 (EN 60529)

Electric shock protection class ...................................................................... III (IEC 61140)

Resistance to mechanical factors, according to GOST17516-72 .................................... M4

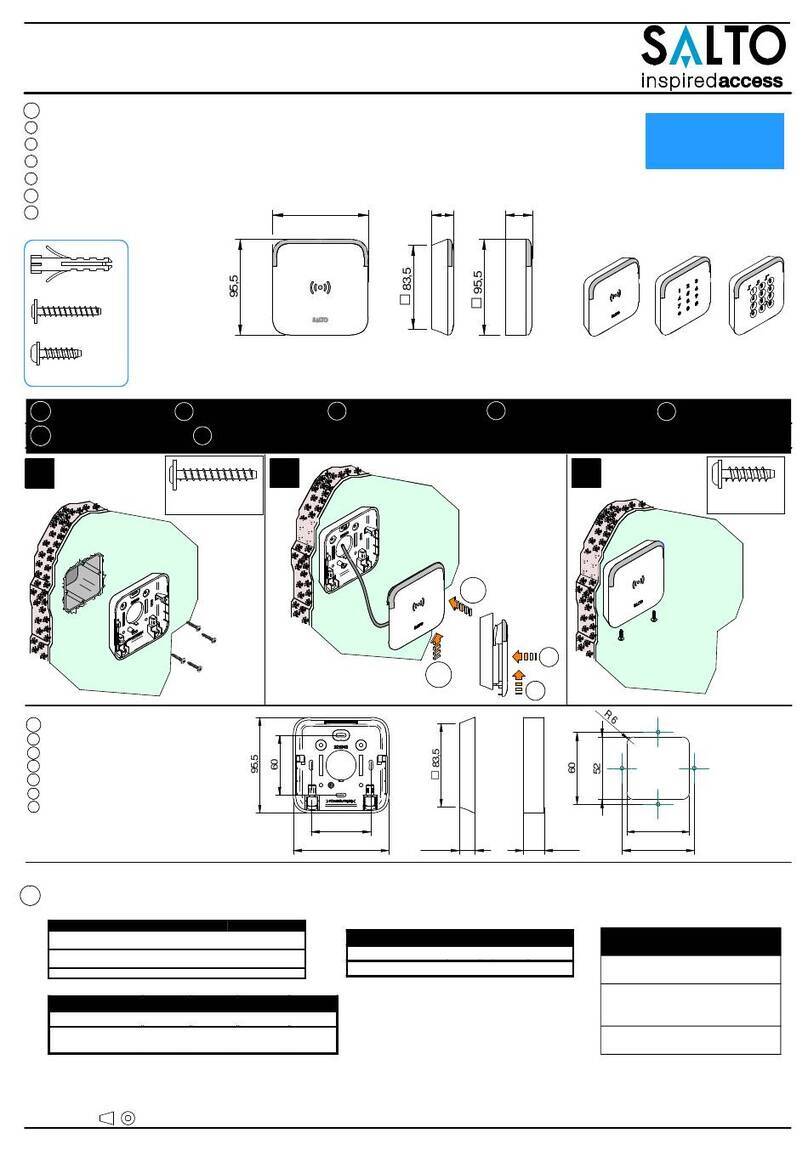

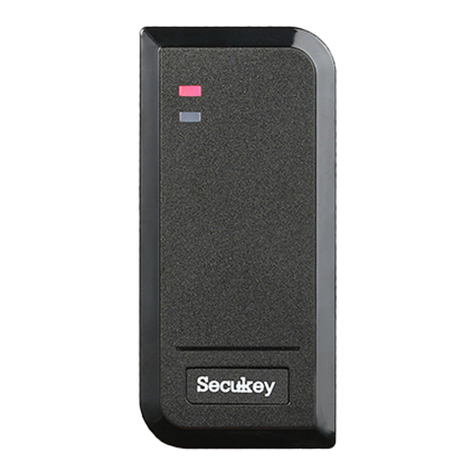

Reader dimensions (without cable) ............................................................. 1454623 mm

Reader weight .................................................................................................... max. 220 g

3. DELIVERY SET

Reader RP-15.2 ............................................................................................................ 1

Metal base-plate ........................................................................................................... 1

Assembly set:

Plastic dowels ..................................................................................................... 4

Screws ................................................................................................................ 4

Package ........................................................................................................................ 1

Certificate and Operation Manual ................................................................................. 1

As a power supply it is recommended to use DC source with linear voltage stabilization and

output pulsation amplitude max. 50 mV.

4