IMPORTANT SAFETY INFORMATION

Clean air of correct air pressure is recommended for the power supply for this tool. A

maximum of 90 PSI at the tool is recommended for most air tools of this class. Check

specifications section for recommended pressure. (Depending on length of air hose and

other circumstances, air pressure at compressor may need to be increased to 100 PSI to

ensure 90 PSI at the tool.)

Water in the air hose and compressor tank contributes to reduced performance and

damage of the air tool. Drain the air tank and filters before each use and as necessary to

keep the air supply dry.

Hose length over 25’ causes loss in line pressure. Increase hose I.D. or increase

compressor pressure to compensate for the pressure loss. Use an in-line pressure

regulator with gauge if air inlet pressure is critical.

AIR SOURCE

13. Check for damaged parts. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts

or mounting fixtures; and any other condition that may affect proper operation. Any

part that is damaged should be properly repaired or replaced by a qualified technician.

14. Maintenance. For your safety, maintenance should be performed regularly by a

qualified technician using original PERFORMANCE TOOLS® replacement parts.

Failure to do so can lead to accidents for the operator. Use of any other parts will void

the warranty. Only use accessories intended for use with this tool. Approved

accessories are available from Performance Tool®. Use only accessories that are

recommended by the manufacturer for your model. Accessories that may be suitable

for one tool may become hazardous when used on another tool.

WARNING: Repetitive motions or exposure to vibration may be harmful to your hands and arms.

WARNING: This product and its packaging contain a chemical known to the State of California

to cause cancer, birth defects, or other reproductive harm.

WARNING: The warnings, cautions, and instructions discussed in this instruction manual cannot

cover all possible conditions and situations that may occur. It must be understood by the

operator that common sense and caution are factors which cannot be built into this product, but

must be supplied by the operator. Read and understand all of the instructions provided in the

instruction manual of this product, as well as, any other tool (s) used with this product.

1. If an automatic oiler is not used, add a few drops of pneumatic tool oil to the airline

connection before use. Add a few more drops after each hour of continual use.

2. While the air hose is disconnected from the tool, unscrew the Blade Retainer (9) and

install the desired blade. Screw the Blade Retainer (9) back on, holding the blade and

tighten securely.

3. Attach the air hose to the air source. While holding the air knife firmly in one hand and

the other safely out of the way of the blade, turn the air source on.

4. To begin use, push the safety catch on the Throttle Lever (23) forward by pushing the

top of the device forward. A stable two-handed grip on this tool is best.

5. Depress the Throttle Lever (23) to activate the air knife blade.

6. If the tool requires more force to accomplish the task, verify that the tool receives

sufficient, unobstructed airflow (CFM) and increase the pressure (PSI) output of the

regulator up to the maximum air pressure rating for this tool.

CAUTION! To prevent tool and accessory failure, resulting in injury:

- Do not exceed the tools maximum air pressure rating of 90 PSI.

If the tool still does not have sufficient force at maximum pressure and sufficient airflow,

then a larger tool may be required.

7. To prevent accidents, turn off the tool by releasing the Throttle Lever (23), detach the air

supply, safely discharge any residual air pressure in the tool after use. Clean external

surfaces of the tool with clean, dry cloth, and apply a thin coat of tool oil. Then store the

tool indoors out of children's reach.

8. Do not remove the safety catch. It has been included for your safety. Without it, the tool

could activate when the tool is bumped against something, set down on its lever, or

when someone picks up the tool, accidently pressing on the Throttle Lever (23)

activating the blade.

VIBRATION PRECAUTIONS

Air Hose

Blade Retainer

Throttle Lever

OPERATION

This tool vibrates during use. Repeated or long-term exposure to vibration may cause

temporary or permanent physical injury, particularly to the hands, arms and shoulders. To

reduce the risk of vibration-related injury:

1. Anyone using vibrating tools regularly or for an extended period should first be examined

by a doctor and then have regular medical check-ups to ensure medical problems are

not being caused or worsened from use. Pregnant women or people who have impaired

blood circulation to the hand, past hand injuries, nervous system disorders, diabetes, or

Raynaud's Disease should not use this tool. If you feel any medical or physical

symptoms related to vibration (such as tingling, numbness, and white or blue fingers),

seek medical advice as soon as possible.

2. Do not smoke during use. Nicotine reduces the blood supply to the hands and fingers,

increasing the risk of vibration-related injury.

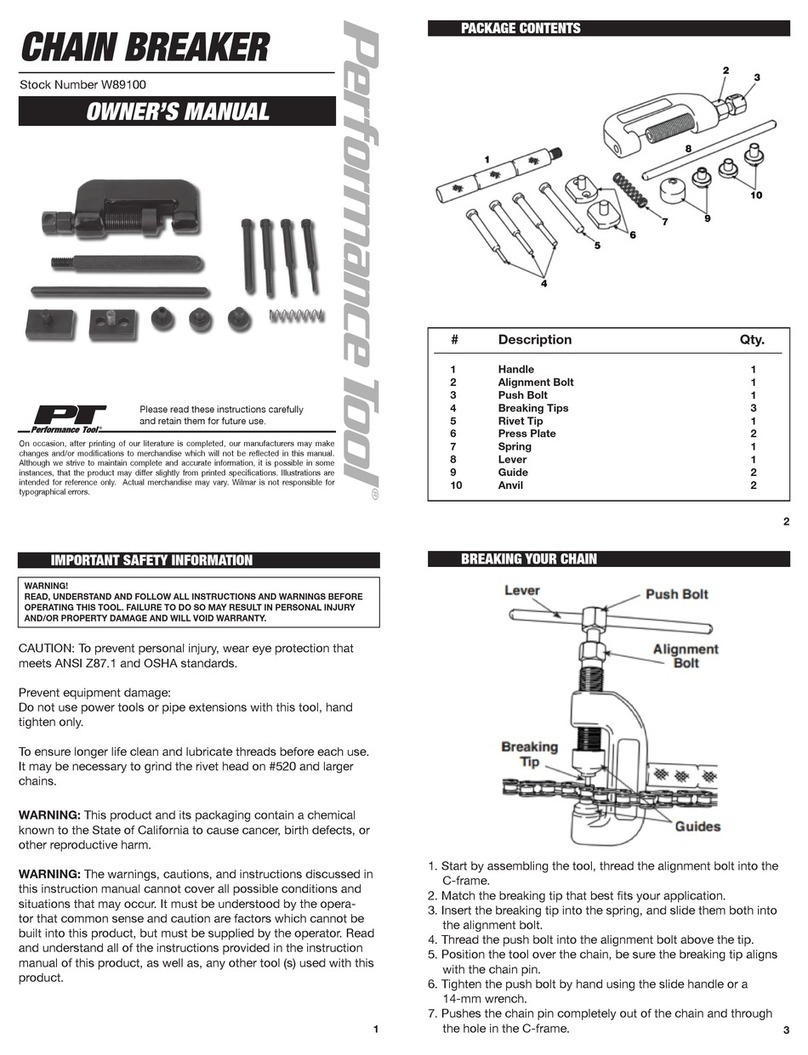

CHANGING BLADES

1. Remove the Blade Retainer (9C) using the Hex Key Wrench (41). The blade can be

mounted in 12 different positions at 30˚ increments.

2. Retighten the Blade Retainer (9C) and check all screws to ensure they are on tight and

secure.

Blade