Before You Begin

Site Preparation

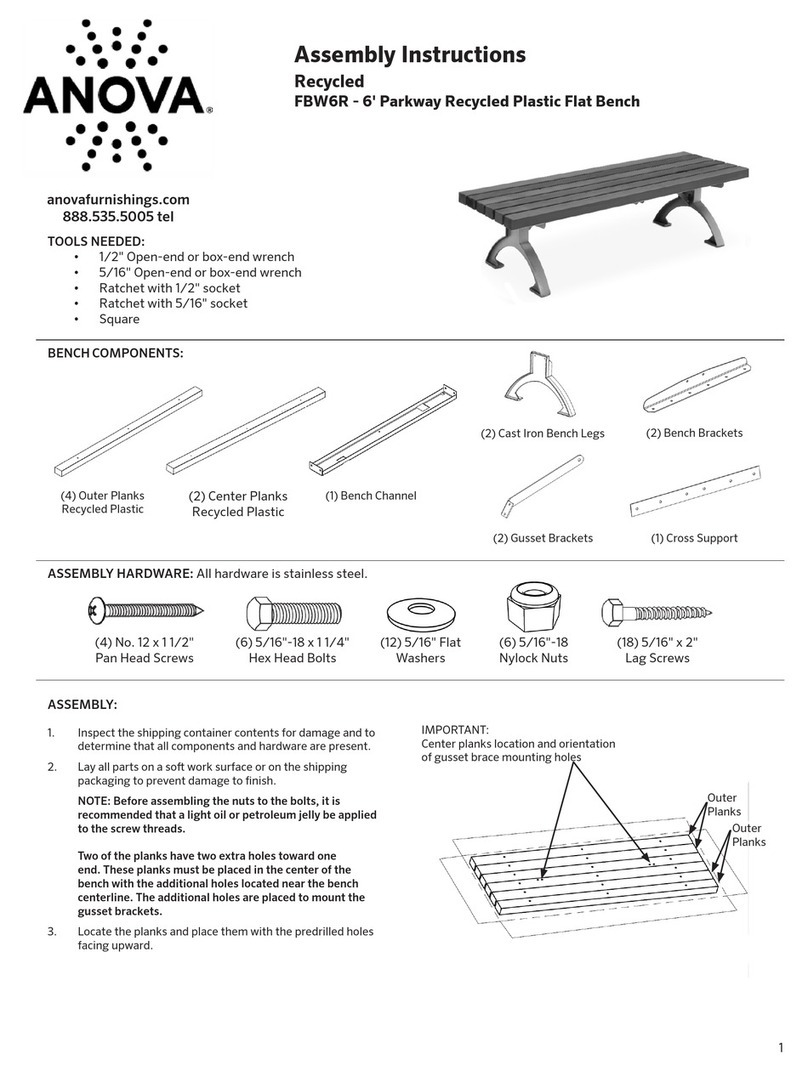

Tools Needed

2

Please always check with your local building codes, they will vary from state to state.

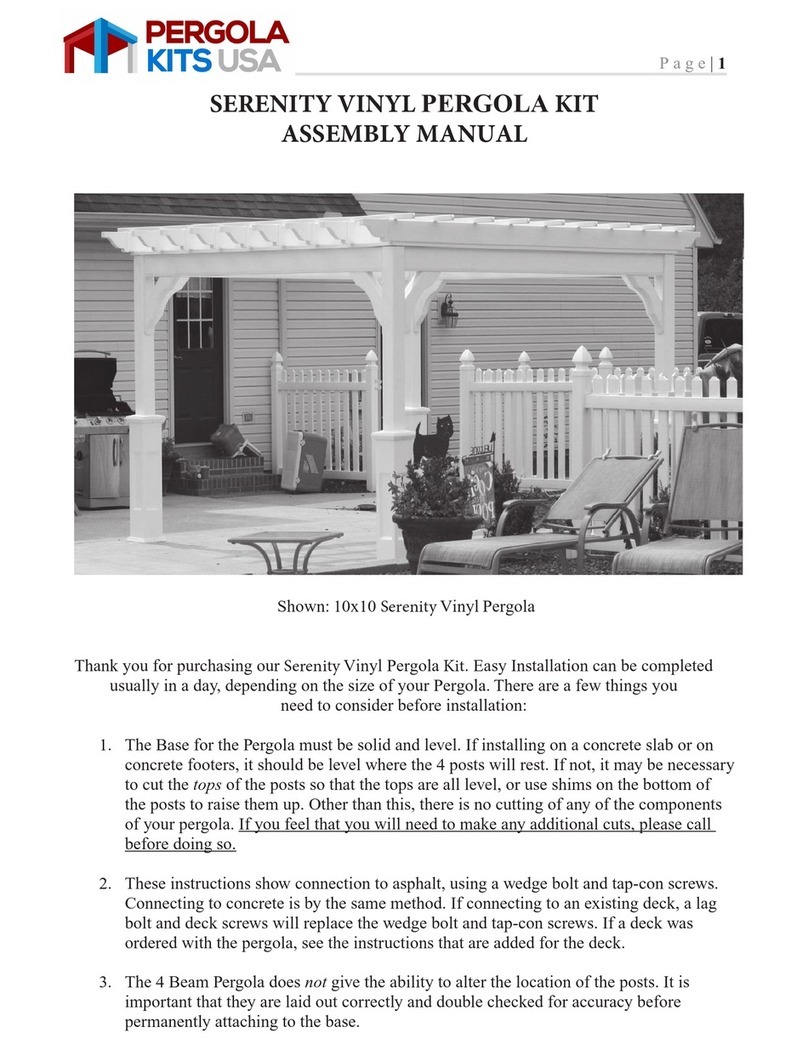

The base for the Pavilion must be solid and level. If installing on a concrete slab or on concrete footers, they

should be level where the posts will rest. If they are not, it may be necessary to cut the bottom of the posts

so that the bottoms are all level. Other than this, no cutting is necessary. If you feel that you will need to

make any additional cuts, please contact us before doing so. Making cuts without calling first may make

installation difficult or void our warranties.

When connecting to concrete, use wedge bolts, which are included in the kit. If connecting to an existing

deck, a lag bolt and deck screws (not included) will replace the wedge bolt.

The Pavilion does not give the ability to alter the location of the posts. It is important that they are laid out

correctly and double checked for accuracy before permanently attaching it to the base.

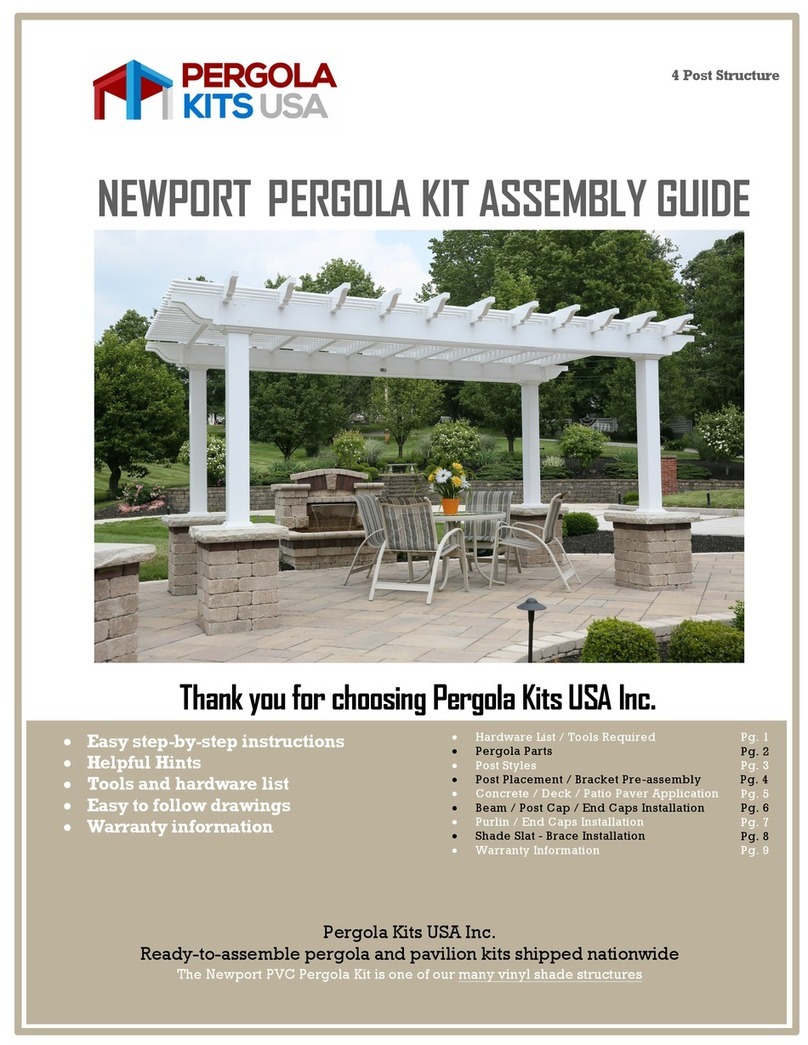

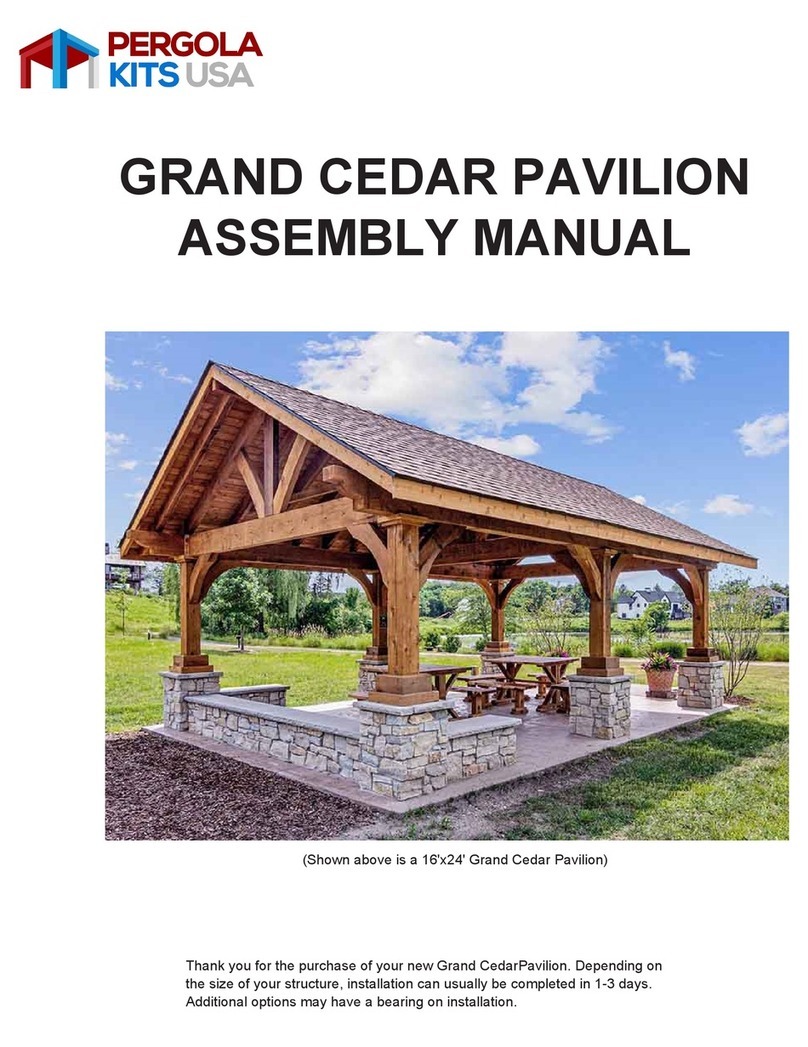

NOTE: These instructions are for building a standard, rectangular pavilion. “Eaves side” references the long

side and “gable side” references the short side (See front page image). If your pavilion has custom dimen-

sions with a longer gable side or square dimensions with equal sides, this reference point will need to be

adjusted appropriately by the builder during installation. CALL WITH ANY QUESTIONS.

It is important that the site is properly prepared before beginning assembly. It is imperative that the site

be level. There are a few choices when installing this structure, the two most common are to anchor the

posts to concrete pad/wood decking or attaching to a concrete footer or two Sonotubes. Sinking the

posts into the ground is not recommended unless it is called for by your local building codes.

Anchoring the posts to concrete/wood decking, is the most common method and is also the simplest.

Please provide a level concrete or wood decking surface, and then lay out the template on the surface.

Mark out the squares where the posts and brackets will go. Line up the markings that were made and

this is where to set the posts. Posts cannot be anchored into loose pavers or stone. Customer assumes risk

if not anchored into concrete or decking joists. This is the method that will be used for the following

instructions:

Please check with the local building codes for the depth required for the footers/concrete slab. Also if

using concrete footers make sure that all of the tops of the footers are level with each other before

starting to build. Contact your Project Advisor with any questions that you may have.

Hammer drill, hammer, level, tape measure, C clamps, socket set, ladder, circular saw