Dx350_06d_oi_e.docx / Jul-20 page 4 / 67

Table of Contents

Safety Instructions and Responsibility ..........................................................................6

General Safety Instructions.............................................................................................................6

Use according to the intended purpose ..........................................................................................6

Installation.......................................................................................................................................7

EMC Guidelines ...............................................................................................................................8

Cleaning, Maintenance and Service Notes ....................................................................................8

Introduction ..................................................................................................................9

Operation mode ...............................................................................................................................9

Function diagram ...........................................................................................................................10

Electrical Connections ................................................................................................11

DC Power Supply ...........................................................................................................................11

Auxiliary Voltage Output ...............................................................................................................11

DX350: Incremental Input A, B......................................................................................................12

DX355: Incremental Input A, /A, B, /B ..........................................................................................13

Control Inputs ................................................................................................................................14

Analog Output (Option AO/AR) .....................................................................................................14

Serial interface (Option AO/AR/CO/CR)........................................................................................15

Control-Output (AO/AR/CO/CR) ....................................................................................................15

AC Power supply (Option AC)........................................................................................................16

Relay-Output (Option RL)...............................................................................................................16

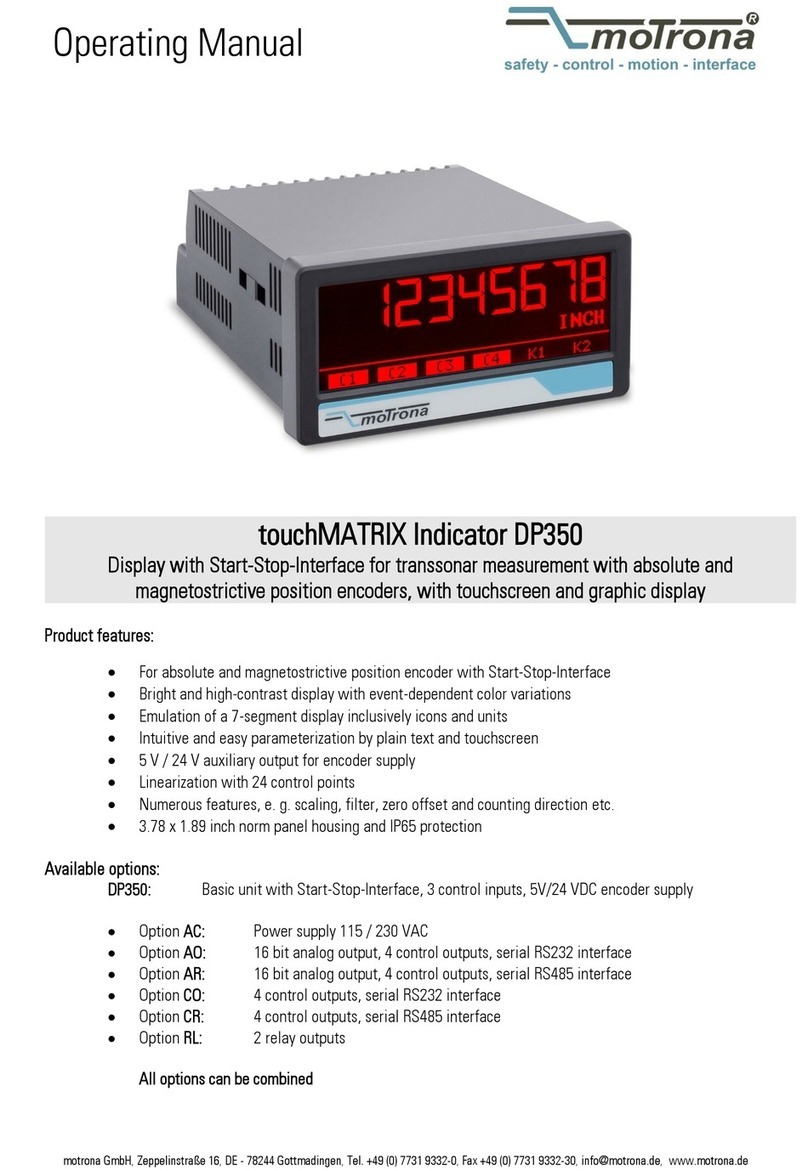

Display and touch screen............................................................................................17

Screen structure for parametrization ............................................................................................17

Screen structure in operation........................................................................................................18

Error messages ..............................................................................................................................19

Parameter / Overview-Menu Structure .......................................................................21

General Menu................................................................................................................................23

Mode Speed ..................................................................................................................................26

Mode Process Time .......................................................................................................................28

Mode Timer ...................................................................................................................................30

Mode Counter................................................................................................................................32

Mode Velocity................................................................................................................................34

Preselection Values .......................................................................................................................36

Preselection 1 Menu......................................................................................................................37

Preselection 2 Menu......................................................................................................................41

Preselection 3 Menu......................................................................................................................42

Preselection 4 Menu......................................................................................................................43

Serial Menu ...................................................................................................................................44

Analog Menu .................................................................................................................................46

Command Menu ............................................................................................................................48

Display Menu.................................................................................................................................50

Linearization Menu........................................................................................................................53

Appendix ....................................................................................................................54

Data readout via serial interface ..................................................................................................54

Modbus RTU Interface...................................................................................................................55

Parameter setting.................................................................................................................................................55

Modbus Communication ......................................................................................................................................56