Copyright Phason Inc. Printed in Canada

All rights reserved. 32943003

Table of contents

Chapter 1: Introduction ..................................................................................................... 4

Introducing AutoFlex Connect .................................................................................................................. 4

Features ................................................................................................................................................ 4

Available modules ................................................................................................................................. 5

Chapter 2: Installation ....................................................................................................... 7

What you need to know before installing.................................................................................................. 7

Understanding power surges and surge suppression ......................................................................... 7

Reducing electrical noise using filters .................................................................................................. 8

Electrical ratings.................................................................................................................................... 9

Using power contactors to increase the capacity of relays .................................................................. 9

Enclosure dimensions and mounting guidelines.................................................................................. 9

AutoFlex layout.................................................................................................................................... 11

AutoFlex Mini layout ............................................................................................................................ 12

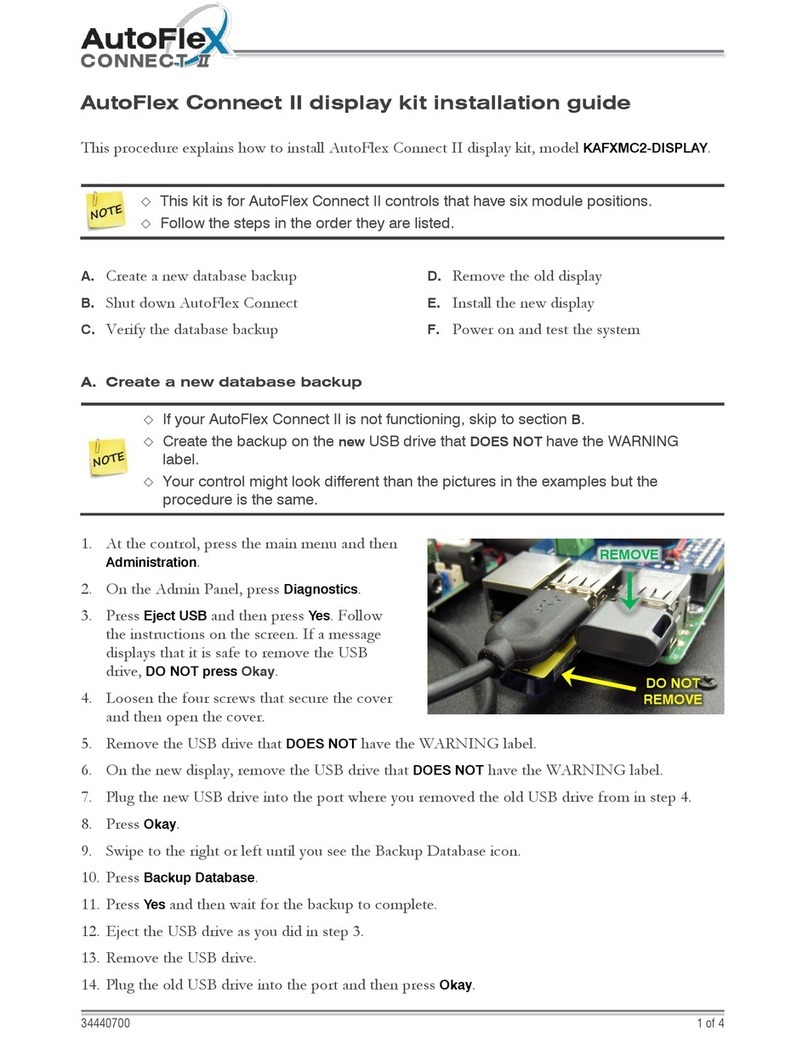

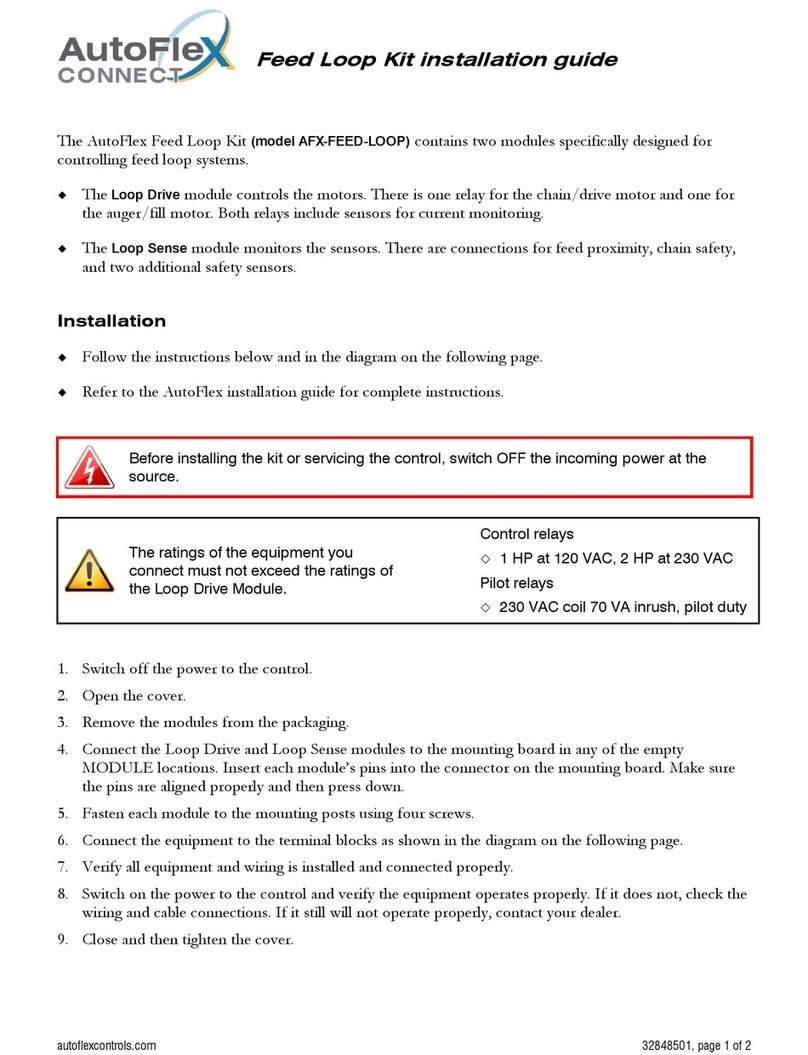

Connecting equipment to modules ........................................................................................................ 13

Connecting equipment to Actuator Modules...................................................................................... 13

Connecting sensors and devices to Input Modules ........................................................................... 15

Connecting equipment to Relay Modules........................................................................................... 18

Connecting equipment to Variable AC Modules................................................................................. 20

Connecting equipment to Variable Chimney Modules ....................................................................... 21

Connecting equipment to Variable DC Modules ................................................................................ 22

Connecting an alarm system .............................................................................................................. 23

Connecting the power source............................................................................................................. 25

Finishing the installation.......................................................................................................................... 25

Chapter 3: Network configuration................................................................................... 26

Remote access........................................................................................................................................ 26

UPnP security tips ............................................................................................................................... 27

Networking options ................................................................................................................................. 27

IP addressing: DHCP or static IP ........................................................................................................ 28

Port forwarding: UPnP or manual forwarding..................................................................................... 29

Chapter 4: Getting started............................................................................................... 31

Logging in ............................................................................................................................................... 31

Getting around ........................................................................................................................................ 32

Create users............................................................................................................................................ 32

Select the AutoFlex type ......................................................................................................................... 33

Select the units of measure..................................................................................................................... 33

Creating zones ........................................................................................................................................ 34

Checking for modules............................................................................................................................. 34

Assigning hardware to zones.................................................................................................................. 35

Adjusting the zone set point ................................................................................................................... 35

Adjusting equipment settings ................................................................................................................. 36

Using the Home page ............................................................................................................................. 36

Appendixes ..................................................................................................................... 37

Appendix A: Troubleshooting ................................................................................................................. 37

Appendix B: Calibrating and troubleshooting actuators......................................................................... 39