I/C FLIGHT GUIDELINES

Made in Vietnam

When ready to fly, first extend the

transmitter aerial.

Operate the control sticks on the

transmitter and check that the control

surfaces move freely and in the

CORRECT directions. ALWAYS land the model INTO the

wind, this ensures that the model lands

at the slowest possible speed.

Switch on the transmitter.

Switch off the transmitter.

Check that the transmitter batteries

have adequate power.

Switch off the receiver.

Switch on the receiver. ALWAYS take off into the wind.

Check that the wings are correctly

fitted to the fuselage. If the model does not respond correctly

to the controls, land it as soon as

possible and correct the fault.

Empty the fuel tank after flying, fuel left

in the tank can cause corrosion and

lead to engine problems.

I/C FLIGHT WARNINGS

Always operate in open areas, away

from factories, hospitals, schools,

buildings and houses etc. NEVER fly

your aircraft close to people or built

up areas.

THE PROPELLER IS DANGEROUS

Keep fingers, clothing (ties, shirt

sleeves, scarves) or any other loose

objects that could be caught or drawn

in, away from the propeller. Take care

at ALL times.

Keep all onlookers (especially small

children and animals) well back from

the area of operation. This is a flying

aircraft, which will cause serious

injury in case of impact with a person

or animal.

NEVER fly near power lines, aerials

or other dangerous areas including

airports, motorways etc.

NEVER use damaged or deformed

propellers or spinners.

DO NOT dispose of empty fuel

containers on a fire, this can lead to

an explosion.

NEVER fly in wet conditions or on

windy or stormy days.

ALWAYS adjust the engine from

behind the propeller, and do not allow

any part of your body to be in line

with the propeller.

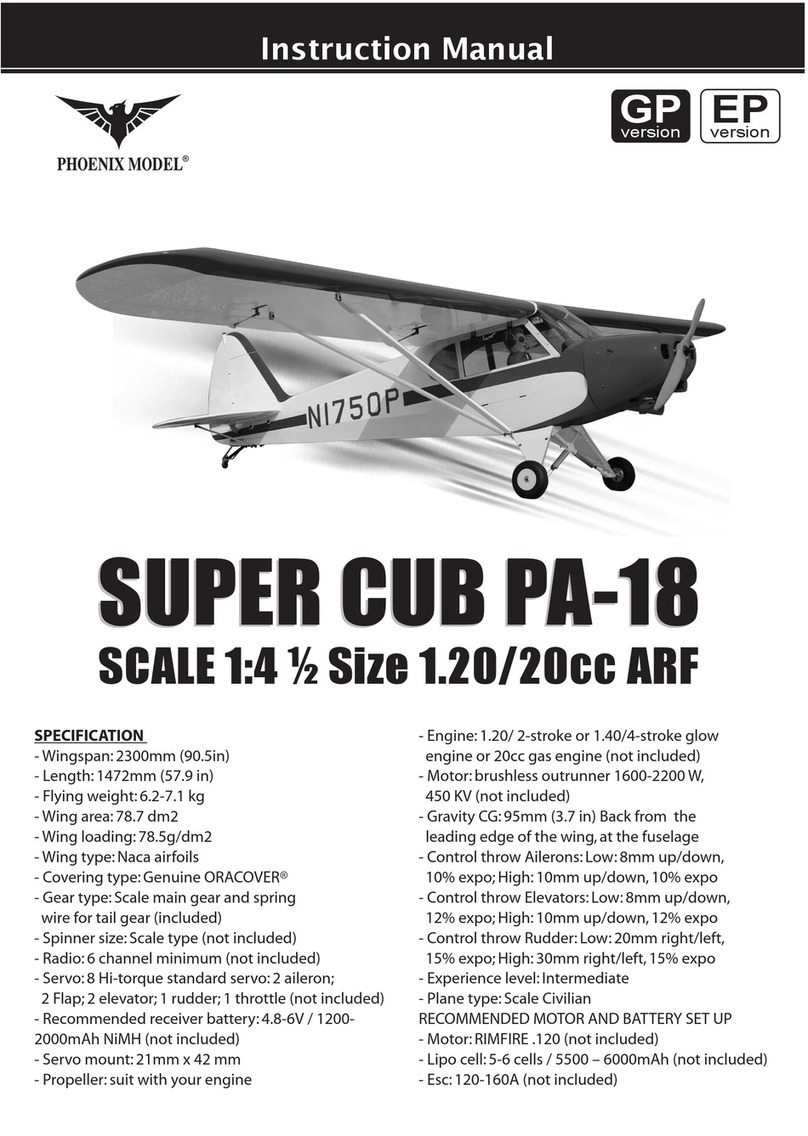

SPECIFICATION

- Wingspan: 1290mm (50.7 in)

- Length: 1778mm (70 in)

- Flying weight: 7000-7400 gr

- Wing area: 48 dm2

- Wing loading: 145g/dm2

- Wing type: Naca airfoils

- Covering type: Genuine ORACOVER®

- Retract gear type: Air retract gear with CNC

Suspension Metal Struts (included)

- Radio: 6 - 9 channel . 8 mini hi-torque servo

(Hitec HS5245MG): 2 aileron; 2 flap; 1 steering

nose; 1 retract valve ; 2 rudder ; 2 standard

hi-torque servo (minimum 9kg) for 2 elevator

(not included)

- Engine: edf 120mm (not included)

- Gravity CG: 95mm (3,8 in) Back from the

leading edge of the wing, at the fuselage

- Control throw Ailerons: Low: 7mm up/down,

10% expo; High: 10mm up/down, 10% expo

- Control throw Elevators: Low: 11mm up/down,

12% expo; High: 15mm up/down, 12% expo

- Control throw Rudder: Low: 10mm right/left,

15% expo; High: 20mm right/left, 15% expo

- Control throw flap : Mid : 15mm down;

Landing : 20mm down

- Experience level: advanced

RECOMMENDED EDF AND BATTERY SET UP

- EDF: 120mm, Minimum thrust 7 kg. As BVM 3-12S

EVF or Ramtec 120mm …(not included)

- Lipo cell: 12 cells / 5000- 6000mAh 60C

(not included)

- Esc HV 160A Phoenix Casttle (not included)

Instruction Manual

2

THUNDER STREAK

Instruction Manual

TOOLS AND SUPPLIES NEEDED

• Medium C/A glue

• 30 minute epoxy

• 6 minute epoxy

• Hand or electric drill

• Assorted drill bits

• Modeling knife

• Straight edge ruler

SUGGESTION

To avoid scratching your new airplane, do not unwrap

the pieces until they are needed for assembly. Cover

your workbench with an old towel or brown paper,

both to protect the aircraft and to protect the table.

Keep a couple of jars or bowls handy to hold the

small parts after you open the bag.

NOTE:

1. Please trial fit all the parts. Make sure you have

the correct parts and that they fit and are aligned

properly before gluing! This will assure proper

assembly. The THUNDER STREAK EDF 120MM

SCALE 1:6 ARF is hand made from natural

materials, every plane is unique and minor

adjustments may have to be made. However, you

should find the fit superior and assembly simple.

2. The painted and plastic parts used in this kit are

fuel proof. However, they are not tolerant of many

harsh chemicals including the following: paint

thinner, C/A glue accelerator, C/A glue debonder

and acetone. Do not let these chemicals come in

contact with the colors on the covering and the

plastic parts.

1

• 2 bender plier

• Wire cutters

• Masking tape

• Thread lock

• Paper towels

• Rubbing alcohol

PREPARATIONS

Remove the tape and separate the ailerons

from the wing and the elevators from the stab.

Use a covering iron with a covering sock on

high heat to tighten the covering if necessary.

Apply pressure over sheeted areas to

thoroughly bond the covering to the wood.

INSTALLING THE AILERONS

1. Test fit the ailerons to the wing with the hinges.

If the hinges don’t remain centered, stick a pin

through the middle of the hinge to hold it in

position.

TEMPORARY PIN

TO KEEP HINGE

CENTERED

2. Apply six drops of thin CA to the top and bottom

of each hinge. Do not use CA accelerator. After

the CA has fully hardened, test the hinges by

pulling on the aileron.

C.A glue

1

Remove the covering

3

INSTALLING THE AILERON SERVOS

1. Install the rubber grommets and brass eyelets

onto the aileron servo.

2. Using a modeling knife, remove the covering

from over the pre-cut servo arm exit hole on the

aileron servo tray / hatch. This hole will allow

the servo arm to pass through when installing

the aileron pushrods.

7

To the cowl

THUNDER STREAK

Instruction Manual

2

3. Place the servo into the servo tray. Center the

servo within the tray and drill 1,6mm pilot holes

through the block of wood for each of the four

mounting screws provided with the servo.

4

4. Using the thread as a guide and using masking

tape, tape the servo lead to the end of the

thread: carefully pull the thread out. When you

have pulled the servo lead out, remove the

masking tape and the servo lead from the

thread.

Servo lead

5

5. Place the aileron servo tray / hatch into the

servo box on the bottom of the wing and drill

pilot holes through the tray and the servo box

for each of the four mounting screws. Secure

the servo tray in place using the mounting

screws provided ( 2mm x 12mm ).

6. Repeat step # 2 - # 5 to install the second

aileron servo in the opposite wing half.

INSTALLING THE CONTROL HORNS

1. Remove the covering from the slot on the

bottom of the aileron.

2. Insert the control horn into the slot and secure it

by using C.A glue.

6

To the cowl

8

Remove the covering

9

3. Repeat step # 1 - # 2 to install the control horn

on the opposite aileron.

C.A glue

control

THUNDER STREAK

Instruction Manual

3

INSTALLING THE AILERON LINKAGES

1. Working with the aileron linkage for now, thread

one clevis at least 14 turns onto one of the

threaded wires.

8. Insert the 90 degree bend down through the

hole in the servo arm. Install one nylon snap

keeper over the wire to secure it to the arm.

Install the servo arm retaining screw and

remove the masking tape from the aileron.

9. Repeat step # 4 - # 8 to install the second

aileron linkage. After both linkages are

completed, connect both of the aileron servo

leads using a Y-harness you have purchased

separately.

Silicone Tube

13

10

11

2. Attach the clevis to the outer hole in the control

horn. Install a silicone tube on the clevis.

3. Locate one nylon servo arm, and using wire

cutters, remove all but one of the arms. Using a

2mm drill bit, enlarge the third hole out from the

center of the arm to accommodate the aileron

pushrod wire.

4. Plug the aileron servo into the receiver and

center the servo. Install the servo arm onto the

servo. The servo arm should be perpendicular

to the servo and point toward the middle of the

wing.

5. Center the aileron and hold it in place using a

couple of pieces of masking tape.

6. With the aileron and aileron servo centered,

carefully place a mark on the aileron pushrod

wire where it crosses the hole in the servo arm.

7. Using pliers, carefully make a 90 degree bend

down at the mark made. Cut off the excess

wire, leaving about 4mm beyond the bend.

12

INSTALLING THE CONTROL HORNS for flap

Repeat step #1 - #3 from installing the control

horn for aileron to install the control horn for

flap.

INSTALLING THE flap LINKAGE

Repeat step #1 - #9 from installing the aileron

linkage to install the flap linkage.

14

THUNDER STREAK

Instruction Manual

13

Aileron Control

7mm

7mm

Rudder Control

10mm

10mm

Flap Control

15mm

Elevator Control

11mm

11mm

LATERAL BALANCE

After you have balanced a plane on the C.G.

You should laterally balance it. Doing this will

help the airplane track straighter.

5. Turn the airplane upside down. Attach one loop

of heavy string to the engine crankshaft and

one to the tail wheel wire. With the wings level,

carefully lift the airplane by the string. This may

require two people to make it easier.

6. If one side of the wing fall, that side is heavier

than the opposite. Add small amounts of lead

weight to the bottom side of the lighter wing

half's wing tip. Follow this procedure until the

wing stays level when you lift the airplane.

CONTROL THROWS

1. We highly recommend setting up a plane using

the control throws listed.

2. The control throws should be measured at the

widest point of each control surface.

3. Check to be sure the control surfaces move in the

correct directions.

Ailerons : 7mm up 7mm down

Elevator : 11mm up 11mm down

Rudder : 10mm right 10mm left

Flap T/O: 15mm - Landing 20mm

LOW RATE

95mm

55

8. Remove the covering.

56

Remove the

covering

Remove the covering

51

54

7. Repeat these step from installing the aileron

linkages to install the rudder linkages.

4. Secure the servo plate.

5. Remove the covering.

53

C.A glue

52

Remove the covering

6. Install and glue the rudder control horn.

50

3. Install the rudder servo.

Screw

9. Remove the covering from the fuselage.

49

Remove the covering

2. Remove the covering.

THUNDER STREAK

Instruction Manual

9

INSTALLING THE VERTICAL STABILIZER

1. Repeat these step from the installing aileron for

the installing rudder.

48

C.A glue

47

41

C.A glue

4. Insert the carbon tube to the elevator and glue

it by C.A glue.

44

42

Screw

43

Screw

Elevator servo

46

Clevis M3 Link-ball M3

INSTALLING THE ELEVATOR LINKAGES

40mm

Make the same way from installing the aileron

linkages for installing the elevator linkges.

5. Attach and secure the horizontal stabilizer to

the fuselage using aluminum control horn. Each

control horn secure by 2 screw and using “Loctite”

lock these screw.

6. Make the same way for the second elevator.

THUNDER STREAK

Instruction Manual

8

45

63

64

1. Slide the air inlet to the fuselage.

4. Wooden ring for EDF (Included with the kit) to

connect the air outlet. (using this part when the

out side dimension of EDF smaller than the

inside dimension of the air outlet). If your EDF

is 3-12S BVM, this part must be used.

5. Secure the EDF.

60

61

62

INSTALLING THE EDF (Electric ducted fan)

system

2. Trim 1 hole from the air outlet for the wires of EDF.

3. Slide the air outlet to the fuselage.

59

58

Epoxy glue

Wooden ring

Remove the covering

10. Slide the extension servo lead through the

fuselage. Install the vertical stabilizer and glue it

using epoxy glue.

57

Servo lead

THUNDER STREAK

Instruction Manual

10 Screw

THUNDER STREAK

Instruction Manual

6

31

Crimp

32

M3 Clevis

34

33

35

Metal connectorZip tie

36

Air tank

1. Install the servo to the fuselage.

2. The air valve.

3. Attach the air valve to the servo.

4. Install the air tank.

5. Connect the air tube to the air valve control as

drawing below.

INSTALLING THE AIR CONTROL SYSTEM

8. Slide and secure two cable rod to the nose gear.

9. Slide and secure two cable rod to the steering

arm servo.

THUNDER STREAK

Instruction Manual

7

37

38

INSTALLING THE HORIZONTAL STABILIZER

We are hightly recommended using the digital

servo with the minimum torque 9kg.

1. Install two elevator servo to the fuselage.

40

Remove the covering

3. Remove the covering from the Horizontal

Stabilizer for the elevator joiner.

2. Carbon tube and aluminum arm control.

39

INSTALLING THE LANDING GEAR

SUPERLOCK AIR RETRACTS

VALUE ONE WAY

3 WAY CONNECTOR

AIR SUPPLY

VALVE CONTROL

4 WAY

CONNECTOR

4 WAY CONNECTOR

SERVOAIR TANK

MAIN GEAR

MAIN GEAR

NOSE GEAR

65

6. Slide and fix the air outlet.

THUNDER STREAK

Instruction Manual

11

67

C.A glue

68

66

C.A glue

70

9. Trim the plastic inlet lip.

8. Glue the wooden belt to the air inlet.

10. Glue the plastic inlet lip to the fuselage using

C.A glue.

71

72

69

7. The wooden belt for EDF (Included with the kit)

to connect the air inlet to the EDF.

Air cooling exhaust plastic

C.A glue

Wooden

belt

C.A glue

INSTALLING THE MAIN AIR RETRACT gear

1. Trim the plastic wheel well.19

Air tube

4. Place the retract to the wing and pull out the air

tube through the wing section.

21

Screw

22

Screw

20

Screw

7. Lock-up the axle.

THUNDER STREAK

Instruction Manual

4

16

15

3. Install the tube to the air retract.

2. Glue the plastic wheel well in place.

17

6. Install and secure the wheel.

5. Secure the retract.

C.A glue

18

350mm

350mm

4. Install the tube to the air retract.

5. Secure the air retract.

28

Screw

25

26

C.A glue

Steering nose servo

24

3. Install the steering nose servo into the servo tray

in the fuselase.

2. Glue the wheel well by C.A glue to the fuselage.

INSTALLING THE NOSE AIR RETRACT gear

1. Trim the plastic wheel well.

THUNDER STREAK

Instruction Manual

5

Screw

8. Make the same way for the opposite gear retract.

6. Secure the nose wheel.

7. Secure the alxe.

M3

30

Screw

29

Trim

Screw

23 27

500mm

500mm

THUNDER STREAK

Instruction Manual

12

Joining the fuselage

- Joining the fuselage using 3 aluminum tube.

12. Glue the air cooling exhaust plastic by C.A glue.

74

11. Cut the hole on the fuselage for installing the

air cooling exhaust plastic.

73

Remove the

covering

C.A glue

75

Joiner

76

Screw

OPEN AND CLOSE the canopy

BALANCING

1. It is critical that your airplane be balanced

correctly. Improper balance will cause your

plane to lose control and crash.

THE CENTER OF GRAVITY IS LOCATED

95mm BACK FROM THE LEADING EDGE OF

THE WING, AT THE FUSELAGE. BALANCE A

PLANE UPSIDE DOWN WITH THE FUEL

TANK EMPTY.

2. Mount the wing to the fuselage. Using a couple

of pieces of masking tape, place them on the

top side of the wing 95mm back from the

leading edge, at the fuselage sides.

3. Turn the airplane upside down. Place your

fingers on the masking tape and carefully lift

the plane.

4. If the nose of the plane falls, the plane is nose

heavy. To correct this first move the battery

pack further back in the fuselage. If this is not

possible or does not correct it, stick small

amounts of lead weight on the fuselage under

the horizontal stabilizer. If the tail of the plane

falls, the plane is tail heavy. To correct this,

move the battery and receiver forward or if this

is not possible, stick weight into the firewall.

When balanced correctly, the airplane should

sit level or slightly nose down when you lift it up

with your fingers.

Here is our set up for testing flying.

- 12 cell thunder power 5000 mAh 70c.

- BVM 3-12S EDF.

- ESC 160A phoenix.

77

Open and Close

78

Lipo battery