08/2020

Table of Contents

Product Overview 7

General Information 7

Laser Device 8

Objects Suitable for Scanning 9

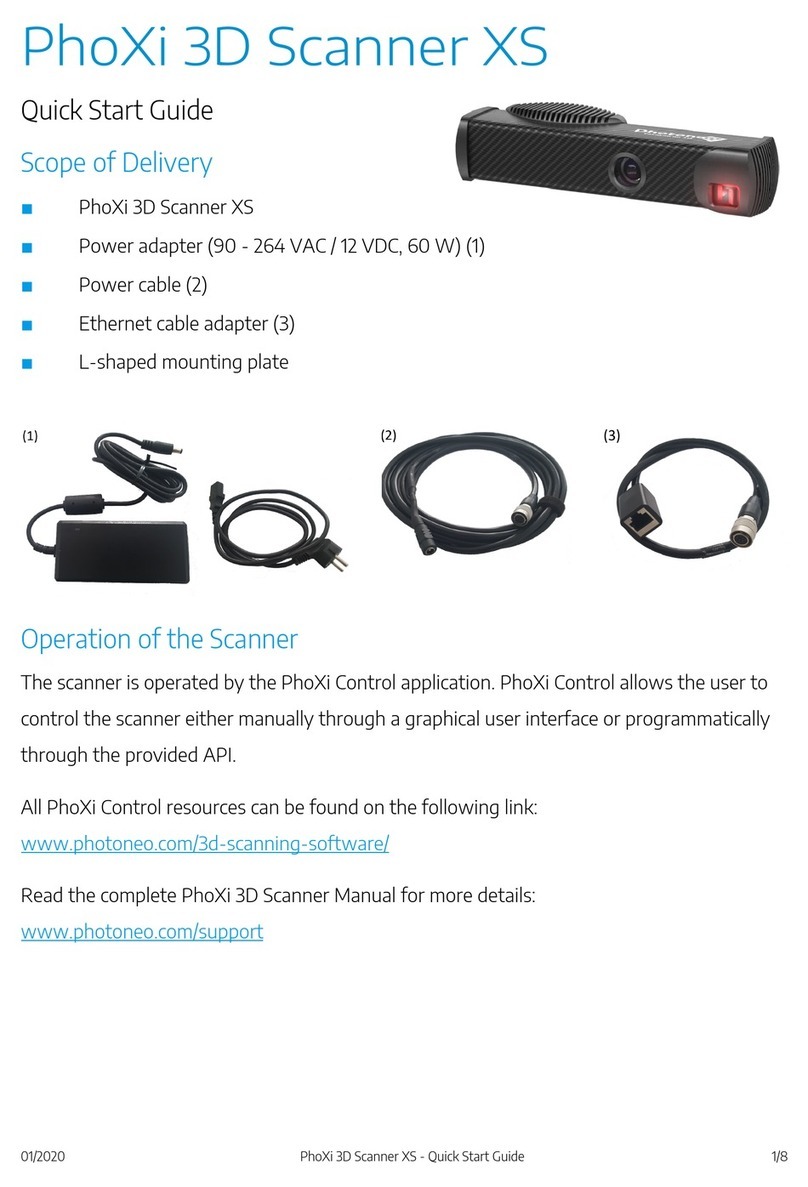

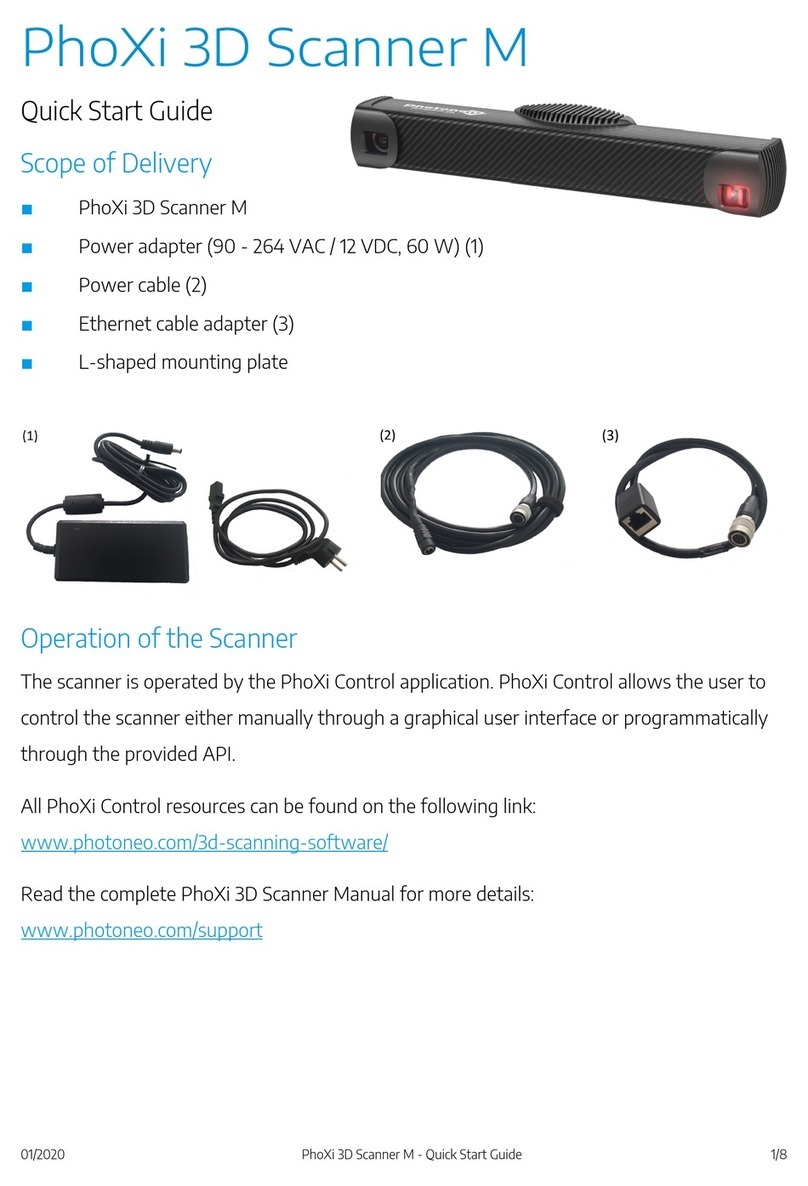

Scope of Delivery 11

Installation 12

Guidelines for Installation 12

Powering the Device & Data Connection 12

Powering Through PoE Connector 13

Powering by 24V 13

Status LEDs 14

Supported Network Topologies 15

Mounting Restrictions 16

Movement During Scanning 16

Strong Electric Field 16

Clearance for Cooling and Wiring 16

Configuration 17

PhoXi Control 17

Hardware Parameters 19

Power Over Ethernet Connector 19

Powering Requirements 19

24V Power Connector 20

Powering Requirements 20

Projection Unit 21

Environmental Conditions 21

Transport 21

Operation 22

Scanning Parameters 23

Operation Temperature 23

Datasheet Parameters Explanation 23

Depth Map Resolution 23

Point to Point Distance 23

Calibration Accuracy 24

Temporal Noise 24

Data Acquisition Time 24

Cleaning Instructions 30

Compliance with Standards 31

Declaration of Conformity 31