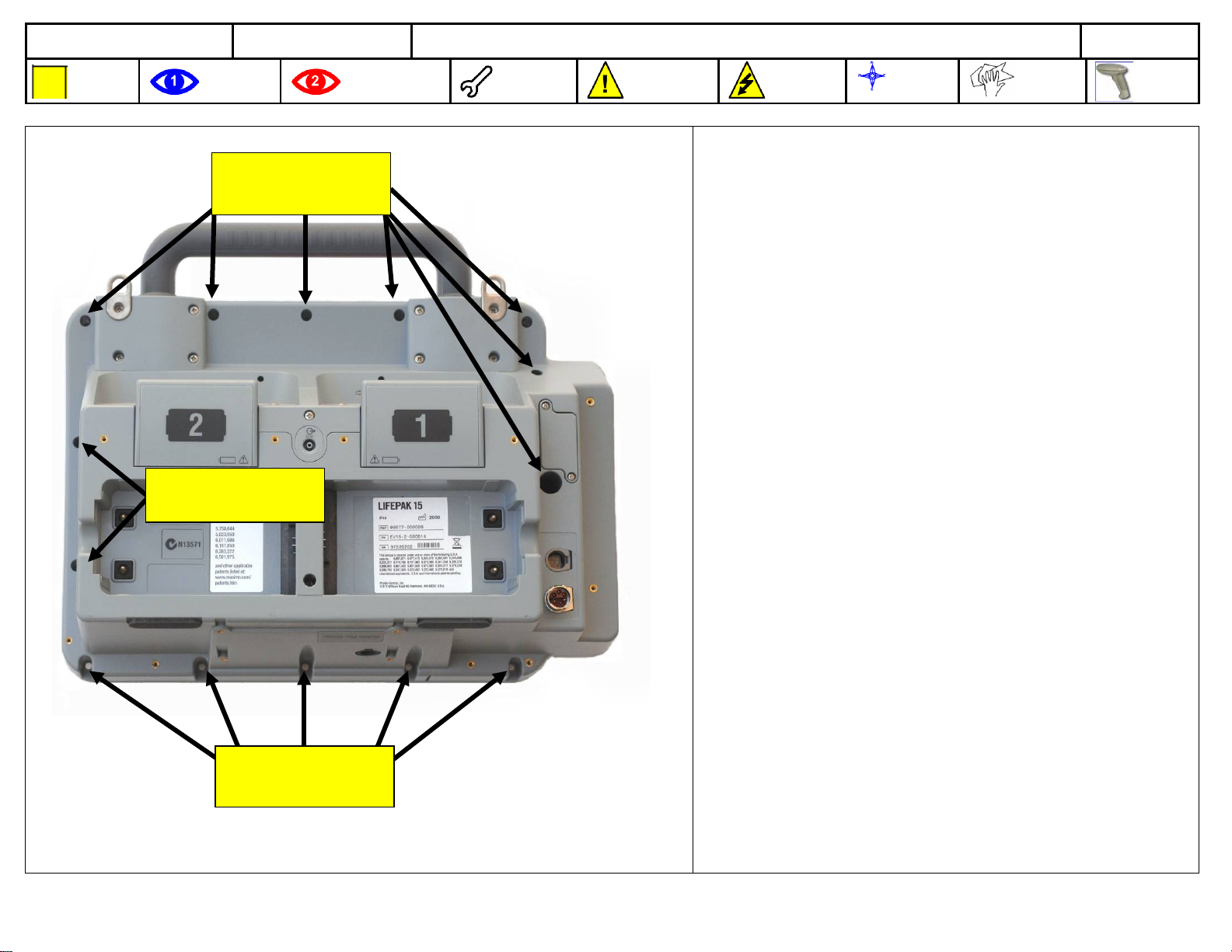

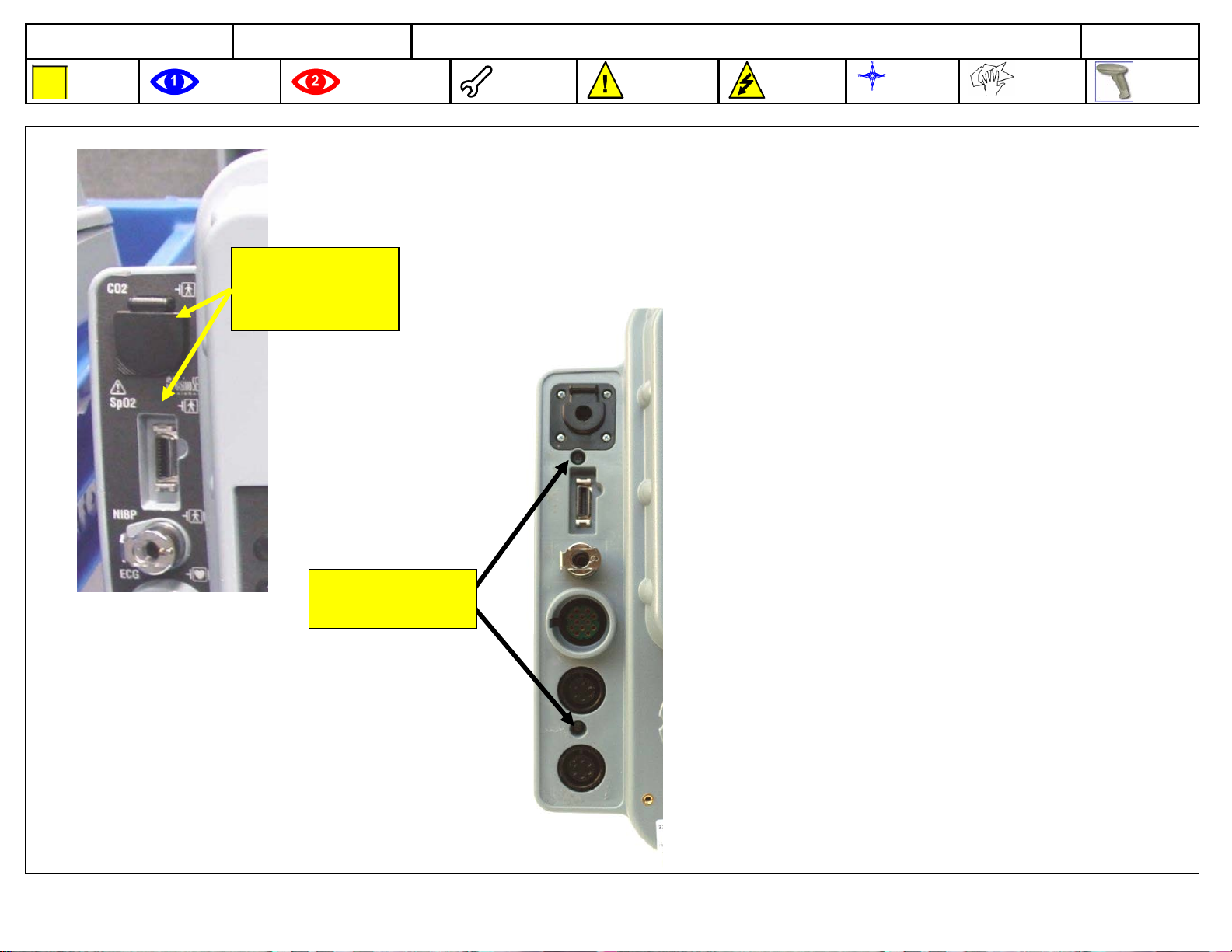

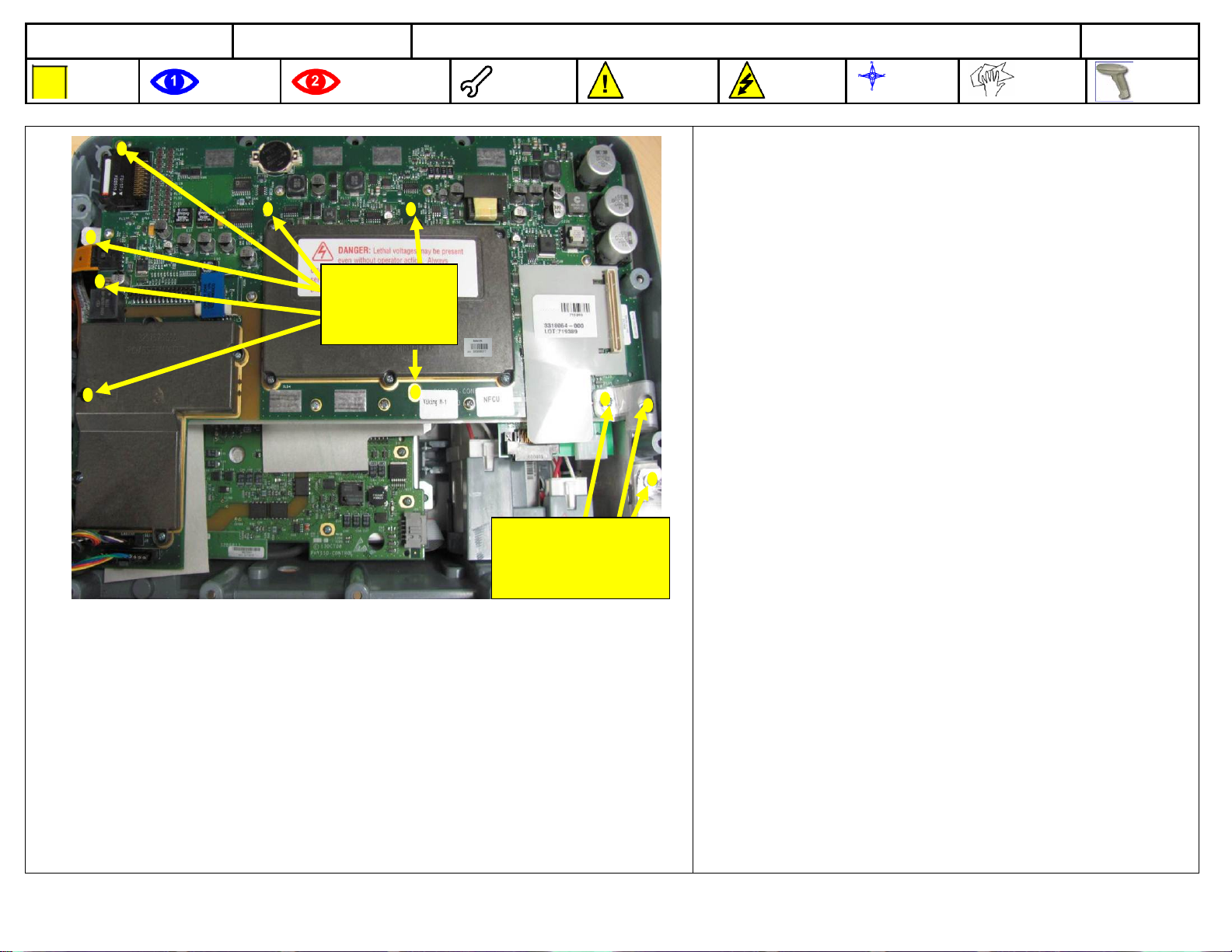

Physio Control LIFEPAK 15 V4 User manual

Other Physio Control Medical Equipment manuals

Physio Control

Physio Control Lifepak CR2 LIFELINKcentral User manual

Physio Control

Physio Control LPCR2 User manual

Physio Control

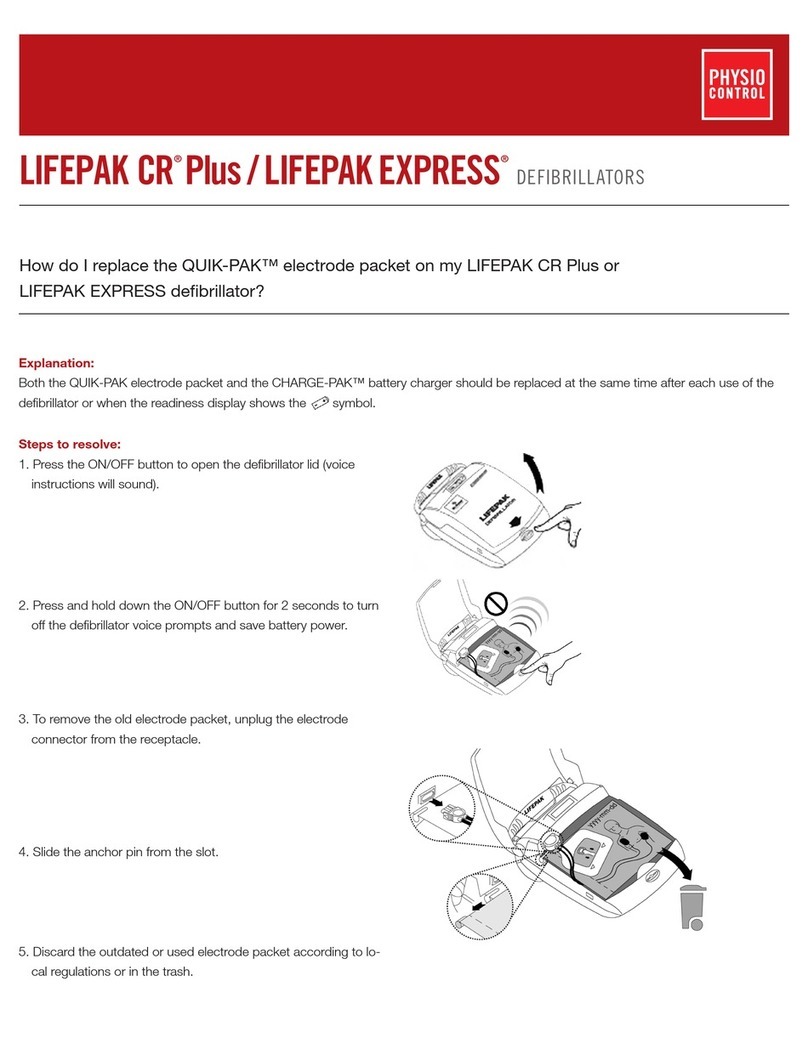

Physio Control LIFEPAK CR PLus User manual

Physio Control

Physio Control LIFEPAK 15 V4 User manual

Physio Control

Physio Control Lifepak CR2 LIFELINKcentral User manual

Physio Control

Physio Control HeartStart MRx User manual

Physio Control

Physio Control LIFEPAK 15 User manual

Physio Control

Physio Control Lifepak CR2 LIFELINKcentral User manual

Physio Control

Physio Control lucas 2 User manual

Physio Control

Physio Control lucas 2 User manual

Physio Control

Physio Control LIFEPAK 20 User manual

Physio Control

Physio Control Lifepak CR2 LIFELINKcentral User manual

Physio Control

Physio Control LIFEPAK CR PLus User manual

Physio Control

Physio Control LIFEPAK 20 User manual

Physio Control

Physio Control Lifepak CR2 LIFELINKcentral User manual

Physio Control

Physio Control LIFEPAK 20 User manual

Physio Control

Physio Control LIFEPAK 15 Technical manual

Physio Control

Physio Control LIFEPAK CR PLus Guide

Physio Control

Physio Control LIFEPAK 20 User manual

Physio Control

Physio Control LIFEPAK 12 User manual

Popular Medical Equipment manuals by other brands

Getinge

Getinge Arjohuntleigh Nimbus 3 Professional Instructions for use

Mettler Electronics

Mettler Electronics Sonicator 730 Maintenance manual

Pressalit Care

Pressalit Care R1100 Mounting instruction

Denas MS

Denas MS DENAS-T operating manual

bort medical

bort medical ActiveColor quick guide

AccuVein

AccuVein AV400 user manual