PRECAUTION

GENERAL PRECAUTION

The apparatus described in this manual is a device subject to pressure

installed in systems under pressure;

The apparatus in question is normally installed in systems for

transporting flammable gases (natural gas, for example).

PRECAUTION FOR THE OPERATORS

Before proceeding with installation, commissioning or

maintenance, operators must:

Examine the safety provisions applicable to the installation in

which they must work;

Obtain the authorisations necessary for working when

required;

Use the necessary means of individual protection (helmet,

goggles, etc.);

Ensure that the area in which they operate is fitted with the

means of collective protection envisaged and with the

necessary safety indications.

HANDLING

The handling of the apparatus and of its components must only be

carried out after ensuring that the lifting gear is adequate for the loads

to lift (lifting capacity and functionality). The apparatus must be

handled using the lifting points provided on the apparatus itself.

Motorised means must only be used by the persons in charge of them.

PACKING

The packing for transportation ofequipment and of relevant spare parts

are designed and shaped to avoid damage to any part during

transportation, warehousing and handling activities. Therefore the

equipment and spare parts shall be kept into their packing until their

installation in the final site. After packing is open, check that no

damage occurred to any goods. If damage occurred inform the supplier

and keep packing for any verification.

INSTALLATION

The installation of the pressure regulator has to occur in compliance

with the provisions (laws or standards) in force in the place of

installation.

In detail, natural gas plants have to show features in compliance with

the law provisions and standard requirements in force in the place of

installation or at lease in compliance with standards EN 12186 or EN

12279; in detail, it is necessary to meet the provisions of paragraphs

6.2, 7.5.2, 7.7, 9.3 of the standard EN 12186 and 6.2, 7.4, 7.6, 9.3 of

the EN 12279 standard. The installation in compliance with such

standards minimizes the risk of fire hazard and the formation of

potentially explosive atmospheres.

The valve is not equipped with external pressure limitation devices;

therefore, it has to be installed making sure that the operating pressure

of the assembly on which it is installed does not exceed the maximum

allowable pressure (PS).

Therefore, the user, as deemed necessary by the same, shall install on

the assembly suitable pressure limitation systems, as well as provide

the plant with suitable relief or drain systems in order to discharge the

pressure and fluid contained in the plant before proceeding with any

inspection and maintenance activity.

If the installation of the apparatus requires the application of

compression fittings in the field, these must be installed following the

instructions of the manufacturer of the fittings themselves. The

choice of the fitting must be compatible with the use specified for the

apparatus and with the specifications of the system when envisaged.

COMMISSIONING

Commissioning must be carried out by adequately trained personnel.

During the commissioning activities, the personnel not strictly

necessary must be ordered away and the no-go area must be properly

signalled (signs, barriers, etc.).

Check that the settings of the apparatus are those requested; if

necessary, reset them to the required values in accordance with the

procedures indicated in the manual.

When commissioning, the risks associated with any discharges into the

atmosphere of flammable or noxious gases must be assessed.

In installations in natural gas distribution networks, the risk of the

formation of explosive mixtures (gas/air) inside the piping must be

considered.

CONFORMITY TO DIRECTIVE 97/23/EC (PED)

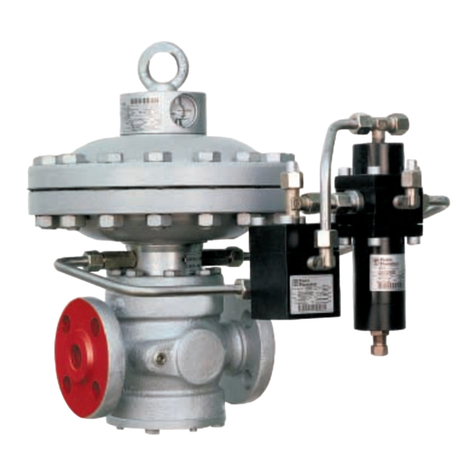

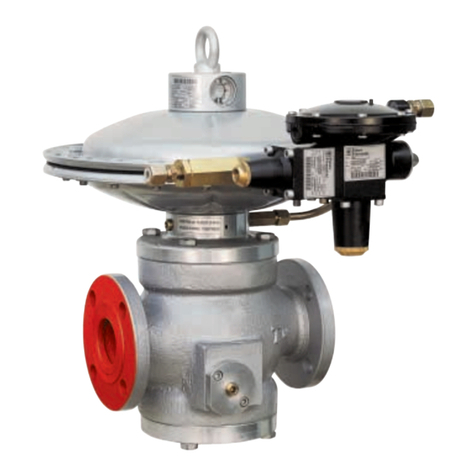

Pressure regulator Dival 600 is classified as pressure accessory

according to directive 97/23/EC (PED).

The pressure regulator Dival 600 with embedded block device, with

pressure switch for tripping in case of maximum pressure, is defined as

a safety accessory according to PED Directive and, therefore, it can be

used both as a pressure accessory and a safety accessory, always

according to the PED Directive.

The configuration of the regulating pressure regulator plus in line

monitor regulator is defined as safety accessory according to the PED

Directive.

In this case the user shall verify that the maximum allowable pressure

(PS) of pressure equipment to be protected is consistent with setting

and closing class (SG) of monitor regulator; the pressure inside

pressure equipment shall be lower than 110% of PS.

Conformity with Directive 97/23/EC and CE marking of pressure

regulator and relevant accessory require installation in the system with

minimum requirements according to EN 12186).