Contents

Operating Manual PSEN ma1.3b-24 VA

22227-EN-03 | 3

Introduction ............................................................................................................................4

Validity of documentation.......................................................................................................... 4

Using the documentation .......................................................................................................... 4

Definition of symbols................................................................................................................. 4

Safety ...................................................................................................................................... 5

Intended use ............................................................................................................................. 5

Safety regulations ..................................................................................................................... 5

Safety assessment ................................................................................................................... 5

Use of qualified personnel ........................................................................................................ 6

Warranty and liability ................................................................................................................ 6

Disposal .................................................................................................................................... 6

For your safety.......................................................................................................................... 7

Unit features ...........................................................................................................................7

Function description ............................................................................................................. 8

Block diagram ........................................................................................................................... 8

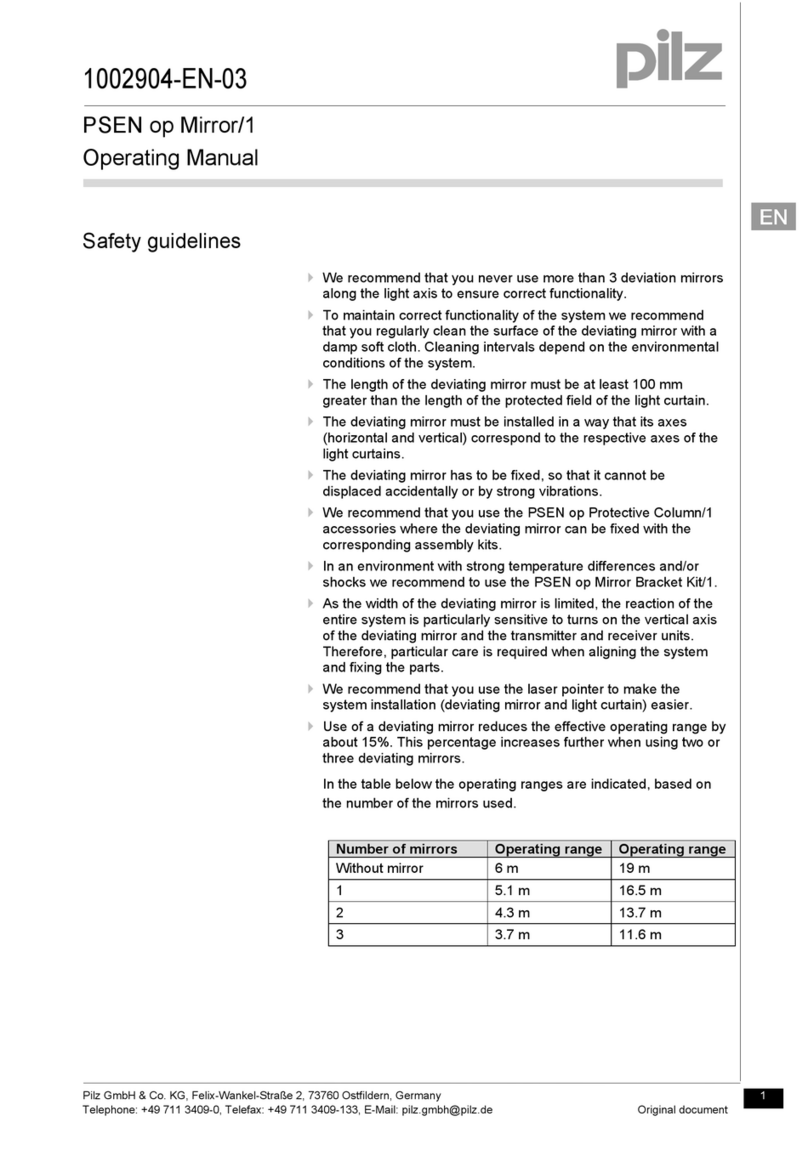

Operating distances.................................................................................................................. 8

Lateral and vertical offset.......................................................................................................... 9

Wiring ......................................................................................................................................9

Pin assignment ......................................................................................................................... 10

Requirements and connection to evaluation devices ........................................................ 10

Installation ..............................................................................................................................13

Adjustment ............................................................................................................................. 16

Periodic test ...........................................................................................................................16

Dimensions in mm .................................................................................................................16

Technical details ....................................................................................................................17

Safety characteristic data ......................................................................................................... 19

Order reference ......................................................................................................................19

System...................................................................................................................................... 19

EC declaration of conformity ................................................................................................ 19