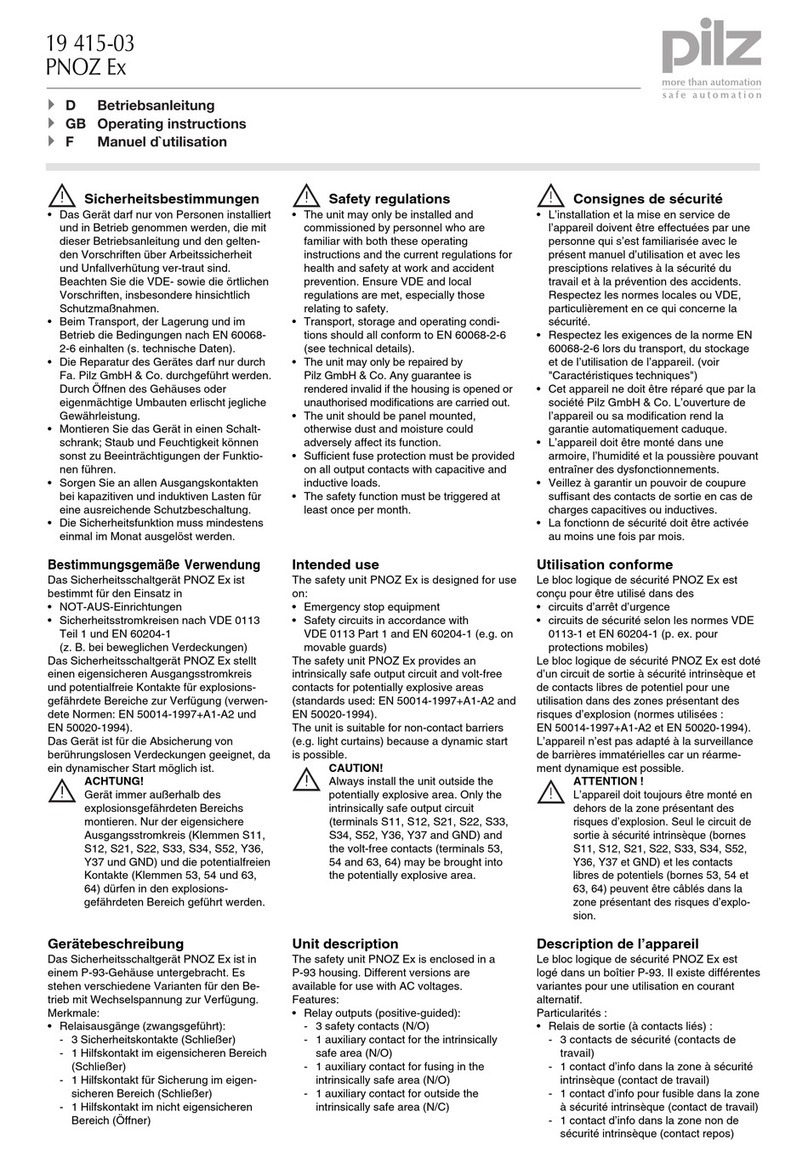

Installation Manual: PSS 3056 Series 2-3

Supplying the I/Os

• The digital inputs and outputs require a 24 V supply (see connection

diagrams in Chapter 5). Check that the voltage supplied from the

external power supply corresponds

• We recommend that the PSS and the I/Os are fed through two separate

power supplies. This will mean that any breaks in the supply to the I/Os

can be kept away from the CPU.

• The external 24 V power supply must be capable of supplying a

maximum current which is calculated from the sum of all the inputs

multiplied by 10 mA, plus the total current from the maximum number of

outputs that can be driven simultaneously.

•CAUTION!

The tolerance on the supply voltage for the PSS power supply is + 20 %

or -15 % maximum. Safe operation cannot be guaranteed outside this

range.

• To achieve the lowest possible residual ripple (< ± 1.2 V), we

recommend that you install a three-phase bridge rectifier or regulated

supply.

• The fuse between the external power supply and the supply terminals on

the outputs protects the cabling. The size of the fuse will depend on the

cable cross section and on local regulations.

•WARNING!

Safe electrical isolation must be ensured for the external 24 V supply.

Failure to do so could result in electric shock. Power supplies must

conform to DIN VDE 0551 / EN 60 742 and DIN VDE 0160.

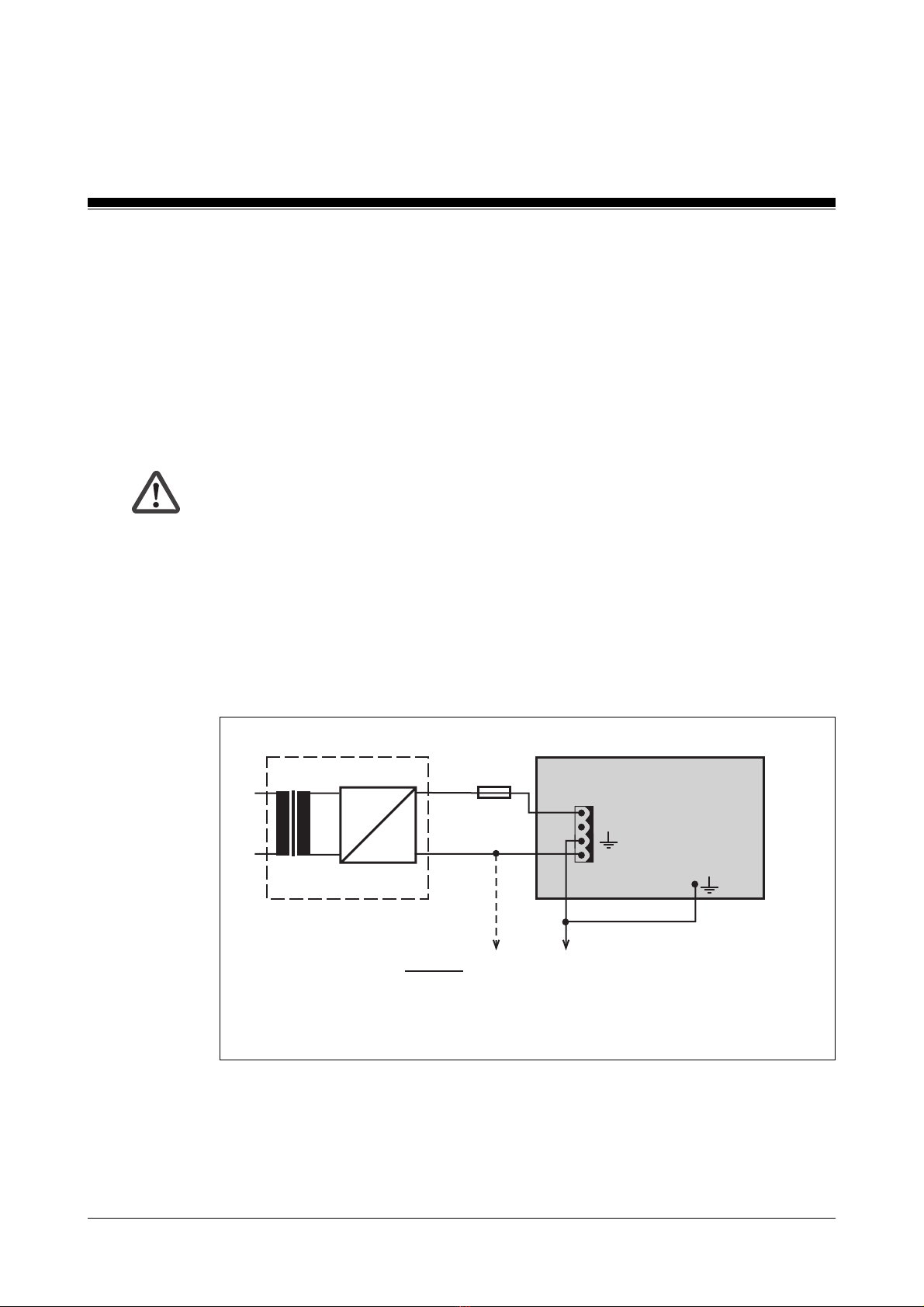

• The external power supply should be connected to the supply terminals

on the I/Os as shown overleaf.

There must be no direct connection between “N” and the 0 V output on

the external power supply.

The 0 V connections on all the 24 V power supplies should be connected

and the 0 V mains earthed at a single point. The connection of the 0 V

supply to the central earth bar or earth fault monitor must be in

accordance with the relevant national regulations (such as EN 60 204,

VDE 0113, NFPA 79-1991:17-7, NEC: Article 250, for example).

Artisan Scientific - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisan-scientific.com