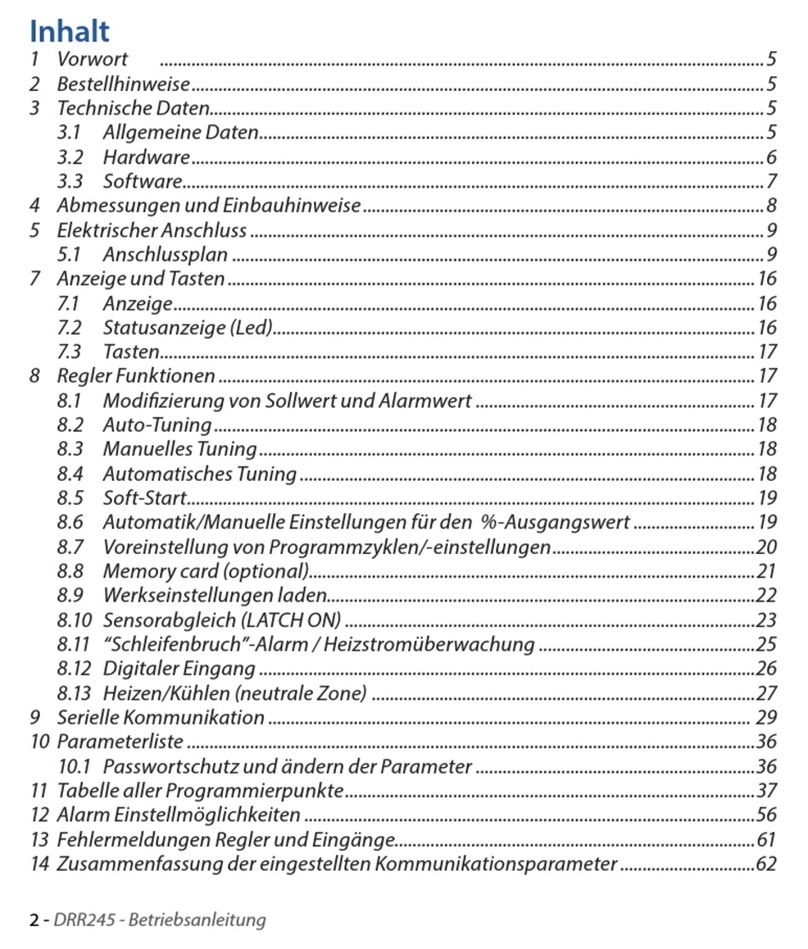

Sommario

1 Norme di sicurezza ...........................................................................32

2 Identicazione del modello............................................................32

3 Dati tecnici ..........................................................................................33

3.1 Caratteristiche generali .........................................................33

3.2 Caratteristiche hardware ......................................................33

3.3 Caratteristiche software........................................................33

4 Dimensioni, installazione e schema di collegamento ............34

4.1 Collegamenti elettrici............................................................35

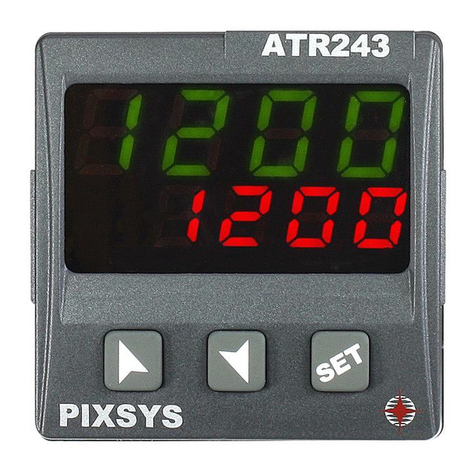

5 Funzione dei led e del tasto ............................................................36

5.1 Signicato delle spie di stato (led).......................................36

5.2 Tasto ............................................................................................37

5.3 Dip switch ..................................................................................37

6 Funzioni del regolatore ...................................................................37

6.1 Tuning “Automatico”..............................................................37

6.2 Lancio dell’AutoTuning “Manuale”.....................................38

6.3 Tuning “sincronizzato”...........................................................38

6.4 Regolazione automatico / manuale

per controllo % uscita.............................................................39

6.5 Caricamento valori di default ..............................................40

6.6 Heater Break Alarm su TA

(Trasformatore Amperometrico).........................................40

6.7 Funzionamento in doppia azione (caldo-freddo)..........41

7 Comunicazione Seriale....................................................................43

8 Tabella parametri di congurazione...........................................47

9 Modi d’intervento allarme..............................................................55

10 Tabella segnalazioni anomalie.....................................................58

11 Summary of conguration parameters......................................59