7

TABLE OF CONTENTS

What You Can Do With This Machine ............................................................................................ 9

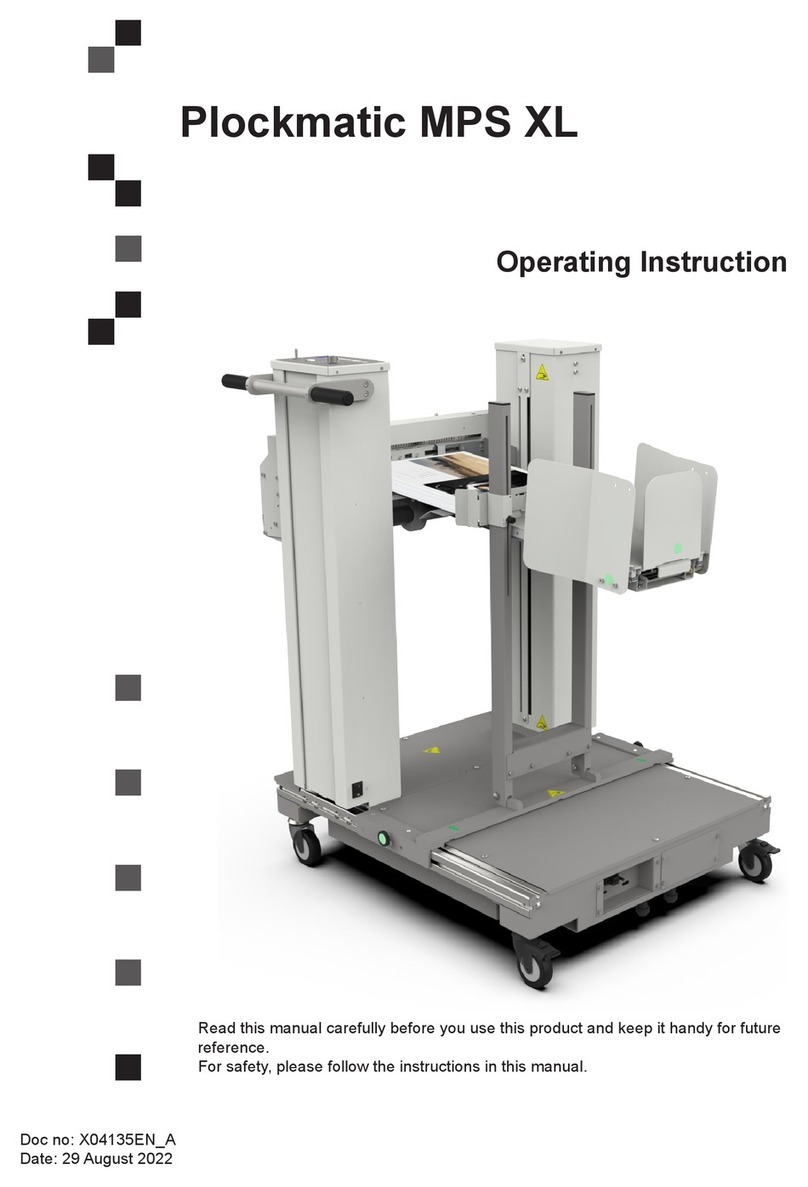

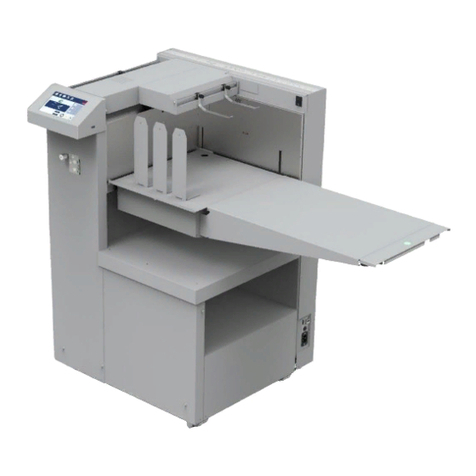

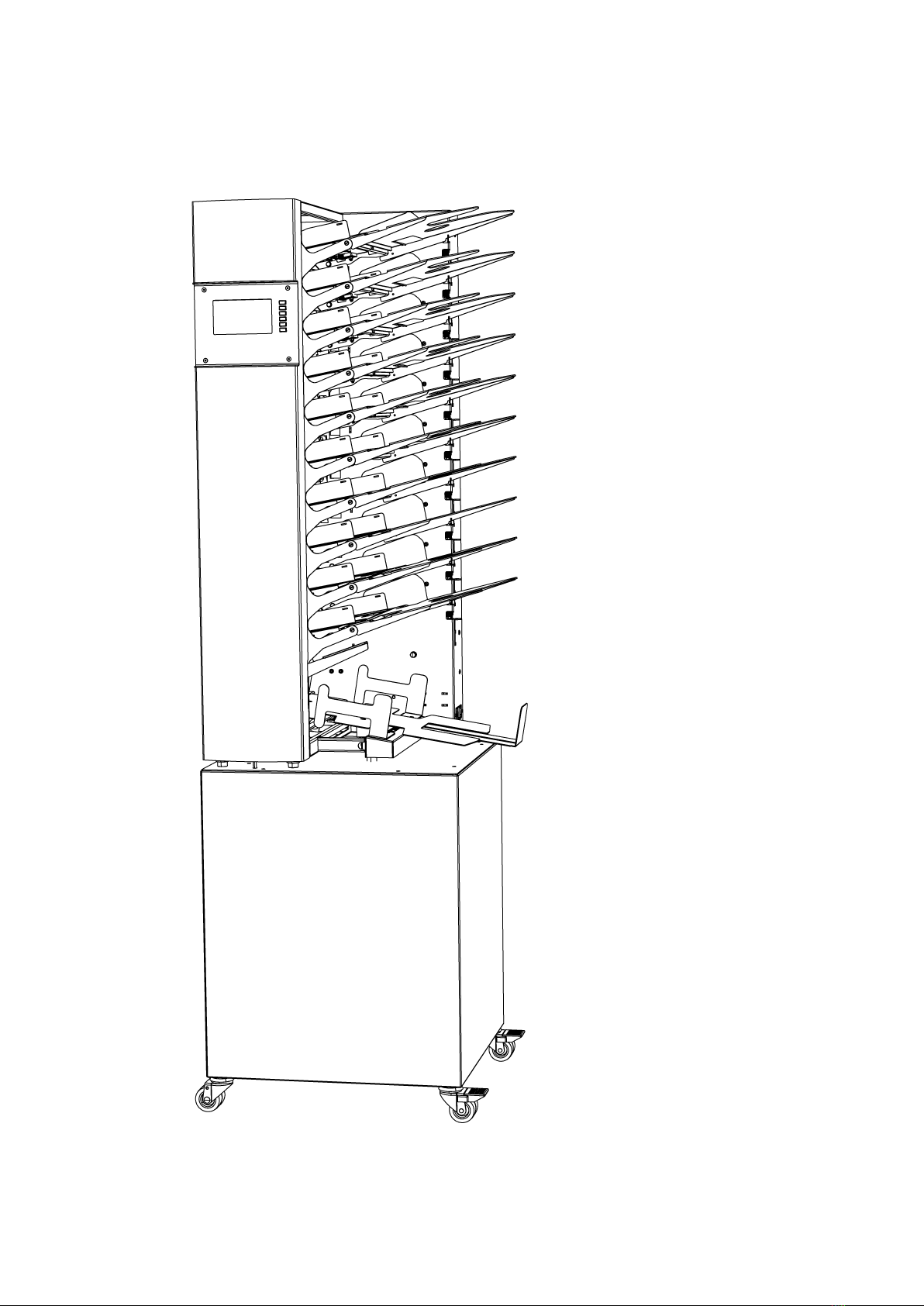

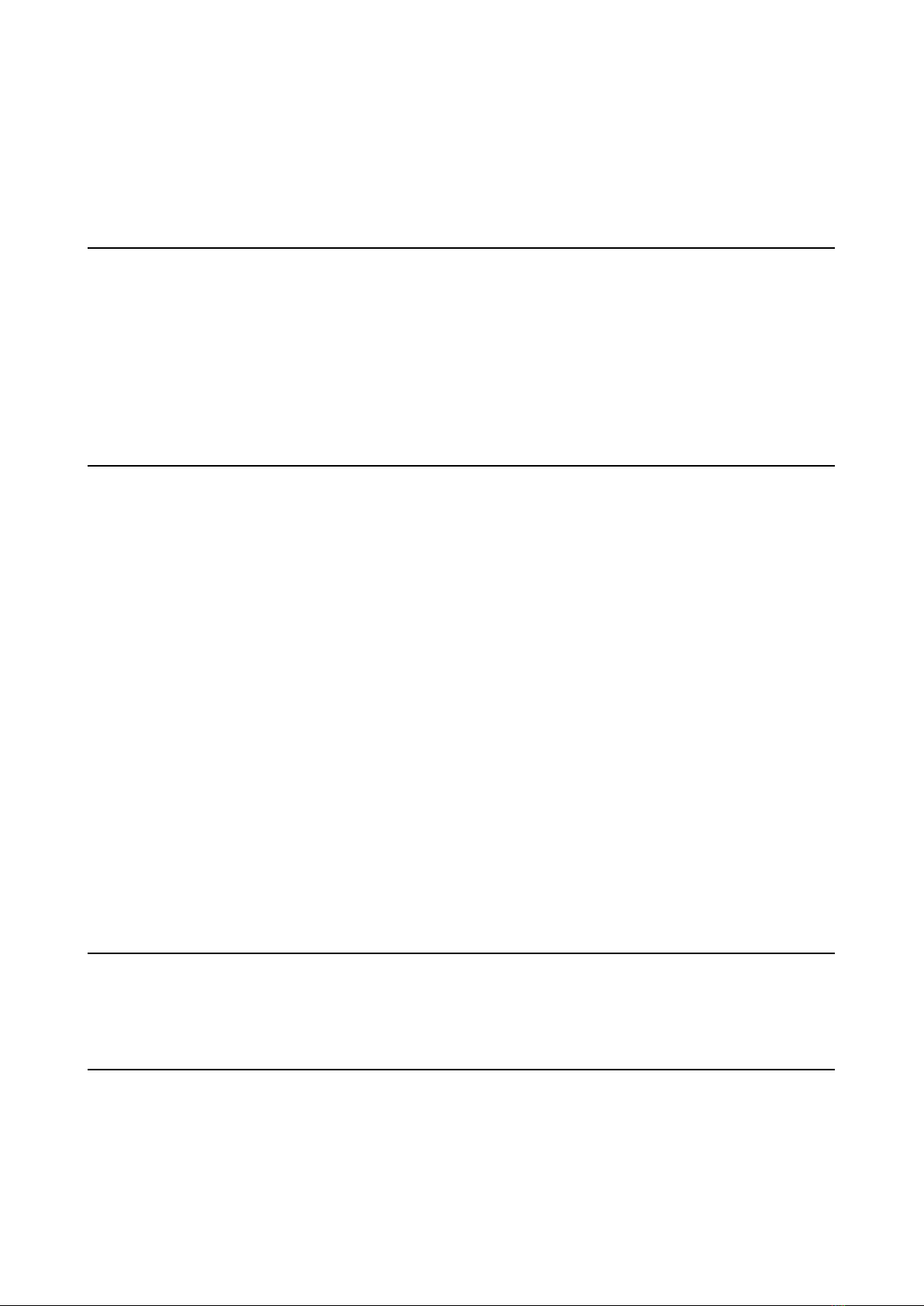

Main Components ......................................................................................................................... 10

General ....................................................................................................................................... 10

General, continued ..................................................................................................................... 11

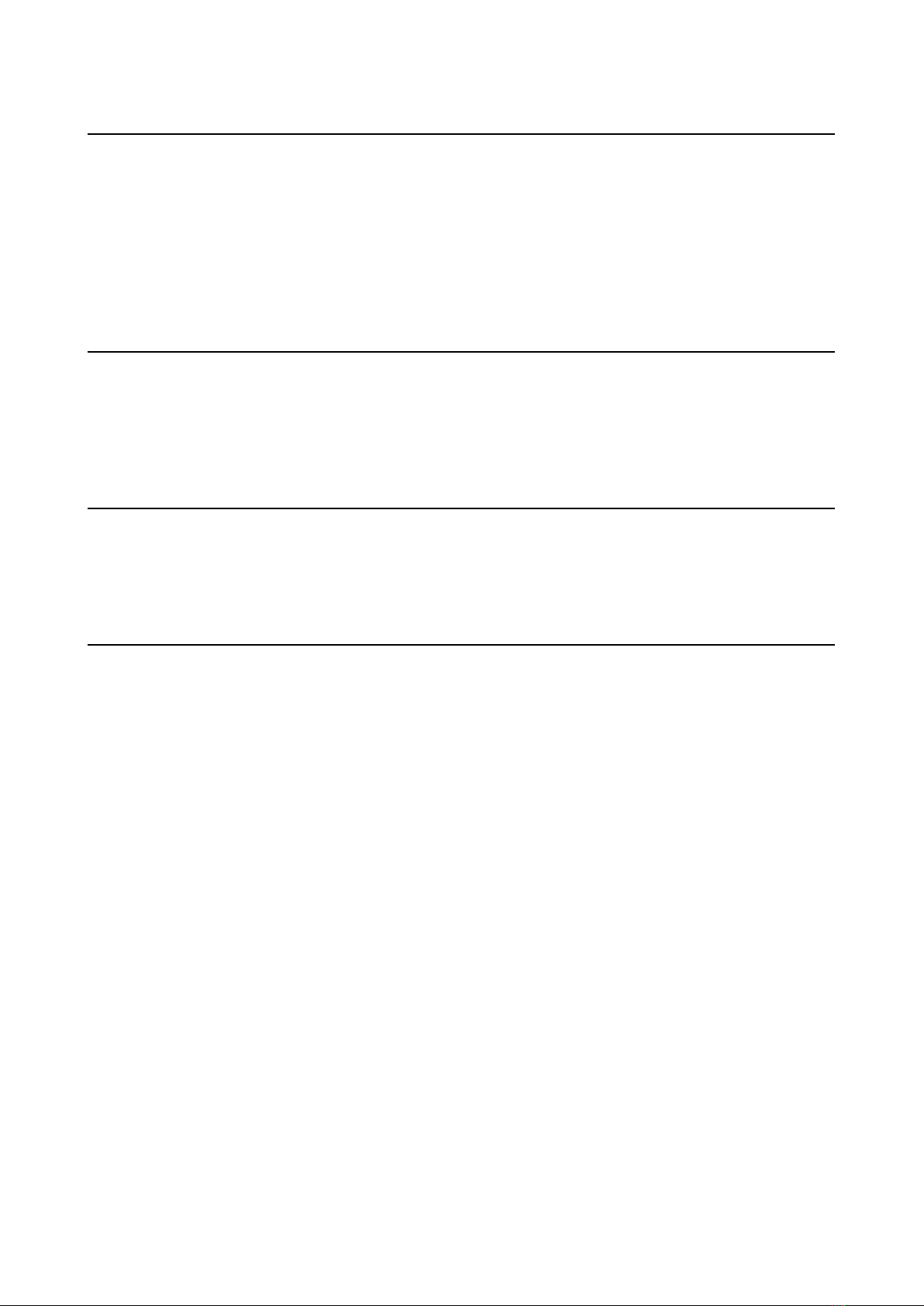

ACF 510...................................................................................................................................... 12

1. Basics

Turning On / Off the Power ........................................................................................................... 13

Loading the bins............................................................................................................................ 15

Loading sheets, standard procedure .......................................................................................... 15

Loading sheets while running ..................................................................................................... 15

Feed pressure lever ...................................................................................................................... 16

Stacker............................................................................................................................................ 16

Internal Stacker .......................................................................................................................... 16

Extension Bin position.................................................................................................................. 17

2. Running the System

Collating ......................................................................................................................................... 19

Using the C/CF/AC/ACF 510 as a Collator................................................................................. 19

Collating Programs ..................................................................................................................... 21

Auto Bin Select Mode............................................................................................................................21

Insert Sheet Mode.................................................................................................................................21

Alternate Bin Mode................................................................................................................................21

Alternate Cover Mode ...........................................................................................................................22

Block Mode............................................................................................................................................22

Manual Bin Select Mode .......................................................................................................................22

Feeding........................................................................................................................................... 23

Using the CF/ACF 510 as a Feeder ........................................................................................... 23

Feeder Programs........................................................................................................................ 25

Basic programming ............................................................................................................................... 25

Advanced Programming........................................................................................................................26

Dual Mode ...................................................................................................................................... 27

Increasing capacity of the CF/ACF 510 (Feeding and Collating) ............................................... 27

Dual Mode Programming ......................................................................................................................28

Finishing......................................................................................................................................... 29

Internal Stacker........................................................................................................................... 29

Booklet Maker............................................................................................................................. 29

Counters......................................................................................................................................... 30

Counters ..................................................................................................................................... 30

3. Air Pre-Separation

Air Flow .......................................................................................................................................... 31

Setting the Air Flow..................................................................................................................... 31

Air Flow Settings......................................................................................................................... 32

4. Jobs

Job Handling.................................................................................................................................. 33

Retrieving a job........................................................................................................................... 33

Storing a job................................................................................................................................ 34

Deleting a Job............................................................................................................................. 35