TABLE OF CONTENTS

What You Can Do with This Machine...................................................................................8

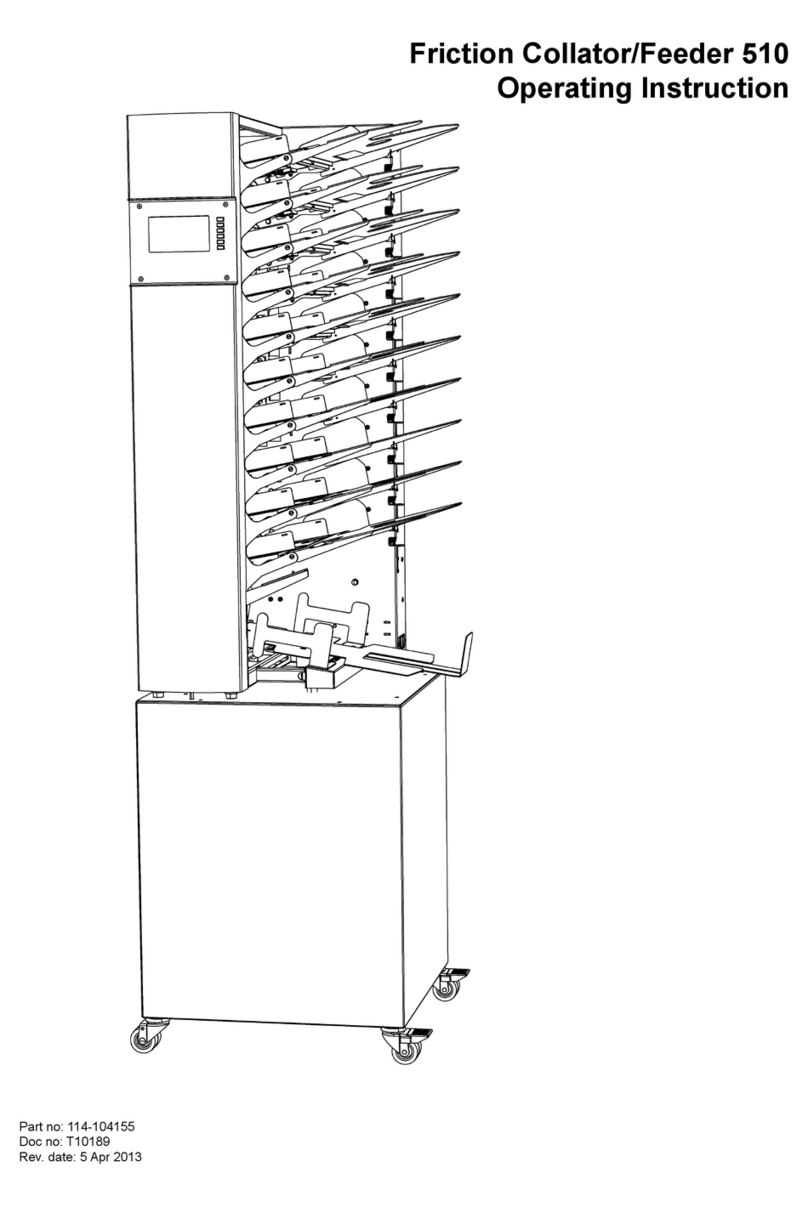

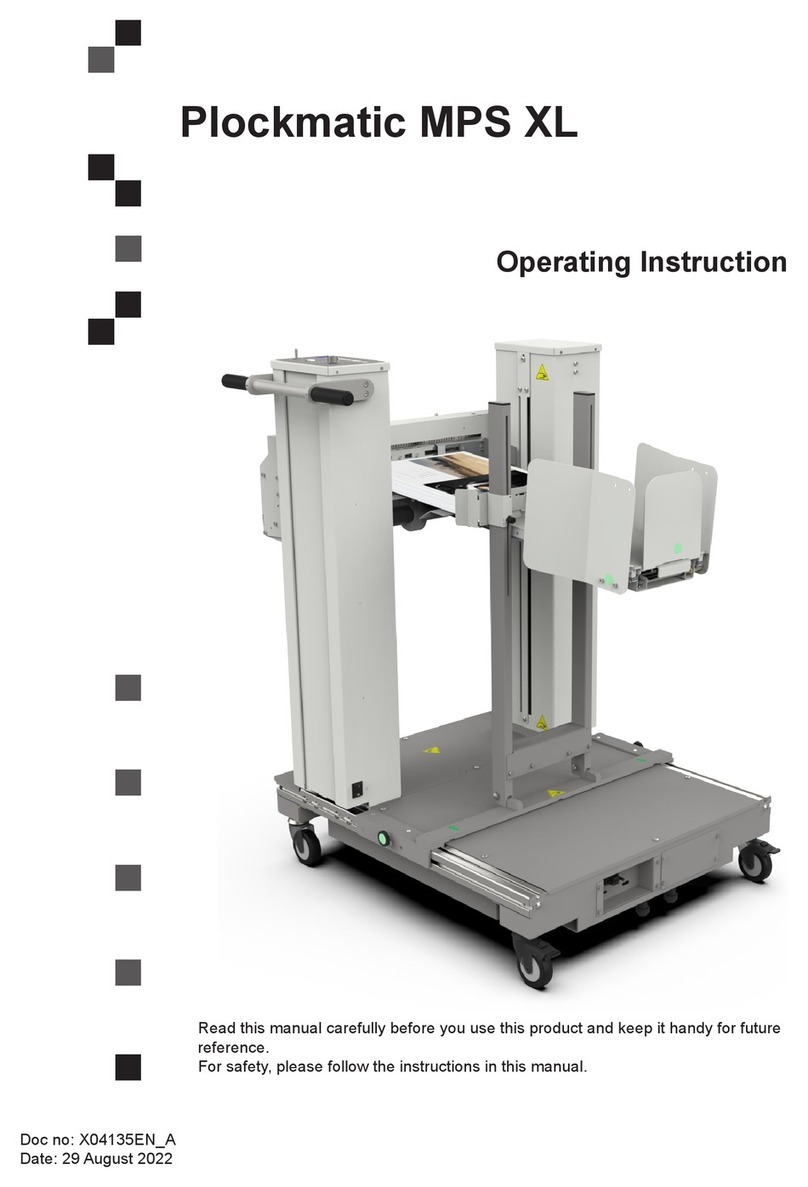

Guide to Components.................................................................................................... 9

VFL Feeder ................................................................................................................. 9

Feed Area.................................................................................................................. 10

User Interface............................................................................................................ 11

Tools and Accessories................................................................................................. 12

1Basics............................................................................................................................13

Paper........................................................................................................................... 13

Paper Guidelines....................................................................................................... 13

2Setting Up a Job ...........................................................................................................14

Getting Started............................................................................................................. 14

Turning the Machine On and Off............................................................................... 14

Paper Stack Preparation ........................................................................................... 15

Loading Paper........................................................................................................... 17

Feeder Table Extension............................................................................................ 18

The Home Screen........................................................................................................ 19

Overview ................................................................................................................... 19

Paper Size................................................................................................................. 20

Saving and Loading Jobs.......................................................................................... 22

Counters.................................................................................................................... 23

The Tools Screen ........................................................................................................ 24

Overview ................................................................................................................... 24

Feeder Settings......................................................................................................... 25

Checking for Software Updates................................................................................. 26

3Troubleshooting ...........................................................................................................27

Misfeeds / Jams........................................................................................................... 27

General...................................................................................................................... 27

Misfeed / Jam in the Feeder...................................................................................... 27

Fault Codes ................................................................................................................. 28

General...................................................................................................................... 28

List of Fault Codes .................................................................................................... 29

Accuracy Checks......................................................................................................... 32

Separation Pad Check .............................................................................................. 32

How to Get Support..................................................................................................... 33

4Remarks.........................................................................................................................34

Do’s and Don’ts ........................................................................................................... 34

Where to Put Your Machine......................................................................................... 35

Machine Environment................................................................................................ 35

Power Connection..................................................................................................... 35

Access to Machine .................................................................................................... 36

Maintaining Your Machine........................................................................................... 37

Recommended Weekly Operator Maintenance ........................................................ 37

Limitations of the VFL Feeder...................................................................................... 38

5Specifications ...............................................................................................................39

Machine Specification.................................................................................................. 39

General...................................................................................................................... 39

Physical Characteristics ............................................................................................ 39

Paper handling.......................................................................................................... 39

EU DECLARATION OF CONFORMITY [1] .................................................................. 40