Instr 9926739 Rev 02 2018-09 Page 2 of 9

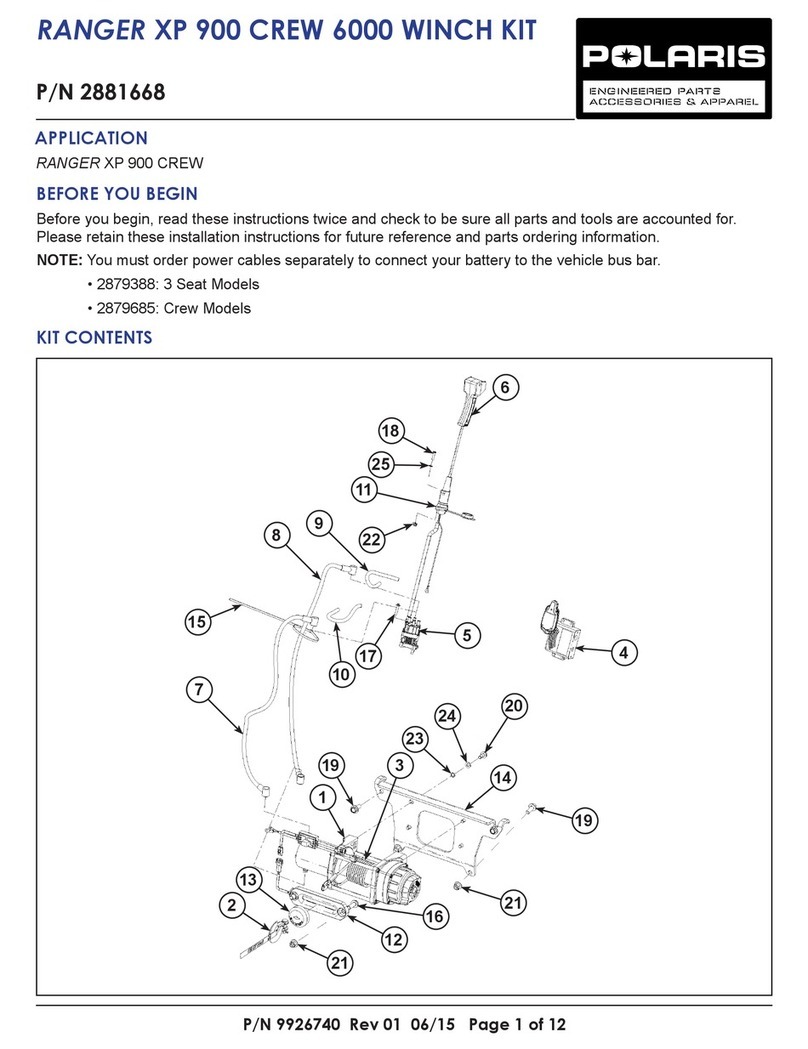

REF QTY PART DESCRIPTION PART NUMBER

3 1 Roller-Fairlead 2411847

4 1 Cable, Steel - 7/32 inch 2878889

5 1 Contactor 4015095

6 1 Remote Switch 4013466

7 1 Power Cable, Winch, Black 6 GA, 250 mm 4013470-250

8 1 Power Cable, Winch, Red 6 GA, 250 mm 4013471-250

9 1 Remote Socket 4014228

10 1 Plate, Mounting 5439929

11* 10 Cable Tie 7080492

12 1 Cable, Winch, Yellow 6 GA, 800 mm 4013468-800

13 1 Cable, Winch, Blue 6 GA, 800 mm 4013469-800

14* 2 Screw, Hex Flange - M10 X 1.5 X 30 7517425

15* 4 Screw, Torx®Pan Head - #10–32 X 1 7518246

16* 2 Screw, Torx®Pan Head - M5 X 0.8 X 20 7518980

17* 2 Screw, Hex Flange - M10 X 1.5 X 25 7519071

18* 4Screw, Torx®Truss Head - M8 X 1.25 X 20 7519260

19* 4 Nut, Hex Flange, Locking - M10 X 1.5 7547423

20* 2 Nut, Hex Flange, Locking - M5 X 0.8 7547427

21* 2 Washer, Flat - M5 7556724

22* 2 Screw, Hex Flange - M10 X 1.5 X 20 7519905

1 Winching Guide 9923644

1 Instructions 9926739

Items marked (*) are included in Hardware Kit PN 2879172. Hardware kit is universal and contains additional

parts not used for this installation.

TOOLS REQUIRED

• Safety Glasses

• Cutting Tool

• Drill

• Drill Bit: 1/4 inch (6 mm)

• Hole Saw: 1–1/16 inch (27 mm)

• Pliers, Push Pin Rivet

• Screwdriver, Phillips

• Socket Set, Metric

• Socket Set, SAE

• Socket Set, Torx®Bit

• Torque Wrench

• Wrench Set, Metric

IMPORTANT

Your 4500 HD WINCH KIT is exclusively designed for your vehicle. Please read the installation instructions

thoroughly before beginning. Installation is easier if the vehicle is clean and free of debris. For your safety, and to

ensure a satisfactory installation, perform all installation steps correctly in the sequence shown.