-2-

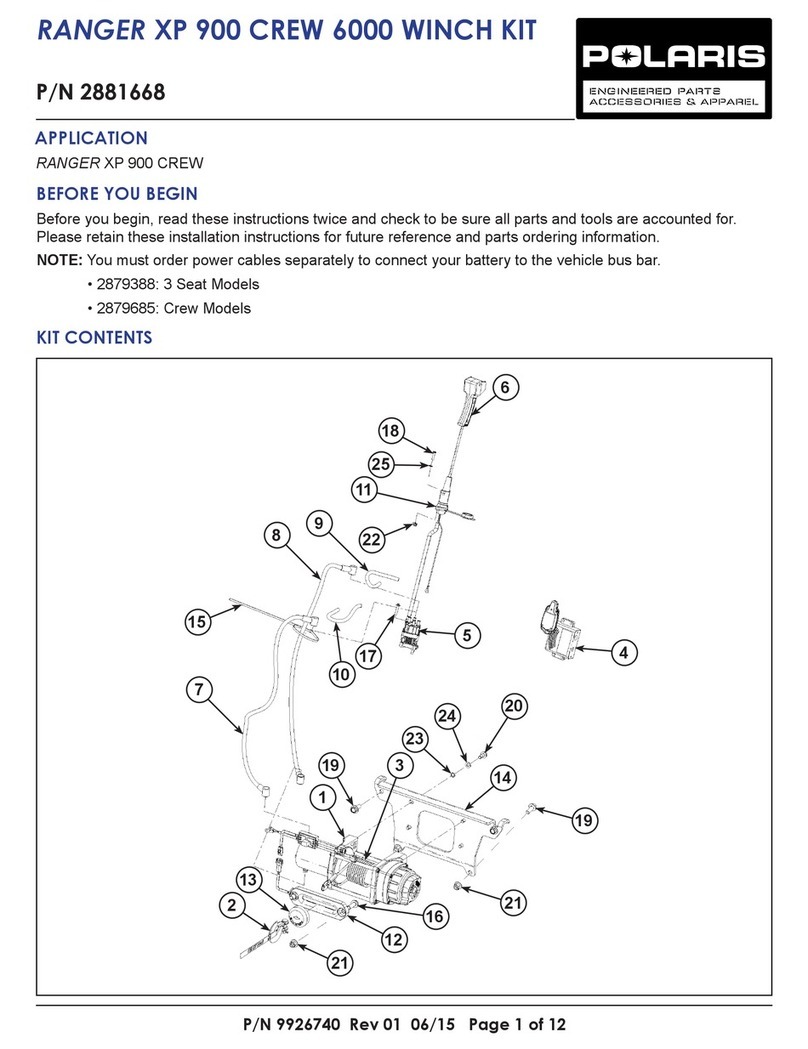

4500 Winch Kit Contents:

Ref Qty Part Description Part Number

1 1 Winch-Polaris, 4.5, BTM SPL 2204855

2 1 Hook-Latch, Winch 2411836

3 1 Fairlead, HAWSE, MACH, WIDE 2879148

4 1 Stop-Magnet, Bumper, Rubber 5414619

5 1 Rope Kit, Winch, 45, UHMW 2879187

6 1 Contactor-Winch 4013465

7 1 Remote-Switch, Winch 4013466

8 1 Socket-Winch 4014228

9 1 Cable-Winch, Yellow 6 GA, 480mm 4013468-480

10 1 Cable-Winch, Blue 6 GA, 400mm 4013469-400

11 1 Power Cable, Winch, Winch, Black 6 GA, 375mm 4013470-375

12 1 Power Cable, Winch, Winch, Red 6 GA, 375mm 4013471-375

13 1 Power Bracket, Winch, Red RZN 5257962

14 1 Mount-Fairlead, 4.5, RZN 5258106

15 1 Cable-Assembly, Battery to Terminal Block 4014577

16*2 Screw-M5x0.8X208.8TXPH ZOD 7518980

Ref Qty Part Description Part Number

20*6 Screw-RHCAR-MX10X1.5X25 8.8 ZOD 7519372

21*4 Screw-M12x1.75X25 8.8 HXFL ZOD 7519072

22*4 Screw-HXFL-M8X1.25X20 8.8 ZOD P3 7519133

23*2 Screw-SH-M10X1.5X25 8.8 ZPB D513 7517358

1 Instructions 9924528

1 Manual-Winch Guide 9923644

0 Service Kit Handle, HD Winch 2205265

Item marked (*) are included in Hardware Kit PN 2205119.

3

11

2

14

9

12

7

8

15

10

13

6

5

1

4