Instr 9927474 Rev 01 2017-02 Page 9 of 14

WIRELESS REMOTE OPERATION

• When properly installed, the wireless remote will

allow you to operate the winch from off the vehicle,

which can be a safe way to operate the winch when

done properly.

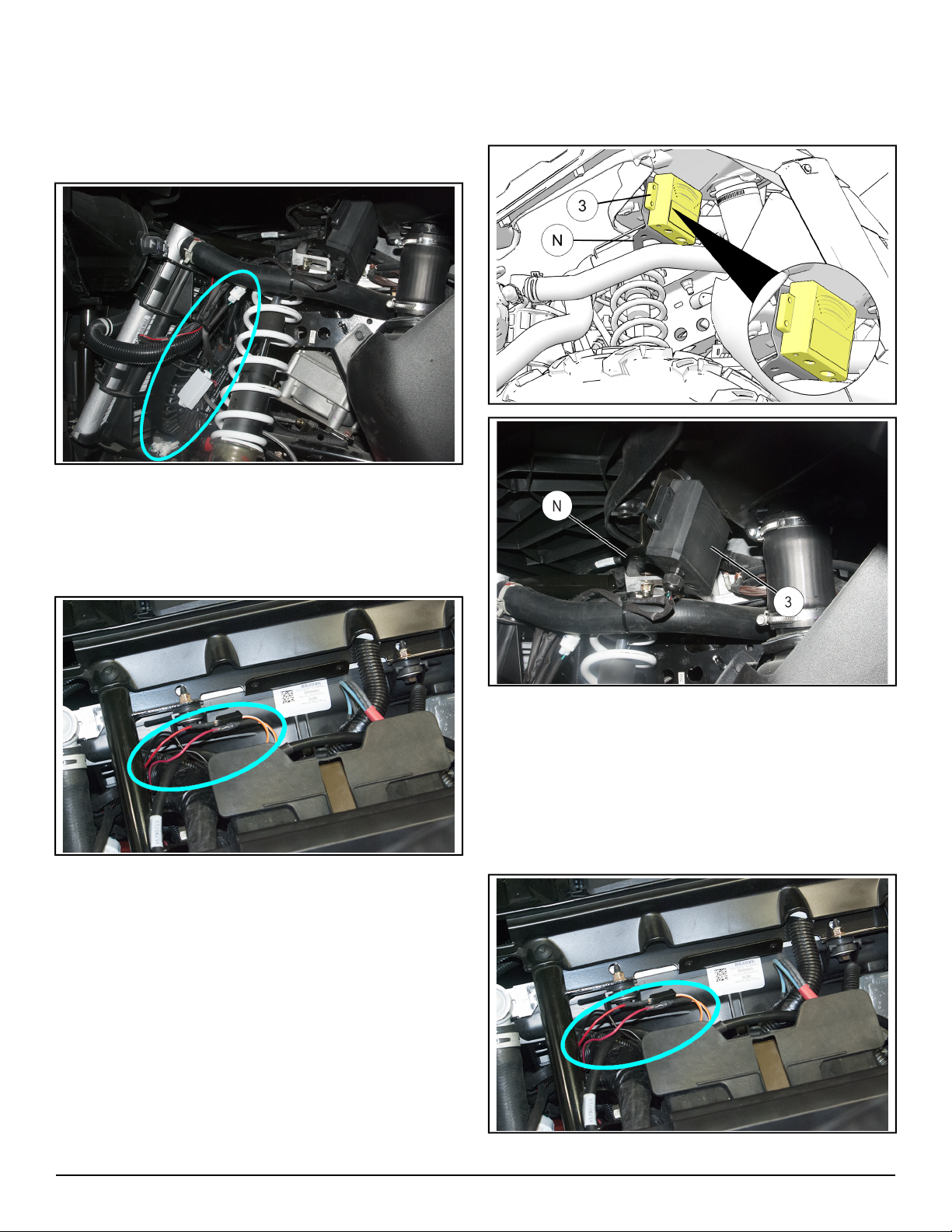

• To use the wireless remote, hold the small "On/Off"

button for three seconds or until the LED light on the

remote turns on. If the vehicle is on so that the

winch is receiving power, the wireless remote

should operate the winch as if you were using the

winch switch qlocated on the handlebar. If the

remote is not operating properly, see the

troubleshooting information at the end of the

instructions.

• The remote will automatically turn itself off after 30

seconds of inactivity. You will therefore need to turn

the remote back on if it has been more than 30

seconds since the prior use.

• To manually turn off the remote, hold the small "On/

Off" button for 3 seconds or until the LED light turns

off. The remote will automatically turn itself off after

30 seconds of inactivity.

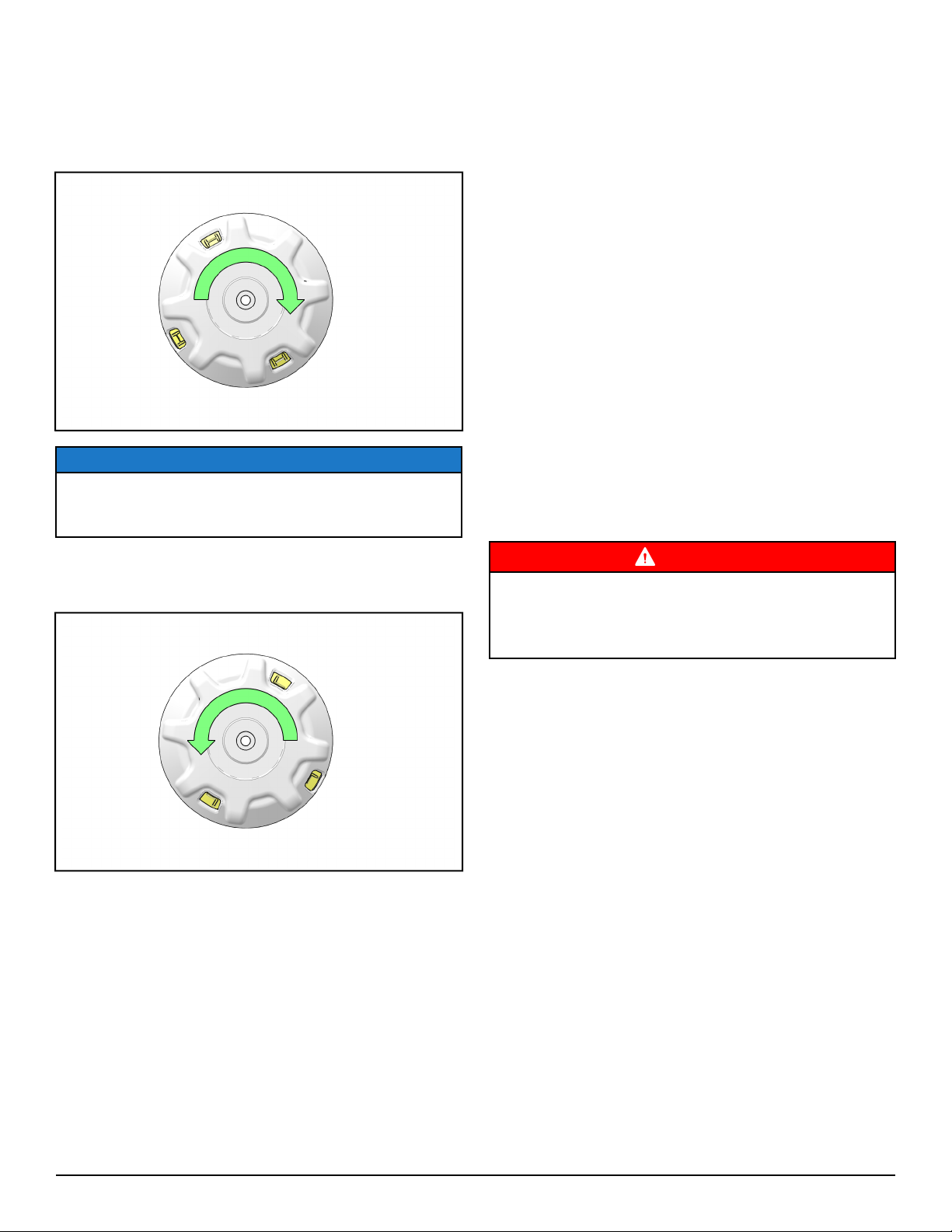

• See the illustration below for proper wireless remote

operation.

•

AUTOSTOP OPERATION

The Autostop system is meant to help prevent

damage to the winch system from over-tightening of

the rope, but is not meant to prevent all foreseeable

winch damage. The winch is very powerful and care

should be exercised whenever it is in operation. The

winch operator is always responsible for using the

winch properly and the Autostop system should only

be used as a secondary preventive measure to help

prevent damage to the winch from over-tightening the

rope.

The Autostop system works when the black rubber

puck nears the aluminum fairlead h. Stop magnets j

in the puck trigger sensors in the fairlead, which

prevent the contactor from pulling in the winch rope

any further.

During final inspection, confirm that the Autostop is

functioning properly. Troubleshooting steps are given

in that section to help diagnose and correct any

problems.

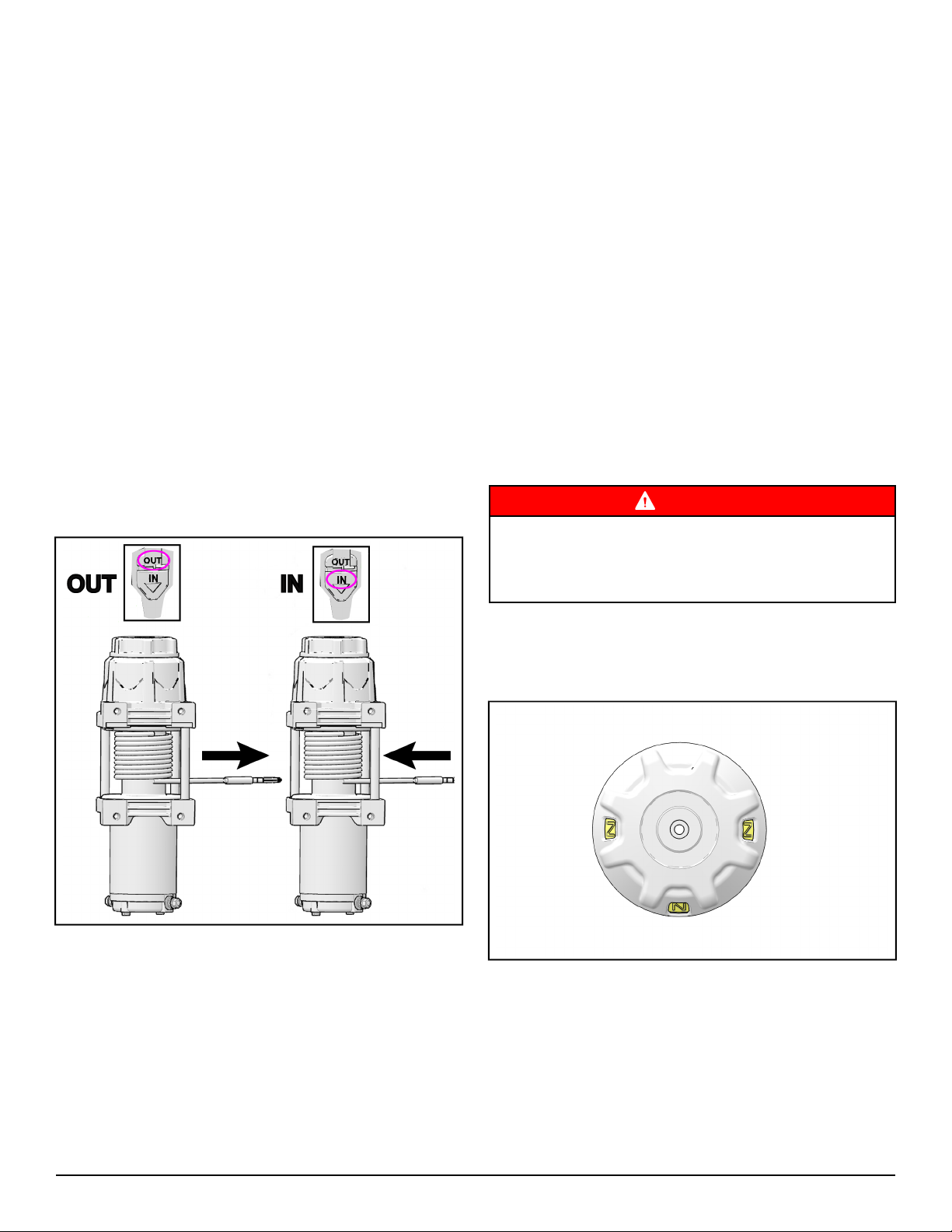

GEAR SELECTION

WARNING

Attempting to shift the winch while the rope is under

tension is dangerous and can result in injuries or

death. Make sure the winch rope is not in tension

before shifting the winch between gears.

Your winch is equipped with three different gear

settings. High, Neutral and Low. When in neutral the

“N” marking will show thru the cutout window on the

shift knob. See photo below.