Instr 9927473 Rev 01 2016-12 Page 10 of 13

During final inspection, confirm that the Autostop is

functioning properly. See the troubleshooting section

to help diagnose and correct any problems.

GEAR SELECTION

WARNING

Attempting to shift the winch while the rope is under

tension is dangerous and can result in injuries or

death. Make sure the winch rope is not in tension

before shifting the winch between gears.

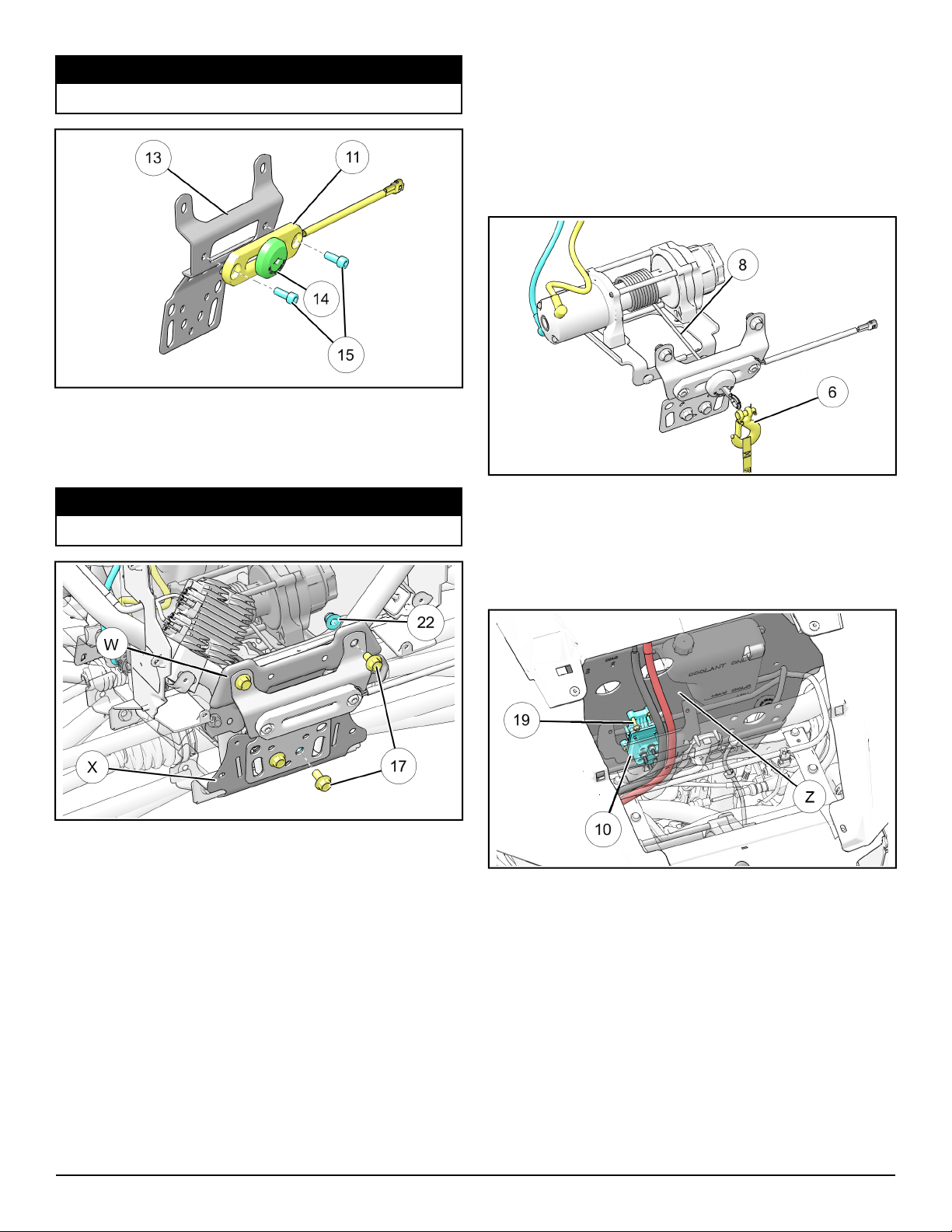

Your winch is equipped with three different gear

settings. High, Neutral and Low. When in neutral the

“N” marking will show thru the cutout window on the

shift knob. See photo below.

The high gear setting is meant for rapid recovery

mode only and should not be used while the rope is

under load. To shift into high gear, rotate the gear

shifting knob clockwise until the “H” marking shows

thru the cutout window on the shift knob. See photo

below.

NOTE

High gear is for rapid recovery of the winch rope

only. It is not intended for pulling and will reduce the

life of the winch if used under load.

To shift into low, rotate the gear shifting knob counter-

clockwise until the “L” marking shows thru the cutout

window on the shift knob. See photo below.

RAPID RECOVERY WINCH FUNCTION

NOTE

Rapid Recovery is for recovering the winch rope

only. It is not intended for pulling and will reduce the

life of the winch if used under load.

Your winch is equipped to quickly reel in the winch

rope when being used under no-load conditions.

Using this feature will significantly reduce the time it

takes to rewind your rope after use.

When to use

Use Rapid Recovery to quickly reel the rope in or out

to speed up the recovery process. The rope speed is

approximately five times the speed of standard

operation, so caution should be taken to always reset

the winch to “Low” gear after using the Rapid

Recovery so the speed of the winch will not take the

operator by surprise. Do not pull loads while in Rapid

Recovery gear.

How to shift

To operate the Rapid Recovery, make sure the winch

is not in operation and the rope is not in tension.

Rotate the shift knob fully clockwise to engage “High”

gear (Rapid Recovery). Pulling slightly on the winch

rope by hand will help the gears align and the shift to

be completed. Use Rapid Recovery only to reel in the

rope with “No Load”, then rotate the shift knob back to

“Low” gear (standard operating mode) by rotating the

knob back fully counter-clockwise.

WARNING

Attempting to shift the winch while the rope is under

tension is dangerous and can result in injuries or

death. Make sure the winch rope is not in tension

before shifting the winch between gears.