P/N 9926740 Rev 01 06/15 Page 2 of 12

IMPORTANT

Your Polaris RANGER XP 900 CREW 6000 WINCH KIT is exclusively designed for your vehicle.

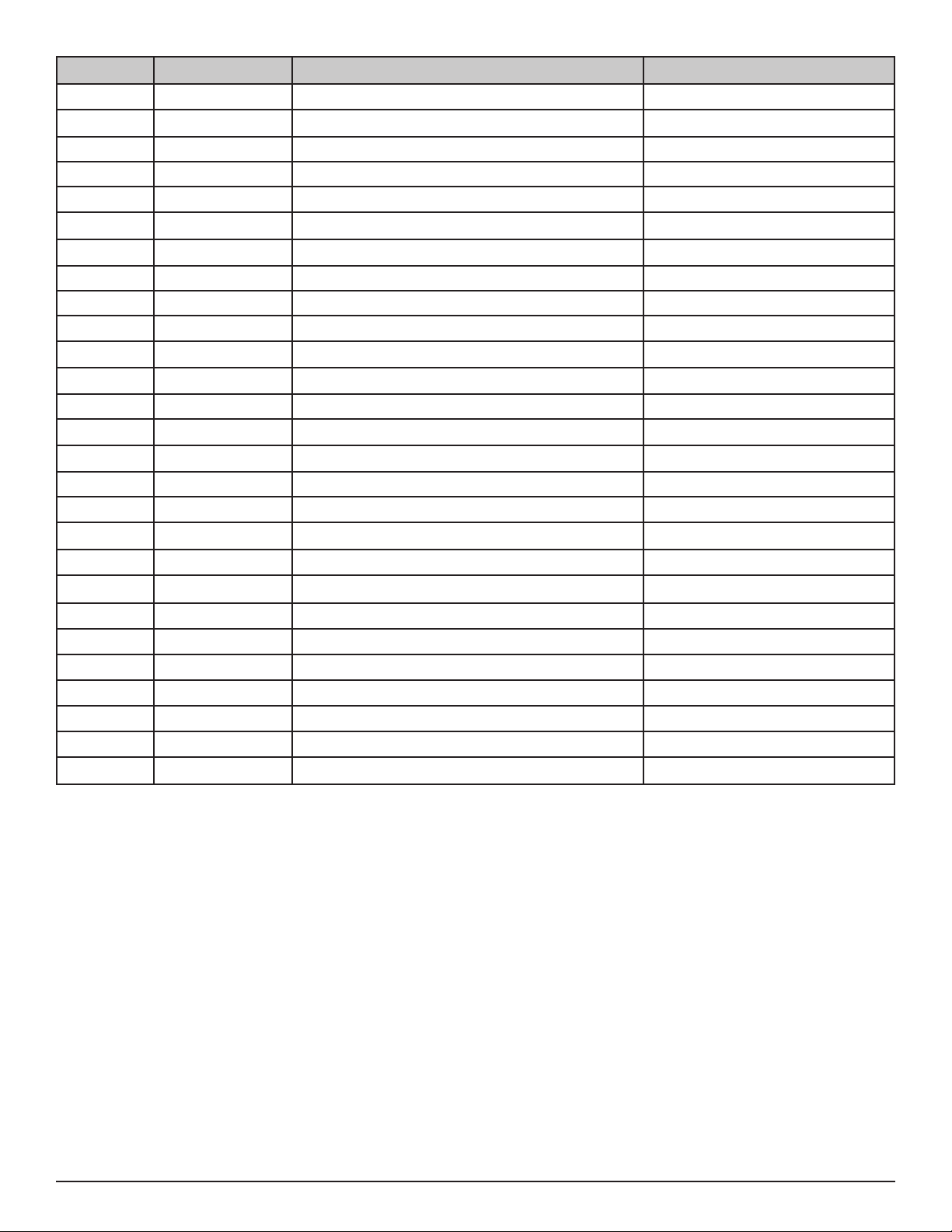

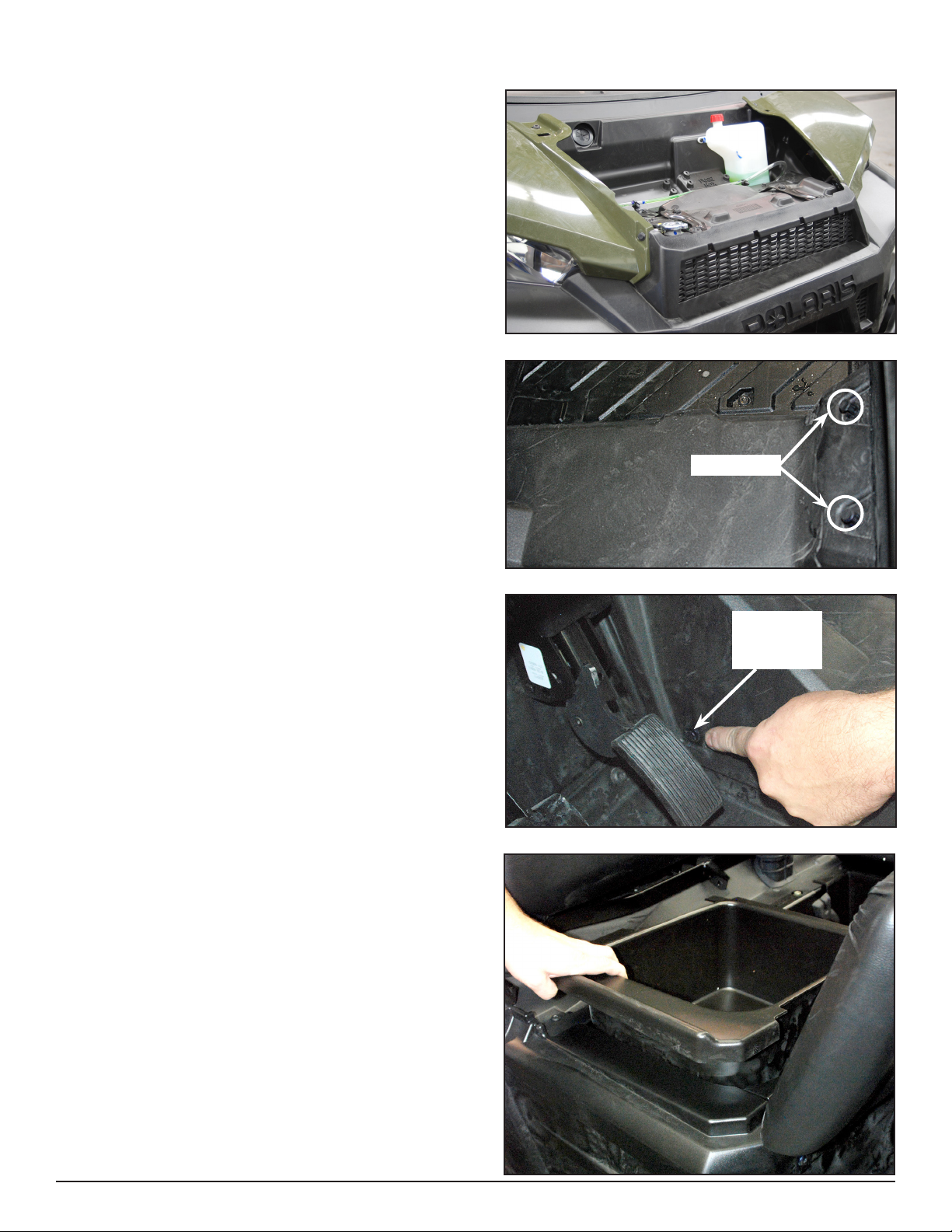

Please read the installation instructions thoroughly before beginning. Installation is easier if the

vehicle is clean and free of debris. For your safety, and to ensure a satisfactory installation, perform

all installation steps correctly in the sequence shown.

TOOLS NEEDED

Standard and Metric Socket Set Standard and Metric Wrench Set Phillips Screwdriver

Drill and Drill Bit Set 1 1/16” Hole Saw or Drill

APPROXIMATE ASSEMBLY TIME

60 mins

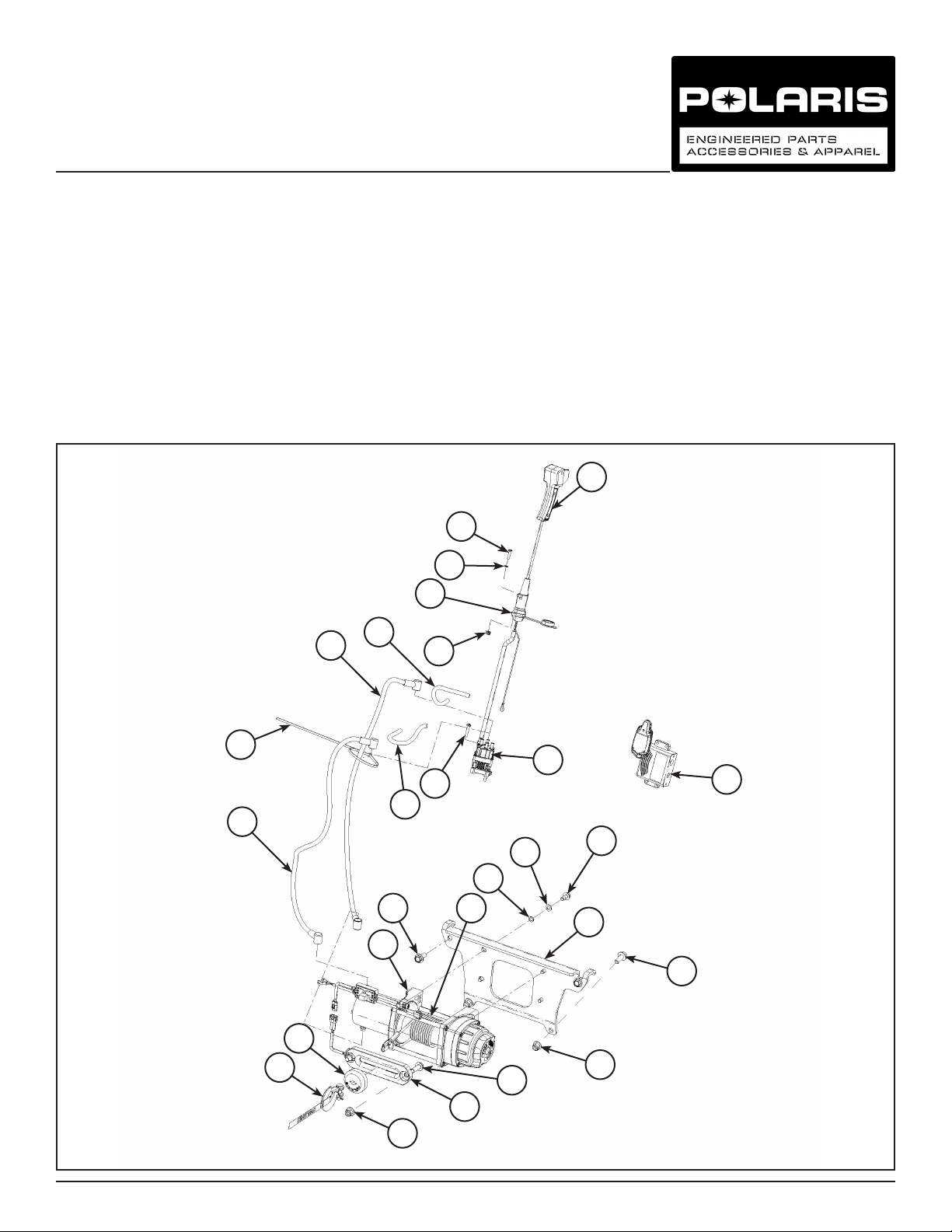

Ref Qty Part Description Part Number

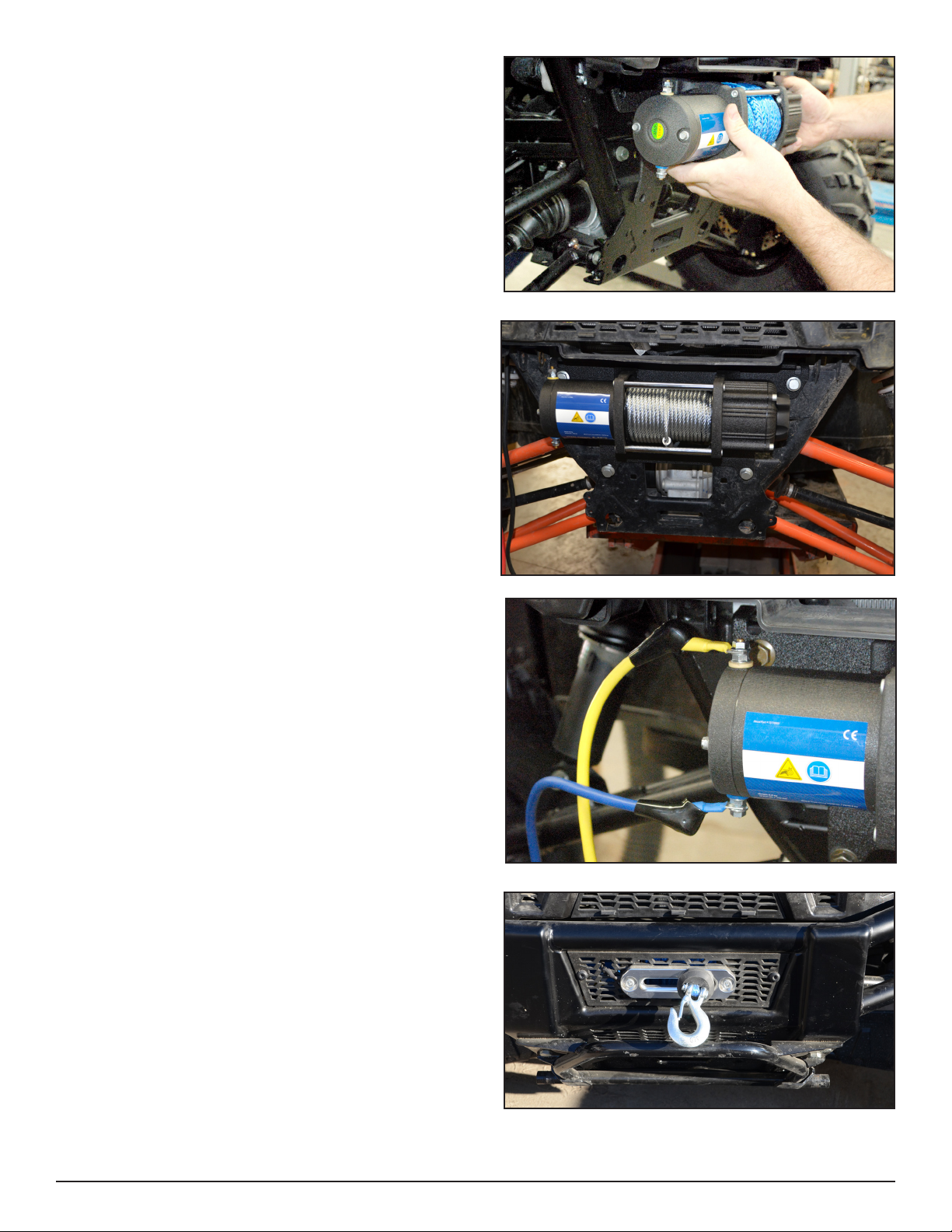

1 1 Winch-POLARIS, 6.0 2204856

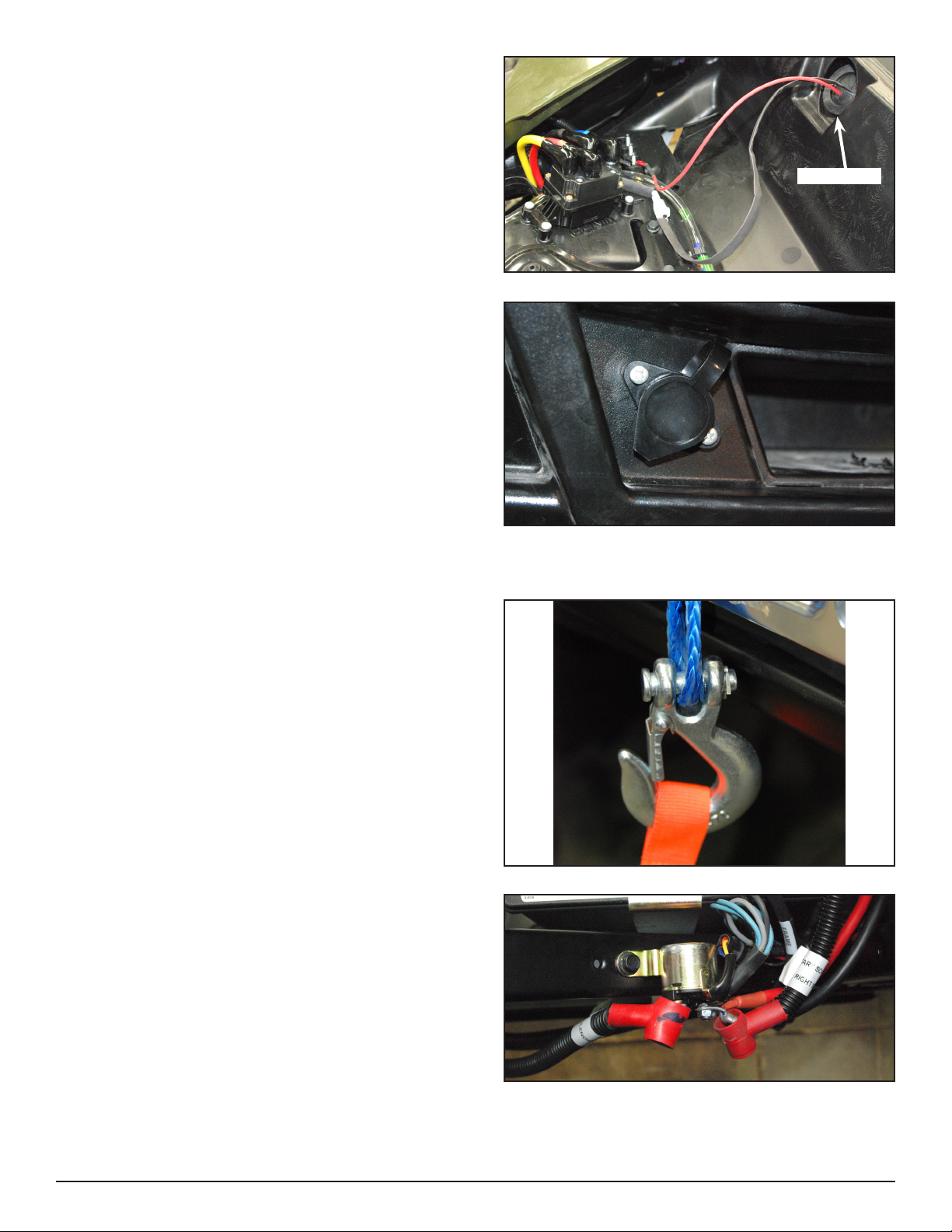

2 1 Hook-Latch, Winch 2412964

3 1 Rope Kit, Winch 2879188

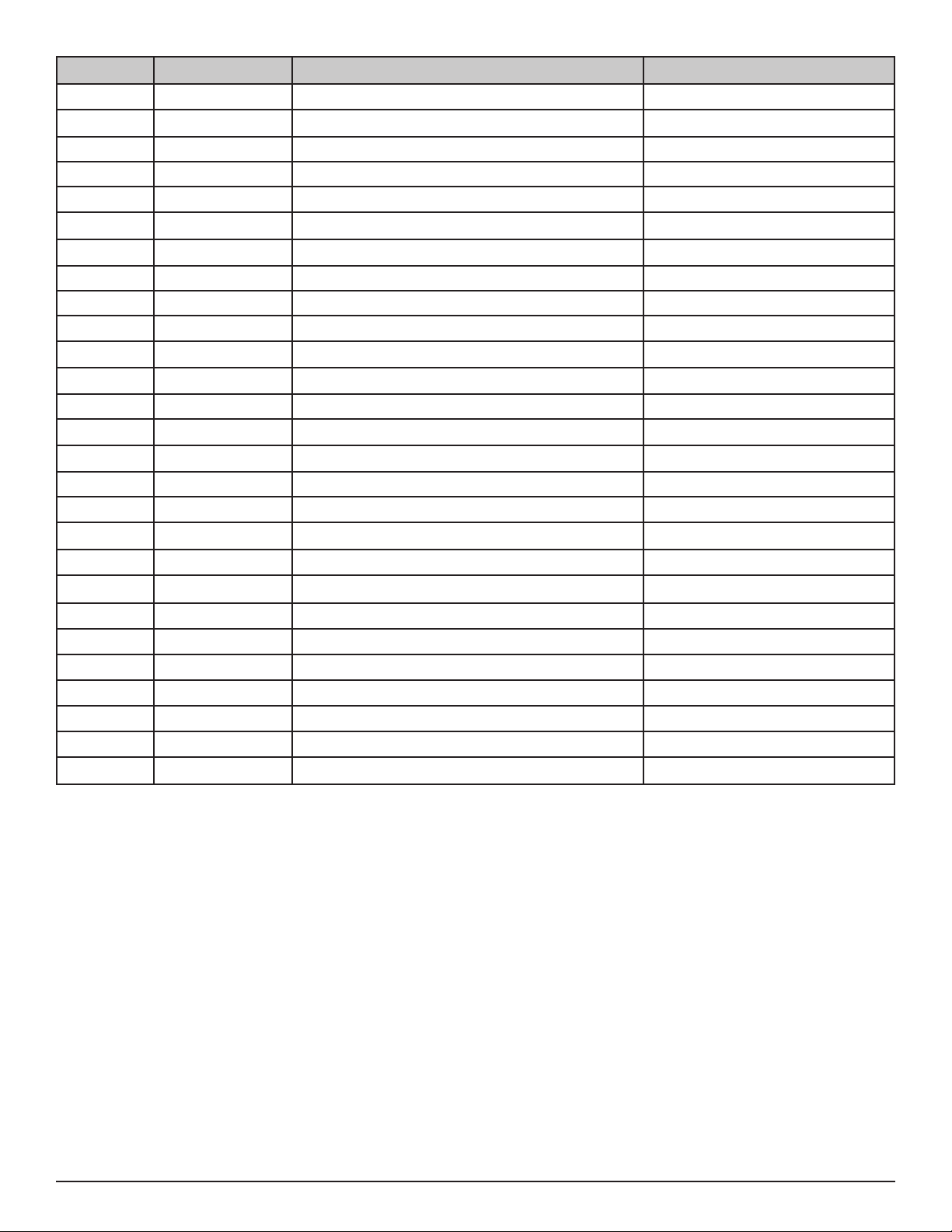

4 1 Wireless Remote Winch 2879316

5 1 Contactor Winch 4015095

6 1 Remote Switch, Winch 4013466

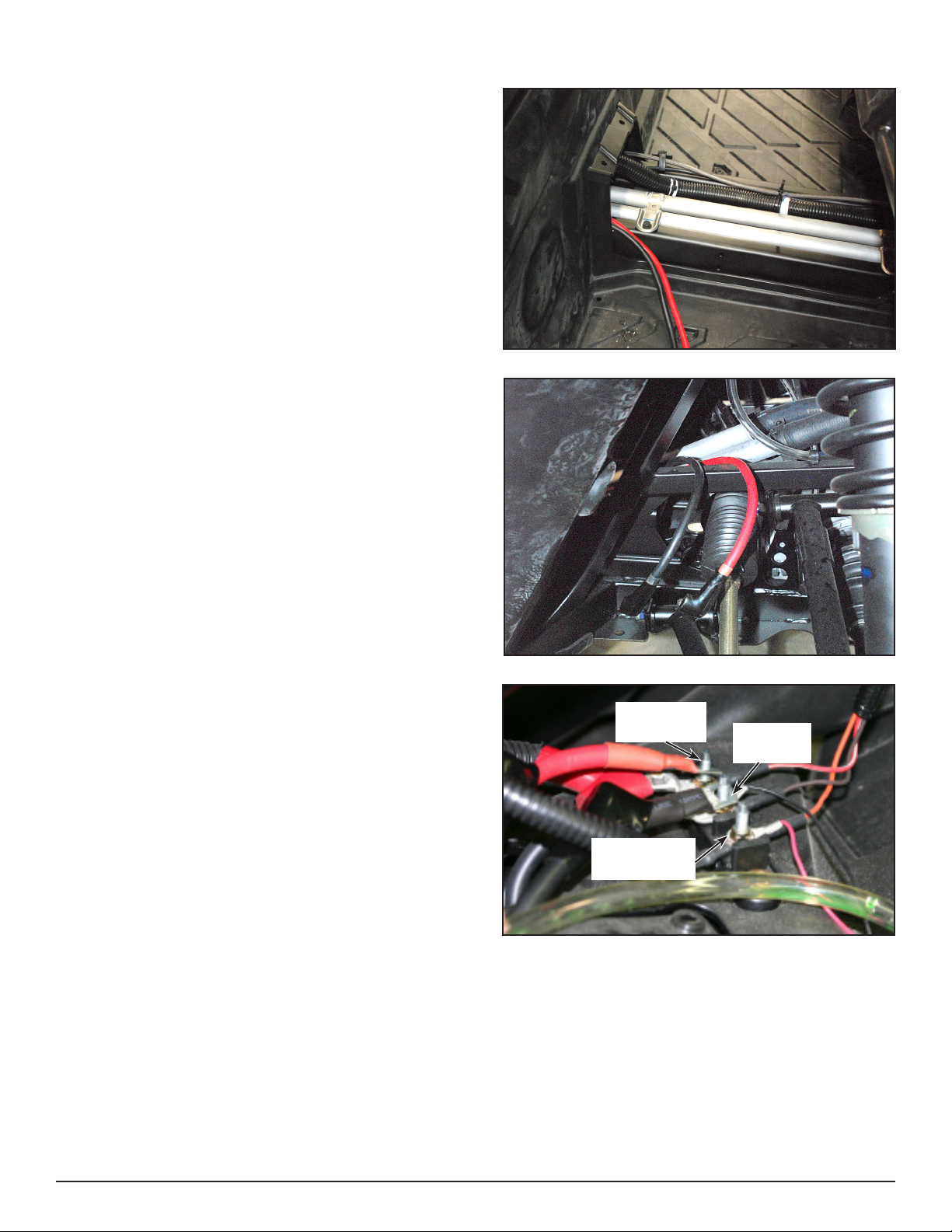

7 1 Cable-Winch, Yellow, 6 GA, 800 MM 4013468-800

8 1 Cable-Winch, Blue, 6 GA, 800 MM 4013469-800

9 1 Power Cable, Winch, Black 4013470-250

10 1 Power Cable, Winch, Red 4013471-250

11 1 Remote Socket - Winch, Long 4014228

12 1 Fairlead, Wide, Mach *KIT 2881692

13 1 Magnet Stop, Rubber Bumper *KIT 2881692

14 1Mount Winch, 4500 5439929

15 10 Panduit Strap 7080492

16* 2 Screw-HXFL - M10 X 1.5 X 30 -

17* 4Screw-#10 - 32 X 1 -

18* 2Screw-M5 X 0.8 X 20 -

19* 4Screw-M10 X 1. 5 X 25 -

20* 4Screw-HXFL M8 X 1 .25 X 25 -

21* 4Nut-M10 X 1.5 -

22* 2Nut-M5 X 0.8 -

23* 4M8 Lock Washer -

24* 4Washer-0.62 X 0.330 X 0.060 -

25* 2M5 Flat Washer -

1Winching Guide 9923644

1 Instructions 9926740

ITEMS MARKED (*) ARE INCLUDED IN HARDWARE KIT PN 2879172.