3

WARNING

DANGER

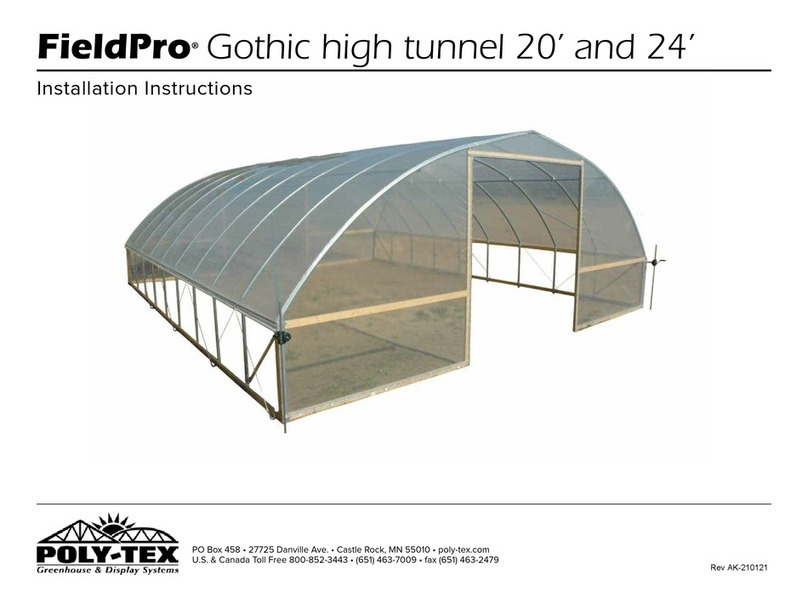

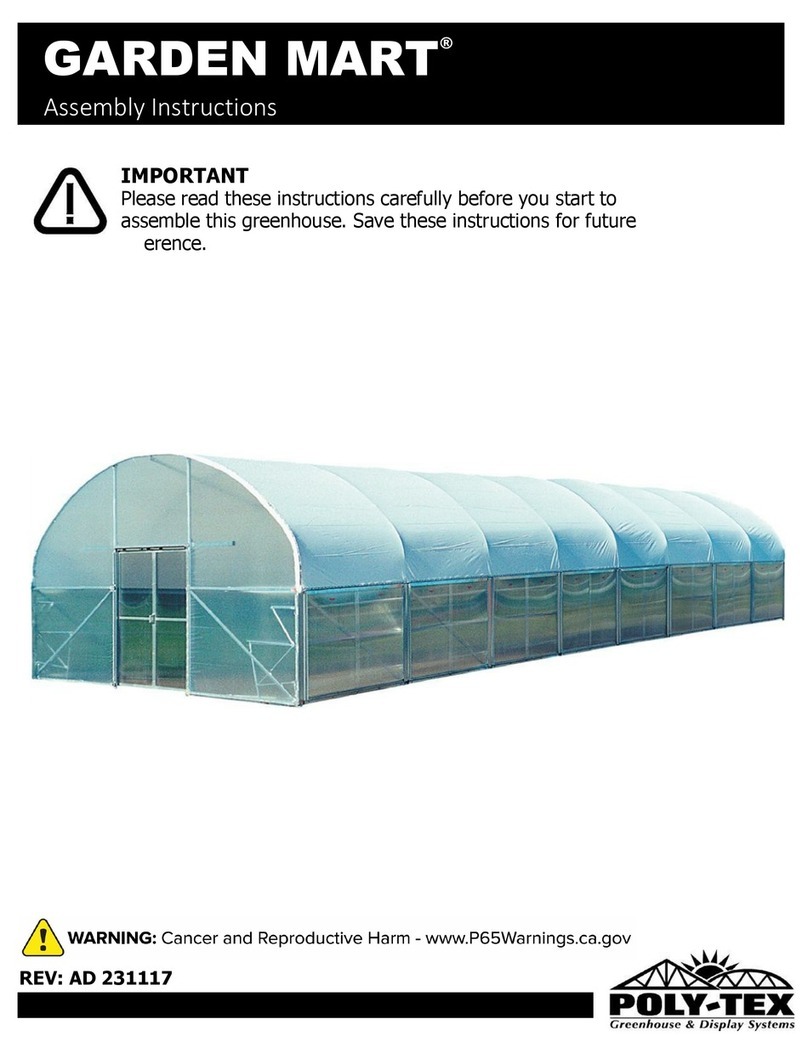

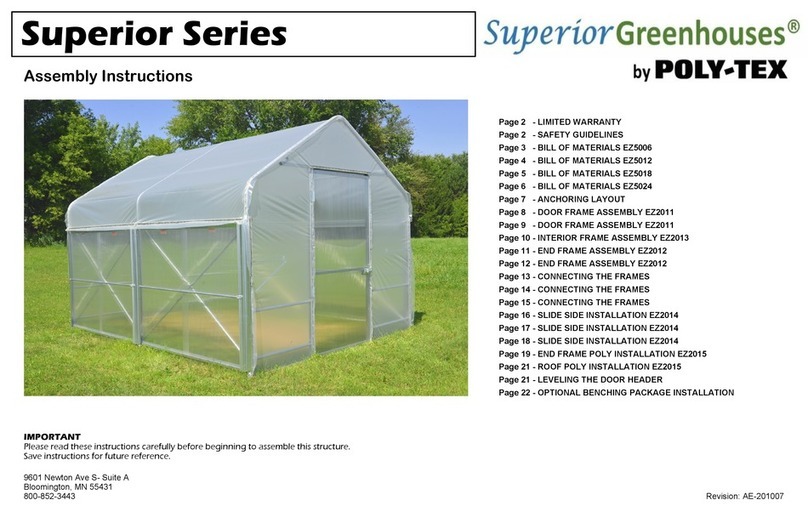

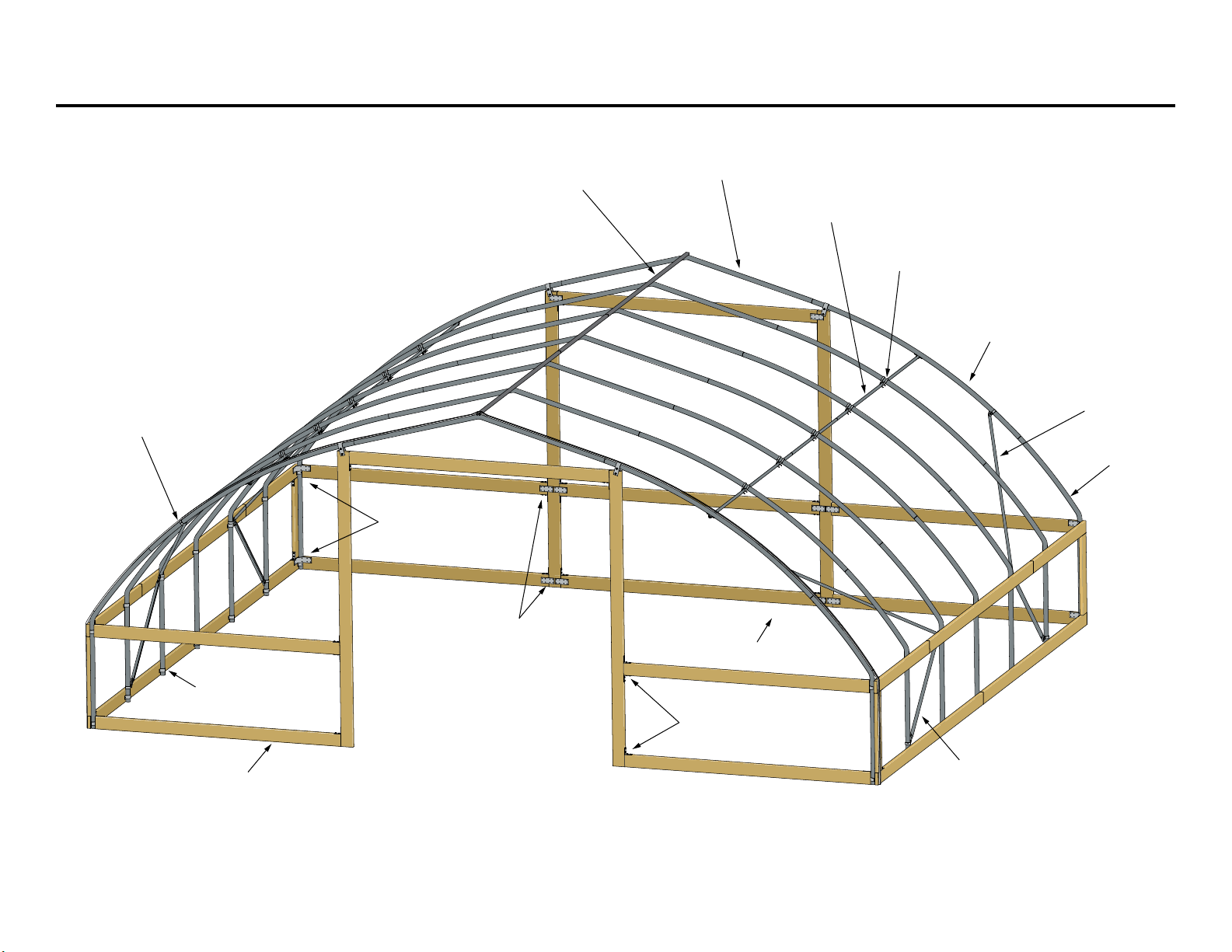

Overview of assembly procedure

DANGER

Do not overload structure.

WARNING

Do not walk on polycarbonate sheets.

Safety Guidelines

Poly-Tex does not warrant that this structure or foundation will comply with local or state

building codes. There is no guarantee of the load capacity of the structure for snow, wind,

seismic, or other loads unless buyer has received certified engineering drawings with the

structure, and Poly-Tex does not warrant that the frame or foundation will comply with

local or state building codes in buyer’s location.