1. SAFETY INSTRUCTIONS

2. INTRODUCTION & APPLICATIONS

Thank you for purchasing a Sealey product. Manufactured to a high standard this product will, if used according to these instructions and properly maintained, give

you years of trouble free performance.

IMPORTANT: READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS AND CAUTIONS.

USE THE TOOL CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE

AND/OR PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. PLEASE KEEP INSTRUCTIONS SAFE FOR FUTURE USE.

WARNING! Ensure Health and Safety, local authority and general

workshop practice regulations are adhered to when using tools.

DO NOT use tools if damaged.

Maintain tools in good and clean condition for best and safest

performance.

Ensure that a vehicle which has been jacked up is adequately

supported with axle stands and that the wheels are chocked.

Ensure that the rear axle is adequately supported, refer to the

vehicle manufacturer’s service instructions, or a proprietary

manual.

Wear approved eye protection. A full range of personal safety

equipment is available from your Sealey dealer.

Wear suitable clothing to avoid snagging. Do not wear jewellery

and tie back long hair.

DO NOT use air tools to operate the force screw.

IMPORTANT: The force screw must be kept well lubricated.

IMPORTANT: This manual is provided as a guide only, refer to

the vehicle manufacturer’s service instructions, or a proprietary

manual, to establish the current procedure and data.

WARNING! Failure to heed safety and warning instructions may

result in damage and/or personal injury and will invalidate the

warranty.

WARNING! The warnings, cautions & instructions referred

to in this manual cannot cover all possible conditions and

situations that may occur. It must be understood that

common sense and caution are factors which cannot be

built into this product, but must be applied by the operator.

Remove/install rear sub-frame bushes on Ford Focus.

Can be used in situ - no need to remove sub-frame from vehicle.

Ford Focus MK1 1998 – 2004.

IMPORTANT: This tool is designed to aid removal of the suspension bush.

• Adequate consideration should be made to lubricate or otherwise

easethetofthebushpriortouseofthistool.

• We suggest that the bush is thoroughly lubricated and the area

around the bush cleaned.

• The threads of the tool should also be thoroughly lubricated in

use.

• An Impact Socket must NOT be used with this tool.

• Stripped threads and bent thrust cups are not accepted

warranty claims on this tool.

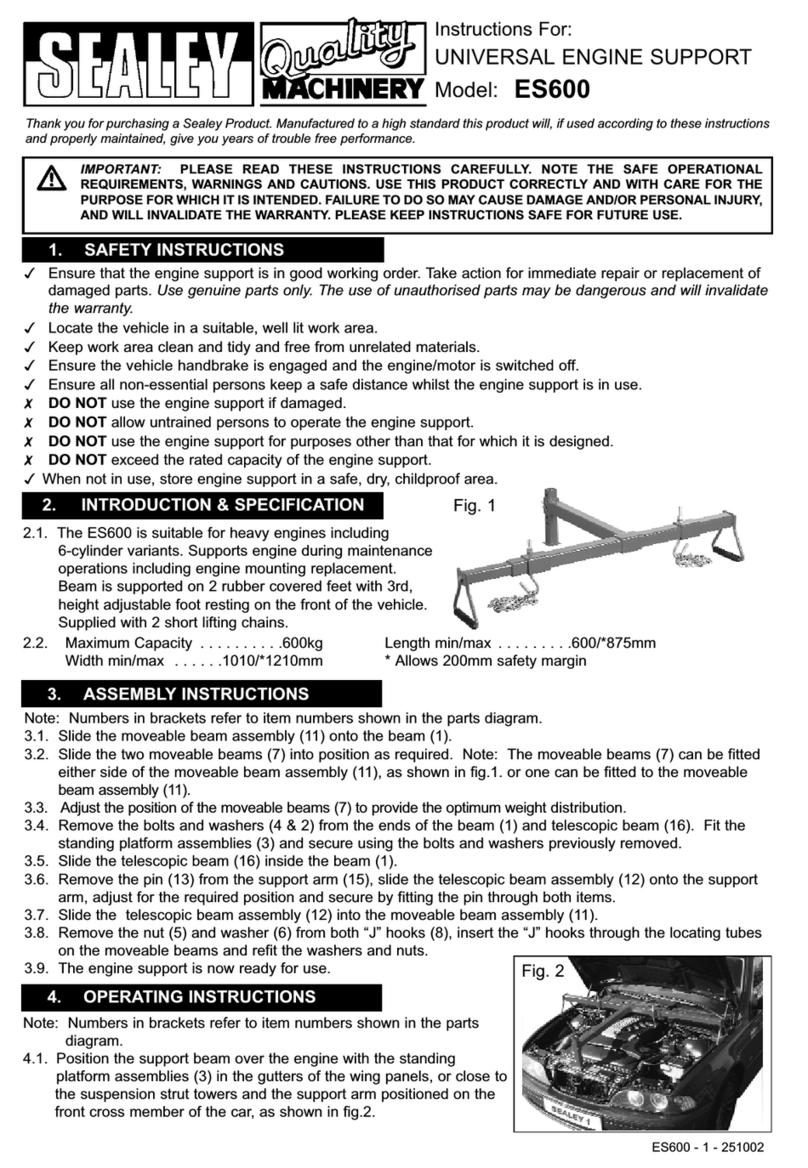

3. OPERATION

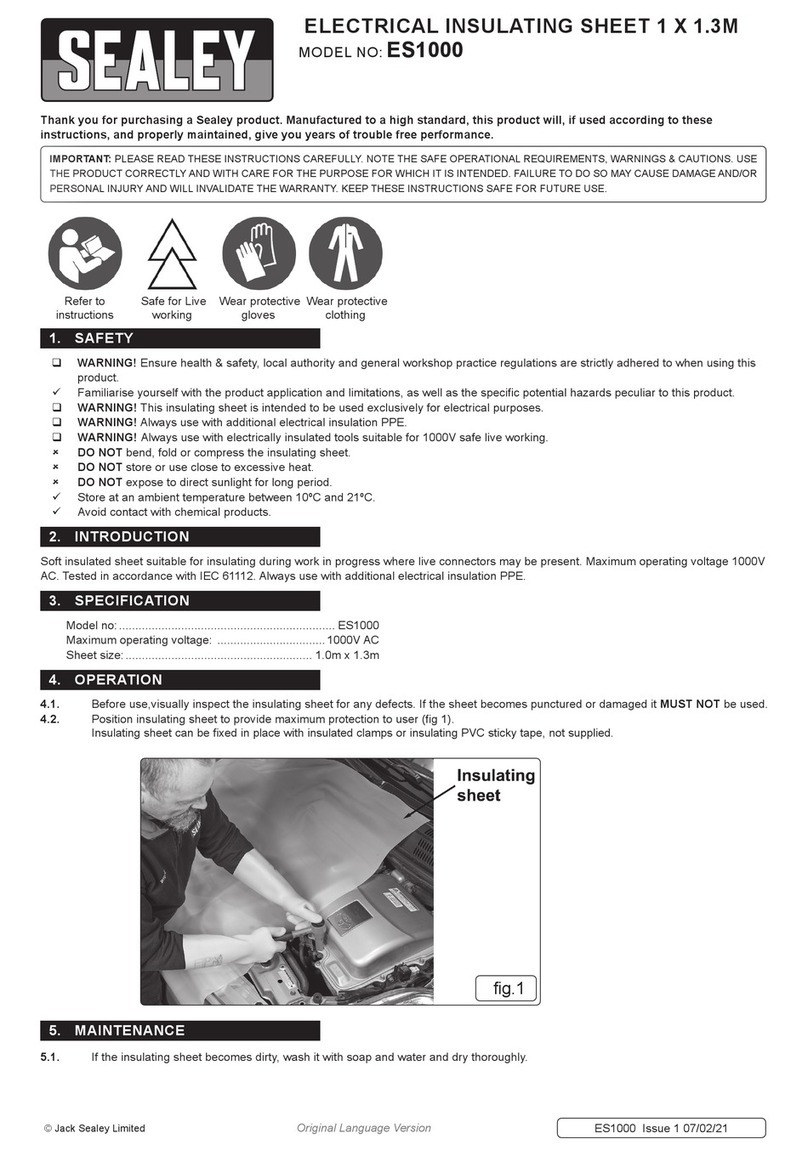

NOTE! Pictures taken with the trailing arm removed from vehicle

for clarity.

NOTE! The tool will insert the bush to the correct depth, but

before installing the new bush, refer to the vehicle

manufacturer’s service instructions, or a proprietary manual, to

establish the correct horizontal alignment/positioning of the bush

in the trailing arm.

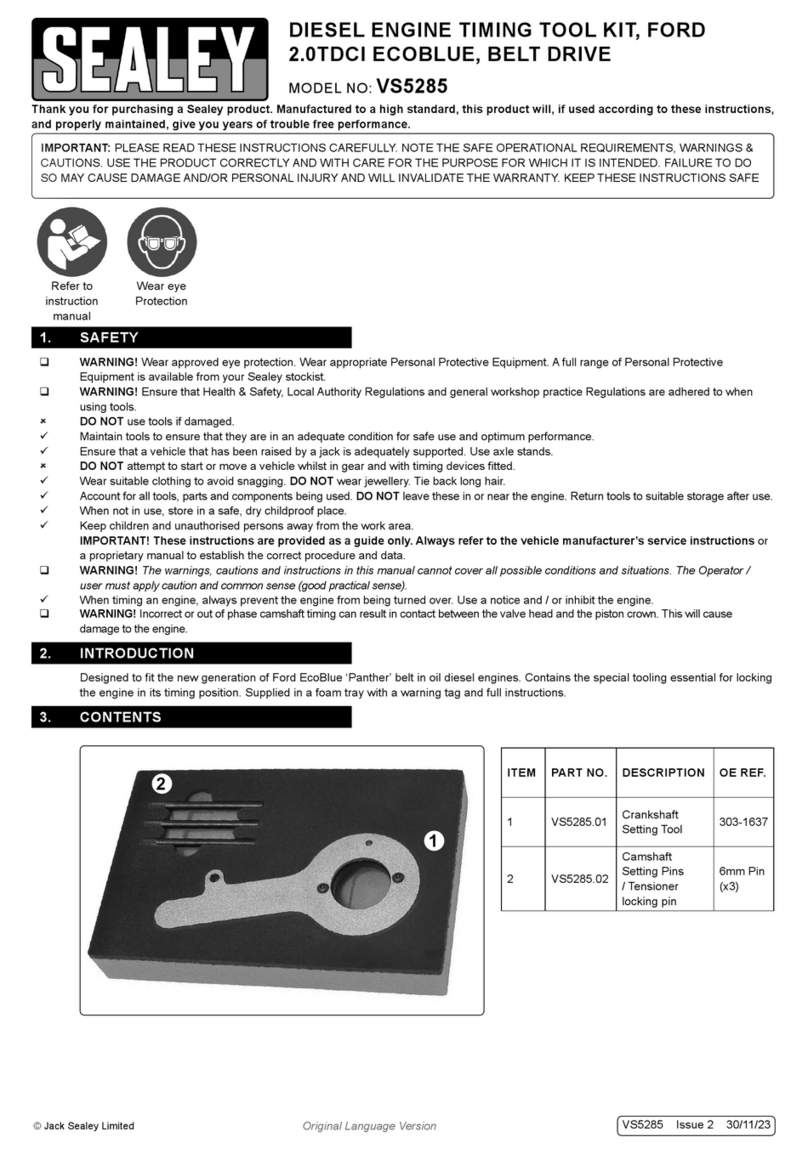

Bush before removal from trailing arm.

VSE4780.V2 Issue No. 1 - 28/06/13

ALWAYS KEEP FORCE SCREW

WELL LUBRICATED.

DO NOT USE AIR TOOLS

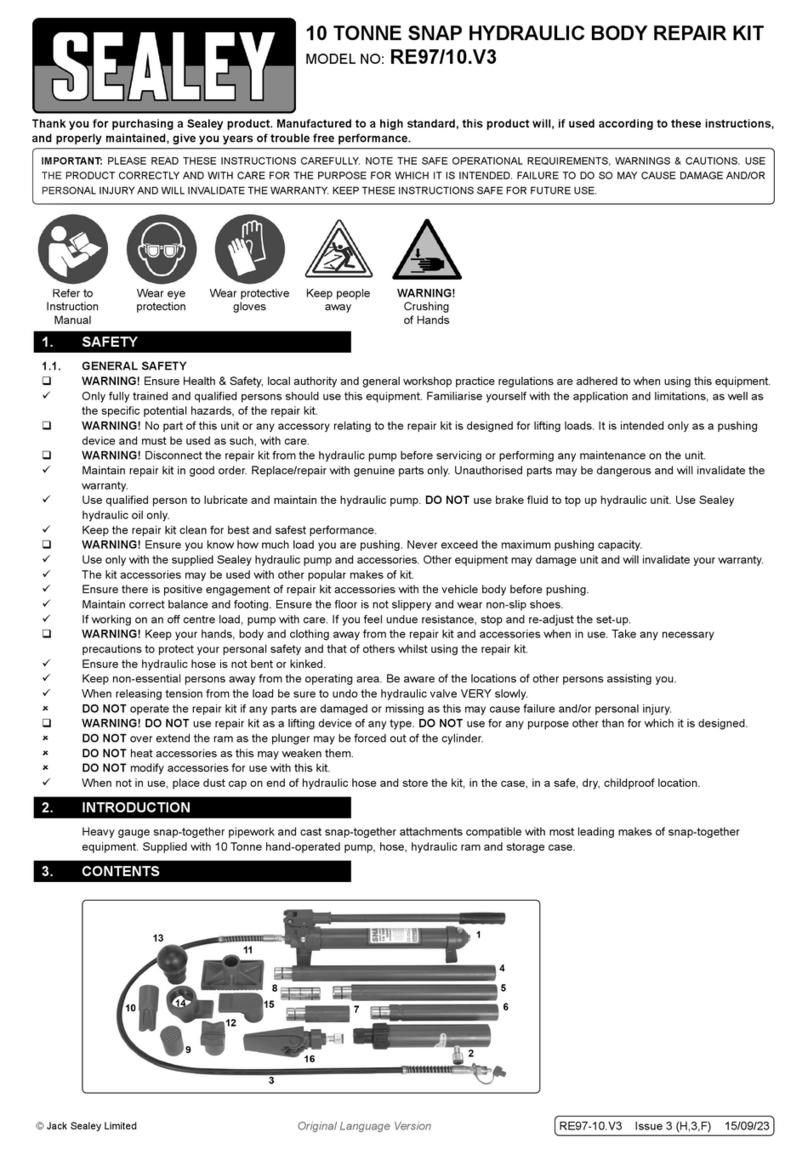

Bush Removal Press

Force Screw

Bush Replacement Press

INSTRUCTIONS FOR:

REAR BUSH TOOL

FORD FOCUS MK1 1998 - 2004

Model No: VSE4780.V2

Force screw maximum load 150Nm. Exceeding this load will shorten the life of the force screw. The

force screw is considered to be a consumable item and is NOT covered under warranty.

Original Language Version

© Jack Sealey Limited