2 3

www.power-tec.co.uk www.power-tec.co.uk

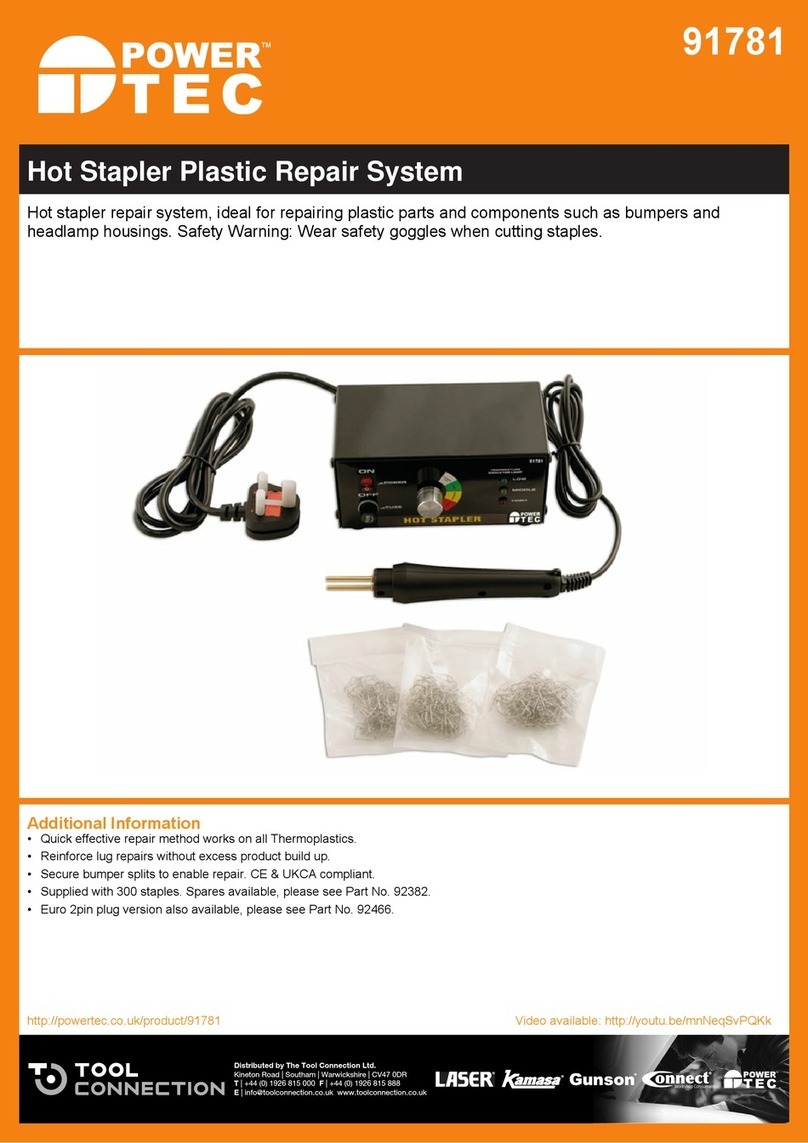

Hot Stapler Plastic Repair System

- Professional

92478

Hot Stapler Kit - Rechargeable

Controls: Operation:

Note: It is worthwhile practicing on some scrap plastic components to familiarise yourself

with how much heat needs to be applied (length of time control button Cis depressed) to

get a staple to a temperature where it will slide into the plastic being repaired, and to get

a feel of how much pressure is required to ensure that you don’t push straight through the

component. Red hot is too hot - release control button.

Hot Staple Repair:

• Clean the plastic surface to be repaired of any contaminants prior to repair.

• Choose suitable staple for type of repair and insert it into the tips. Staple arms can be

bent if required to achieve access.

• Prepare plastic for repair by butting together

• Heat staple by pressing and holding the control button Cfor 4-5 seconds (see note above

- do not let staple become red hot).

• Press the staple gently against the plastic to be repaired; push staple until it is about half

way through material, then twist through about 10-15°.

• Release control button Cand hold the staple on the repair until the plastic cools and it

feels firm.

• Slowly withdraw the tool, leaving the head of the staple in place.

• Cut of the protruding ends of the staple with side cutters or similar. Hold on to protruding

ends during the cutting operation. (Wear eye protection.)

• When repairing large areas or long cracks, repeat the procedure at 1-3cm intervals.

• Remove the remaining ends of the staple with sander.

• Continue with repair in the normal way.

Charge Protection:

The cordless hot stapler features over-charge and over-discharge protection. If the

worklight-power-on LED Bdoes not function and staples are not heating up, the charge

protection has been activated. In this case connect the charger and recharge the stapler

to restart.

AStaple tips

BLED worklight (power ON)

CControl button

DCharge socket

EStaples

Charging:

(NOTE: Charge the battery fully before first use.)

Red low-battery LED will illuminate when battery charging is necessary.

Plug charger into electrical socket and connect to charge socket Din cordless hot stapler.

Flashing green LED indicates the stapler is charging. Solid green LED indicates the

stapler is fully charged.

Unplug the charger and the stapler is ready for use.